Computer Input Output Devices93-2003

-

Upload

chauhan-rajendra -

Category

Documents

-

view

202 -

download

0

Transcript of Computer Input Output Devices93-2003

Seminar Report On

COMPUTERINPUT-OUTPUT DEVICES-The Computer Interfaces

Prepared By: Chauhan Rajendra G(6058). Popat Pratik P(6056).

COMPUTER INPUT OUTPUT DEVICES

CERTIFICATE

This is to certify that Mr.Chauhan Rajendra G.(6058) and Mr Popat Pratik P.(6056) students of semester-V IT Engineering, of Shantilal Shah Engineering College,Bhavnagar have satisfactorily completed a report on “Computer Input-Output Devices” and submitted on .

2 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Guide Staff in Charge Head of Department

3 | P a g e

COMPUTER INPUT OUTPUT DEVICES

AKNOWLEDGEMENT

We are sincerely thankful to Beena V Thanki who thoroughly guided me and devoted her precious and valuable and pin-point suggestion in preparation of my project report on Bluetooth-Wireless Technology.

We are also thankful to principal,S.S.Engg.College due to whom we are able to prepare this paper with almost care.

Chauhan Rajendra G.(6058)

and

Popat Pratik P(6056)

IT Engg V SEM

S.S.Engg.College.

Bhavnagar.

4 | P a g e

COMPUTER INPUT OUTPUT DEVICES

CONTENTS

1. Introduction …………………….………………………..5

2. Input devices ……………………………………………...7

Mouse ……………………………………………………..7

Graphics tablet …………………………………………………… 11

Joystick …………………………………………………….16

Barcode reader …………………………………………………….20

Light pen …………………………………………………….19

Pointing stick …………………………………………………….26

Digital camera …………………………………………………….29

Magnetic ink character reader …………………………………………………….36.

Micro phone …………………………………………………….38

Touch screen …………………………………………………….50

3. Output devices ..……………………………………………………54

Printer ………………………………………………..……54

Plotter ……………………………………………………..64

4. References ..……………………………………………………68

5 | P a g e

COMPUTER INPUT OUTPUT DEVICES

1. Introduction

The computer will be of no use unless it is able to communicate with the outsideworld.

Input/Output devices are required for users to communicate with the computer.In simple

terms, input devices bring information INTO the computer and outputdevices bring

information OUT of a computer system. These input/output devices arealso known as

peripherals since they surround the CPU and memory of a computersystem.

The computing literature often draws a sharp distinction between input and output;

computer scientists are used to regarding a screen as a passive output device and a mouse as a

pure input device. However, nearly all examples of human-computer interaction require both

input and output to do anything useful. For example, what good would a mouse be without

the corresponding feedback embodied by the cursor on the screen, as well as the sound and

feel of the buttons when they are clicked? The distinction between output devices and input

devices becomes even more blurred in the real world. A sheet of paper can be used to both

record ideas (input) and display them (output). Clay reacts to the sculptor’s fingers yet also

provides feedback through the curvature and texture of its surface. Indeed, the complete and

seamless integration of input and output is becoming a common research theme in advanced

computer interfaces such as ubiquitous computing (Weiser, 1991) and tangible interaction

(Ishii & Ullmer, 1997). Input and output bridge the chasm between a computer’s inner world

of bits, and the real world perceptible to the human senses. Input to computers consists of

sensed information about the physical environment. Familiar examples include the mouse,

which senses movement across a surface, and the keyboard, which detects a contact closure

when the user presses a key. However, any sensed information about physical properties of

people, places, or things can serve as input to computer systems. Output from computers can

comprise any emission or modification to the physical environment, such as a display

(including the cathode ray tube (CRT), flat-panel displays, or even light emitting diodes),

speakers, or tactile and force feedback devices (sometimes referred to as haptic displays). An

interaction technique is the fusion of input and output, consisting of all hardware and

software elements, that provides a way for the user to accomplish a low-level task. For

6 | P a g e

COMPUTER INPUT OUTPUT DEVICES

example, in the traditional graphical user interface, users can scroll through a document by

clicking or dragging the mouse (input) within a scroll bar displayed on the screen (output).

The fundamental task of human-computer interaction is to shuttle information

between the brain of the user and the silicon world of the computer. Progress in this area

attempts to increase the useful bandwidth across that interface by seeking faster, more

natural, and more convenient means for users to transmit information to computers, as well as

efficient, salient, and pleasant mechanisms to provide feedback to the user. On the user’s side

of the communication channel, interaction is constrained by the nature of human attention,

cognition, and perceptual-motor skills and abilities; on the computer side, it is constrained

only by the technologies and methods that we can invent. Research in input and output

centers around the two ends of this channel: the devices and techniques computers can use for

communicating with people, and the perceptual abilities, processes, and organs people can

use for communicating with computers. It then attempts to find the common ground through

which the two can be related by studying new modes of communication that could be used

for human-computer interaction (HCI) and developing devices and techniques to use such

modes. Basic research seeks theories and principles that inform us of the parameters of

human cognitive and perceptual facilities, as well as models that can predict or interpret user

performance in computing tasks. Advances can be driven by the need for new modalities to

support the unique requirements of specific application domains, by technological

breakthroughs that HCI researchers attempt to apply to improving or extending the

capabilities of interfaces, or by theoretical insights suggested by studies of human abilities

and behaviors, or even problems uncovered during careful analyses of existing interfaces.

These approaches complement one another, and all have their value and contributions to the

field, but the best research seems to have elements of all of these.

7 | P a g e

COMPUTER INPUT OUTPUT DEVICES

2. Input devices

One of most common input devices is a computer terminal.The typical terminal has a

keyboard so that data can be typed into the computer and a screen to display what is being

typed.

There are many input devices such as keyboard,mouse and many others some of

them are describe here,

Mouse

In computing, a mouse (plural mouses, mice, or mouse devices) is a pointing device that

functions by detecting two-dimensional motion relative to its supporting surface. Physically,

a mouse consists of an object held under one of the user's hands, with one or more buttons. It

sometimes features other elements, such as "wheels", which allow the user to perform various

system-dependent operations, or extra buttons or features can add more control or

dimensional input. The mouse's motion typically translates into the motion of a pointer on a

display, which allows for fine control of a Graphical User Interface.

The name mouse, originated at the Stanford Research Institute, derives from the

resemblance of early models (which had a cord attached to the rear part of the device,

suggesting the idea of a tail) to the common mouse.[

The first marketed integrated mouse – shipped as a part of a computer and intended

for personal computer navigation – came with the Xerox 8010 Star Information System in

1981. However, the mouse remained relatively obscure until the appearance of the Apple

Macintosh; in 1984 a prominent PC columnist commented the release of this new computer

with a mouse: “There is no evidence that people want to use these things.

A mouse now comes with most computers and many other varieties can be bought

separately.

