Construction · TRISTAR ENGINEERING & CHEMICAL COMPANY Inline Heaters TRISTAR ENGINEERING &...

Transcript of Construction · TRISTAR ENGINEERING & CHEMICAL COMPANY Inline Heaters TRISTAR ENGINEERING &...

Application

In this type of heater the heating elements are tubular. The tubular elements are brazed or welded to the tube sheet / sleeve. Rest of the construction is common.

The heating elements can be cartridge or open bobbin which are inserted in casing pipes, these pipes are welded to the tube sheet. It is easy to replace these elements as they are not welded or brazed. Heater body need not be disassembled to replace the elements.

Inline heaters or circulation heaters are heating units designed to heat flowing fluids including gases. Inline heaters consist of heating elements welded or Brazed to a tube sheet which rests on a vessel with a matching flange. The vessel consists of inlet from where the fluid enters the vessel chamber and moves over the heating elements picking up heat evenly towards the outlet on the other end of the vessel. These heaters offer high efficiency since most of the heat is generated within the fluid.

Inline Heaters withTubular Heating Elements

Inline heaters are used to raise the temperature of the liquid in the pipeline instantaneously.

Liquid Heating

Electric heaters provide a cost effective means for heating air and common industrial gases such as Argon, Helium and Nitrogen amongst other gasses.

Gas Heating

Heaters are used to increase the enthalpy and quality of steam. Inline heaters are used to make up for losses on steam distribution line.

Steam Superheating

Inline Heaters with Cartridge / Open Bobbin Heating Elements

www.tristarengg.co.in

TRISTAR ENGINEERING & CHEMICAL COMPANY

Inline(Circulation)

Heaters

TRISTAR ENGINEERING & CHEMICAL COMPANY

Construction

Tristar circulation heater systems are skid mounted plug and play systems. These consist of Inline Heaters, Temperature and Pressure monitoring devices, Control Panels, Pumps and other equipments as per the process requirement. Field installation would involve connecting inlet and outlet to piping network and wiring the power connection to the control panel.

The selection of proper inline heater requires careful evaluation of the process, our experienced team shall assist you in designing and procuring the right heater. We shall assist you in calculation of heat energy requirement for the application, proper selection of Heating elements and watt density, Vessel material, flanges, temperature control and monitoring devices. A heater designed for your application not only ensures that it provides a long trouble free service but also ensures that your process requirements are not compromised on.

Applications where tubular elements are used

FlangesAs per ANSI B16.5, CS, SS 304, SS 316

Kilowatt RatingFrom 1 kW to 500 kW and above

Design Code - ASME Sec VIII Div I

VesselCS, SS 304 , SS 316 and other materials to suit yourrequirement. The shell and nozzles are selected basedon the design parameters.

•consideration process parameters.

• Optimal watt density for long trouble free life, no charring/coking of fluid. We recognize that each fluid is differentfrom another and hence watt density is decided based onthe properties of fluid in consideration.

• Even Heat distribution over the surface of the elementavoiding hot spots.

• Approved Weatherproof (IP 55) and Flameproof enclosures (IP 66), on request.

• Heating elements are easily replaceable without dismantling the heater body (Flanged immersion with

cartridge/open bobbin elements)

• Passivated SS Plug and SS element sheath for use incorrosive solutions, on request.

• Variety of Temperature Control and Measurement devices.

Customized to suit your requirements taking into

Features of Tristar Heaters

•• Heat Transfer Oil Heating• Fuel Oil Pre Heating

Water Heating • Heavy oils • Freeze Protection• Steam, Air and Gas Heating

Applications where cartridge / open bobbin heating elements can be used

•• Jacket Water Heating• Fuel Oil Preheating

Heavy weight Fuel oil

TRISTAR ENGINEERING & CHEMICAL COMPANY

Inline Heaters

TRISTAR ENGINEERING & CHEMICAL COMPANY

W-41 B, MIDC Rabale, Off Thane Belapur Road, Navi Mumbai 400 701.

Phone: +91-22-2769 6865 | Fax: +91-22-27692586E-mail: [email protected], [email protected] Web: www.tristarengg.co.in

Heating ElementsCS, Copper, SS 304, SS 316, SS 321, Incoloy, Titanium andTeflon / PTFE (Polytetrafluorethylene) coated.

AccessoriesDrain Valve, Pressure Gauge, Pressure Relief Valve, Flow Switch,Pressure Switch, Pump Interlock Relay, Low Liquid Cutoff.

Pressure and temperature limiting controls must be used on heaters to ensure safe operation in the event of system malfunctions. These are also used to deenergize the elements and prevent element damage and extend the life of the heater. Thermostats, RTD, Thermocouple, PID etc.

Safety Devices

Electrical TestsResistant Test, Insulation Test, High Voltage Test, kW, Voltageand Ampere Test, Hydrostatic Test (inprocess)

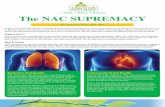

TERMINAL BOX

TEMPERATURE GAUGE

PRESSURE GAUGE

VENT

OUTLET NOZZLE

JUNCTION BOX

HEATER BODY

HEATER ELEMENTS

DRAIN

MOUNTING SKID

INTERNAL WIRING

THERMOSTATS(CONTROL+SAFETY)

INSULATION

INLET NOZZLE

PUMP

TRISTAR MAKE INLINE CIRCULATION HEATER

NOTE: FLAMEPROOF TERMINAL & JUNCTION BOX AS PER CLIENT REQUIREMENT

![Morningstar Tristar Manual[1]](https://static.fdocuments.in/doc/165x107/5695d2761a28ab9b029a81ce/morningstar-tristar-manual1.jpg)