Confidex Sustain Brochure

Transcript of Confidex Sustain Brochure

Confidex Sustain®

The world’s first cradle to cradle CarbonNeutral® building envelope

CI/SIB (4-) Nh

June 2011

2 Copyright Tata Steel UK Limited 2011 www.colorcoat-online.com

BECAUSESUSTAINABLEPRODUCTSMATTER

About Tata Steel Tata Steel, formerly known as Corus, is one ofEurope's largest steel producers. We servemany different and demanding marketsworldwide, including aerospace, automotive,construction, energy and power, andpackaging. Our primary steelmakingoperations in the UK and the Netherlands aresupported by a global sales and distributionnetwork.

Innovation and continuous improvement areat the heart of our performance culture. Weaim to create value by offering a sustainableand value-added steel product rangesupported by unrivalled customer service. Byworking in partnership with you, we find thebest solutions to meet your needs and helpyour business to perform.

Our European operations are a subsidiary ofTata Steel Group, one of the world’s top tensteel producers. With a combined presence innearly 50 countries, the Tata Steel Groupincluding the Europe operations, Tata SteelThailand and NatSteel Asia, has approximately80,000 employees across five continents and acrude steel production capacity of over 28million tonnes.

Colorcoat® brandColorcoat® is the internationally recognisedmark of quality and metal envelope expertiseexclusively manufactured by Tata Steel atShotton Works in North Wales. It covers arange of pre-finished steel productsspecifically developed for roof and wallcladding systems for the building envelope.

As a leader in metal building envelopes fornearly 50 years, we have made sustainability akey part of what we do and how we work withthe market. The environmental challenges weall face are significant, we are working hard toreduce our impact and to be a part of thesolution.

We have set ourselves a challenging target todeliver a 50% reduction in Shotton Work’s CO2

emissions by 2012, and are already on the wayto achieving this. We focus on responsiblymanaging our impact, and as such ourShotton site is a designated Site of SpecialScientific Interest. We have reduced site wasteto landfill in 2010 by 54%, and have helpedthe local council find an alternative tolandfilling household waste.

In terms of our products in use, we look atthem through their whole life including therole they can play in reducing building’soperational impacts. We work with leadinguniversities to research and publishinformation about designing energy efficient buildings. In 2009/10 we developedpre-finished steel products to reduce lightingrequirements, support renewabletechnologies and facilitate water harvesting.

BES 6001 responsible sourcingTo show our commitment, Colorcoat® productsare certified to BES 6001, the recognisedstandard for responsible sourcing, and throughConfidex Sustain® we are taking action toreduce to zero the unavoidable CO2 emissionsproduced by Colorcoat HPS200 Ultra® andColorcoat Prisma® pre-finished steel productsand the cladding systems they become part of.

Colorcoat Connection® helpline +44 (0) 1244 892434 Copyright Tata Steel UK Limited 2011 3

Confidex Sustain® offers the firstCarbonNeutral® building envelope in theworld, measuring and offsetting its impactfrom cradle to cradle i.e. from manufacturethrough installation and use to end of life interms of re-use, recycling or disposal.

For every 1kg of CO2 emitted by themanufacture and installation of the pre-finished steel, cladding,fixings and insulation we will offset1kg in climate friendly projectsoverseas.

These have a social as well as environmentalbenefit and sees us investing in renewableenergy and energy efficiency projects invarious locations worldwide.

Building on the success of the Confidex®Guarantee, the first and most reliableconstruction product guarantee, ConfidexSustain® offers a zero carbon buildingenvelope system. It goes beyond consideringjust one element of the cladding system toassess and offset all parts including theinternal and external pre-finished steelcladding sheets, fixings and insulation.

Confidex Sustain® is available when aColorcoat HPS200 Ultra® or Colorcoat Prisma®pre-finished steel is used as part of aColorcoat® assessed cladding system with aColorcoat® PE 15 liner sheet.

Balance for the environmentUsing Life Cycle Assessment data for each part of the cladding system, we can accuratelyidentify how much gas that contributes toglobal warming has been emitted at eachstage of the process from manufacture andinstallation, to use and end of life, re-use,recycling or disposal.

