Confronting Carbonates

Transcript of Confronting Carbonates

Bernard Montaron, Theme Director of Carbonates at Schlumberger writes on thechallenges of carbonate reservoirs.

132 Oil Review Middle East Issue Five 2008

EENHANCED OIL RECOVERY is aparticularly significant factor forcarbonate reservoirs, sincetraditionally recovery tends to be low

from these fields. Bernard Montaron ofSchlumberger explains.

Carbonate reservoirs hold around 60 per centof the world’s oil and 40 per cent of the world’sgas. However, the heterogeneous nature of therock presents challenges for petroleumengineers. To help address exploration andproduction issues specific to carbonate fields,Schlumberger has set up a dedicated carbonateR&D centre in Dhahran. This is a region whichholds 62 per cent of the world’s hydrocarbonreserves. In fact, the Middle East is dominatedby carbonate fields, with around 70 per cent ofoil and 90 per cent of gas reserves held withinthese reservoirs.

Carbonate formationsCarbonate reservoirs present a challenge, in part,due to the history of the rock formation.Carbonates rocks are formed locally by thedeposition of minute marine organisms, coraland algae, together with the precipitation ofcalcium carbonate in shallow, warm water. Bycontrast, the sand and sediment that formsandstone reservoirs tends to be swept longdistances by rivers and currents before settlingin sites such as deltas and beaches.

One important difference between these tworeservoirs types is that sand (a siliconcompound) is chemically inert when comparedto calcium carbonate. Carbonate rock initiallyhas a high porosity of 35 per cent - 75 per cent,but this decreases sharply as the rock ages. Over

Abu

Dha

bi In

tern

atio

nal P

etro

leum

E

xhib

itio

n &

Co

nfe

ren

ce

A

DIP

EC

2008

The complex world of carbonates: vugs

Confronting

carbonates

United Arab Emirates | Qatar | Kuwait | Saudi Arabia | Oman | Egypt | Sri Lanka

Corporate Office +971 4 885 4449

www.amanabuildings.com

Arab Emirates | QUnited

Corporate

.amwww

Arabia | Oman | Egypt | Sri LanQatar | Kuwait | Saudi

fice +971 4 885 4449e Offf

ldings.commanabui

ka

at Ras Abu Fontas, Doha

9

m

116_140_ADIPEC:Layout 1 22/10/2008 18:50 Page 132

eons of time, as the rock iscompressed deep underground, itscharacter is changed due to achemical process called diagenesis.During this process, the poreschange in size and geometry.Understanding the complexheterogeneous rock matrix can bevery problematic.

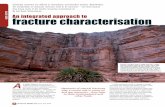

Diagenesis can create styloliteflow barriers, which extend overlarge areas, creating a dramaticeffect on field performance. Therock may also be fractured bygeological processes caused bypressure within the earth‘s crustarising from continental drift. Alarge fracture corridor maymeasure 10 m wide, 100 m highand a kilometre long. The historyand topography of a carbonateformation provides some idea of the likelyposition, orientation and direction of theselarge corridors. Some may run along the crestof a fold where the formation has been subjectto bending. But shear stress will tend to resultin a crush zone because of the slippage of therocks on either side of a failure.

This is a very important consideration forreservoir management because major fracturecorridors can have a permeability a thousandtimes greater or more than the surrounding rockmatrix. On the positive side, fracture corridorscan provide highways for draining the reservoirs.However, the fracture corridors are also an easy

path for water, and injected gas, tobreak through to production wells.Fractures can also lead to problemsduring drilling, such as mud lossesand stuck pipe.

Fracture cluster mapping workflowLast year the Fracture ClusterMapping (FCM) workflow waslaunched to improve fracturecharacterisation and themodelling of carbonate reservoirs.The workflow integrates Q-Technology services, boreholemeasurements and Petrel seismic-to-simulation software with expertinterpretation and flexible workprocesses, resulting in improvedproduction performance.