8 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Mechanical mouse devices

Bill English, builder of Engelbart's original mouse, invented the ball mouse in 1972 while

working for Xerox PARC. The ball-mouse replaced the external wheels with a single ball that

could rotate in any direction. It came as part of the hardware package of the Xerox Alto

computer. Perpendicular chopper wheels housed inside the mouse's body chopped beams of

light on the way to light sensors, thus detecting in their turn the motion of the ball. This

variant of the mouse resembled an inverted trackball and became the predominant form used

with personal computers throughout the 1980s and 1990s. The Xerox PARC group also

settled on the modern technique of using both hands to type on a full-size keyboard and

grabbing the mouse when required.

The ball mouse utilizes two rollers rolling against two sides of the ball. One roller

detects the forward–backward motion of the mouse and other the left–right motion. The

motion of these two rollers causes two disc-like encoder wheels to rotate, interrupting optical

beams to generate electrical signals. The mouse sends these signals to the computer system

by means of connecting wires. The driver software in the system converts the signals into

motion of the mouse pointer along X and Y axes on the screen.

Ball mice and wheel mice were manufactured for Xerox by Jack Hawley, doing

business as The Mouse House in Berkeley, California, starting in 1975.

Based on another invention by Jack Hawley, proprietor of the Mouse House, Honeywell

produced another type of mechanical mouse. Instead of a ball, it had two wheels rotating at

off axes. Keytronic later produced a similar product.

9 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Modern computer mice took form at the École polytechnique fédérale de Lausanne

(EPFL) under the inspiration of Professor Jean-Daniel Nicoud and at the hands of engineer

and watchmaker André Guignard. This new design incorporated a single hard rubber

mouseball and three buttons, and remained a common design until the mainstream adoption

of the scroll-wheel mouse during the 1990s.]

Another type of mechanical mouse, the "analog mouse" (now generally regarded as

obsolete), uses potentiometers rather than encoder wheels, and is typically designed to be

plug-compatible with an analog joystick. The "Color Mouse," originally marketed by Radio

Shack for their Color Computer (but also usable on MS-DOS machines equipped with analog

joystick ports, provided the software accepted joystick input) was the best-known example.

Mechanical or opto-mechanical

A mouse described as simply "mechanical" has a contact-based incremental rotary encoder, a

system prone to drag and unreliability of contact. Opto-mechanical mice still use a ball or

crossed wheels, but detect shaft rotation using an optical encoder with lower friction and

more certain performance.

Optical mice

An optical mouse uses a light-emitting diode and photodiodes to detect movement relative to

the underlying surface, rather than moving some of its parts – as in a mechanical mouse

Modern optical mice

Modern surface-independent optical mice work by using an optoelectronic sensor to take

successive pictures of the surface on which the mouse operates. As computing power grew

cheaper, it became possible to embed more powerful special-purpose image-processing chips

in the mouse itself. This advance enabled the mouse to detect relative motion on a wide

variety of surfaces, translating the movement of the mouse into the movement of the pointer

and eliminating the need for a special mouse-pad. This advance paved the way for

widespread adoption of optical mice. Optical mice illuminate the surface that they track over,

using an LED or a laser diode. Changes between one frame and the next are processed by the

image processing part of the chip and translated into movement on the two axes using an

10 | P a g e

COMPUTER INPUT OUTPUT DEVICES

optical flow estimation algorithm. For example, the Avago Technologies ADNS-2610 optical

mouse sensor processes 1512 frames per second: each frame consisting of a rectangular array

of 18×18 pixels, and each pixel can sense 64 different levels of gray

11 | P a g e

COMPUTER INPUT OUTPUT DEVICES

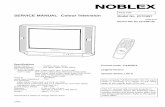

Graphics tablet

A graphics tablet (or digitizing tablet, graphics pad, drawing tablet) is a computer input

device that allows one to hand-draw images and graphics, similar to the way one draws

images with a pencil and paper. These tablets may also be used to capture data or handwritten

signatures.

A graphics tablet (also called pen pad or digitizer) consists of a flat surface upon

which the user may "draw" an image using an attached stylus, a pen-like drawing apparatus.

The image generally does not appear on the tablet itself but, rather, is displayed on the

computer monitor. Some tablets however, come as a functioning secondary computer screen

that you can interact with directly using the stylus.

Some tablets are intended as a general replacement for a mouse as the primary

pointing and navigation device for desktop computers.

12 | P a g e

COMPUTER INPUT OUTPUT DEVICES

800px-Wacom_Graphire4_tablet

Operation

There have been many attempts to categorize the technologies that have been used for graphics tablets. Some of the resulting categories include:

Passive tablets

Passive tablets, most notably those by Wacom, make use of electromagnetic induction

technology, where the horizontal and vertical wires of the tablet operate as both transmitting

and receiving coils (as opposed to the wires of the RAND Tablet which only transmit). The

tablet generates an electromagnetic signal, which is received by the LC circuit in the stylus.

The wires in the tablet then change to a receiving mode and read the signal generated by the

stylus. Modern arrangements also provide pressure sensitivity and one or more switches

(similar to the buttons on a mouse), with the electronics for this information present in the

stylus itself, not the tablet. On older tablets, changing the pressure on the stylus nib or

pressing a switch changed the properties of the LC circuit, affecting the signal generated by

the pen, which modern ones often encode into the signal as a digital data stream. By using

electromagnetic signals, the tablet is able to sense the stylus position without the stylus

having to even touch the surface, and powering the pen with this signal means that devices

used with the tablet never need batteries. Wacom's patents don't permit their competitors to

employ such techniques.

Active tablets

Active tablets differ in that the stylus used contains self-powered electronics that generate

and transmit a signal to the tablet. These styli rely on an internal battery rather than the tablet

for their power, resulting in a bulkier stylus. Eliminating the need to power the pen means

that such tablets may listen for pen signals constantly, as they do not have to alternate

between transmit and receive modes, which can result in less jitter.

13 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Optical tablets

Optical tablets operate by a very small digital camera in the stylus, and then doing pattern

matching on the image of the paper. The most successful example is the technology

developed by Anoto.

Acoustic tablets

Early models were described as spark tablets -- a small sound generator was mounted in the

stylus, and the acoustic signal picked up by two microphones placed near the writing surface.

Some modern designs are able to read positions in three dimensions.

Electromagnetic tablets

Wacom's are one example of a graphics tablet that works by generating and detecting an

electromagnetic signal: in the Wacom design, the signal is generated by the pen, and detected

by a grid of wires in the tablet. Other designs such as those by Pencept generate a signal in

the grid of wires in the tablet, and detect it in the pen.

Capacitative tablets

have also been designed to use an electrostatic or capacitative signal. Scriptel's designs are

one example of a high-performance tablet detecting an electrostatic signal. Unlike the type of

capacitative design used for touchscreens, the Scriptel design is able to detect the position of

the pen while it is in proximity to, or hovering above, the tablet.

For all these technologies, the tablet can use the received signal to also determine the

distance of the stylus from the surface of the tablet, the tilt (angle from vertical) of the stylus,

and other information in addition to the horizontal and vertical positions.

Compared to touch-sensitive touchscreens, a graphics tablet generally offers much higher

precision, the ability to track an object which is not touching the tablet, and can gather much

more information about the stylus, but is typically more expensive, and can only be used with

the special stylus or other accessories.

