continous casting

-

Upload

alexi-junior -

Category

Documents

-

view

31 -

download

0

description

Transcript of continous casting

HORIZONTAL & VERTICAL CONTINUOUS CASTING PLANTS

HORMESA offers a variety of options for pre-melting furnaces, suitable with the needs of any foundry.

Melting furnaces for Copper and Copper Alloys, Aluminum, Ferrous, Precious Metals and any Special alloys.

• Crucible gas/oil furnaces HORCBG. (1)

• Induction channel furnaces ROB. (2)

• Medium frequency induction furnaces EGP. (3)

HORMESA also offers VIBRATING CHARGING MACHINES (4) for chips and scrap charging into melting units.

Also SPECIAL ISOLATED LAUNDERS (5) and HYDRAULIC TILTING LADLES (6) for molten metal transportation from Pre-Melting furnace to Holding furnace.

Holding and casting furnaces for Copper and Copper Alloys, Aluminum, Ferrous, Precious Metals and any Special alloys.

• Crucible gas/oil furnaces HORCBG . (1)

• Electric furnaces with graphite resistance technology HORMESA RF. (7)

• Induction channel furnaces ROB-HCC. (8)

• Medium frequency induction furnaces EGP-HCC. (9)

HORMESA also offers Melting and Casting in one furnace.

All our models are custom made, and can be made with special modifications for the customer needs.

HORMESA is specialist in various methods of continuous casting of ferrous, non-ferrous metals, and any special alloy. HORMESA has a laboratory for test casting of non common alloys, size, speed and casting method.

• HCC - Horizontal. (1)

• VUCC - Vertical Upwards. (2)

• VDCC - Vertical Downwards. (3)

HORMESA uses traction system with AC Servo motors in all our continuous casting plants.

AC Servo motors allows to control, speed, acceleration, deceleration and stop time, getting a smoother surface.

Continuous casting methods: HCC (4), VUCC (5), VDCC (6)

HORMESA supplies various post-casting equipment, in order to give a complete solution. Some of our post-casting equipment are:

• Bar shaver. (7)

• Cutting saw. (8)

• Continuous extrusion machine. (9)

In combination of all the equipment listed above, from Pre-Melting to Post-Casting we can obtain from scrap or chips, some of the products shown below. Below are shown some examples of complete plants and it final products.

Pre-Melting Furnaces

Melting/Holding Furnaces

Casting Machines

Post-Casting Equipment

1

2

3

4

1 PRE-MELTING 2 MELTING/HOLDING 3 CASTING 4 POST-CASTING

(1)

(4)

(2)

(8)

(8)

(5)

(3)

(9)

(9) (6)

1 MF - MELTING

1 MF - MELTING

2 ROB/RF - CASTING

2 ROB/RF - CASTING

3 VUCC

3 HCC

4 C. EXTRUSION

4 SHAVER - SAW

(2)

(5)

(3)

(6)

(1)

(4)

(7)

VERTICAL UPWARDS CONTINUOUS CASTING PLANT FOR PRODUCTION OF COPPER STRIPS AND PROFILES

HORIZONTAL CONTINUOUS CASTING PLANT FOR PRODUCTION OF COPPER & COPPER ALLOY BARS - BRONZES, BRASSES

Transformer Strip Copper Bus Bars Copper Strips Copper Profiles

HORMESA can produce plants combining different methods of casting (HCC – VUCC – VDCC) in the same casting furnace I the customer wants to produce both copper bars and copper wire rods, or brass wire rods with brass strips, etc.

Our specialists in engineering and metallurgy give us a great versatility in the design of any projectShaved Bars Bars before – after shaving

Holding Furnaceor Tundish Water-cooled

copper jacket

Secondarycooling

Withdrawalunit

Breakring

Casting

Graphitemold

LiquidCopper

Heaters

Melting Section Casting Section

Scrap and VirginMetals Feedstock

Cast Strands

Casting DieAssemblies

Graphite Filterand Bed System

Carbonaceouscover

(7)

CONTINUOUS CASTING SOLUTIONS

CONTINUOUS CASTING SOLUTIONS

SERVICE 24/7

Las Marineras, 13-17 E-28.864 Ajalvir, Madrid, EspañaPh: +34 918 874 039Fax: +34 918 844 382

Email: [email protected] • www.conticast.com

Edge Technology With Best Quality Equipment

Anything that is thinkable...we can make it

Principal

Offices

Representatives

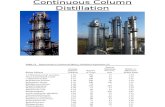

VERTICAL CONTINUOUS CASTING PLANTS HORIZONTAL CONTINUOUS CASTING PLANTS

In HORMESA we give the entire solution from the metal to the final product. Bellow we will show different type of plants for different products.

