Conductor Rail Heating Litrature 01 02 10 - GrayBar · GrayBar Reference GB Ref Issue: 01 Author:...

Transcript of Conductor Rail Heating Litrature 01 02 10 - GrayBar · GrayBar Reference GB Ref Issue: 01 Author:...

GrayBarReference GB Ref: PI/CRH/001 Issue: 01 Author: SC Ford

Conductor Rail Heating Product Information Pack

GrayBar Limited Tel: 0044 (0) 1933 676700 Fax: 0044 (0) 1933 676800

Page 1 of 16 Issue 14/06/2010

Self-Regulating Conductor Rail Heating

For Network Rail & London Underground

Railway Infrastructure

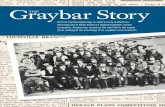

Fig.1 Network Rail 3rd Rail Infrastructure, South East UK:

The photograph above illustrates the typical freezing conditions that can result in costly train delaysand failures. This can be due to ice forming on the conductor rail surface resulting in poor electricalcontact from the collector shoe and potential ‘sticking’ of the shoe when the train is stationary. Top contact conductor rails, such as shown in Fig 1, can benefit from self-regulating heating in criticalareas. Location: UK.

GrayBarReference GB Ref Issue: 01 Author: SC Ford

Conductor Rail Heating

GrayBar Limited Tel: 0044 (0) 1933 676700 Fax: 0044 (0) 1933 676800

Page 2 of 16 Issue 14/06/2010

Title page ..................................................................................................................................... 1

Contents ...................................................................................................................................... 2

Glossary....................................................................................................................................... 3

1 OVERVIEW .................................................................................................................... 4

1.1 Conductor Rail Heating .................................................................................................. 4

2 SPECIFIC ADVANTAGES OF USING SR CON RAIL HEATING ................................. 7

2.1 The main benefits of using self-regulating heaters are as shown below; ....................... 72.2 Typical Train Depot in wintry conditions. ........................................................................ 8

3 PRODUCT SPECIFICATION ....................................................................................... 10

4 DETAILS OF CABLE MANAGEMENT........................................................................ 11

4.1 Method of control.......................................................................................................... 124.3 Diagrams showing the various types of conductor rail (topside and bottom contact) withdetail of the spring clip fixing arrangement shown for top contact rail systems. ......................... 13

5 POWER REQUIREMENTS.......................................................................................... 15

Table of Figures

Fig.1 Network Rail 3rd Rail Infrastructure, South East UK: _____________________________________ 1Fig 2: Conductor Rail Junction Layout –Location LUL ________________________________________ 5Fig 3: Top contact conductor rail with Graybar self-regulating heating. ___________________________ 6Fig 4: Wintry conditions with no apparent conductor rail heating. Location LUL Neasden Depot, UK____ 8Fig: 5 Conductor rail, termination with fibreglass heat shield channel clearly visible _________________ 9Fig 6: Self-Regulating Heater Element ______________________________________________________ 9Fig 7: Conductor Rail Self-Regulating Heater Strip –PTC characteristic __________________________ 10Fig.8 Cables__________________________________________________________________________ 11Fig 9: Internal layout of a typical conductor rail heating control cubicle. Location, Sweden___________ 12Fig 10: Internal layout of existing control cubicle, ____________________________________________ 13Fig 11: Power Requirement Table_________________________________________________________ 15Fig 12: Graybar Self-regulating Conductor Rail and Point Heating System, Location Stockholm. ______ 16

GrayBarReference GB Ref Issue: 01 Author: SC Ford

Conductor Rail Heating

GrayBar Limited Tel: 0044 (0) 1933 676700 Fax: 0044 (0) 1933 676800

Page 3 of 16 Issue 14/06/2010

Glossary

The following terms apply specifically to this document:

PI Product Information

CRH Conductor Rail Heating

SR Self-Regulating

CRH/750/NR/xxx

GrayBar,Network Rail Heater Part Number Prefix for conductor rail heater

Con Rail Conductor Rail or Contact Rail

PTC Positive Temperature Coefficient

NR Network Rail

SL Stockholm Metro Sweden

LUL London Underground Ltd

GrayBarReference GB Ref Issue: 01 Author: SC Ford

Conductor Rail Heating

GrayBar Limited Tel: 0044 (0) 1933 676700 Fax: 0044 (0) 1933 676800

Page 4 of 16 Issue 14/06/2010

1 Overview

The purpose of this document is to provide product information on Graybar self-regulating conductorrail heating. The conductor rail heating system is manufactured by:

GrayBar Ltd

10 Fleming Close

Park Farm Industrial Estate

Wellingborough

Northants

NN8 6UF

UK

1.1 Conductor Rail Heating

On third and fourth rail infrastructure it can be beneficial to provide electric strip heating on to theconductor rails when the ambient temperature is hovering around zero degrees Celsius resulting inthe top surface of the rail being prone to the formation of ice which would affect the collection ofpower by the train.