14 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Some tablets, especially inexpensive ones aimed at young children, come with a corded

stylus, using technology similar to older RAND tablets, although this design is no longer used

on any normal tablets.

Puck

After styli, pucks are the most commonly used tablet accessory. A puck is a mouse-like

device that can detect its absolute position, as opposed to mice, which can only sense their

relative velocity on a surface (most tablet drivers are capable of allowing a puck to emulate a

mouse in operation, and many pucks are marketed as “mice.”) Pucks range in size and shape,

some are externally indistinguishable from a mouse, while others are fairly large device with

dozens of buttons and controls. Professional pucks often have a reticule or loupe which

allows the user to see the exact point on the tablet's surface targeted by the puck, for detailed

tracing and CAD work.

Uses

General uses

Graphics tablets, because of their stylus-based interface and ability to detect some or all of

pressure, tilt, and other attributes of the stylus and its interaction with the tablet, are widely

considered to offer a very natural way to create computer graphics, especially two-

dimensional computer graphics. Indeed, many graphics packages are able to make use of the

pressure (and, in some cases, stylus tilt or rotation) information generated by a tablet, by

modifying the brush size, shape, opacity, color, or other attributes based on data received

from the graphics tablet.

In East Asia, graphics tablets, or pen tablets as they are known, are widely used in

conjunction with input method editor software (IMEs) to write Chinese, Japanese, Korean

15 | P a g e

COMPUTER INPUT OUTPUT DEVICES

characters (CJK). The technology is popular and inexpensive and offers a methodology for

interacting with the computer in a more natural manner than typing on the keyboard, with the

pen tablet supplanting the role of the computer mouse. Uptake of handwriting recognition

among users of latin script has been slower.

Tablets are also popular for technical drawings and CAD, as one can put a piece of

paper on them without interfering with their function. Finally, tablets are gaining popularity

as a replacement for the computer mouse as a pointing device. They can be more intuitive to

some users than the mouse, as the position of the pen on the tablet typically corresponds to

the location of the pointer on the GUI shown on the computer screen. Those artists using the

pen for graphics work will as a matter of convenience use the tablet and pen for standard

computer operations rather than put down the pen and find the mouse.

Graphics tablets are available in various sizes and price ranges; A6-sized tablets being

relatively inexpensive and A3-sized tablets being far more expensive. Modern tablets usually

connect to the computer via a USB interface.

A solution for injuries

Advocates of tablets and pens cite relief from occupational overuse syndrome varieties such

as repetitive strain injury. Sufferers of carpal tunnel syndrome also report good results. This

is because the use of a computer mouse tends to be very repetitive on the wrist, whereas

operating a pen is more natural and tends to involve the movement of the entire arm .

16 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Joystick

A joystick is an input device consisting of a stick that pivots on a base and reports its angle

or direction to the device it is controlling. Joysticks are often used to control video games,

and usually have one or more push-buttons whose state can also be read by the computer. A

popular variation of the joystick used on modern video game consoles is the analog stick.

The joystick has been the principal flight control in the cockpit of many aircraft,

particularly military fast jets, where centre stick or side-stick location may be employed (see

also Centre stick vs side-stick).

Joysticks are also used for controlling machines such as cranes, trucks, underwater

unmanned vehicles and zero turning radius lawn mowers. Miniature finger-operated joysticks

have been adopted as input devices for smaller electronic equipment such as mobile phones.

17 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Arcade sticks

An arcade stick is a large-format controller for use with home consoles or computers. They

use the stick-and-button configuration of some arcade cabinets, such as those with particular

multi-button arrangements. For example, the six button layout of the arcade games Street

Fighter II or Mortal Kombat cannot be comfortably emulated on a console joypad, so

licensed home arcade sticks for these games have been manufactured for the Xbox 360.

Technical details

Most joysticks are two-dimensional, having two axes of movement (similar to a mouse), but

one and three-dimensional joysticks do exist. A joystick is generally configured so that

moving the stick left or right signals movement along the X axis, and moving it forward (up)

or back (down) signals movement along the Y axis. In joysticks that are configured for three-

dimensional movement, twisting the stick left (counter-clockwise) or right (clockwise)

signals movement along the Z axis. These three axes - X Y and Z - are, in relation to an

aircraft, roll, pitch, and yaw.

An analog joystick is a joystick which has continuous states, i.e. returns an angle

measure of the movement in any direction in the plane or the space (usually using

potentiometers) and a digital joystick gives only on/off signals for four different directions,

and mechanically possible combinations (such as up-right, down-left, etc.). (Digital joysticks

were very common as game controllers for the video game consoles, arcade machines, and

home computers of the 1980s.)

Additionally joysticks often have one or more fire buttons, used to trigger some kind

of action. These are simple on/off switches.

Some joysticks have force feedback capability. These are thus active devices, not just

input devices. The computer can return a signal to the joystick that causes it to resist the

movement with a returning force or make the joystick vibrate.

Most I/O interface cards for PCs have a joystick (game control) port. Modern

joysticks mostly use a USB interface for connection to the PC.

18 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Industrial applications

In recent times, the employment of joysticks has become common place in many industrial

and manufacturing applications, such as; cranes, assembly lines, forestry equipment, mining

trucks, and excavators. In fact, the use of such joysticks is in such high demand, that it has

virtually replaced the traditional mechanical control lever in nearly all modern hydraulic

control systems.

Due to the highly hands-on, rough nature of such applications, the industrial joystick

tends to be more robust than the typical video-game controller, and able to function over a

high cycle life. This led to the development and employment of Hall Effect sensing to such

applications in the 1980s as a means of contactless sensing. Several companies produce

joysticks for industrial applications using hall effect technology.

The two global manufacturers that serve the largest OEM's like Caterpillar, John

Deere, AGCO, CNH, JLG, GENIE and others are DeltaTech Controls

[www.deltatechcontrols.com] and Penny and Giles Controls [www.pennyandgiles.com].

Penny and Giles Controls also designs and manufactures joysticks for powered wheelchair

controls and radio remote controls.

In North America there are 3 small regional manufactures that also service the

industry; OEM Controls [www.oemcontrols.com], Otto Engineering

[www.ottoexcellence.com] and PQ Controls [www.pqcontrols.com].

In Europe there are several manufacturers that supply into specialized market sectors,

like for example crane controls, aviation, etc.. One of the European global joystick suppliers

is the Swiss company Genge & Thoma AG [www.gengethoma.com], supplying standard and

tailor made industrial grade joysticks.

The larger manufactures of Joysticks are able to customize joystick handles and grips

specific to the OEM needs while small regional manufacture concentrate on selling standard

products at higher prices to smaller OEM's.

Assistive technology

Specialist joysticks, classed as an assistive technology pointing device, are used to replace the

computer mouse for people with fairly severe physical disabilities. Rather than controlling

19 | P a g e

COMPUTER INPUT OUTPUT DEVICES

games these joysticks plug into the USB port and control the mouse pointer. They are often

useful to people with athetoid conditions, such as cerebral palsy, who find them easier to

grasp than a standard mouse. Miniature joysticks are also available for people with conditions

involving muscular weakness such as muscular dystrophy or motor neurone disease. They are

also used on electric powered wheelchairs for control since they are simple and effective to

use as a control method.

