Concord Oct10

-

Upload

yogesh-jain -

Category

Documents

-

view

94 -

download

8

Transcript of Concord Oct10

Oct - Dec 2010 • Volume-33 • Issue-4

FocusL&T’s capabilities from the very beginning of its inception are aligned to serve the national interest and country’s development. This has earned the Company the axiom “Builders to the Nation” and in-tune with this adage, L&T is continuing its quest of contributing its best to the industrial and infrastructural development of the country.

L&T has made a significant contribution to the development of India’s transportation sector, be it the hi-tech highways, bridges, tunnels, viaducts, ports, airports and railways. In all these projects, L&T has taken the lead by introducing pioneering construction techniques, resulting in execution of projects with innovation, high quality and speed.

L&T has been associated with Delhi Metro Rail Corporation (DMRC) for more than a decade and has executed some of the most critical projects under Phase I and Phase II of Delhi Metro covering both elevated and underground metro rail corridors including station buildings. The good work carried out by DMRC in Delhi is now extended to other metros and L&T is actively involved in Bangalore, Chennai and Hyderabad cities.

In this issue of ECC Concord, we bring to you our success story in building Phase - II projects under Delhi Metro where L&T was involved in five packages. Apart from this, the issue also delineates the expansion project at Maruti’s Manesar facility, Cairn India’s Barmer project and Hindustan Zinc project at Rajpura Dariba mine. The kaleidoscope section, as usual, presents a colorful array of important events that occurred during the third quarter of the current fiscal.

Hope, you will find these articles interesting along with many other kaleidoscope items.

Happy reading.

- Editor

In this issueOct - Dec 2010 • Volume - 33 • Issue - 4

Editor : V. S. Ramana

Editorial team : K. Sridharan | Alex Benjamin

V. Ramesh Kumar | Gopi Kannan. S

V. Eswar | Ashwin Chand | Mayura. K

Subha Anand

Photography : V. S. Natanavelu

Design & layout : Global Print Design, Chennai

330

34 42

Delhi Metro Rail Corporation Delhi’s traffic and pollution solution

Maruti Buildings for gearing up production

Cairn India Burning the midnight oil at Barmer

Hindustan Zinc Ltd Rajpura Dariba - The Zinc Thing

Kaliedoscope

Inauguration ................................. 46

New Orders ................................... 49

Events ........................................... 51

Corporate Sustainability ............... 59

Awards .......................................... 66

ECC CONCORD Oct - Dec 2010 3

Metro - Delhi’s traffic and pollution solution

The exploding population of Delhi and the resultant traffic snarls on road comes as no big surprise. But what can be truly astonishing is the fact that the number of vehicles on the roads of Delhi is more than that of the three other major Indian metros put together. The Government, in order to mitigate this problem, aimed at discouraging private mode of transport and encouraging public mode through the introduction of quality rail based MRTS or the Mass Rapid Transit System. Developed countries include such systems in their city planning even when the population touches 1 million. This is done so that the city can

handle the burden of population and yet allow for free flow of traffic in a planned and phased manner.

The city administration of Delhi has to deal with a growing population of 16 million, a figure that very few cities in the world face today. But on the positive side, Delhi has offered itself for upgrading to the MRTS by having wide roads (that form 23% of the city) with excellent connectivity. Another attribute that favoured faster implementation of MRTS at Delhi is that majority of land are Government owned and consequently lesser worries regarding acquisition of private land.

Phase 1

Delhi Metro Rail Corporation, was incorporated in 1995 with equal equity partnership between Government of India and Government of National Capital Territory of Delhi. Phase 1 of Delhi Metro has already earned the credit of being a passenger friendly, clean, safe and fast mode of transport in the Capital region. Costing close to Rs.105.7 billion, Phase 1 of Delhi Metro primarily comprises of three lines (I, II & III) that totals a length of 62.29km.

Line I runs between Shahdara to Rithala covering a distance of 22.06km, with 18 stations and 18 trains available at a frequency of 4 minutes during peak time. Line II

Underground rail corridor for Delhi Metro

ECC CONCORD Oct - Dec 2010 4

runs between Vishwavidyalaya and Central Secretariat Stations covering a distance of 10.84kms and has 10 underground stations. Line III is operating between Barakhamba– Dwarka section and covers a distance of 32.10kms with 31 stations. In 1988, the construction of Metro Rail Project commenced. The Shahdara – Tis Hazari section was commissioned in 2002;Tis Hazari – Inderlok section in 2003; Inderlok – Rithala in 2004.

The first underground section between Vishwavidyalaya and Kashmere Gate was inaugurated in 2004 and the Kashmere Gate – Central Secretariat was completed in 2005. The benefits of Phase I project include 1.5 million commuter trips per day siphoned off the roads with 1,650 less buses on the roads; Increase in average speed

of road buses from 10.5 km/h to 14 km/h; Saving of 2 million man-hours per day and the fuel cost of approximately Rs.650 crores per year; Reduction in pollution (30%) and accidents (30%).

DMRC Phase II

If one were to look at the Metro map of Delhi, it would present a vibrant picture with colourful lines intersecting the populous city. Each metro line is represented by colours

Phase 1 Network

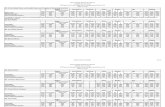

LineLength (Kms)

No. of Stations

Line No.1- Shahdara-Tri Nagar-Rithala 22.06 18

Line No.2- Vishwavidyalaya-Central Secretariat 10.84 10

Line No.3- Indraprastha-Barakhamba Road-Dwarka Sub City

32.10 31

Total 65.00 59

Various components of an underground station

Top down excavation method with diaphragm wall

Colourful lines that intersect Delhi

The Red Line was the first line of the Metro and connects Rithala in the west to Dilshad Garden in the east, covering a distance of 25.09 km

The Yellow Line was the first underground line running for 44.36 km (27.56 mi) from north to south and connects Jahangirpuri with HUDA City Centre

The Blue Line is the first Metro line that connects areas outside Delhi. It is partly overhead and partly underground connecting Dwarka Sub City in the west with the satellite city of Noida in the east, covering a distance of 47.4 km

Green Line is the first standard-gauge corridor of the Delhi Metro. This fully elevated line connects Mundka with Inderlok, covering a distance of 15.1 km

The Violet Line is the most recent line of the Metro, covering 15 km connecting Sarita Vihar to Central Secretariat

ECC CONCORD Oct - Dec 2010 5

such as red, yellow, blue, green, and violet. This colour coding has made it elementary and simple for commuters to identify the network and travel with ease. As of October 2010, the whole of Phase-I and parts of Phase-II are complete, with the network comprising five lines with 130 metro stations and a total length of 156 km.

L&T and DMRC

Under Phase I, L&T was involved as a Joint Venture partner in the design and construction of civil, mechanical and electrical works for DMRC – MC1B package comprising of 7km tunnelling using tunnel boring machines and construction of six underground station buildings. This included construction of cut and cover tunnel structure between Ch. (-) 1.52km and (-) 2.05km, Mandi House underground station and a ramp on the extension of Barakhamba Road-Connaught Place-Dwarka Section (Line No.3) and Barakhamba Road – Indraprastha section for DMRC.

Construction for DMRC predominantly included methodology such as cut & cover, top-down and bottom-up.

Construction process of top down method

Construction of diaphragm wall y

Installation of plunge columns & ytension piles

Install dewatering and re-charge ywells

Excavation upto roof slab level at y3m from natural ground level

Construction of roof slab y

Excavation below roof slab and yupto concourse slab

Construction of concourse slab y

Excavation below concourse yslab to base slab bottom level

Installation of waterproofing ysystem including drainage layer

Construction of base slab over yno-drainage layer

Construction of up-walls and yplatform slab

Develop plunge column into ypermanent columns from concourse to roof slab & base slab to concourse slab

Construction process of cut & cover method

Installation of dewatering well yat least 6 m below the formation level in case of aluvium soil

Installation of recharging well y

Installation of soldier piles y

Manual excavation upto 1.8m ydepth to search utilities and suitable supporting system if detected. Installation of timber lagging is done simultaneously

Excavation with machine yupto 1m below the 1st layer strut

Installation of 1st layer strut y

Proceed with 2nd level yexcavation upto 1m below the 2nd layer strut

Installation of 2nd layer strut y

Excavation in progresses for D wall

Bottom up excavation method with soldier piling

ECC CONCORD Oct - Dec 2010 6

Repeat this procedure till yformation level is reached

Monitor the soil displacement yperiodically

Construction of the concrete ytunnel/station

Sand filling at the side of the y

tunnel/station and soil filling upto ground level

Simultaneous de-lagging in ycorrelation with the progress of backfilling but not more than 1m at any point of time

Remove the soldier pile y

Stop dewatering and plug the ydewatering wells

Restore the road and other yexisting installation as it was earlier

In Phase II, L&T was awarded five packages that included

BC 15 Udyog Bhawan 1. Underground Station & Tunnel

BC 17 Green Park 2. Underground Station & Tunnel

BC 18 Hauz Khas 3. & Malviya Nagar Underground Station & Tunnel

BC 19 A / C Saket 4. Underground Station & Tunnel C 5 Airport Link Tunnel5.