There are five main reasons why conductor rail heating should be considered:

1. To prevent the formation of ice on the top of the rails thus enabling sufficient power transferfor continuous operation of the rolling stock.

2. To prevent the shoe gear from ‘sticking’ to the rail when the train is stationary.

3. To prevent potential ‘burnout’ of the shoe gear due to severe arcing between the rail and shoe.

4. To ensure continuous current supply to the rolling stock minimising intermittent disruption ofsupply.

5. To minimise train fault displays leading to stoppage and costly traffic delays.

The net result of all these issues will inevitably result in serious delays and disruption to traffic alongthe route concerned. Although it is not necessary to heat the whole of the third rail system it isbeneficial to heat the rail at certain critical locations where there will be heavy traction current drawsuch as at the initial departure from stations and on rising gradients.

Following the policy of heating railway points in order to mitigate the effects of ice and snow itbecomes apparent that the electric heating of the conductor rail at certain locations on 3rd and 4th

rail DC infrastructure would result in a further benefit towards fully operational railway infrastructurein adverse weather conditions.

GrayBarReference GB Ref Issue: 01 Author: SC Ford

Conductor Rail Heating

GrayBar Limited Tel: 0044 (0) 1933 676700 Fax: 0044 (0) 1933 676800

Page 5 of 16 Issue 14/06/2010

Fig 2: Conductor Rail Junction Layout –Location LUL

In other countries where 3rd rail DC infrastructure has to function to allow the normal operation ofrolling stock in adverse weather conditions the use of electric conductor rail heating is either beingconsidered or has been used for many years.

The cost of the installation and the energy consumption is outweighed by the benefit to the trainoperator and therefore this could also be of particular interest in the UK, in view of the recentoperational problems caused by ice formation on the conductor rail in freezing conditions.

The initial capital outlay with the installation of conductor rail heaters and the financial return can bemeasured over a period of time based on the incidents of conductor rail icing and the frequency oftraffic over a particular route.

In addition if the train operator demands continuous operation of all infrastructure equipment with afully reliable system in all weather conditions and with ambient temperatures down to -15deg.C.Then conductor rail heating must be the solution at certain critical locations.

Drawing depicts typicalfixing positions shown ofconductor rail heater.

GrayBarReference GB Ref Issue: 01 Author: SC Ford

Conductor Rail Heating

GrayBar Limited Tel: 0044 (0) 1933 676700 Fax: 0044 (0) 1933 676800

Page 6 of 16 Issue 14/06/2010

Fig 3: Top contact conductor rail with Graybar self-regulating heating.

The above photograph illustrates a conductor rail installation using Graybar Self-Regulating heatinginstalled and retained in position using mechanical spring clips. The use of a wooden cover board isfitted here and this is provided to afford added protection from ice and snow settling on the railsurface.

GrayBarReference GB Ref Issue: 01 Author: SC Ford

Conductor Rail Heating

GrayBar Limited Tel: 0044 (0) 1933 676700 Fax: 0044 (0) 1933 676800

Page 7 of 16 Issue 14/06/2010

2 Specific Advantages of using SR Con Rail Heating

Electric conductor rail heating can be in the form of series resistance or self-regulating heatingelements attached to the upper web of the conductor rail, positioned as close to the underside of therail head as possible for maximum heating efficiency.

Both types of heater can be supplied in long circuit lengths, however with self-regulating heaterelements the heater consists of a semi-conducting polymer between two bus wire conductorsrunning the length of the product therefore, unlike series resistance and constant wattage heaters,there is no filament to burn out and the heater will only draw the optimum power in response to therail temperature. Also the self-regulating heater, being of a parallel circuit configuration, canrespond to different rail temperatures along the same circuit length. It therefore follows that, undercertain conditions, the heater will draw more power at the more exposed end of the circuit whencompared to the other end of the same circuit.

In addition the heater derives its power from the 750Volt DC conductor rail traction supply makingthe installation very simple and cost effective.

2.1 The main benefits of using self-regulating heaters are as shown below;

Heater is available for operation at a nominal 750Volts DC

Maximum power consumption 200 watts per metre

Long Continuous Circuit Lengths of heater are possible

The heater element has an fully insulated sheath

The heater is flexible making installation easier, safer and can easily conform to the railprofile.