Hat switch

Hat switch - at top, in green

A hat switch is a control on some joysticks. It's also known as a POV (point of view) switch.

It allows one to look around in their virtual world, browse menus etc. For example, many

flight simulators use it to switch the player's views, while other games sometimes use it as a

substitute for the D-pad.

The term hat switch is a sanitization of the term "Coolie Hat", named for the similar-looking

headgear, which may be considered offensive.

In a real aircraft, the hat switch may control things like aileron or rudder trim.

20 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Barcode reader

A barcode reader (or barcode scanner) is an electronic device for reading printed barcodes.

Like a flatbed scanner, it consists of a light source, a lens and a light sensor translating optical

impulses into electrical ones. Additionally, nearly all barcode readers contain decoder

circuitry analyzing the barcode's image data provided by the sensor and sending the barcode's

content to the scanner's output port.

Types of barcode readers

Methods

Scanning methods are distinguished by the amount of operator manipulation required:

Pen or wand-type readers: requires the operator to swipe the pen over the code.

Semi-automatic handheld readers: The operator need not swipe, but must at least position the reader near the label

Fix-mount readers for automatic reading: The reading is performed laterally passing the label over the reader. No operator is required, but the position of the code target must coincide with the imaging capability of the reader.

Reader gates for automatic scanning: The position of the code must be just under the gate for short time, enabling the scanner sweep to capture the code target successfully.

21 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Types of technology

The reader types can be distinguished as follows:

Pen type readers

Pen type readers consist of a light source and a photodiode that are placed next to each other

in the tip of a pen or wand. To read a bar code, the tip of the pen moves across the bars in a

steady motion. The photodiode measures the intensity of the light reflected back from the

light source and generates a waveform that is used to measure the widths of the bars and

spaces in the bar code. Dark bars in the bar code absorb light and white spaces reflect light so

that the voltage waveform generated by the photo diode is a representation of the bar and

space pattern in the bar code. This waveform is decoded by the scanner in a manner similar to

the way Morse code dots and dashes are decoded.

Laser scanners

Laser scanners work the same way as pen type readers except that they use a laser beam as

the light source and typically employ either a reciprocating mirror or a rotating prism to scan

the laser beam back and forth across the bar code.As with the pen type reader, a photodiode is

used to measure the intensity of the light reflected back from the bar code. In both pen

readers and laser scanners, the light emitted by the reader is tuned to a specific frequency and

the photodiode is designed to detect only this modulated light of the same frequency.

CCD Readers

CCD readers (also referred to as LED scanner) use an array of hundreds of tiny light sensors

lined up in a row in the head of the reader.[1] Each sensor measures the intensity of the light

immediately in front of it. Each individual light sensor in the CCD reader is extremely small

and because there are hundreds of sensors lined up in a row, a voltage pattern identical to the

pattern in a bar code is generated in the reader by sequentially measuring the voltages across

each sensor in the row. The important difference between a CCD reader and a pen or laser

scanner is that the CCD reader is measuring emitted ambient light from the bar code whereas

pen or laser scanners are measuring reflected light of a specific frequency originating from

the scanner itself.

Camera-Based Readers

22 | P a g e

COMPUTER INPUT OUTPUT DEVICES

2D imaging scanners are the fourth and newest type of bar code reader currently available.

They use a small video camera to capture an image of a bar code. The reader then uses

sophisticated digital image processing techniques to decode the bar code. Video cameras use

the same CCD technology as in a CCD bar code reader except that instead of having a single

row of sensors, a video camera has hundreds of rows of sensors arranged in a two

dimensional array so that they can generate an image.

There are a number of open source libraries for barcode reading from images. These

include the ZXing project, which reads one- and two-dimensional barcodes using Android

and JavaME, the JJIL project, which includes code for reading EAN-13 barcodes from

cellphone cameras using J2ME, and Zebra (Changed name to ZBAR?), which reads various

one-dimensional barcodes in C. Even web site integration, either by image uploads (e.g.

Folke Ashberg: EAN-13 Image-Scanning and code creation tools) or by use of plugins (e.g.

the Barcodepedia uses a flash application and some web cam for querying a database), have

been realized options for resolving the given tasks.

Omni-Directional Barcode Scanners

Omni-directional scanning uses "series of straight or curved scanning lines of varying

directions in the form of a starburst, a lissajous pattern, or other multiangle arrangement are

projected at the symbol and one or more of them will be able to cross all of the symbol's bars

and spaces, no matter what the orientation.

Omni-directional scanners almost all use a laser. Unlike the simpler single-line laser

scanners, they produce a pattern of beams in varying orientations allowing them to read

barcodes presented to it at different angles. Most of them use a single rotating polygonal

mirror and an arrangement of several fixed mirrors to generate their complex scan patterns.

Omni-directional scanners are most familiar through the horizontal scanners in

supermarkets, where packages are slid across a glass or sapphire window. There are a range

of different omni-directional units available which can be used for differing scanning

applications, ranging from retail type applications with the barcodes read only a few

centimetres away from the scanner to industrial conveyor scanning where the unit can be a

couple of metres away or more from the code.

23 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Omni-directional scanners are also better at reading poorly printed, wrinkled, or even torn

barcodes

24 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Light pen

A light pen is a computer input device in the form of a light-sensitive wand used in

conjunction with a computer's CRT TV set or monitor. It allows the user to point to displayed

objects, or draw on the screen, in a similar way to a touch screen but with greater positional

accuracy. A light pen can work with any CRT-based display, but not with LCD screens

(though Toshiba and Hitachi displayed a similar idea at the "Display 2006" show in Japan),

projectors and other display devices.

A light pen is fairly simple to implement. The light pen works by sensing the sudden

small change in brightness of a point on the screen when the electron gun refreshes that spot.

By noting exactly where the scanning has reached at that moment, the X,Y position of the

pen can be resolved. This is usually achieved by the light pen causing an interrupt, at which

point the scan position can be read from a special register, or computed from a counter or

timer. The pen position is updated on every refresh of the screen.

The light pen became moderately popular during the early 1980s. It was notable for

its use in the Fairlight CMI, and the BBC Micro. Even some consumer products were given

light pens, in particular Thomson's TO7 and TO7/70 computers. Because the user was

required to hold his or her arm in front of the screen for long periods of time, the light pen

fell out of use as a general purpose input device.

The first light pen was created around 1952 as part of the Whirlwind project at MIT.

Since the current version of the game show Jeopardy! began in 1984, contestants have

used a light pen to write down their wagers and responses for the Final Jeopardy! round.

25 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Since light pens operate by detecting light emitted by the screen phosphors, some nonzero

intensity level must be present at the coordinate position to be selected.

26 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Pointing stick

The pointing stick (trademarked by IBM as the TrackPoint & by Synaptics as the

Touchstyk) is an isometric joystick used as a pointing device (compare especially touchpad

and trackball). It was invented by research scientist Ted Selker. It is present on many brands

of laptops, including IBM's line of ThinkPad laptops (now made by Lenovo), Toshiba

Satellite laptops, HP business notebooks and on Dell Latitudes under the name of Track

Stick. It has also been observed on computer mice and on some desktop keyboards (as an

integrated pointing device).