Phase II Network*

LineLength (Kms)

No. of Stations

Shahdara – Dilshad Garden 3.09 3

Indraprastha – Noida Sector 32 City Centre 15.07 11

Yamuna Bank – Anand Vihar ISBT 6.17 5

Vishwavidyalaya – Jahangir Puri 6.36 5

Inderlok – Kirti Nagar -Mundka 18.46 15

Central Secretariat – HUDA City Centre 27.45 19

Dwarka Sector 9 to Dwarka Sector 21 2.76 2

Airport Express Line 22.70 6

Anand Vihar – KB Vaishali 2.57 2

Central Secretariat – Badarpur 20.04 15

Total 124.63 83*courtesy www.delhimetrorail.com

Delhi Metro Map - Phase 1 & 2

ECC CONCORD Oct - Dec 2010 7

BC 15 - Udyog Bhawan underground station and tunnel

The scope of work of the package BC 15 was to design and construct an underground station plus the tunnel by cut & cover method including all temporary support works, design of temporary works, formwork, staging, shuttering, utility diversion, traffic diversion etc.

Scope of work

Construction of diaphragm wall yfor station – 800mm thick

Excavation between Diaphragm yWall including/excluding temporary supports and excavation between soldier Piling including instillation of soldier piling, struts, etc.

Waterproofing with 2mm thick PVC yMembrane for Station & Tunnel

Concreting (M35/M20/M15) yfor Station & Tunnel

Single tube twin Tunnel (Cut & yCover) North Side - 40m

Twin tunnel (Cut & Cover) South ySide – 110m

Roof Slab y

Concourse Slab y

Base Slab y

Plenum Walls y

Platform Slab y

Public Staircase & fireman ystaircases

UPE Walls y

Vent shafts y

Entry & Exits with integration ywith the existing traffic

Underground Ancillary Buildings. y

all other Equipment Rooms like yECS/TV, SER, SCR etc. including Cable Ducts from ASS for Designated Contractor Access.

All other Equipment Rooms like yECS/TV, SER, SCR etc. including Cable Ducts from ASS for Designated Contractor Access - Lift & Escalators

Track way Basic Structure for yDesignated Contractor Access – Track work

Station concourse Paid/Free yAreas for Designated Contractor Access - AFC (Udyog Bhawan Station) including EFO & TOM.

Provision of station & substation ystructures, utility diversion & relocation etc.

All works necessary to provide yinter-modal transfer facilities for pedestrians & road users at ground level & access into station.

All temporary & permanent yutilities including foul drainage to be connected into public services.

Work in progress at Udyog Bhawan underground station

ECC CONCORD Oct - Dec 2010 8

Co-ordination & interfacing with yother contractors/consultants for track work. System- Wide work etc.

All temporary traffic diversion yworks which will be required

for the smooth flow of Traffic in order to carry out the works without any interruptions including all safety precautions, signage, barricading, emergency lighting etc.

All aspects of quality assurance, yincluding testing of materials and other components of work.

Shifting of Utilities coming in ythe area of work. Manpower

Major Equipment

Cranes : 3 nos.

Batching Plant : 1no.60cu.m + 1 no. 30 cu.m

Boom Placer : 1 no.

Excavator : 5 nos.

Loaders : 2 nos.

Total Station : 1 nos.

Diaphragm Wall Rig : 1 nos.

Piling Rig : 1 nos.

Bar Bending Machine : 6 nos.

Bar Cutting Machine : 6 nos.

Generator : 3 nos.

Transit Mixers : 11 nos.

Udyog Bhawan station after completion

Excavation works in progress at Hauz Khas

ECC CONCORD Oct - Dec 2010 9

deployment for road diversions. Ensuring cleanliness of Road.

Submission of completion y(As Built) drawings and other related documents as specified.

Site Clearance and dismantling yof obstructions etc., before commencement of work.

Setting out & layout of the works, ybench marks and provision of necessary labour, instruments and appliances.

Cleaning of site and handing over y

Maintenance of completed yWork during the period of Maintenance

The BC 15 package takes paramount importance among all other packages in Phase II because the underground station and the

running tunnel on both sides are located right below one of the most important and VVIP areas of the country. Due to the presence of important Government buildings and residence of eminent leaders

and bureaucrats, diverting traffic for construction posed a great challenge and all activities had

to be planned in such a manner that construction caused minimal possible hindrance to these VVIPs.

The underground station and the tunnel were to be located below the road. The width of the station varies from 12 m to 26 m and the depth was 16 m. The station design consisted of Base Slab at 16 m depth which were to be used for track work, platform at 13 m and equipment at concourse level at 9 m depth for passenger ticketing and rooms for functioning of station; and at the top is the roof slab at 2 m depth. Once the roof slab is completed, back filling needs to be done after which the roads need to be laid.

During peak period labour strength was at 1200 with staff strength at 34. Both the labour

Major quantities

Diaphragm Wall : 7650 sq.m

Concrete : 55,000 cu.m

Reinforcement Steel : 8,145 t

Structural Steel : 2,600 t

Excavation : 2,10,000 cu.m

Backfilling : 48,000 cu.m

Waterproofing : 35,000 sq.m

I m dia Pilling : 2400 rmt

Doka Steel : 500 t

Security screening at Udyog Bhawan

ECC CONCORD Oct - Dec 2010 10

and staff were divided into two shifts to execute the job round the clock.

Construction Methodology

North tunnel measuring 38 m was done using cut and cover method, followed by bottom up station, top-down station and another tunnel at the south side measuring 110m.

Safety Health & Environment and Project Quality

Barricading the construction yzone

Monitoring instruments ylike settlement points, Piezometer, Inclinometer, Load Cell and Strain Gauges were installed to monitor the movement of structure on a daily basis

Air and Noise monitoring was ydone on quarterly basis and

control measures were taken appropriately

Medical tests were carried out yfor all labours before induction

Cranes were provided with ySafe Load Indicators (SLI) and tools & tackles were inspected by an external agency before implementing at work

Dumpers were provided with yreverse horns and backlights. Drivers were checked for alcohol consumption through alcohol monitoring machine

Diversion boards were placed yat frequent intervals for proper vehicular traffic diversion

Traffic marshals were provided yto manage traffic

Noise Proof Power Generators ywere used

Columns were marked with yFluorescent paint for easy visibility during excavation

Safety, Health and Environment Statistics (as of Oct 2010)

Total man-hours : 5377780

No of First-Aid cases : 55

No of reportable accidents : NIL

No of fatal accidents : NIL

Total workmen covered under Tetanus Immunization : 306

No of reportable sick cases : NIL

Total workmen who have undergone medical examination : 4414

Tree Plantation / Tree Cut : 241/ 86

Environmental Accidents : NIL

Awards

ISO 14001:2004 and OHSAS y18001:1999.

Prashansa Patra in Construction ySafety Awards from National Safety Council – India

Passengers alighting at Udyog Bhawan station

ECC CONCORD Oct - Dec 2010 11

Secretariat – Viswavidhalya corridor constructed under Phase - I. The Green Park station is also strategic in location as it is located below the arterial road of Delhi called Aurobindo Marg.

Scope of work

Design of the station – 318 m and ytunnels on both side of station (including cross passages) – 486m. The Design was done by M/s Mott Mac Donald

Tunnel breakthrough after drive from Hauz Khas to Green Park

Trial run of metro train during construction of Green Park station

BC 17 - Green Park Underground Station & Tunnel

Located in South Delhi, the Green Park station falls in the corridor between Central Secretariat to Gurgoan. With Gurgoan gaining significance as a business hub, there is a heavy traffic of commuters proceeding for work

to this area from Delhi. There are 9 underground stations in this corridor which is an extension of the Central

Major quantities

Concrete : 85,000 cu.m

Reinforcement Steel : 14,500 t

Structural Steel : 4,200 t

Excavation : 3,50,000 cu.m

Backfilling : 1,25,000 cu.m

Doka Steel : 800 t

ECC CONCORD Oct - Dec 2010 12

Construction of underground ystation by cut & cover method including entry-exit structures, utility galleries, equipment rooms, etc.

Construction of underground ytunnels on both sides of station by cut & cover method

Traffic diversion including ydiversion of roads for construction of station and tunnel

Installation of steel walkway yinside the tunnel

Block work for equipment and yancillary rooms in station

Restoration of roads and other ystructure after construction

Diversion and restoration of civil yutilities, electrical utilities and telecom utilities fouling in the alignment

Construction of client office y

Interfacing with architectural, ysystem contractors like E&M, signaling& telecommunication, lift for access to equipment

rooms, installation of equipment etc.