This is balanced and offset by Tata Steelproactively, investing in climate friendlyprojects which make use of renewable sourcessuch as wind and solar, and also improve theefficiency with which energy is used.

What is Confidex Sustain®

Confidex Sustain®

offers the firstCarbonNeutral®building envelope in the world, measuring and offsetting its impact from cradle to cradle.

4 Copyright Tata Steel UK Limited 2011 www.colorcoat-online.com

Key Benefits:• Assesses the environmental impact of the

pre-finished steel cladding system fromcradle to cradle.

• Covers the whole pre-finished steelcladding system, not just one element.

• Provides peace of mind for the supply chainin the specification of the most sustainablepre-finished steel products and claddingsystems available. These will deliver long-term building envelope solutions with theultimate levels of performance.

• Provides an important source ofdifferentiation for designers and buildingowners as more people select climatefriendly brands and products.

• Offered by Tata Steel who has an excellenttrack record for developing well researched,robust and credible products and services,which deliver peace of mind and realbenefit for the supply chain.

Key Features:• Offsets the unavoidable CO2 emissions

associated with the pre-finished steelcladding system, insulation and fixings.

• Includes emissions from the pre-finishedsteel cladding system during manufacture,installation, use and end of life, re-use,recycling and disposal.

• Backed by a robust, reliable and fullytraceable process for investing in climatefriendly projects underpinned by theCarbonNeutral Protocol.

• Does not need to be passed along or tradedwithin the supply chain to secure thebenefits of zero carbon.

• Provides a direct link between Tata Steeland the client, who will be the mainbeneficiary of the CarbonNeutral® buildingenvelope.

• Simple to register for, applications can bemade at project design stage.

Tata Steel is able to offer Confidex Sustain® zero carbon building envelope systems becausewe have full traceability and composition information for all elements of the pre-finishedsteel and cladding system, including insulation and fixings.

THE BENEFITS AND FEATURES OFCONFIDEX SUSTAIN®

Colorcoat Connection® helpline +44 (0) 1244 892434 Copyright Tata Steel UK Limited 2011 5

Since it’s launch Confidex Sustain® hasachieved external recognition from thefollowing awards:

• 2008 - Confidex Sustain® won SustainableProduct of the Year, CIWM Awards forEnvironmental Excellence.

• 2008 - Confidex Sustain® won ConstructionProducts Innovation & Achievement award.

• 2008 - Confidex Sustain® short-listed forBuilding Magazine’s Sustainable Product ofthe Year.

External recognition

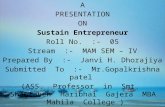

Creating a sustainable systemFigure 1. Cradle to cradle analysis

The cradle to cradle analysis covers all life cycle stages.

Production of system componentsIncludes impacts from:• Production of pre-finished steel and spacer bars.• Production of insulation.• Production of fixings and plastic components.

TransportIncludes impacts from:• Delivery from Tata Steel to system manufacturer.• Delivery to site.• Delivery of insulation and other system components to site.

The difference between the number of vehiclesrequired to transport built-up and composite systemsto site is also accounted for.

End of lifeIncludes impacts from:• Composite panel steel content 79% recycled, 15% re-used, 6% landfill.• All insulation to landfill (foam and mineral wool). Although they have the potential to be recycled, current practice for demolition and other limitations, results in most insulants being landfilled.• 95% recovery of foam-filled composite panel blowing agent by fridge recycling process.

UseAs Colorcoat HPS200 Ultra® and Colorcoat Prisma® aremaintenance free, no significant environmental exchangesoccur during the building lifetime.

System installationIncludes impacts from:• Allowances made for cladding side and end laps.

System manufactureIncludes impacts from:• Profiling of pre-finished steel for cladding.• Composite panel manufacture (foam and mineral wool).• 6% of foam-filled composite panel blowing agent lost in manufacture.

THE ZERO CARBON BUILDINGENVELOPE

6 Copyright Tata Steel UK Limited 2011 www.colorcoat-online.com

Environmental Product DeclarationsAn Environmental Product Declaration (EPD)provides a summary of the environmentalimpacts of a product or system during eachstage of its life. The data published for eachof the Colorcoat® assessed cladding systemsis based on an initial Life Cycle Analysis (LCA)study that we conducted in 2002 inaccordance with the international standardISO 14040-3. This LCA has subsequentlybeen refined and extended to include moreproducts and systems. Some importantpoints arise from this work.