Modelling fracture systems hasalways been and still is a challenge forgeoscientists in the oil industry. The FCMworkflow helps to make better decisions for thelocation of injectors and producers, plan welltrajectories, improve production predictions andform a comprehensive Discrete Fracture Network(DFN) model. It makes a clear distinction

133Oil Review Middle East Issue Four 2007

Abu D

habi International Petroleum

Exh

ibitio

n &

Co

nfe

ren

ce

A

DIP

EC

2008

Steam Generators for Refineries

Steam Generators for Power Production

Hot Oil Systems for Crude Oil Heating

Hot Oil Heaters for Oil Pumping Systems

Hot Water - Glycol Boilers

Waste Heat Recovery Boilers

Produced Water De-Oiling & Filtration Systems

Condensate Polishing Systems

Deaerators for Boiler Feed Water

Injection Water Filtration

Desalination & Demineralisation Packages

Drinking Water Makers

Package-Type Sanitary Water Treatment Units

Energy & Ecology

Artes

Energia

Italian Solutionsfor Heating & Water Treatment in Oil & Gas Applications

Artes Ingegneria S.p.A.

Via Resistenza 12 20068 Peschiera B. Milano Italy

Bono Energia S.p.A.

Via Resistenza 12 20068 Peschiera B. Milano Italy

www.bono.itwww.bono.it [email protected]@bono.it

VISIT US at

ADIPEC 2008

Italian Pavillon H2/24-8

Fracture porosity

116_140_ADIPEC:Layout 1 22/10/2008 18:50 Page 133

The topography of the field suggested thatthere would be extensive cracking along a foldrunning in a NNW to SSW direction. This thesiswas supported by an initial run of discontinuityextraction software (DES) when it was used toprocess high resolution Q-Technology seismicdata. However, this was not the full story.Borehole data from one well also showed more

than 400 open fractures runningperpendicular to the main fracturecluster. Sequential steps of theworkflow were then used, with filterwindows, to produce more finelydetailed fracture images at a seriesof azimuths (angles) and inclinations(dips) windows.

The constrained computer runsrevealed additional fracture clusters.The filtered images were finallymerged together to produce anoverall 3D picture of the fracturecorridors. The results were correlatedwith data from the four existingwells, and two new ones. Theavailability of an accurate fracturecorridor map has great benefits forreservoir management, both toenhance production by extending

the area that can be drained by each productionwell, and to avoid a water breakthrough surprise.

Understanding reservoir producibilityFCM addresses production concerns at areservoir scale; however it is equallyimportant to understand reservoir producibilityfrom a rock-textural perspective at the pore

134 Oil Review Middle East Issue Five 2008

between diffuse fractures that can bemodelled using geo-statisticaltechniques, and fracture corridor'highways' that must be detectedand placed in the reservoir modelat their exact field location.

In practice, the frkacture clustermaps can be used in conjunctionwith technology that allows drillersto steer wells to the most favourabletargets within the reservoir.PeriScope directional, deep imagingwhile drilling, is particularly useful inthis respect as it enables petroleumengineers to geosteer horizontaldrains using measurement-while-drilling (MWD) and logging-while-drilling (LWD) technology.

Applying the workflowIn one example, the FCM workflow was appliedto five carbonate fields located in northernKuwait. One of these fields provided aparticularly good test site for validating theworkflow, because further drilling was takingplace in the complicated structure. Four wellshad been drilled at the start of the study, withtwo further wells drilled as the study progressed.

Abu

Dha

bi In

tern

atio

nal P

etro

leum

E

xhib

itio

n &

Co

nfe

ren

ce

A

DIP

EC

2008

Dubai Office:Dubai Internet City, PO Box 500096, Dubai, United Arab EmiratesTel: + 971 4 391 3134 Fax: + 971 4 391 3138e-mail: [email protected]

Head Office:Alain Charles Publishing LtdUniversity House, 11-13 Lower Grosvenor Place, London, SW1W 0EX, UKTel: +44 (0) 20 7834 7676 Fax: +44 (0) 20 7973 0076e-mail: [email protected]

www.alaincharles.com

AfricaAfricaCovering Oil, Gas and Hydrocarbon Processing

AlainCharlesPublishing Ltd

Serving the world of business

Be seen by thoseBe seen by thosethat matter inthat matter in

the region’sthe region’sOil & Gas sectorsOil & Gas sectors

Be seen by thosethat matter in

the region’sOil & Gas sectors

Be seen by thosethat matter in

the region’sOil & Gas sectors

The “Lighting

Africa” challenge

Show of independents

Nigeria aims to make

NNPC a global player

Seismic activity

in Mozambique

and Tanzania

New generation

tension leg platforms

Positive long-term

benefits with

laser coating

Wi-fi on offshore oil

platforms

Training - extreme

software extends

engineering capabilities

Oil Review

Africa

- Issue Four 2008

TECHNICAL

FOCUS

New generation

tension leg platforms

Page 60

COMMUNICATIONS

Going to sea wirelessly

Page 74

Africa

Africa

Covering Oil, Gas and Hydrocarbon Processing

Issue Four 2008NIGERIA

A new-look NNPC

is slowly emerging

Page 22

Europe m10, Ghana CD18000, Kenya Ksh200, Nigeria N330, South Africa R25, UK £7, USA $12