The construction of Underground Station and Tunnel at Green Park was also a mission critical task due to presence of enormous utilities and heavy traffic on the arterial Aurobindo Marg. The Underground Station and Tunnel was to be constructed just below the surface of the road. The width of the station was 20 m and depth of station below Ground Level at 16 m. The station consisted of Base Slab at 16 m Depth which is to be used for track work, platform at 13 m depth for passengers boarding the train and equipment rooms for working of Station, Concourse Level at 9 m depth for Passenger Ticketing and Rooms for functioning of Station; and at top is the roof slab at 4 m depth. Above roof Slab backfilling was

Major Equipment

Cranes : 6 nos

Batching Plant : 1 no. 60 cum + 1 no. 30 cu.m

Boom Placer : 1 no

Excavator : 8 nos

Loaders : 3 nos

Total Station : 2 nos

Diaphragm Wall Rig : 2 nos

Piling Rig : 2 nos

Bar Bending Machine : 10 nos

Bar Cutting Machine : 8 nos

Generator : 5 nos

Transit Mixers : 11 nos

Entry gates at Green Park station

ECC CONCORD Oct - Dec 2010 13

done and then restoration of road was done.

Traffic survey conducted before commencement of construction indicated that traffic density Passenger Car Units (PCU) at this stretch was already more than 1 (i.e. the existing road width was insufficient for carrying traffic). The maximum road width available was 42 m and minimum was 35 m width. Out of this, construction activit ies would occupy 25 m leaving only 10 to 17 m for vehicular traffic. Top down Construction methodology was adopted for Station and Bottom up methodology for the tunnels.

At peak period this package had a labour strength of 2000 labours and staff strength at 60

who were divided into day and night shifts.

Awards & achievements

ISO 14001:2004 and OHSAS y18001:1999

RoSPA Gold Award for ycontribution towards Occupational Health and Safety

Completed 9.5 million safe yman hours

A train arrives on the platform at Green Park station

Green Park station with metro trains on both the platforms

ECC CONCORD Oct - Dec 2010 14

ECC CONCORD Oct - Dec 2010 15

ECC CONCORD Oct - Dec 2010 16

BC 18 -Hauz Khas & Malviya Nagar Underground Station & Tunnel

Scope of work

Design & build two underground metro stations including 3.2 km of twin tunnel was awarded to the Metro Tunnelling Group Joint Venture of which L&T is a partner. Hauz Khas station was constructed using cut and cover method and top-down approach method while Malviya Nagar was done by using bottom up approach. The scope also included construction of associated entry / exit structures, utilities galleries, AC plant rooms, pump houses, water tanks, diesel generator set room, etc. All the surface restoration including restoration of utilities was also part of this lump-sum contract. The contract also included getting all the necessary approvals

and clearances from various Government authorities.

Corridor overview

Tunnel Length : 3144.046 m

Station Length : 618.4 m (Hauz Khas = 318 m ; Malviya Nagar =300.4m)

No. of rings : 5300 nos

Width of rings : 1.2 m

Avg. segments cast/day : 15 nos

Start of Tunnelling : 4th Jan, 08

End of Tunnelling : 20th April, 09

No. of drives : Three x Twin

Avg. daily progress in tunnels : 10 rings/day

Avg. weekly progress in tunnels : 70 rings/week

Highest monthly progress achieved : 362 rings (B7 East Tunnel) during May ‘08

No of Cross Passages (NATM Method) : 5 Nos.

Major achievements at Hauz Khas Station

52 trees that were to be cut during yflyover diversion were saved

Utility of trunk sewer of 1200 ymm dia diverted using TBM trenchless technique for a length of 280m.

Top down construction - roof slab casting in progress at Hauz Khas

Quantities for Hauz Khas & Malviya Nagar Stations ( MTG ) :

RCC : 86500 cu.m

Rebar used : 13200 t

Earthwork : 326000 cu.m

Diaphragm Wall :16343 sq.m (932 m)

Waterproofing : 26570 sq.m

Plunge Columns : 34 nos. (1.2 m dia)

Soldier Piles : 680 nos.

Rock Excavation : 12000 cu.m

Soil Anchors : 721 nos.

ECC CONCORD Oct - Dec 2010 17

Optical fibre cable of 2400 ypairs crossing the station was meticulously supported below the deck and accommodated in backfilling

600 dia sewer line diverted at y6m depth using part trenchless and part open-cut method

An alternative arrangement ywas planned for smooth and unhindered flow of traffic

All the affected works were yrestored to the satisfaction of Laxman public school - the major contributors of land for the station

This was the only station in the ywhole corridor having 1200 mm thickness Diaphragm wall due to its heavy design on account of 5-6 m overburden on top of roof slab of station box.

Hauz Khas station had been ythe model station for various new activities such as block works, erection of smoke down station, cavity wall construction, finishing items, etc.

Major Equipment

TBM : 2Nos.

Crane : 450mt, 150mt, 75mt

Locomotive : 2 nos.

Segment wagon : 2 nos.

Grout car : 1 no. (3.5 cu.m)

Muck wagon : 5 nos. (10 cu.m)

Grout batching plant :1 no. (30 cu.m / hr)

Power supply : 1000 KVA DG – 3 nos.

Chilled water : Chiller plant installed at surface

Compressed air : Compressors installed at surface to operate man lock and other equipment

Ventilation : Fans installed at surface with ducting extending continuously with tunnel progress

Base slab RC work in progress at Hauz Khas station

Rebar of steps at entrance - Hauz Khas station

ECC CONCORD Oct - Dec 2010 18

Major Challenges

Land Acquisition was a major ychallenge in the beginning as the Malviya Nagar station was situated on DDA land having legal cases pending since 1982

The central part of 180 m long ystretch out of 300 m length was of rocky strata (from -10 m depth) so it was not possible to execute Diaphragm Wall. It was sought to re-design the station using bored piles with embedment of 1 m in the rock and soil anchors to retain the soil while proceeding for excavation

Executing diaphragm wall yneeded operation of hydraulic rigs with a swing radius of 9 m. This operation was partly blocking the gate of Laxman

Hauz Khas station after completion

Bottom up construction at Malviya Nagar station box

ECC CONCORD Oct - Dec 2010 19

public school. Inconvenience was avoided by establishing a time frame to work on the diaphragm wall only after the school hours

Hauz Khas Station encountered ymajor utilities on the southern part of the ring road such as major water lines (700 dia, 200 dia, and 1800 mm dia SWD and 1200 mm dia )and sewer line at 10 m depth

During construction of panel no. y123,a 600 dia sewer line which was not shown in the drawing was encountered. This was overcome by first closing the panel by soft concrete and diverting the sewer line to an alternate path

Tunnel was constructed with yproper alignment and within tolerance

The tunneling was completed y

safely despite the fact that alignment passes below the old Begumpur villages with many underground basements and high rise buildings

All the contractors were ysensitized on crucial due dates to plan on their tight interface and civil works

Lifting and lowering of heavy y

D-Wall cage being lowered

Entrance of Malviya Nagar station

ECC CONCORD Oct - Dec 2010 20

TBM components and their movement was an interface challenge

Safety

MTG was adjudged the best ysafe site among all DMRC

Sites of the Corridor and Trophy was awarded by lieutenant Governor of Delhi

Safety helmets, shoes, ygoggles, helmets with tinted shields and gloves were provided as per the requirement of the task

Safety official’s weekly yinspection

Daily PEP talks, alcohol yconsumption monitoring and training programmes

Clean and hazard free house ykeeping

Completed 16.5 million safe yman hours

Saket underground station after completion

Excavation works in progress – side soil retaining using soldier piles and soil anchors at Malviya Nagar

ECC CONCORD Oct - Dec 2010 21

BC 19 A & BC 19 C - Saket Underground Station & Tunnel

BC 19 A - Saket Underground Station

Scope for this package includes design and construction of underground station at Saket by cut & cover method on Central Secretariat – Qutub Minar Corridor. This too is an important corridor of Delhi metro that connects North Delhi to South Delhi and going upto Gurgaon cutting across a very densely populated and frequently commuted area in the Capital.