The pointing stick operates by sensing applied force (hence it is also known as an

isometric joystick), by using a pair of resistive strain gauges. The velocity of the cursor

depends on the applied force. On a QWERTY keyboard, the stick is embedded between the

'G', 'H' and 'B' keys, and the mouse buttons are placed just below the Spacebar. The mouse

buttons can be operated right-handed or left-handed due to their placement below the

keyboard along the centerline.

The pointing stick has a replaceable rubber cap, traditionally red on the ThinkPad but

also found in other colors on other machines. The cap can be a slightly rough "eraser head"

material (Classic Dome) or other optional shapes (Soft Dome or Soft Rim).

Features

The sensitivity of the TrackPoint is usually adjustable, and can be set to provide an extremely

light touch.

27 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Press-to-select is an optional feature, where a sharp tap on the pointing stick is equivalent to a

button-click. The button thus clicked can be configured to be 1, 2 or 3. However, it is quite

easy to accidentally "click" the mouse when typing.

Together with software wheel-emulation, the Trackpoint (and 3 buttons) can provide

almost the entire behavior of a 3-button, 2-wheel mouse. Tapping button-2 will generate a

middle-click; holding button-2 while simultaneously moving the pointer will generate vertical

and horizontal scrolling events.

The TrackPoint III and the TrackPoint IV have a feature called Negative Inertia that

causes the cursor's velocity to "overreact" when it is accelerated or decelerated. Negative

Inertia is intended to avoid feeling of inertia or sluggishness when starting or stopping

movement[2]. Usability tests at IBM have shown that it is easier for users to position the

cursor with Negative Inertia, and performance is 7.8% better .

Problems

Cursor drift is a ubiquitous problem among pointing sticks, requiring frequent recalibration.

However, TrackPoints automatically recalibrate when the stick recognizes a steady cursor

drift; to trigger a recalibration, the user must lift his or her finger temporarily off the

TrackPoint for about 1 second.

History

The concept of TrackPoint was created in 1984 by Ted Selker, a PARC researcher. He

learned about a study that demonstrated that it takes relatively long time, three-quarters of a

second, for a computer user to shift his hand from the keyboard to the mouse, and as much

time to shift back. Ted Selker wanted to construct a device that would largely eliminate this

delay. Selker built a model of a pointing stick, but actually had no time to work on it. Three

years later, working at IBM, Selker was able to refine the TrackPoint design and transform

his invention into a product..

Comparison with touchpads

The pointing stick can be used in ultra-compact netbooks (see Sony Vaio P, for

example) where there would be no place for a touchpad.

28 | P a g e

COMPUTER INPUT OUTPUT DEVICES

The pointing stick is especially liked by touch-typists and IT professionals because it is one

of the few pointing devices which does not require the user to remove their fingers from the

home row. The device has a very loyal user base, with users who refuse to buy a laptop

unequipped with the device. Some users even choose to wear a TrackPoint cap as a badge to

show their support.

Subjective claims

Some people find it easier to finely position the pointer than when using a touchpad because

there is virtually no 'dead zone'. Some users feel that pointing stick causes less wrist strain,

because user does not need to avoid resting wrists on a touchpad, usually located just below

the keyboard. Some people find them more appealing for mobile gaming than a touchpad,

because the track-point allows infinite movement without repositioning.

One criticism is that because the pointing stick depends on the user applying pressure,

it can cause hand cramps (although this can be partly solved by setting the sensitivity to high,

and lifting the finger when the pointer is not being moved). Another criticism is that it

stresses the index finger and may lead to RSI injuries. In addition, a finger slipping off of the

stick can lead to accidental pressing of one or more keys in immediate proximity.

Objective studies comparing pointing stick and touchpad

performance

A number of ergonomic studies to compare trackpoint and touchpad performance have been

done . Most studies find that touchpad is slightly faster; one study found that "the touchpad

was operated 15% faster than the trackpoint. Another study found that average object

selection time was faster with a touchpad, 1.7 sec compared to 2.2 sec with a trackpoint, and

object manipulation took 6.2 sec with a touchpad, on average, against 8.1 sec with trackpoint.

It should be noted that these studies measured pointing performance only and cannot

verify or disprove the claim that trackpoint is faster in a mix of pointing and typing actions.

29 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Digital camera

A digital camera (or digicam for short) is a camera that takes video or still photographs, or

both, digitally by recording images via an electronic image sensor.

Many compact digital still cameras can record sound and moving video as well as still

photographs. In the Western market, digital cameras outsell their 35 mm film counterparts.

Digital cameras can do things film cameras cannot: displaying images on a screen

immediately after they are recorded, storing thousands of images on a single small memory

device, recording video with sound, and deleting images to free storage space. Some can cro

pictures and perform other elementary image editing. Fundamentally they operate in the same

manner as film cameras, typically using a lens with a variable diaphragm to focus light onto

an image pickup device. The combination of the diaphragm and a shutter mechanism is used

to admit the correct amount of light to the imager, just as with film; the only difference is that

the image pickup device is electronic rather than chemical.

Digital cameras are incorporated into many devices ranging from PDAs and mobile

phones (called camera phones) to vehicles. The Hubble Space Telescope and other

astronomical devices are essentially specialised digital cameras.

Compact digital cameras

Compact cameras are designed to be small and portable and are particularly suitable for

casual and "snapshot" use, thus are also called point-and-shoot camera. The smallest,

generally less than 20 mm thick, are described as subcompacts or "ultra-compacts". Compact

cameras are usually designed to be easy to use, sacrificing advanced features and picture

quality for compactness and simplicity; images can usually only be stored using lossy

compression (JPEG). Most have a built-in flash usually of low power, sufficient for nearby

subjects. Live preview is almost always used to frame the photo. They may have limited

motion picture capability. Compacts often have macro capability, but if they have zoom

capability the range is usually less than for bridge and DSLR cameras. Generally a contrast-

detect autofocus system, using the image data from the live preview feed off the main imager,

focuses the lens.

Typically, these cameras incorporate a nearly-silent leaf shutter into their lenses.

30 | P a g e

COMPUTER INPUT OUTPUT DEVICES

To enable lower costs and smaller size, these cameras typically use image sensors

with a diagonal of approximately 6 mm, corresponding to a crop factor around 6. This gives

them weaker low-light performance, greater depth of field, generally closer focusing ability,

and smaller components than cameras using larger sensors.

Bridge cameras

Bridge or SLR-like cameras are higher-end digital cameras that physically and ergonomically

resemble DSLRs and share with them some advanced features, but share with compacts the

use of a fixed lens and a small sensor. Like compacts, most use live preview to frame the

image. Autofocus is achieved using the same contrast-detect mechanism, but many bridge

cameras feature a manual focus mode for greater control.

Fujifilm FinePix S9000.