• The durability of a product will always affectthe results of an LCA because of theenvironmental impact of maintenance, andthe need to replace less durable productsduring the lifespan of the building. Nearly50 years of development has enabled us toensure that Colorcoat® by Tata Steel is themost advanced pre-finished steel productavailable with the most comprehensive andextensive guarantees for long-termdurability.

• A series of sensible assumptions have beenmade to take into account transport ofcladding materials between manufacturinglocations, installation and end of life.

• End of life scenarios for pre-finished steelcladding systems are based upon currentpractice. For built-up systems this meansthe steel content is recycled, whilstinsulation is sent to landfill. Factoryinsulated composite panels are recoveredvia the reward route to minimise the escapeof blowing agents which can have a highimpact on global warming.

• There are many reasons why the Colorcoat®assessed cladding systems have slightlydifferent environmental impacts, althoughsteel and insulation content predominatesthe analysis. Confidex Sustain® allows all ofthe assessed cladding systems to achievezero carbon status.

• The EPD summarises the environmentalcredentials of a cladding system. Thisinformation can be used in conjunctionwith whole life cost data, aestheticconsiderations, appropriate maintenanceregimes and other building specific factorssuch as speed of construction to determinethe optimum cladding solution for yourbuilding. We continually review and updatethe LCA to ensure they fully reflect the lateststandards, the latest EPDs are availableonline at www.colorcoat-online.com/epd

Colorcoat Connection® helpline +44 (0) 1244 892434 Copyright Tata Steel UK Limited 2011 7

Since 1965 we have developed closestrategic relationships with a small numberof market leading roof and wall claddingsystem manufacturers.

Specifying Colorcoat® products through oneof these strategic partners ensures access tothe very best technical guidance, quickavailability and the highest levels of qualityand service. Together we provide a qualitybuilding envelope solution that deliverspeace of mind.

Criteria for Colorcoat® cladding systemassessment:Through the Colorcoat® brand we have assessed a range of cladding systemsmanufactured in the UK and Ireland. Each ofthese Colorcoat® assessed systems is designedto perform to the highest standards of thermalperformance, air-tightness and structuralperformance, and can be recycled at the end oftheir life, ensuring the client receives the mostsustainable cladding system.

Confidex Sustain® is available with each of these cladding systems when they useColorcoat HPS200 Ultra® or Colorcoat Prisma®pre-finished steel for the external sheet andColorcoat® PE 15 for the internal sheet.

The following manufacturers haveColorcoat® assessed systems which areincluded in the Confidex Sustain® offer:

• CA Group• Eurobond Laminates• Euroclad• SpeedDeck• Tata Steel• Tegral Metal Forming• Trimo

For a full list of cladding systems whichqualify for Confidex Sustain® please visitwww.colorcoat-online.com/epd

Figure 2. Colorcoat® Supply Chain

8 Copyright Tata Steel UK Limited 2011 www.colorcoat-online.com

COLORCOAT®

ASSESSEDCLADDINGSYSTEMS

The Colorcoat® Supply ChainUncoated steel coil Pre-finished steel coil

Coil coater

Building

Systemmanufacturer

Colorcoat Connection® helpline +44 (0) 1244 892434 Copyright Tata Steel UK Limited 2011 9

• Ensure Colorcoat HPS200 Ultra® and/orColorcoat Prisma® by Tata Steel are specifiedfor the exterior roof and/or walls.

• Ensure Colorcoat® PE 15 is specified for theinterior roof and/or walls.

• Use a Colorcoat® assessed cladding system.For a list of Colorcoat® assessed claddingsystems visit www.colorcoat-online.com

Applications should be made at the start ofthe building project using the ConfidexSustain® registration form, Part 1, availableonline at www.colorcoat-online.com/sustain

This form gives us brief details which allows usto ensure that we have adequate carbonallowances available on building completion.Anyone in the supply chain can register, butmore commonly it is the system manufactureron behalf of the client.