The Saket station measures about 285 m alongwith 3 entry and exits that measure an average of 80m. The contract also includes a double storied ancillary building. During peak period this package

Concreting of roof slab at Hauz Khas station

Major Quantities

Excavation (Upto 17 m depth) : 170000 cu.m

Backfilling : 42000 cu.m

Soldier Piles (Depth upto 24 m) : 632 nos

Diaphragm Wall (800 mm) : 6400 sq.m

Plunge Columns (1 m Dia & 20 m Depth) : 43 nos

Roof Slab (Depth 500mm to 1200mm) : 11500 sq.m

Concourse Slab (Depth 400mm to 750mm) : 6000 sq.m

Base Slab (Depth 500mm to 1000mm) : 11500 sq.m

Platform Slab (Depth 500mm to 1000mm) : 3396 sq.m

External Walls (500mm to 800mm) : 6000 sq.m

Internal RCC Walls (200mm to 800mm) : 3000 sq.m

Solid Block Wall (200mm) : 12000 sq.m / 2400 cu.m

Waterproofing : 13000 sq.m

Concrete (M35) in all RCC Works : 43000 cu.m

Reinforcement Steel (Fe500) in all RCC Works : 6600 MT

Structural Steel (in Soldier Piles, Struts & Walers) : 2500 MT

ECC CONCORD Oct - Dec 2010 22

involved close to 900 labour and 34 staff.

Underground station Construction Methodology

Top–Down Method (adopted for y30%of Station Construction)

Diaphragm Wall – Roof Slab – yConcourse Slab – Base Slab – Internal Works

Bottom-Up Method (adopted for y40% Station Construction)

Base Slab – Side Walls – yConcourse Slab – Side Walls – Roof Slab – Internal Works

This type of combining two construction methodology for the same structure is an innovative attempt and couplers were used

extensively in Diaphragm Wall for ease in construction and to save time and cost. Koden Ultrasonic Tests were performed to check the verticality of diaphragm walls while construction and thereby avoid cost of rework.

Challenges faced

The fabrication and installation yof 32 m long, heavy struts (weighing upto 18.5 t) and welding with walers upto a depth of 15 m below ground level in 3 layers

Erection in true vertical position yof huge diaphragm wall panel reinforcement cage weighing over 22 t and measuring 6 m in length and 22 m deep

Installation of heavy 2.2 m ydiameter hume pipes, each weighing 9 tons at a radius of over 20 m in a confined nala

Safety of existing nearby structures ywas constantly monitored and ensured by installing various instruments such as Tiltmeters, Strain gauges & load cells

NATM tunnel shafts at Saket

Herenkenith make S-198 TBM duly refurbished

ECC CONCORD Oct - Dec 2010 23

A section of completed tunnel at Saket

BC 19 C - Saket Underground Link Tunnel

Design and Construction of Underground Link Tunnel &

Ramp between Saket & Qutub Minar (both excluding) by Cut & Cover Method on Central Secretariat – Qutub Minar Corridor of Delhi MRTS Project.

This project employed 600 laborers and 33 staff during peak periods.

Construction Methodology

Bottom-Up Method (for Tunnel y& Ramp Construction)

New Austrian Tunnelling Method y(NATM) for tunnel construction

Soil Anchors were used in place yof regular structural struts and walers in NATM tunnel shaft in order to have spacious working platform. This saved time and ensured safety to a large extent

‘Compaction grouting’ was yintroduced to make soil conditions stable in Nala portion, below which NATM tunnel had to pass

Major Quantities

Soil & Rock Excavation (Upto 17 m Depth) : 220000 cu.m

Backfilling : 110000 cu.m

Soldier Piles (Depth upto 24 m) : 720 nos

Roof Slab (Depth 800mm) : 11500 sq.m

Base Slab (Depth 800mm) : 12300 sq.m

External Walls (Thk 800mm) : 15700 sq.m

Internal Walls (Thk 500mm) : 5000 sq.m

Waterproofing : 15300 sq.m

NATM Lining (600 mm) : 9000 sq.m

Concrete (M35) in all RCC Works : 49000 cu.m

Reinforcement Steel (Fe500) in all RCC Works : 5700 MT

Structural Steel (in Soldier Piles, Struts & Walers) : 3400 MT

ECC CONCORD Oct - Dec 2010 24

The Tunnel Boring Machine is a huge, incredible piece of equipment that can forge its way through hard rock , sand or soil, hollow out tunnels without any disturbance to the surroundings .In DMRC Phase II 12 nos. of TBM were used in the construction of tunnelling for various sections. This is a world record as it is the highest number of TBMs used in a single location thus far.

Major Components of TBMCutter Disc1. - To excavate rock or soft ground by the rotation of an assembly of teeth or cutting wheels under pressure against rock face.

Shield Skin2. - keeps the soil from getting into the machine and to provide a safe working space for the workers.

Pushing Jack3. - To be in full contact with the erected segment and hydraulically extend as the cutter disc turns and thrusts forward.

Main Drive4. - To provide a force in rotating the cutter disc.

Screw Conveyor 5. - To move the spoil at the cutter disc and feed onto a conveyor system.

Erector6. - To erect the segments to form a complete ring after shoving at the tail of the TBM.

Back Up Facilities 7. - To travel with the TBM and to service the operation of annular grouting, welding, extension of ventilation, power and track etc.

TUNNEL BORING MACHINE (TBM)Parts of EPB (Earth Pressure Balance) type TBM

Initial Drive

Completion of Drive

Main Drive

Disassembly of TBM

Erected Segments6) Erector3) Pushing Jack1) Cutter Disc

2) Shield Skin5) Screw Conveyor 7) Back Up Facilities

4) Main Drive

ECC CONCORD Oct - Dec 2010 25

Some of the important features at the Airport Metro Express Link stations include:-

Direct baggage check-in facility yat New Delhi Railway Station and Shivaji stadium

Wide lifts at all stations to yaccommodate passengers with luggage

Multilevel parking is planned at yNew Delhi Station and regular parking bay at Shivaji Stadium

Dwarka Sector-21 station will yhave an interchange between Airport Express Line and Line3

Airport Express line has been ybuilt over eight busy roads which carry a substantial volume of traffic, including the Ring Road, National Highway 8, Ridge Road and Sardar Patel Marg. Once completed this metro

C 5 - AIRPORT LINK TUNNEL

C5 package forms part of the Airport Express Line of Delhi Metro that connects the 23-kilometre stretch between Connaught Place and Indira Gandhi International Airport (IGI). This is also known as Orange Line and will be operated by the Delhi Airport Metro Express Pvt. Limited (DAMEL), a subsidiary of Reliance Infrastructure, the concessionaire of the Line. The metro trains on this line will be the fastest in the country and will travel up to 135 km/h instead of 80 km/h as on the other metro lines.

Once completed, this line will provide high speed connectivity from the city to airport with advanced features such as baggage check-in and issuance of boarding pass facility at certain metro stations. This project

also envisages stations with wider lifts in order to accommodate passengers with luggage and multilevel parking at stations.

There are six proposed stations on this line known as City Airport Terminals (CATs) and all the stations will be secured through a network of CCTV cameras.

Major Equipment

TBM with all accessories : 2 units

Cranes : 7 nos

Gantries : 7 nos

EOTS : 2 nos

Vacuum lifters : 02 nos

Batching plant/grout plants : 4 nos

DGs (diff. Capacities) : 12 nos

Boom Placer : 01 nos

Excavators : 02 nos

Precast tunnel ring segments on the airport link

ECC CONCORD Oct - Dec 2010 26

line is expected to reduce traffic volumes and pollution on these arterial roads

The total 23 km stretch of Airport line is divided into 7 Contract packages namely AMEL – C1 to

C7, and Larsen & Toubro Limited – Shanghai Urban Construction Group - JV has been entrusted to construct AMEL-C5 “Design &

Construction of Tunnel between IGI Airport Station and Dwarka Sector 21 Station (Excluding Stations)”. This AMEL-C5 Package is the link

Major Quantities

Tunnelling by TBM : 1.587 km x 2 Lines (5.70m Dia)

Cut &Cover Tunnel : 813 m x 2 Lines

Shafts : 02 nos

No. of Segment Rings : 2116 nos

Cross Passages : 04 nos

Excavation works : 2,60,000 cu.m

Backfilling works : 1,90,000 cu.m

Concreting Works : 42000 cu.m

TMT-Rebar Works : 5800 m

Structural Steel Works : 3000 t

Water Proofing : 12,000 sq.m

Hauz Khas entry - exit excavation

Transportation of muck by rail system

ECC CONCORD Oct - Dec 2010 27

tunnel between the IGI station and Dwarka sector 21 stations

The contract for AMEL-C5 awarded to L&T-SUCG JV includes design and construction of tunnel between IGI station and Dwarka Sector 21 station (excluding stations).