Due to the combination of large physical size but a small sensor, many of these cameras have

very highly specified lenses with large zoom ranges and fast apertures, partially

compensating for the inability to change lenses. A typical example is the lens on the

Panasonic FZ50, a 35-420mm equivalent lens with an aperture of 1:2.8-3.7. To reduce

aberrations in a lens with such ambitious specifications, these have quite complex

constructions, using multiple aspheric elements and often anomalous-dispersion glass. To

compensate for the reduced sensitivity of their small sensors, these cameras almost always

include an image stabilization system of some kind to enable longer handheld exposures.

These cameras are sometimes marketed as and confused with digital SLR cameras since the

appearance is similar. Bridge cameras lack the reflex viewing system of DSLRs, have so far

been fitted with fixed (non-interchangeable) lenses (although in some cases accessory wide-

angle or telephoto converters can be attached to the lens), can usually take movies with

sound, and the scene is composed by viewing either the liquid crystal display or the electronic

31 | P a g e

COMPUTER INPUT OUTPUT DEVICES

viewfinder (EVF). They are usually slower to operate than a true digital SLR, but they are

capable of very good image quality (with sufficient light) while being more compact and

lighter than DSLRs. The high-end models of this type have comparable resolutions to low

and mid-range DSLRs. Many of these cameras can store images in lossless RAW format as

an option to JPEG compression. The majority have a built-in flash similar to those found in

DSLRs.

Digital single lens reflex cameras

Digital single-lens reflex cameras (DSLRs) are digital cameras based on film single-lens

reflex cameras (SLRs). They take their name from their unique viewing system, in which a

mirror reflects light from the lens through a separate optical viewfinder. In order to capture an

image the mirror is flipped out of the way, allowing light to fall on the imager. Since no light

reaches the imager during framing, autofocus is accomplished using specialized sensors in

the mirror box itself. (Note that most modern DSLRs feature a "live view" mode that

emulates the live preview viewing system of compact cameras in the event that this method is

desirable.)

These cameras have much larger sensors than the other types, typically 18 mm to 36

mm on the diagonal (crop factor 2, 1.6, or 1). This gives them superior low-light

performance, less depth of field at a given aperture, and a larger size.

They make use of interchangeable lenses; each major DSLR manufacturer also sells a

line of lenses specifically intended to be used on their cameras. This allows the user to select

a lens designed for the application at hand: wide-angle, telephoto, low-light, etc. So each lens

does not require its own shutter, DSLRs use a focal-plane shutter in front of the imager,

behind the mirror.

Because of the need to quickly flip the mirror out of the way at the moment of

exposure, DSLRs make a distinctive "clack" noise when an image is shot.

Electronic viewfinder, interchangeable lens cameras

In late 2008 a new type of camera emerged, combining the larger sensors and interchangeable

lenses of DSLRs with the live preview viewing system of compact cameras, either through an

electronic viewfinder or on the rear LCD. These are simpler and more compact than DSLRs

32 | P a g e

COMPUTER INPUT OUTPUT DEVICES

due to the removal of the mirror box, and typically emulate the handling and ergonomics of

either DSLRs or compacts. As of 2009 the only such system is Micro Four Thirds, borrowing

components from the Four Thirds DSLR system.

Digital rangefinders

A rangefinder is a user-operated optical mechanism to measure subject distance once widely

used on film cameras. Most digital cameras measure subject distance automatically using

acoustic or electronic techniques, but it is not customary to say that they have a rangefinder.

The term rangefinder alone is sometimes used to mean a rangefinder camera, that is, a film

camera equipped with a rangefinder, as distinct from an SLR or a simple camera with no way

to measure distance.

Line-scan camera systems

A line-scan camera is a camera device containing a line-scan image sensor chip, and a

focusing mechanism. These cameras are almost solely used in industrial settings to capture an

image of a constant stream of moving material. Unlike video cameras, line-scan cameras use

a single array of pixel sensors, instead of a matrix of them. Data coming from the line-scan

camera has a frequency, where the camera scans a line, waits, and repeats. The data coming

from the line-scan camera is commonly processed by a computer, to collect the one-

dimensional line data and to create a two-dimensional image. The collected two-dimensional

image data is then processed by image-processing methods for industrial purposes.

Line-scan technology is capable of capturing data extremely fast, and at very high

image resolutions. Usually under these conditions, resulting collected image data can quickly

exceed 100 MB in a fraction of a second. Line-scan-camera–based integrated systems,

therefore are usually designed to streamline the camera's output in order to meet the system's

objective, using computer technology which is also affordable.

Line-scan cameras intended for the parcel handling industry can integrate adaptive focusing

mechanisms to scan six sides of any rectangular parcel in focus, regardless of angle, and size.

The resulting 2-D captured images could contain, but are not limited to 1D and 2D barcodes,

address information, and any pattern that can be processed via image processing methods.

Since the images are 2-D, they are also human-readable and can be viewable on a computer

33 | P a g e

COMPUTER INPUT OUTPUT DEVICES

screen. Advanced integrated systems include video coding and optical character recognition

(OCR).

Integration

Many devices include digital cameras built into or integrated into them. For example, mobile

phones often include digital cameras; those that do are sometimes known as camera phones.

Other small electronic devices (especially those used for communication) such as PDAs,

laptops and BlackBerry devices often contain an integral digital camera, as do some some

digital camcorders.

Due to the limited storage capacity and general emphasis on convenience rather than

image quality, the vast majority of these integrated or converged devices store images in the

lossy but compact JPEG file format.

Mobile phones incorporating digital cameras were introduced in Japan in 2001 by J-Phone. In

2003 camera phones outsold stand-alone digital cameras, and in 2006 they outsold all film-

based cameras and digital cameras combined. These camera phones reached a billion devices

sold in only five years, and by 2007 more than half of the installed base of all mobile phones

were camera phones.

Integrated cameras tend to be at the very lowest end of the scale of digital cameras in

technical specifications, such as resolution, optical quality, and ability to use accessories.

With rapid development, however, the gap between mainstream compact digital cameras and

camera phones is closing, and high-end camera phones are competitive with low end stand-

alone digital cameras of the same generation.

Conversion of film cameras to digital

34 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Digital single-lens reflex camera

When digital cameras became common, a question many photographers asked was whether

their film cameras could be converted to digital. The answer was yes and no. For the majority

of 35 mm film cameras the answer is no, the reworking and cost would be too great,

especially as lenses have been evolving as well as cameras. For most a conversion to digital,

to give enough space for the electronics and allow a liquid crystal display to preview, would

require removing the back of the camera and replacing it with a custom built digital unit.

Many early professional SLR cameras, such as the NC2000 and the Kodak DCS

series, were developed from 35 mm film cameras. The technology of the time, however,

meant that rather than being a digital "backs" the bodies of these cameras were mounted on

large, bulky digital units, often bigger than the camera portion itself. These were factory built

cameras, however, not aftermarket conversions.

A notable exception is the Nikon E2, a camera followed by Nikon E3, using

additional optics to convert the 35mm format to a 2/3 CCD-sensor.

A few 35 mm cameras have had digital camera backs made by their manufacturer,

Leica being a notable example. Medium format and large format cameras (those using film

stock greater than 35 mm), have a low unit production, and typical digital backs for them cost

over $10,000. These cameras also tend to be highly modular, with handgrips, film backs,

winders, and lenses available separately to fit various needs.