Once the building envelope is complete, Part 2of the online registration process must becompleted. This includes details of the system,the size of the project and the Colorcoat®product used so that the offsetting can becalculated and undertaken.

Again, this form is available electronically onwww.colorcoat-online.com/sustain. If anyproblems are experienced or you have anyquestions regarding the form, please contactthe Colorcoat Connection® helpline on+44 (0) 1244 892434.

Following registration, the building owner/occupier will receive a Confidex Sustain®certificate with details of how much carbonhas been offset and the types of project weare investing in.

Specifying Colorcoat®

products through our strategic

partners ensuresaccess to the

very best technical

guidance.

How to apply for Confidex Sustain®To benefit from the Confidex Sustain® zero carbon building envelope, building projects willneed to:

THE CARBONNEUTRAL COMPANY

Since 1997, The CarbonNeutral Company hasworked with over 300 major businesses andthousands of small and medium-sizedcompanies in 32 countries to develop offsetinclusive carbon management programmes.

CarbonNeutral® is the registered trademark ofThe CarbonNeutral Company and is a globalstandard to certify that businesses havemeasured and reduced their CO2 emissions tonet zero for their company, products,operations or services.

Permission to display the CarbonNeutral®mark is only given to clients whose carbonreduction programme is implemented inaccordance with The CarbonNeutral Protocol.

Working with The CarbonNeutralCompany, a world leading providerof carbon reduction solutions,Confidex Sustain® provides a robustand fully auditable process toneutralise unavoidable emissions.

10 Copyright Tata Steel UK Limited 2011 www.colorcoat-online.com

The Protocol assures quality of offset projects,carbon footprint assessments andcommunication and is regularly reviewed byan Independent Advisory Group. Thecompany’s ‘audit trail’ includes an annualindependent verification of CarbonNeutral®programmes – from contracts with carbonoffset partners through to contracts withclients and everything in between.

Carbon offset projectsThe CarbonNeutral Company purchasescarbon offsets in emission reduction projectsaround the world on behalf of Tata Steel.Buying one tonne of carbon offsets meansthere will be one less tonne of carbon dioxidein the atmosphere than there would otherwisehave been.

We have has chosen a range of renewableenergy and energy efficiency projects whichhave all been third party verified, accepted by an independent certification standard and meet the standards outlined in TheCarbonNeutral Protocol.

Colorcoat Connection® helpline +44 (0) 1244 892434 Copyright Tata Steel UK Limited 2011 11

CASE STUDIESRetail distribution centreProLogis, Pineham, Northampton

The 618,500 sq. ft. distribution centre forSainsbury’s in Northampton set newbenchmarks in sustainable design, with helpfrom Confidex Sustain®.

By specifying a pre-finished steel buildingenvelope at the outset, the sustainabilitycredentials of the project are alreadyexceptionally high, due to the co-operationof the supply chain, using Confidex Sustain®.

Architect: RPS Burks Green

System manufacturer: CA Group

Main contractor: Buckingham Group Ltd.

Cladding contractor: CA Roofing Services

Colorcoat® products used: Colorcoat HPS200® (Roof) Goosewing Grey.Colorcoat Prisma® (Walls) Alaska Grey, Whiteand Oyster.

Confidex® Guarantee: 30 years

Year completed: 2008

Carbon Offset: 14,146 tonnes of CO2

Colorcoat HPS200® has now been superceded byColorcoat HPS200 Ultra®.

12 Copyright Tata Steel UK Limited 2011 www.colorcoat-online.com

“The majority of the building envelope hasa CarbonNeutral® status, without doubt, it isthe use of Confidex Sustain® that sets thisproject head and shoulders above otherretail distribution developments.”Richard Smyth, associate at achitects RBS Group, Newark.

Bulmers bottling plantAnnerville, Clonmel, County Tipperary, IrelandAs well as its success in the Irish drinksmarket, Bulmers can claim its bottling plantbenefits from the world’s first cradle tocradle CarbonNeutral® building envelope.

Through Confidex Sustain®, the plant canensure that virtually all of the buildingscomponents are traceable from manufactureto end of use.