FINAL PRODUCT: Copper & Copper alloys wire rod (VUCC Process) FINAL PRODUCT: Copper & Copper alloys Bars or strips (HCC Process)

FINAL PRODUCT: Aluminum billets (Semi-continuous casting Process) FINAL PRODUCT: Steel wire or billets (HCC Process)

1 HCC - CASTING 2 MILLING MACHINE 3 SHEAR 4 COILERS

Vibrating charger

Vibrating charger Vibrating charger

MF inducion furnace. MELTING

MF inducion furnace. MELTING MF inducion furnace. MELTINGAC Servo strand haul systemHCC TRACTION SYSTEM

Semi continuous casting machine HOR CSC

Degassing and Filter system

Cutting Saw Cutting Saw

Bar shaver & Straightener Homogenizing furnace HOR HH

Introduction Channel FurnaceHOLDING & CASTING

Continuous extrusion

Launder

Launder Launder

Swarf treatment system

Holding & Casting Furnace(GRAPHITE OR INDUCTION)

Reverberatory furnace HOR SH HOLDING

Ladle

Ladle Ladle

Dryer

Spectrometer

Conticast Software

Conticast Software

AC Servo strand haul systemVUCC TRACTION SYSTEM

Copper Strips Zinc Rod

Continuous extrusion machines. Continuous extrusion can be used in order to get copper strip or copper bus bar.

With this plants we can get a production from 2000Ton/yearup to 100000Ton/year

* Continuous extrusion apply only for copper and aluminum

Casting of different alloys: Copper, Brasses, Bronzes, Zinc, Cadmium.

Scrap inputScrap input Scrap preparation basic package

Scrap input

Finished strip or bus bar ourtput

Finished billet output

Finished billet

output

MoltenMetal

MoltenMetal

MoltenMetal

MoltenMetal

MoltenMetal

MoltenMetal

MoltenMetal

MoltenMetal

Degas test

Casted billet Casted billet

Cutbillet

Cutbillet

Aluminium chips

MoltenMetal

Casted wire rod

Coldwater IN

Coldwater IN

Coldwater IN

Coldwater INCold

water IN

Coldwater OUT

Coldwater OUT

Coldwater OUT

Coldwater OUTCold water OUT

CoolingSystem

CoolingSystem

CoolingSystem

Grain refiner feeder

CoolingSystem

Dies CoolingSystem

From1 to 12

Strands

HORMESA can supply plants for brass strips for keys factories, up to 5000Ton/year

Process varies from bar casting in the POST-CASTING. After continuous casting it’s used; STRIP SURFACE MILLING MACHINE, HYDRAULIC SHEAR, AND COILERS. Variable speed hydraulic lifting and lowering system

• Hydraulic drive table

• Control desk including all the parameters

• Stainless steel water resistant material

• State of the art Aluminium dies

Degassed filteredmoltenmetal

Produce billets from 3” to 10”

HORMESA is expert in horizontal continuous casting of steel. We can cast from wire with very small cross section up to 100 – 120mm steel billets.

We use induction heated tundish with special coil design.

Special design steel billet casting mould

Special design steel wire casting mould

Mould holder

In HORMESA’s laboratory we are continuously doing tests to improve casting process and trying the casting of different alloys.The customer can ask the test of the casting of an specific alloy before purchasing to be sure about each project accomplishment .

PROJECT TURN KEYMANAGEMENTAvailable on request from HORMESA

• Project definition consultancy.

• Specification of equipment and scope of supply.

• Coordination of equipment purchase, delivery, installation, start up and commissioning.

• Coordination of technical service support.