The very large sensor these backs use leads to enormous image sizes. The largest in

early 2006 is the Phase One's P45 39 MP imageback, creating a single TIFF image of size up

to 224.6 MB. Medium format digitals are geared more towards studio and portrait

photography than their smaller DSLR counterparts; the ISO speed in particular tends to have

a maximum of 400, versus 6400 for some DSLR cameras.

35 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Magnetic ink character recognition

Magnetic Ink Character Recognition, or MICR, is a character recognition technology

adopted mainly by the banking industry to facilitate the processing of cheques. The process

was demonstrated to the American Bankers Association in July 1956, and was almost

universally employed in the U.S. by 1963]. On September 12, 1961, Stanford Research

Institute (now SRI International) was awarded U.S. Patent Number 3,000,000 for invention of

MICR; the patent was assigned to General Electric. MICR is standardized by ISO 1004.

The major MICR fonts used around the world are E-13B and CMC-7. The E-13B

font was chosen by George Jacobi, who was working for General Electric at the time.Almost

all Indian, US, Canadian and UK checks now include MICR characters at the bottom of the

paper in the E-13B font. Some countries, including France, use the CMC-7 font developed by

Bull.

The 14 characters of the E-13B font. The control characters bracketing each numeral

block are (from left to right) transit, on-us, amount, and dash.

An example of the CMC-7 MICR font. Shown are the 15 characters of the CMC-7

font. The control characters after the numerals are (from left to right) internal, terminator,

amount, routing, and an unused character.

In addition to their unique fonts, MICR characters are printed with a magnetic ink or

toner, usually containing iron oxide. Magnetic printing is used so that the characters can be

reliably read into a system, even when they have been overprinted with other marks such as

cancellation stamps. The characters are first magnetized in the plane of the paper with a

North pole on the right of each MICR character. Then they are usually read with a MICR

read head which is a device similar in nature to the playback head in an audio tape recorder,

36 | P a g e

COMPUTER INPUT OUTPUT DEVICES

and the letterforms' bulbous shapes ensure that each letter produces a unique waveform for

the character recognition system to provide a reliable character result. Examples of MICR

waveforms have been developed and can be displayed using spreadsheet applications like

Microsoft Excel or compatible.

The "13" in the name "E-13B" comes from the 0.013 inch grid used to design that

font.

The error rate for the magnetic scanning of the numbers at the bottom of a typical

check is smaller than with optical character recognition systems. For well printed MICR, the

can't read rate is usually less than 1% while the substitution rate (misread rate) is in the order

of 1 per 100,000 characters.

In 1960s, the MICR fonts became a symbol of modernity or futurism, leading to the

creation of lookalike "computer" typefaces that imitated the appearance of the MICR fonts,

but, unlike real MICR fonts, had a full character repertoire. These checks were typically

printed on impact printers.

The concept of utilizing desktop printers for check printing revolutionized the check

printing business and companies began to manufacture MICR toner for desktop laser printers.

37 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Microphone

A microphone, sometimes colloquially called a mic or mike (both pronounced /ˈmaɪk/), is an

acoustic-to-electric transducer or sensor that converts sound into an electrical signal.

Microphones are used in many applications such as telephones, tape recorders, hearing aids,

motion picture production, live and recorded audio engineering, in radio and television

broadcasting and in computers for recording voice, VoIP, and for non-acoustic purposes such

as ultrasonic checking.

Neumann U87 condenser microphone

The most common design today uses a thin membrane which vibrates in response to sound

pressure. This movement is subsequently translated into an electrical signal. Most

microphones in use today for audio use electromagnetic induction (dynamic microphone),

capacitance change (condenser microphone, pictured right), piezoelectric generation, or light

modulation to produce the signal from mechanical vibration.

Varieties

The sensitive transducer element of a microphone is called its element or capsule. A complete

microphone also includes a housing, some means of bringing the signal from the element to

38 | P a g e

COMPUTER INPUT OUTPUT DEVICES

other equipment, and often an electronic circuit to adapt the output of the capsule to the

equipment being driven. Microphones are referred to by their transducer principle, such as

condenser, dynamic, etc., and by their directional characteristics. Sometimes other

characteristics such as diaphragm size, intended use or orientation of the principal sound

input to the principal axis (end- or side-address) of the microphone are used to describe the

microphone.

Condenser, capacitor or electrostatic microphone

Inside the Oktava 319 condenser microphone

In a condenser microphone, also known as a capacitor or electrostatic microphone, the

diaphragm acts as one plate of a capacitor, and the vibrations produce changes in the distance

between the plates. There are two methods of extracting an audio output from the transducer

thus formed: DC-biased and radio frequency (RF) or high frequency (HF) condenser

microphones. With a DC-biased microphone, the plates are biased with a fixed charge (Q).

The voltage maintained across the capacitor plates changes with the vibrations in the air,

according to the capacitance equation (C = Q / V), where Q = charge in coulombs, C =

capacitance in farads and V = potential difference in volts. The capacitance of the plates is

inversely proportional to the distance between them for a parallel-plate capacitor. (See

capacitance for details.) The assembly of fixed and movable plates is called an "element" or

"capsule."

A nearly constant charge is maintained on the capacitor. As the capacitance changes, the

charge across the capacitor does change very slightly, but at audible frequencies it is sensibly

39 | P a g e

COMPUTER INPUT OUTPUT DEVICES

constant. The capacitance of the capsule (around 5–100 pF) and the value of the bias resistor

(100 megohms to tens of gigohms) form a filter which is highpass for the audio signal, and

lowpass for the bias voltage. Note that the time constant of an RC circuit equals the product

of the resistance and capacitance.

Within the time-frame of the capacitance change (as much as 50 ms at 20 Hz audio

signal), the charge is practically constant and the voltage across the capacitor changes

instantaneously to reflect the change in capacitance. The voltage across the capacitor varies

above and below the bias voltage. The voltage difference between the bias and the capacitor

is seen across the series resistor. The voltage across the resistor is amplified for performance

or recording.

AKG C451B small-diaphragm condenser microphone

RF condenser microphones use a comparatively low RF voltage, generated by a low-noise

oscillator. The oscillator may either be amplitude modulated by the capacitance changes

produced by the sound waves moving the capsule diaphragm, or the capsule may be part of a

resonant circuit that modulates the frequency of the oscillator signal. Demodulation yields a

low-noise audio frequency signal with a very low source impedance. The absence of a high

bias voltage permits the use of a diaphragm with looser tension, which may be used to

achieve wider frequency response due to higher compliance. The RF biasing process results

in a lower electrical impedance capsule, a useful byproduct of which is that RF condenser

microphones can be operated in damp weather conditions which could create problems in

DC-biased microphones whose insulating surfaces have become contaminated. The

Sennheiser "MKH" series of microphones use the RF biasing technique.

Condenser microphones span the range from telephone transmitters to inexpensive karaoke

microphones to high-fidelity recording microphones. They generally produce a high-quality

audio signal and are now the popular choice in laboratory and studio recording applications.