Architect: John Allen Architects

System manufacturer: Euroclad (Ireland)

Main contractor: Sisk & Mulcahy Construction

Sub contractors: Paddy Wall & Sons - Phase 1Gleeson Roofing, N. Ireland - Phase 2

Colorcoat® product used: Colorcoat HPS200® (Roof and Walls)Meadowland Green, Hamlet and GoosewingGrey

Confidex® Guarantee: 30 years

Year completed: 2007

Carbon Offset: 934 tonnes of CO2

Colorcoat Connection® helpline +44 (0) 1244 892434 Copyright Tata Steel UK Limited 2011 13

“We would definitely go down the Confidex Sustain® route again. It enables us to contribute to the Bulmers policy on environmental issues.” John Allen, project architect.

OUR COMMITMENTTO SUSTAINABILITY

14 Copyright Tata Steel UK Limited 2011 www.colorcoat-online.com

Is it just green-wash?Some may argue that offsetting schemes arejust green-wash. We don’t see this as the casefor Confidex Sustain®, it is more an additionalbenefit that we can offer on top of our longterm commitment to reducing our impact onthe environment. At Tata Steel, we arecommitted to making the products societyneeds and to making them in the safest andmost responsible way possible. We believethat this joint focus on our products and ourprocesses demonstrates our real commitmentto providing a better quality of life for peoplewithout compromising the future.

Sustainable steelSteel is an essential material, intrinsic to ourway of life and to the products society willdemand in a sustainable future. Steel is amaterial that is used, not consumed. It isrecycled and used again, without any loss ofquality, time after time. At Tata Steel, we arecommitted to making the products societyneeds and to making them in the mostresponsible way possible.

This means, practically, that we commit to:• Producing steel products for the future.• Investing in sustainable steel-making.• Improving our existing processes.• Facilitating the recycling loop.

Our steel enables our customers to make safercars, more energy-efficient buildings andinfrastructure, easily-recoverable andrecyclable packaging and many otherproducts which help to move society towardsour vision of a sustainable future.

Colorcoat® manufactureIn terms of waste, Colorcoat® products usesteel made by Tata Steel in Port Talbot from acombination of recycled steel scrap and ironore, they are then manufactured at our site inShotton. This is a designated Site of SpecialScientific Interest, demonstrating our ability tomanage our site operations withoutcompromising biodiversity. We maintain thelagoons on our site as an internationallyimportant breeding ground for several speciesof sea-birds.

We have a target to reduce Shotton site CO2

emissions by 50%, this will save nearly 100ktof CO2 annually. Strategies for delivering thisinclude a move from road to 100% rail for allfeedstock coming from South Wales. A focuson process and operational energy reductioninitiatives such as installation of variablespeed drives and energy efficient lighting; andparticipation in an energy from waste scheme.Figure 3 shows our achievement to date andour planned reductions for the future.

Within Shotton we set targets to ensure theefficient use of materials such as Zinc andpaint to minimise waste. Over 95% of our Zincpot waste is reclaimed and recycled for use insecondary die making and as an ingredient incosmetics. We also recover the solvents usedfor washdowns between paint colour changes.These are taken offsite to be filtered, distilledand then return to Shotton as a 50% recycledblend.

Colorcoat® in use A key part of sustainable design is specifyingproducts that offer long-term performancewith no maintenance such as that offered bythe Confidex® Guarantee. This provides coverfor Colorcoat HPS200 Ultra® and ColorcoatPrisma® for up to 40 years with norequirement for inspection or maintenance toretain its validity.

We have worked closely with the leadingarchitectural school at Oxford BrookesUniversity to look at the operational impactsof a building and identify what contributionpre-finished steel cladding can make to itsefficient running.

This work has revealed that the operationalCO2 of a building can far outweigh theembodied CO2 associated with the buildingfabric and construction which on very largebuildings can account for as much as 80% oftotal CO2 of the building life cycle. Optimisingthe building envelope efficiency throughinsulation, high air-tightness levels andminimising linear thermal bridging can reducethe operational impacts.