Scope of Work

Construction of TBM launching ychamber

Pre-cast of tunnel ring ysegments

Construction of twin bored ytunnel by TBM method

Construction of TBM receiving ychamber

Construction of cross passages yconnecting bored tunnels

Providing soldier pile system yand excavation for underground

tunnel with strut – waler system

Construction of box tunnel by ycut & cover method

Providing waterproofing system y

Backfilling works & removal of ysolder piles

Shifting of utility services y

Settlement monitoring activities y

Building survey works y

Construction Methodology

Tunnel by TBM method, y

Work in progress at Saket underground station

Utility services at an underground station

ECC CONCORD Oct - Dec 2010 28

Electrical panels at an underground station

Inaguration of Central Secretariat - Qutab Minar section at Udyog Bhawan underground station

excavation / boring by EPB machine and precast segment erection

Cut & Cover tunnel by soldier ypiling , excavation with strut-waler system and box construction by bottom-up method

Cross passages by NATM y

Challenges

Alignment of tunnel in DIAL and prevention of settlement

Delhi International Airport Limited (DIAL) was apprehensive that the underground tunnel may lead to settlement and create problems for the operation of planes on the runway. It was also considered that the airport operations may have to be stopped during the construction of tunnel by TBM. Through detailed and continuous meetings it was agreed that the final settlement will be brought down to less than 5mm by employing technical and engineering solutions. 280 monitoring stations were fixed in areas such as villages/Taxiway/Apron and were continuously monitored by deploying 12 staff. Through such proactive measures the

airport operation was not hampered even for a single day during the construction of the tunnel.

Cross Passages inside Bored Tunnels

Construction of cross passages in between bored tunnel is done as per NFPA guidelines for fire escape. This is done at intermediate distances of 250 m from tunnel / station. The cross passage was completed quickly and efficiently through monitoring of works and

by adapting the methodology of NATM.

Miscellaneous services at Arrival Shaft

Services like water pipeline, Sewer line, Electrical line were encountered during construction of Arrival Shaft near IGI Airport which affected the completion of Shaft by 2 months. Continuous interaction with concerned authorities/agencies resulted in the shifting of utilities. Unique techniques such as trenchless boring methods were adopted to enable the continuous flow of vehicular traffic above the restricted working area.

Interface problems/issues with adjoining sections

Regular meetings with the representatives of adjoining sections were held to complete the activity as per schedule and to avoid any joint connection.

Control of Oxygen Level and Air Quality

Systems and gadgets to provide emergency respiratory protection was ensured through self-rescuers, personal breathing apparatus, tunnel gas monitoring and 60 HP ventilation

ECC CONCORD Oct - Dec 2010 29

fan systems were provided for a continuous flow of fresh air into the tunnel.

Social issues between Indian and Chinese team - this was resolved by assigning clear roles and responsibilities for each team.

Major Achievements

Tunneling works completed ywithin tolerance - 40 days ahead of schedule

Very cordial relationship with ylocal residents helped in closure of 34 Bore Wells identified on the alignment line.

Total settlement in DIAL/ yTaxiway/Apron achieved within International parameters

No cracks/settlement observed yin old houses of nearby villages

Taxiway/Apron was not closed yeven for a single day during construction

Terminal 3 building that was yunder construction in DIAL went ahead smoothly without any settlement/disturbance

Consistent customer rating of y“Excellent” for Safety standards

Project Safety Statistics

Total Man - Hours Worked : 3475821

No. of workmen screened till date : 4655 (May 2010)

No. of medical examination conducted : 4655 (May 2010)

No. of Tool Box Talks Conducted : 2196 (May 2010)

No. of External Audits Conducted : 08

No. of Internal Audits Conducted : 06

No. of Mars Audits Conducted : 30

No. of Electrical Audits Conducted : 30

No. of NCR Generated : 775

No. of NCR Complied with : 775

No. of site Observations : 430

No. of Observations complied : 430

No. of HSE Meetings conducted : 30

No. of HSE Risk Assessments done :43

No. of safe work procedures made : 45

AwardsRoSPA -2010 Silver Award for yOccupational Health & Safety Standards

ISO 14001-2004 certification for yimplementation of environmental management systems

Certificate for 1million and 2 ymillion safe man hours from Airport Line Consultant ALC (DMRC)

Compiled by

Gopi Kannan. S with inputs from Project Managers -

D.D. Khot, Jatinder Shukla,

Dharmendra Kumar Sharma,

R.G. Saini & S.V. Rao

View of metro on an elevated corridor

ECC CONCORD Oct - Dec 2010 30

Maruti is a household name in India and is the country’s largest passenger car manufacturer offering 14 different models with over 160 variants. Presently Maruti Suzuki India Limited (MSIL) is producing 1.2 million vehicles annually and as part of enhancing their production to 1.5 million, MSIL have ventured to expand their existing diesel car assembly plant at IMT Manesar, 30 km from the existing factory located at Gurgaon, in the state of Haryana, India.

Scope of work

MSIL invited L&T’s Construction Division to participate in the bid for Civil Works related to vehicle assembly plant and awarded

the Contact on a Design & Construct basis in the month of February 2010. The contract was on an item rate basis with a stipulated schedule of 11 months from the contractual date of commencement. The scope for Design & Engineering includes preparation and submission of detailed structural and architectural drawings and follow-up for obtaining the statutory approvals from local authorities and submission of ‘As-Built ’ drawings on project completion.

The construction scope includes detailed planning, mobilization of required resources, sequencing and monitoring of the operations and completing the project within

the specified contract duration. Major structures in the contract aggregating to a total shop area

Major Quantities

Description Quantity

Earthwork : 1231969 cu.m

Concrete work : 65860 cu.m

Reinforcement : 4826894 kg

Formwork : 149597 sq.m

Masonry : 3691 cu.m

Flooring : 139842 sq.m

Structural steel work : 9501544 kg

Aluminium work : 22094 kg

Sheeting works : 60000 sq.m

Road work : 649238 sq. m

View of Maruti assembly line

Buildings for gearing up production

ECC CONCORD Oct - Dec 2010 31

of 70000 sq.m includes building of Press shop (9000 sq.m built-up area), Weld shop (12000 sq.m), Body Paint shop (10000 sq.m), Assembly shop (22000 sq.m), KD Ware house, Bumper Paint shop, Road work and Utility structures. During peak periods the project site employed about 2000 labourers and 64 staff.

Construction Highlights

Press Shop: Two press pits involving deep excavation of 7 m with 2450 cu.m of raft concreting.

Weld Shop: Trusses of 24 m (weight - 9 t) span to be fabricated and erected in a single piece.

Paint Shop: 38 steel columns of 21

m height and 96 plate girder of span upto 16.5 m. It also has three sludge pits which are 6 m deep.

Assembly: Involves conveyor pit and shower pit for total area of 1200 m.

Plant and Machinery deployed

Batching Plant - 30 cu.m/hr y

Transit Mixer – 7 nos y

Hydra (14 t capacity) – 15 nos y

Welding Machine – 276 nos y

Tyre mounted crane (75 t ycapacity) – 3 nos

Silent Generators - 9 nos with ycombined capacity of 2000 KVA

Challenges faced – Brownfield OperationOne of the major challenges faced was that the project site was located adjacent to the existing plant that was operational. Hence construction activities had to planned in such

Excavation adjacent to the existing plant in progress

Structural works in progress

ECC CONCORD Oct - Dec 2010 32

a manner that it did not disrupt or inconvenience the day-to-day operation of the existing unit. Another aspect of concern was that the soil condition was silty where excavations upto a depth of 7 meters (for construction of press pit) posed a major challenge. This challenge was mitigated after several discussions with the client and it was decided to adapt the methodology of steep cut with shoring.

Another crucial challenge in terms of delivery was that MSIL required demanding interim milestones viz. handing over of fifty percent area of paint shop by the middle of December 2010 and KD shop phase II by November 2010. In order to achieve such demanding targets extra manpower and resources were planned in advance and mobilized.

SafetyIn order to emphasize the importance of safety, all new employees getting

on-board the MSIL project site, be it staff or labourer, were made to attend a Safety Induction training programme on the very first day of joining. Safety meetings were held on a daily basis headed by the Safety incharge and a representative

from each site to discuss safety lag, if any, at a particular site or any other safety concerns which can prove hazardous to the workforce. The basic aim of such meetings was to proceed towards an objective of zero accident. To a large extent these

Workers cleaning the floor after completion of building

Work in progress at the KD shop

ECC CONCORD Oct - Dec 2010 33

measures were effective in resolving numerous safety issues. By ensuring safety awareness, the project site was able to achieve 2.82 safe million hours as on December 2nd 2010. MSIL site has also been awarded the Bi-annual EHS Rolling Trophy for the period April’10 to September’10.

Quality control

The QC team worked towards ensuring proper quality standards of the raw materials such as cement, sand, aggregates, admixture, fly-ash as well as the finished products i.e. concrete and fabricated steel. The

quality laboratory was well equipped with scientific instruments calibrated to conform to Indian Standards and to test the materials at the required testing frequencies.