Nigeria’s Minister for Energy, Odein

Ajumogobia - See page 42

Countering corrosion - composite repair technology

REGULAR FEATURES: News Contracts Events Calendar IT update Company profiles Products & Innovations

Connected porosity

116_140_ADIPEC:Layout 1 22/10/2008 18:51 Page 134

scale. The Schlumberger Carbonate Advisorpetrophysics and productivity analysis,launched this year, centers on characterisationand size partitioning of the pore geometry byusing texture-sensitive borehole logs, such asnuclear magnetic resonance and capturespectroscopy. It is a comprehensive formationevaluation system that leverages poregeometry analysis to confirm theidentification of petrophysical rock types(mineralogy and pore system class), determinefluid saturations and estimate permeabilitiesand relative permeabilities.

Many different measurements are needed tobuild-up a picture of the petrophysical propertiesand producibility of a carbonate formation. Somemeasurements such as photoelectric effect,gamma ray and nuclear magnetic resonanceprovide information about the nature of the rockand its pores, while others, such as resistivity,provide information about its fluid content andmobility. It is the integration of all the availabledata that is key to determining the potentialproductivity of a formation. Carbonate Advisor isan interpretive methodology that integratespetrophysical data in three sequential steps. Thefirst step determines the lithology and porosityof the rock. This evaluation is then used in the

second step to estimate the pore type andpermeability. In the third step, relativepermeability and fluid saturations are derivedfrom a detailed analysis of the radial variation ofresistivity measurements.

Traditionally, petrophysical properties areoften determined from core samples, which areshipped to laboratory for assessment. However,in many cases, key petrophysical characteristics,such as porosity, pore type and permeabilityfrom core measurements may not be availablefor days, weeks or even months. Carbonate

Advisor, log measurements and analysistechniques, goes a long way to providing criticalpetrophysical information in a fraction of thetime. Results, presented continuously as afunction of well depth, are available just hoursafter data has been acquired from logging tools,enabling critical decisions to be made in atimely manner.

The futureToday, carbonate reservoirs continue to posea number of challenges. After all, therecovery factor from these reservoirs is belowthe 35 per cent average for fields of all typesand some fractured carbonate reservoirs haverecovery factors below 10 per cent. Thechallenge in coming years will be tointegrate data even more effectively toproduce ever-more accurate reservoir models,with an even better definition of features.With continued collaboration to refineexisting techniques and the commitment todevelop specialist new technologies, thefuture for carbonate reservoirs is lookingmore productive. ■

Further information is available fromSchlumberger at ADIPEC 2008.

135Oil Review Middle East Issue Four 2007

Abu D

habi International Petroleum

Exh

ibitio

n &

Co

nfe

ren

ce

A

DIP

EC

2008

World Class Welding Technology

Life Extension by Liner Insertion

WeldLink ™ Connector

www.

petro

logy.c

omPetrology solves challenging

welding problems for international

organisations. We bring expert

management, technology,

equipment and training together

to complete welded pipelines

and systems. We do this in all

environments worldwide.

When welding performance is

key to the success of your project,

Petrology makes it happen.

Petrology inserts polymer liners into

new and old pipelines to maximise

life expectancy by eliminating the

risk of internal corrosion. Instead of

replacing an existing pipeline due to

corrosion, Petrology can rehabilitate

the line by retrofitting a polymer liner.

Build long term certainty into your

future pipeline OPEX

– let Petrology line it.

See u

s at

ADIPEC

in th

e UK p

avili

on

Stand H

8/13

-16

tel: +44 (0) 1389 801700 | fax: +44 (0) 1389 801701 | e-mail: [email protected]

Pet

rolo

gy L

td.,

Riv

er C

lyde

Hou

se, E

rski

ne F

erry

Roa

d O

ld K

ilpat

rick,

Gla

sgow

, G6

0 5E

U, S

cotla

nd

Many differentmeasurements are needed to build-up

a picture of the petrophysical propertiesand producibility of acarbonate formation

116_140_ADIPEC:Layout 1 22/10/2008 18:51 Page 135