The heater can be directly connected to its own 750volt DC conductor rail supply, or via apower supply controller

Due to its non filament construction the heater cannot burnout and has a long service life

Can be easily and quickly installed on to the rail with mechanical spring fixing clips

Heater is installed with thermal grease and a non-metallic heat shield to maximise heattransfer efficiency

Self-Regulating technology optimises the power draw to maintain rail temperature

Well-proven and reliable product has been used in the rail industry for over 20 years.

Easily transportable product enables it to be supplied as a fully factory tested, pre-terminatedroll of product ready for installation.

All product is supplied fully type tested with full traceability

Readily available and manufactured in the UK as a Conductor Rail System Package AsCRH/750/ (customer ident / heater length).

GrayBarReference GB Ref Issue: 01 Author: SC Ford

Conductor Rail Heating

GrayBar Limited Tel: 0044 (0) 1933 676700 Fax: 0044 (0) 1933 676800

Page 8 of 16 Issue 14/06/2010

2.2 Typical Train Depot in wintry conditions.

Fig 4: Wintry conditions with no apparent conductor rail heating. Location LUL Neasden Depot, UK

This location illustrates unheated conductor rail with the top surface covered by snow.Heating the conductor rail would be beneficial in allowing the movement of rolling stock, particularlyin the early hours of the day from overnight storage at the depot.

With increased traffic and inevitable cost penalties it is now imperative that the infrastructure is fullyoperational during adverse weather conditions when snow and ice can disrupt traffic on the network.

GrayBarReference GB Ref Issue: 01 Author: SC Ford

Conductor Rail Heating

GrayBar Limited Tel: 0044 (0) 1933 676700 Fax: 0044 (0) 1933 676800

Page 9 of 16 Issue 14/06/2010

Fig: 5 Conductor rail, termination with fibreglass heat shield channel clearly visible

Fig 6: Self-Regulating Heater Element

Heater example to demonstrate railcontact, termination fixing and heatshield GRP channel (bottom flangespring clip fixing shown).

GrayBarReference GB Ref Issue: 01 Author: SC Ford

Conductor Rail Heating

GrayBar Limited Tel: 0044 (0) 1933 676700 Fax: 0044 (0) 1933 676800

Page 10 of 16 Issue 14/06/2010

3 Product Specification

The CRH Self-Regulating heater element comprises of a semi-conducting polymer mouldedbetween two copper conductors, with an over sheath of PTFE insulation. This construction results ina rugged, durable product designed specifically for harsh railway infrastructure applications.

Fig 7: Conductor Rail Self-Regulating Heater Strip –PTC characteristic

Where the heater is cold,the core contracts

microscopically, creatingmany electrical paths

through the conductivecarbon. The flow of

electricity through the coregenerates heat.

In warmer sections, thecore expands

microscopically,interrupting many

electrical paths. Theincreased electrical

resistance causes theheater to reduce its power

output.

In hot sections, themicroscopic core expansion

disrupts almost all theelectrical paths. With this

high resistance to electricalflow, power output is virtually

zero.

•The outer sheath of the heater element is made from non-conductive PTFEmaterial

•The inner core consists of a semi-conducting carbon loaded polymer which iscan carry high current when the substrate material such as a steel rail is verycold.

•

GrayBarReference GB Ref Issue: 01 Author: SC Ford

Conductor Rail Heating

GrayBar Limited Tel: 0044 (0) 1933 676700 Fax: 0044 (0) 1933 676800

Page 11 of 16 Issue 14/06/2010

4 Details of cable management

Cables for conductor rail heating would typically be rated for continuous operation at 750 volts DC.The positive cable from the heater would normally be bonded to the conductor rail either by a directconnection onto the rail (the rail bond) or via a simple means of isolation, which can be a hookswitch mounted onto the conductor rail.The negative return path for the heater will normally be via a cable onto the traction return rail oradjacent rail bond.The cable will be of EPRPCP unarmoured construction with an insulation level suitable for 750 voltDC.Cables feeding conductor rail heating and their associated controls should be clearly identified withthe circuit identification number and location i.e. the rail to which it is attached.