Future

In order to have close monitoring on the demanding schedules and desired quality, MSIL had deployed a dedicated team from Japan. The high level of quality, timely delivery and close rapport with the MSIL team has helped build a credible and strong rapport with the client. By virtue of such strong relationship management and as a gesture of confidence, MSIL has awarded another order for the further expansion of plant to L&T directly without any tendering. There are further expansion projects in the pipeline with MSIL which L&T hopes to convert to orders.

Mukesh Goel Project Manager

Aerial view of construction activities

Another view of the structure

ECC CONCORD Oct - Dec 2010 34

The Underbelly of the Thar Desert in Rajasthan, India, has been found to contain millions of tonnes of oil and natural gas. It is only a matter of time before this inhospitable and arid desert region would evolve to become a booming economy with many leading companies queuing up to establish their energy projects. Apart from oil and gas, the Thar desert is also fast becoming a hot-spot for lignite coal and coal bed methane. Another striking feature is that this landscape is considered most ideal for establishing large tracts of solar and wind energy fields for tapping green power.

Exploration for oil and gas in the western Rajasthan region began right

from 1954. In January 2004,Cairn Energy of UK, announced the discovery of 450 to 1,100 million barrels of good quality light crude oil at the well, N-B-1, in block RJ-ON-90/1 in northern Rajasthan. Cairn Energy has till date has made 25 discoveries with Mangala being the largest of all.

Cairn India, the operator of the Rajasthan block, holds a 70 percent participating interest with ONGC, its joint venture partner, holding the balance 30 percent. This JV has already invested approximately USD 2 billion in the Rajasthan project and has plans to invest a further USD 1.8 billion by 2011, making it one of the largest onshore oil and gas projects in the country.

Rajasthan oil fields are considered one of the largest oil discoveries in India in more than 20 years. Located at Barmer in North Rajasthan, the Barmer basin has a production capacity of approximately 0.18Million Barrels of Crude Oil Per Day (BOPD) in peak period. The Mangala, Bhagyam and Aishwariya (collectively known as MBA) fields once on peak plateau production of 175,000 BOPD, will contribute to more than 20 percent of India’s domestic crude production. The Mangala Processing Terminal (MPT) will act as the hub for processing crude oil from all the Rajasthan fields.

Burning the midnight oil at Barmer

Plant cable tray & lighting

ECC CONCORD Oct - Dec 2010 35

Having explored the availability of Oil, Cairn was challenged with the task of partnering with a strong EPC contractor who can enthusiastically work in the inclement desert conditions of Thar, mobilise thousands of workmen and procure massive machinery necessary to carry out the operations smoothly. Given its impressive track record, L&T’s Hydro Carbon Division became the

obvious choice of Cairn for executing a project of this magnitude and complexity.

Electrical & Gulf Projects have been closely associated for electrical and instrumentation works with most of the projects executed by Hydro Carbon division. In the Cairn project, the entire package of Electrical, Instrumentation & Telecom works

for Construction of Northern Area Developmental project was awarded to E&GP Operating Company.

The project comprised of setting up of various systems and sub systems with three major elements such as Oil, Gas and Water. Apart from this, captive power plant generation unit should also be developed to provide power for operational needs.

Area : Scope of Work

Mangala Process Terminal (MPT) : All facilities required for production of 0.18mill. bpd

Mangala Oil Wells (MWP) : 160 wells spread over 18 wellpads

RGT : All facilities to meet the requirement of MPT operations

RGT Gas wellpads : 4 gas wellpads

Thumbli Water Field (NR1) : All facilities to meet the requirement of MPT operations

Optical connectivity link : 185 km Optical Fiber work along with Inter-field pipeline to connect MPT to RGT, NR1 & Oil Wellpads

33KV Over-head line : Power transmission from MPT to NR1 and Oil Well pads (38 km) RGT to Gas Wellpads (6 km)

Mangala Process Terminal - Overview

ECC CONCORD Oct - Dec 2010 36

The project is spread over four distinct locations interconnected through pipelines

Mangala Processing Terminal y(MPT)

Raageswari Gas Terminal (RGT) y

Thumbli Water Field (NR1) y

Mangala Oil Field Well Pads y

Electrical power is generated from 4sets of captive power plants each having 12MW 11kV power generator and 3sets of emergency diesel generator having 2.75MVA 6.6kV for plant start-up purpose. The generator power is distributed to various sub-stations inside MPT, Oil well pads & Water field. Along with typical electrical works, the following specialized electrical jobs were executed for this project.

Power Management system y(PMS) : This is the heart of the electrical system which provides the system Integration of all captive power stations, diesel generator and electrical drives into the DCS (Distributed Control System). A Central Control Centre controls the entire power system through DCS

Steam & yE m e r g e n c y Diesel Generator : Installation of Automatic Voltage Control Panel (AVR), s y n c h r o n i z a t i o n panel and associated control cabling is completed for integration and c o m m i s s i o n i n g of Steam Turbine Generator (STG) and Emergency Diesel Generator (EMDG) system

Power Distribution yto Water Field : The generated power from MPT is stepped upto 33kV system and distributed through transmission line to Thumbli water field located 22 km away. This line is connected to Thumbli sub-station and further connected to the Electro Static

Precipitator (ESP) transformer by special “L” type HT termination kit

Power Distribution to yMangala Oil Well pads : The power generated from MPT is stepped-up to 33kV system and distributed to individual well pads through transmission lines having route length of 15 km

Instrumentation System

At any oil well or refinery the instrumentation systems forms the nerve centre of the entire processing cycle. All the processing and production activities are controlled

Scope of work

Electrical

Cable laying : 1700 km

Cable tray Installation : 112 km

Earthing : 150 km

Equipment Erection : 476 nos

Lighting : 3400 nos

Instrumentation

DCS Panel : 350 nos

Cable laying : 1210 km

Instruments : 1250 nos

Loop checking : 4350loops

Telecommunication Works

Fiber Optical cabling : 185 km

Pipeline Intrusion system : 97 km

Access Control System : 190 controllers

CCTV System : 86 cameras

Fence Intrusion System : 36 km

MET System (MPT & RGT) : 2 locations

PAGA System : 800 speakers 105 km cable

Telephone Data Network : 800 phones

Trunk Mobile Radio system : Two 45 m Tower with 3 Repeater Stations

Night View of Boiler Commissioning

ECC CONCORD Oct - Dec 2010 37

and monitored through the instrumentation system. The accuracy of these systems needs to be very high and they have to be versatile enough to provide uninterrupted support with absolutely minimal or no down-time. Since the instrumentation used at the oil and gas refineries have to deal with highly inflammable substance, they come with very high standards and world-class certifications that permit them for use in such highly hazardous environment.

At Barmer, instrumentation of very high accuracy have been imported, supplied, installed and commissioned at the MPT terminal as well as various well pad locations for measurement, control and extraction from the well pads and in separation of crude to Oil, Gas and Water. All the instruments required for the plant have been imported from Europe/USA with certifications for use in highly explosive and hazardous environment. The following are the special instruments provided at various locations of the project:

Nucleonic type level yprofiler : For highly accurate measurement of interface levels between Gas, Oil & Water in the storage tanks

Multi-phase flow meter : y Used for measurement of oil and water content from well pads. Crude oil extracted from the well pads is generally a combination of oil, water, gas and impurities. The multi -phase flow meter helps measure the content of the oil, water and gas in the oil extracted from the well pads

Special Analyzers are used to ymeasure the content of Oil in Water, Oxygen and water conductivity analyzers, Base Sediment and Water (BSW) analyzer for measurement of sediments and water in the Oil

Hundreds of pressure transmitters, ytemperature transmitters and level Instruments on various tanks and pipelines

Telecommunication System

A strong telecommunication system is most essential for the smooth flow of data, communication and security in the processing units as well as the well pads. All upstream facilities were therefore provided with the following specialized telecommunication systems for data, voice communication, security surveillance, access control and intrusion detection:

Fiber optic transmission ysystem consisting of 185 km of 12F, 24F, 48F & 120 fiber optic cables between various well pads to MPT acting as backbone for data and voice communication between the facilities

Control room

View of CCTV operator workstation

ECC CONCORD Oct - Dec 2010 38

As FO cables are traversing yalong the pipeline, these are also used as a means to detect pipeline intrusion detection using suitable computers at either ends of the FO cable

CCTV system consisting yof PTZ and fixed cameras are provided at various well pads and the MPT and RGT terminals. The video is streamed from various well pads to the MPT central control

room through the fiber optic network. The MPT perimeter area is fully covered by the CCTV system using 86 PTZ CCTV cameras for security and surveillance

Fence Intrusion System for ysurveillance of MPT / RGT fence through the use of a fence mounted fiber optic cable which has start and end sensor for detecting and locating intrusion on the

perimeter fence. Intrusion system is fully integrated with CCTV system to provide seamless security monitoring of the environment

Public Address and General yAlarm System consisting of loud speakers, beacons, sounders, announcement consoles etc., for delivering messages and instructions to the personnel working in the plant

Sub station

Metrology SystemTelecom panels

ECC CONCORD Oct - Dec 2010 39

Cairn India has commissioned the world’s longest heated insulated pipeline project that carries crude oil from Barmer in Rajasthan to Salaya located at Gujarat. This crude oil pipeline that measures over 600 km has earned the credit of being the longest of its kind pipeline in the world over similar such pipeline projects in Russia and Indonesia.