With our Colorcoat® Technical Papers, weprovide best practice advice and guidance ondesign and detailing to ensure that buildingsusing Colorcoat® assessed cladding systemscan achieve the very best levels of energyefficiency. For more information visit:www.colorcoat-online.com/technical

Typical CO2

emissions per tonne of steel are now around 50% lower than 50 years ago.

Colorcoat Connection® helpline +44 (0) 1244 892434 Copyright Tata Steel UK Limited 2011 15

0

50

100

150

200

250

2007 2008 2009 2010 2011 2012

Figure 3. Reduction in kt of CO2 at the Shotton site since 2007

For further information on Tata Steel sustainability incentives see our corporate citizenship report available at www.colorcoat-online.com/sustainability

End of lifeUsing appropriate maintenance and remedialaction such as over-painting, Colorcoat®products can last almost indefinitely. Whenthe building envelope does come to the endof its life, there is a well established system forcollecting and processing steel scrap whichhas a positive financial value. Inclusion of steelscrap is an integral part of the steelmanufacturing process. Colorcoat® productscan be recycled indefinitely without any lossof property or performance in the resultingsteel products.

Sustainable Building Envelope CentreDemonstrating our commitment tosustainable construction, together with theLow Carbon Research Institute (LCRI) andWelsh Assembly Government, we areinvesting £6 million to create a ‘SustainableBuilding Envelope Centre’ (SBEC) at Shottonwhich will lead in the development of lowcarbon, low energy technologies. This centreof excellence will accelerate thedevelopment of low and zero carbonsolutions for the built environment usingsteel in combination with other materials.

An existing building on the Shotton site hasbeen refurbished to provide a showcase forthe centre and act as a test rig and provingground for new technologies to demonstrate

them in use. SBEC will be used to test andmonitor new integrated heating, energy andventilation systems on the fabric of thebuilding. The aim is to create a constructionprocess which will enable the façade ofbuildings, both roof and walls, to betransformed from a passive energyconservation role to an active energygeneration, storage and managementfunction.

Port Talbot BOS gas recovery schemeThis is a £60 million investment to capturethe offgas generated in steelmaking for useas an energy source, in the past this wouldhave been flared off. As well as significantlyreducing electricity (15%) and natural gas

(60%) requirements, the scheme reducesPort Talbot’s CO2 emissions by 3%amounting to nearly 300 tonnes per year.This project alone will enable Wales to meetits national emissions target.

Energy from Waste schemeThis scheme on our Shotton site will seecommercial and domestic waste from thelocal area being converted into a solidrecovered fuel that can be processed toprovide a major part of the site's electricityrequirements. As well as providing arenewable energy source, the scheme whichis due to be operational at the end of 2011,will reduce the amount of local waste goingto landfill by 90%.

Tata SteelColors Colorcoat Connection® helplineShotton Works T: +44 (0) 1244 892434Deeside F: +44 (0) 1244 892321Flintshire Email: [email protected] 2NHT: +44 (0) 1244 812345F: +44 (0) 1244 892345www.colorcoat-online.com

Copyright 2011 Tata Steel UK Limited, Registered Office: 30 Millbank London SW1P 4WY, Registered in England No. 2280000

Language English UK 0611

www.colorcoat-online.com

Trademarks of Tata Steel UK Limited(formerly Corus)

Colorcoat, Colorcoat Connection, Colorcoat HPS200,Colorcoat HPS200 Ultra, Confidex, Confidex Sustainand Prisma are registered trademarks of Tata SteelUK Limited.

CarbonNeutral is a registered trademark of theCarbonNeutral Company.

Care has been taken to ensure that the contents ofthis publication are accurate, but Tata Steel EuropeLimited and its subsidiaries, (including Tata Steel UKLimited), do not accept responsibility or liability forerrors or information that is found to be misleading.Suggestions for, or descriptions of, the end use orapplication of products or methods of working arefor information only and Tata Steel Europe Limitedand its subsidiaries accept no liability in respectthereof.

Before using products or services supplied ormanufactured by Tata Steel Europe Limited and itssubsidiaries, customers should satisfy themselves asto their suitability.

Printed with biodegradable vegetable inks onmaterial sourced from responsible managed forests,certified in accordance with the FSC. Contains 10%recovered fibre, diverting waste from landfill.

Copyright 2011 Tata Steel