Fig.8 Cables

GrayBarReference GB Ref Issue: 01 Author: SC Ford

Conductor Rail Heating

GrayBar Limited Tel: 0044 (0) 1933 676700 Fax: 0044 (0) 1933 676800

Page 12 of 16 Issue 14/06/2010

4.1 Method of control

Fig 9: Internal layout of a typical conductor rail heating control cubicle. Location, Sweden

The above illustration shows a solid-state controller for conductor rail heating, which can either bemounted inside a switch-room or installed at a trackside location. In all cases it is vital that thetemperature probes are mounted adjacent to the rail to which the heater is attached. In this examplethis controller has been installed to enable the particular heating circuit to be switched out in thesummer months or when field maintenance is required to be carried out. Many conductor railheating circuits however, when using the self-regulating form of heating, do not require a controllerdue to the much lower current draw of the heater in the summer months due to its response tohigher rail temperatures.

If required the heater controls can bemounted into a GRP cubicle and canswitch the conductor rail heating circuitin auto mode or override.In auto mode the heaters are switchedon and off by means of a controllerwhich detects a combination oftemperature, precipitation and/or railtemperature.

GrayBarReference GB Ref Issue: 01 Author: SC Ford

Conductor Rail Heating

GrayBar Limited Tel: 0044 (0) 1933 676700 Fax: 0044 (0) 1933 676800

Page 13 of 16 Issue 14/06/2010

Fig 10: Internal layout of existing control cubicle,

4.3 Diagrams showing the various types of conductor rail (topside and bottom contact) withdetail of the spring clip fixing arrangement shown for top contact rail systems.

The rail section size and shape determines the specific type of mechanical spring fixing clip to beused and a range is available to retain the heater and heatshield assembly in the correct positionunder the railhead.

Thermal grease is also applied to increase the thermal efficiency between the heater element andthe rail web surface.

Control cubicles can be of a very basicswitch on/off arrangement with basiccircuit protective devices. Within a depotarea this method of operation can bereliable and effective.

GrayBarReference GB Ref Issue: 01 Author: SC Ford

Conductor Rail Heating

GrayBar Limited Tel: 0044 (0) 1933 676700 Fax: 0044 (0) 1933 676800

Page 14 of 16 Issue 14/06/2010

GrayBarReference GB Ref Issue: 01 Author: SC Ford

Conductor Rail Heating

GrayBar Limited Tel: 0044 (0) 1933 676700 Fax: 0044 (0) 1933 676800

Page 15 of 16 Issue 14/06/2010

5 Power Requirements

GrayBar self-regulating conductor rail power requirements;

The CRH type heater is rated at 200 watts per metre max.

The heater operating voltage is a nominal 750 volts with an operating window between 600 voltsand 1200 volts.

The heater can function at AC or DC however for conductor rail heating it is recommended thatthe power be derived from the conductor rail at a nominal 750 volts DC.

The maximum circuit length of the self-regulating heater is 150 metres.

The maximum current draw is 40 amps (150 metre circuit).

3rd Rail DC & 3rd ,4th Rail DC

Maximum Circuit Length = 150Mtrs

Maximum Power Draw = 200 W/M

Maximum Power Draw Per 150 Meters = 30Kw

Maximum Current Draw Per 150 Meters = 40 Amps

Average Nominal Current Draw + 5 to –5 = 27 Amps

Nominal Operating Voltage = 750 Volts

Operating Range Voltage = 600 –1200 Volts

Fig 11: Power Requirement Table

This table is a design guide to enable the power draw of each heater circuit to be calculated oncethe particular heater length has been determined. Where the rail-heating requirement exceeds themaximum circuit length of 150 metres additional heater lengths can be added. The total power drawin any case would not be excessive when compared to traction power draw. The operating windowof the heater (600-1200 volts) ensures effective heating allowing for any supply voltage variation.This is a typical table that would be used in respect of Network Rail 3rd rail DC areas and LondonUnderground Ltd 3rd & 4th Rail DC infrastructure.

GrayBarReference GB Ref Issue: 01 Author: SC Ford

Conductor Rail Heating

GrayBar Limited Tel: 0044 (0) 1933 676700 Fax: 0044 (0) 1933 676800

Page 16 of 16 Issue 14/06/2010

Fig 12: Graybar Self-regulating Conductor Rail and Point Heating System, Location Stockholm.

Fully operational GrayBar self-regulating heating on both points and conductor rail is clearly andeffectively illustrated above.

AppendixDR003: General arrangement drawing of conductor rail Heating

![GR-2994 British Columbia. Supreme Court (Courtenay)...[Jim][Jimmy][Edward] 1987 830397-0044 CO878043 Robinson, John 1987 830397-0044 CO878044 Mjooney, Gladys Margaret 1987 830397-0044](https://static.fdocuments.in/doc/165x107/6052e922e026413ecf79de08/gr-2994-british-columbia-supreme-court-courtenay-jimjimmyedward-1987.jpg)