The unique feature of this pipeline is that the entire pipeline is designed to carry crude oil at temperatures above 65 degree C for reduced viscosity and free flow. In order to maintain temperatures across the length of the pipe, 1 MW gas engine generators have been installed at approximately every 18 kilometers.

Location

The BSPL pipeline, the associated 29 heating stations and the 3 terminals are passing through one of the country’s toughest and rugged desert tracts. Such terrains, coupled with the hostile weather conditions have posed several challenges for logistics and productivity. Such challenges were overcome through:

Minimising the travelling distance for work force yand maximising their productivity during cooler hours of the day

Using double tractors to haul heavy Gas yGenerators and accessories over sandy dunes to remote stations

Project HighlightsWorld’s longest, 600+ km of continuous heat yinsulated pipeline that travels between two states covering approximately 200 villages

SEHMS conductor and accessories installation yattached to 24” Insulated crude oil pipeline and

OFC backbone network, besides 8” gas pipeline at 1.25 m depth

29 heating stations, each having capacity to ygenerate 1 MW power installed across the length of the pipeline for enabling continuous heating

3 terminals with launcher and receiver facility y

Instrumentation and controls integration with ycontrol rooms to prevent the temperature of crude oil falling below 65 degree C

Construction Methodology

Heat tracing a method where the viscosity of the crude oil is maintained at low levels in order to facilitate the flow of the liquid through the pipeline. Unlike the conventional method of heat tracing by wrapping heating coils over the pipe, Cairn India has introduced a more energy efficient solution, from M/s. TYCO Thermals, called Skin Effect Heat Management System (SEHMS). This new technology provides uniform heating by using eddy current losses

In this technology an electrically insulated conductor is installed inside the heat tube and connected to the tube-end at the designed distance. The conductor and the tube are connected in series to AC voltage. The return path of the circuit current is pulled to the inner surface of heat tube by skin effect and with the proximity effect between the heat tube and the conductor. The outer surface of the tube remains grounded. This arrangement constructs the “restive impedance circuit“, which generates heat in the heat tube walls and additional heat is also generated due to eddy current flow through the insulated conductor.

Arjun Rana Project Manager

The World’s longest-of-its-kind, Barmer - Salaya Pipeline Project

Heating station electrical control room

ECC CONCORD Oct - Dec 2010 40

Launcher receiver facilities at Viramgam terminal

Access Control System to yprovide controlled access to plant operators, subcontractor personnel and visitors to various areas of MPT, RGT buildings

Trunked Mobile Radio System yfor voice communication between operators at various locations of the facilities

Telephone and Data Network ySystem and Network Supervisory System

Aero Radio, HF-SSB, yMetrological systems

Challenges

The primary and most critical challenge at the Barmer site is

the extreme weather conditions prevalent in the region throughout the year. Apart from this, sourcing of even basic resources such as water and power was difficult as the sources lie scattered in and around 70 km in the region.

Unprecedented engineering changes witnessed an enormous increase in the scope of work just after a few months of commencement. This change had increased major quantities way beyond the initial projections. For instance, cable laying executed at site alone increased between 80% to 200%(from 1200 km to 2600 km).

The non-availability of both skilled and un-skilled workforce also posed a great challenge. In order to achieve the project completion target, an average of more than 1300 workmen were mobilized during the peak period. Though this was a tough task,

Hot line communication

ECC CONCORD Oct - Dec 2010 41

Heating station (SEHMS) with 1 MW gas engine generator

it greatly helped in mitigating any possibility of delay due to shortage of workforce. Inspite of stiff resistance from the locals, the fiber optic cabling between MPT to RGT (90 km) was completed as per project schedule

Innovation

The E&IC package was originally to be completed in a period of 18 months. However, during the course of engineering, there was a significant increase in the scope and the revised estimated completion was fixed at 26 months. There was a great pressure to innovate the processes and techniques in order to overcome the enormous increase in scope and the demanding time lines.

The innovation started with installation of cable tray in pipe rack. It was implemented

with mechanical mounting arrangement using beam and pitch clamps. Cable laying being the most critical activity in the entire project, meticulous route planning was studied and an alternate route was suggested in order to make faster and effective progress. In order to achieve the target, a totally different organization structure was placed at the site to monitor the rapid progress of cable laying.

Most of the foundation required for supporting the field equipment was pre-cast instead of conventional construction in situ. This was implemented considering the scattered network.

Achievements

Executing a project of such large a scale calls for the best-in-class efforts and commitment, and

when one does that -records are bound to come by.

65 km of cable laying in a ysingle day

Completed 5 Electrical ySubstations in a month for energisation

3.5 million LTI free safe man yhours achieved

Successful Commissioning yand integration of Electronic Fence Intrusion Detection System (8 km) with CCTV system and commissioning of Pipeline Intrusion Detection System (90km) – First-of-its-kind system in India for Oil & Gas sector

18 km of OFC blowing in a ysingle day

M. Shanmuganathan Project Manager, E,I & T

ECC CONCORD Oct - Dec 2010 42

Rajpura Dariba - The Zinc Thing

The Rajpura Dariba mine perhaps represents the oldest mining and smelting operations in the world for extraction of zinc. Timber supports recovered from extensive ancient workings (some timber was intersected by boreholes at a depth of 265 m) have been carbon dated to 2,100 - 2,500 years ago. Early written records available show that in 1382 Maharana Laxman Singh of Mewar reactivated zinc and lead mining near Udaipur. This goes to prove that certainly zinc metal production in India predated that in Europe by several centuries.

The Rajpura-Dariba deposit was rediscovered in 1925 by the Geological Survey of India, and by 1934 it had been shown to extend on strike for a distance of 17 km. In 1970 a lease was granted to Hindustan Zinc Limited (HZL) and thereafter, with the aid of consultancy services from RTZ Consultants, U.K, a mining project was started in 1977, a capital investment of Rs 728.4 million having been sanctioned by the Indian Government. HZL is India’s largest and the world’s second largest integrated producer of zinc and lead, with a global share of approximately 6.0% in zinc. It is a

subsidiary of Sterlite Industries (India) Limited and the London based, Vedanta Resources plc.

The HZL plant is located at Rajpura-Dariba, a small town in the state of Rajasthan. Dariba holds the distinction of being the capital of the former kingdom of Mewar in Rajputana Agency and is reputed as the ‘city of lakes’ worldwide. The total reserves of deposits were estimated at 18 Mt with grades of 7.2% zinc and 1.8% lead. The mine was commissioned in 1983 with a planned production of 40,600 t/y of zinc, 10,500 t/y lead, 445 t of copper, 175 t/y of cadmium and 16t of silver. The first Indian occurrence of renierite is reported from the Cu-rich basal zone of the poly metallic deposit at Rajpura-Dariba.

Scope of workCivil & Structural works, Design and Engineering of EPC 4 Package, Project Management, Procurement and Supply of various equipment, Fabrication, Inspection, Transportation, Unloading including Free Issue Material, Storage, Construction, Installation, Testing, Pre-commissioning, Assistance in commissioning and Handing Over

of the Leaching, Purification and Cell House Package with other common utilities of Phase-III 210000 TPA Zinc Smelter at Dariba Smelter Complex.

Major quantities

Works Quantity

Excavation : 485000 cu.m

Backfilling / Disposal : 575000 cu.m

Concrete : 201585 cu.m

Formwork : 380000 sq.m

Brickwork : 11225 cu.m

Plaster : 88000 sq.m

Reinforcement : 10750 t

Miscellaneous Flooring : 32590 sq.m

Doors & Windows : 3249 sq.m

Structural Fabrication : 10076 t

Structural Erection : 10076 t

Grating : 11850 sq.m

Sheeting : 53392 sq.m

Sand blasting & Painting : 10076 t

Water Proofing : 9186 sq.m

Sanitary & Plumbing : 680 nos

Mastic Lining : 42715 sq.m

PVC Lining : 28650 sq.m

AR Brick Lining : 28950 sq.m

Cell Casting & Alignment : 132 nos

Panoramic view of plant

ECC CONCORD Oct - Dec 2010 43

Upon commissioning this 210,000 tonnes per annum Hydro metallurgical Zinc Smelter, & 100,000 tonnes per annum Lead Smelter and 160 MW Thermal Power Plant at Rajpura Dariba, Hindustan Zinc Limited is poised to become the world’s largest producer of integrated zinc-lead.

Challenges faced

One of the most crucial challenges was the cold bending of SS904L / CS pipes which were used as heating coils in leaching tanks. The cold bending process was needed

to be done in plenty during the peak season. For resolving this issue a Pipe Rolling Machine was designed in-house and custom built by the plant and machinery team of L&T on the site. The addition of this unique machine had increased productivity greatly and helped in completing the project on time.

Among the other challenges, there was a land acquisition issue between the client and the local villagers. After several discussions a suitable commitment was given to villagers that employment

will be provided and new sub-contractors will be appointed along with additional amount per man day as site allowances to all Sub-Contractors.

Plant and Machinery

Description Nov’09 (Peak Period)

Excavator : 3

Rock Breaker : 3

Dumper : 4

JCB : 2

Dozer : 2

Wheel Loader : 1

Vibro Max Roller : 2

Water Tanker : 4

Mixer Machine : 2

Batching Plant (30 Cum / Hr) : 2

Stone Crusher Plant : 1

Transit Mixer : 11

Concrete Pump : 3

Concrete Boom Placer : 1

Bar Shearing Machine : 4

Surface Planer : 6

Circular Saw : 3

Crane - TATA 320 : 5

Crawler Crane – 75 / 80 MT : 5

Crane Tyre Mounted 75 T : 1

Crane Tyre Mounted 40 T : 1

Gantry Crane : 1

Hydra : 9

Plate Bending Machine : 2

MIG Welding Machines : 2

Welding Machines : 234

Radial Drilling Machine : 1

Submerged Arc Welding Machine : 1

Trailer 40 Ft : 6

Tractor Trailer : 2

Truck : 4

Lathe : 1

Overview of Leaching Area - During Construction

Pipe Bending Machine - designed In-house

ECC CONCORD Oct - Dec 2010 44

The location being a dry and arid region there was an acute scarcity of proper potable water and water for construction activities. The heat was also quite unbearable during most parts of the year. Windy conditions would create a lot of dust pollution which was mitigated by sprinkling water at site to suppress dust. The terrain was also rocky in nature which posed a major challenge for construction.

Sustainability

The mining industry has been an area of concern for the environmentalists because of the potential harm the mining activities causes to the surrounding environ and bio-diversity in the mining and the processing areas. But on the contrary, when one visits Rajpura Dariba, the mining town presents a picture of sheer delight and one will change his/her perception towards mining companies. Rajpura Dariba presents a surprisingly pleasant picture of a dust-free and green ambience surrounding the mines.

The growing concern for sustainable environment to meet the present needs without disturbing the assets for the future generation has become a key concept in seeking to integrate the environmental, social and development goals of societies everywhere. As such, the future of mining is inseparable from the pursuit of sustainable environment. Therefore L&T has taken all measures to ensure that the natural resources in the project area remain sustainable. There has been a constant effort towards environmental preservation and recycling. During construction, rocks dumped at a dumping yard were re-used by crushing and utilizing it for further construction work. Waste water was recycled for use in plantation and landscaping.

Land has been used effectively by setting up the plant considering a location away from cultivable land.

Contribution towards nation building

What was once a rural area with scanty vegetation and rainfall patterns has now transformed into a fully developed and thriving town with the construction activity alone offering employment to close to 6500 people. The construction work being carried out by L&T has attracted workers from neighboring villages, giving them an alternative source of income. Earlier Dariba only had a dysfunctional colony and a small shop for serving the needs of the society prior to the initiation of construction of the smelter.

Inside View of “Cell House”

Overview of Leaching Area - After Construction

ECC CONCORD Oct - Dec 2010 45

With the construction of the plant, the old colony has been re-utilized by L&T and made fully functional with a bustling market place, providing major commodities and a new state-of-the-art residential complex. The plant is also expected to infuse a trickle-down effect providing economic and infrastructural development in the neighboring towns.

Rajpura Dariba has a hospital run by Hindustan Zinc Ltd. and a Kendriya Vidyalaya school for providing quality education to the children of the town. The Government of Rajasthan has also recently signed a MOU with Hindustan Zinc Ltd., to upgrade the heart hospital in Udaipur. Through Vedanta Bal Chetna Anganwadi project Hindustan Zinc provides nutrients to the children in the neighboring rural areas by adopting 400 Anganwadis in the four districts of Udaipur, Rajsamand, Bhilwara and Chittorgarh. Today these Anganwadis have a planned diet for the children, water filter for safe drinking water, hygienic toilets, toys

and colourful books to read. Apart from these initiatives, HZL has also helped set up self-help groups to empower women below poverty level to earn a monthly household income of INR 2500.

Today this erstwhile remote village can boast of amazing amenities such as uninterrupted power supply and internet connectivity, copious water supply and good roads. L&T, by partnering with HZL has brought

about a massive transformation in the nearby regions. C o n t r i b u t i n g towards the Nation Building exercise, this will be yet another landmark for L&T in bringing prosperity to rural India

AwardsB r i t i s h y

Safety Council (International Safety Awards) – 2009 (for two consecutive years)

ROSPA (The yRoyal Society for the

prevention of accidents) - 2010 Gold Award

Certificate of Merit award for yachieving 20 Million lost time injury free man-hours during the period : 24th Oct’2008 to 31st Mar’2010

Quality trophy award – 2010 y

AchievementsNew world record of 21 para yliners erection done in a single day. This record had surpassed the earlier L&T record of 19 para liners done in a day at HZL, Chanderiya site

Successful commissioning of y210,000 TPA zinc plant in a record period of 38 days.

Highest concrete quantity in a ymonth, 12862 cu.m

Highest piping erection in a day, y5380 Inch Meter

Highest piping erection in a ymonth, 46934 Inch Meter

444 sq.m rubber lining ycompleted in a day and 5441 sq.m in a month

Mr. J. Suresh Project Manager

Major Quantities – EPC Package (Mechanical works)

Mechanical Quantity

Equipment erection : 2350 t

FRP Tanks : 13 nos

FRP Stacks : 48 nos

FRP Launders : 1730 m

Piping (CS-IBR, CS-Non IBR, SS & PPH)

Fabrication : 90000 inch dia

Erection : 150000 inch m

SS316L (Tanks & Equipment) : 380 t

MS Plates & Structural : 2100 t

Rubber Lining (Inside Tanks & Thickeners) : 23200 sq.m

Acid Proof Brick Lining (Inside Tanks & Thickeners) : 23200 sq.m

Kendriya Vidhyalaya at Dariba

ECC CONCORD Oct - Dec 2010 46

I N A U G U R AT I O N

L&T completes first phase of Mahatma Mandir in 182 days

L&T has set a benchmark by executing the phase I of Mahatma Mandir in a record time of just182 days on design and build basis covering all civil, mechanical, electrical and IT system works. This facility spread Over 4 lakh sq.ft was inaugurated by Hon’ble Chief Minister of Gujarat Shri Narendra Modi, on 12th January 2011 to host the 5th Global Summit, as a part of Vibrant Gujarat 2011 programme.

Thanks to the innovative methods like precast technology, sophisticated construction equipment, tandem lifting using heavy lift cranes (15 cranes and 25 other lifting devices), this remarkable feat was achieved in just 182 days. Design and execution works were carried out in parallel at the project

site, which has achieved 6 million safe man hours with a battalion of 4000 strong work force.

Phase I project of Mahatma Mandir consists of spacious Convention and Business Centre, well-equipped Exhibition halls and service buildings. In the second phase, memorial Salt Mound, a unique Gandhi Sculpture Garden, a Dandi March suspension Bridge with landscaping and water bodies will be taken up. When fully completed, it will host, one of the world’s largest public roof garden, atop the large span column free convention and exhibition centres.

Perspective of the Mahatma Mandir

View of the convention centers with a statue of Mahatma

Shri Narendra Modi, Chief Minister, Gujarat, unveiling the “Vibrant Gujarat 2011”plaque

ECC CONCORD Oct - Dec 2010 47

CSTC at SSU Campus, Bidyadharpur, Cuttack - Odisha, inaugurated

Sri Sri Ravi Shankar along with L&T officials during the inauguration of ‘Vidya’

A Vocational Training Centre called “VIDYA” was set up on 15th November, 2010 at Sri Sri campus, Bidyadharpur, Cuttack, Odisha. This centre has been established by L&T and Sri Sri University as a joint venture. This centre aims to provide vocational training to 200 persons per annum by inducting school dropouts and socially backward youths from rural areas of Odisha in Masonry and Bar-bending trade.