40 | P a g e

COMPUTER INPUT OUTPUT DEVICES

The inherent suitability of this technology is due to the very small mass that must be moved

by the incident sound wave, unlike other microphone types which require the sound wave to

do more work. They require a power source, provided either via microphone outputs as

phantom power or from a small battery. Power is necessary for establishing the capacitor

plate voltage, and is also needed to power the microphone electronics (impedance conversion

in the case of electret and DC-polarized microphones, demodulation or detection in the case

of RF/HF microphones). Condenser microphones are also available with two diaphragms, the

signals from which can be electrically connected such as to provide a range of polar patterns

(see below), such as cardioid, omnidirectional and figure-eight. It is also possible to vary the

pattern smoothly with some microphones, for example the Røde NT2000 or CAD M179.

Electret condenser microphone

First patent on foil electret microphone by G. M. Sessler et al. (pages 1 to 3)

An electret microphone is a relatively new type of capacitor microphone invented at

Bell laboratories in 1962 by Gerhard Sessler and Jim West.The externally-applied charge

described above under condenser microphones is replaced by a permanent charge in an

electret material. An electret is a ferroelectric material that has been permanently electrically

charged or polarized. The name comes from electrostatic and magnet; a static charge is

embedded in an electret by alignment of the static charges in the material, much the way a

magnet is made by aligning the magnetic domains in a piece of iron.

Due to their good performance and ease of manufacture, hence low cost, the vast majority of

microphones made today are electret microphones; a semiconductor manufacturer estimates

annual production at over one billion units. Nearly all cell-phone, computer, PDA and

headset microphones are electret types. They are used in many applications, from high-

quality recording and lavalier use to built-in microphones in small sound recording devices

and telephones. Though electret microphones were once considered low quality, the best ones

41 | P a g e

COMPUTER INPUT OUTPUT DEVICES

can now rival traditional condenser microphones in every respect and can even offer the long-

term stability and ultra-flat response needed for a measurement microphone. Unlike other

capacitor microphones, they require no polarizing voltage, but often contain an integrated

preamplifier which does require power (often incorrectly called polarizing power or bias).

This preamp is frequently phantom powered in sound reinforcement and studio applications.

Microphones designed for Personal Computer (PC) use, sometimes called multimedia

microphones, use a stereo 3.5 mm plug (though a mono source) with the ring receiving power

via a resistor from (normally) a 5 V supply in the computer; unfortunately, a number of

incompatible dynamic microphones are fitted with 3.5 mm plugs too. While few electret

microphones rival the best DC-polarized units in terms of noise level, this is not due to any

inherent limitation of the electret. Rather, mass production techniques needed to produce

microphones cheaply don't lend themselves to the precision needed to produce the highest

quality microphones, due to the tight tolerances required in internal dimensions. These

tolerances are the same for all condenser microphones, whether the DC, RF or electret

technology is used.

Dynamic microphone

Patti Smith singing into a Shure SM58 (dynamic cardioid type) microphone

Dynamic microphones work via electromagnetic induction. They are robust, relatively

inexpensive and resistant to moisture. This, coupled with their potentially high gain before

feedback makes them ideal for on-stage use.

Moving-coil microphones use the same dynamic principle as in a loudspeaker, only

reversed. A small movable induction coil, positioned in the magnetic field of a permanent

magnet, is attached to the diaphragm. When sound enters through the windscreen of the

microphone, the sound wave moves the diaphragm. When the diaphragm vibrates, the coil

moves in the magnetic field, producing a varying current in the coil through electromagnetic

induction. A single dynamic membrane will not respond linearly to all audio frequencies.

Some microphones for this reason utilize multiple membranes for the different parts of the

audio spectrum and then combine the resulting signals. Combining the multiple signals

correctly is difficult and designs that do this are rare and tend to be expensive. There are on

the other hand several designs that are more specifically aimed towards isolated parts of the

audio spectrum. The AKG D 112, for example, is designed for bass response rather than

42 | P a g e

COMPUTER INPUT OUTPUT DEVICES

treble[3]. In audio engineering several kinds of microphones are often used at the same time to

get the best result.

Edmund Lowe using a ribbon microphone

Ribbon microphones use a thin, usually corrugated metal ribbon suspended in a magnetic

field. The ribbon is electrically connected to the microphone's output, and its vibration within

the magnetic field generates the electrical signal. Ribbon microphones are similar to moving

coil microphones in the sense that both produce sound by means of magnetic induction. Basic

ribbon microphones detect sound in a bidirectional (also called figure-eight) pattern because

the ribbon, which is open to sound both front and back, responds to the pressure gradient

rather than the sound pressure. Though the symmetrical front and rear pickup can be a

nuisance in normal stereo recording, the high side rejection can be used to advantage by

positioning a ribbon microphone horizontally, for example above cymbals, so that the rear

lobe picks up only sound from the cymbals. Crossed figure 8, or Blumlein pair, stereo

recording is gaining in popularity, and the figure 8 response of a ribbon microphone is ideal

for that application.

Other directional patterns are produced by enclosing one side of the ribbon in an acoustic trap

or baffle, allowing sound to reach only one side. The classic RCA Type 77-DX microphone

has several externally-adjustable positions of the internal baffle, allowing the selection of

several response patterns ranging from "Figure-8" to "Unidirectional". Such older ribbon

microphones, some of which still give very high quality sound reproduction, were once

valued for this reason, but a good low-frequency response could only be obtained if the

ribbon was suspended very loosely, and this made them fragile. Modern ribbon materials,

including new nanomaterials have now been introduced that eliminate those concerns, and

43 | P a g e

COMPUTER INPUT OUTPUT DEVICES

even improve the effective dynamic range of ribbon microphones at low frequencies.

Protective wind screens can reduce the danger of damaging a vintage ribbon, and also reduce

plosive artifacts in the recording. Properly designed wind screens produce negligible treble

attenuation. In common with other classes of dynamic microphone, ribbon microphones don't

require phantom power; in fact, this voltage can damage some older ribbon microphones.

Some new modern ribbon microphone designs incorporate a preamplifier and, therefore, do

require phantom power, and circuits of modern passive ribbon microphones, i.e., those

without the aforementioned preamplifier, are specifically designed to resist damage to the

ribbon and transformer by phantom power. Also there are new ribbon materials available that

are immune to wind blasts and phantom power.

Carbon microphone

A carbon microphone is a capsule containing carbon granules pressed between two metal

plates. A voltage is applied across the metal plates, causing a small current to flow through

the carbon. One of the plates, the diaphragm, vibrates in sympathy with incident sound

waves, applying a varying pressure to the carbon. The changing pressure deforms the

granules, causing the contact area between each pair of adjacent granules to change, and this

causes the electrical resistance of the mass of granules to change. The changes in resistance

cause a corresponding change in the voltage across the two plates, and hence in the current

flowing through the microphone, producing the electrical signal. Carbon microphones were

once commonly used in telephones; they have extremely low-quality sound reproduction and

a very limited frequency response range, but are very robust devices.

Unlike other microphone types, the carbon microphone can also be used as a type of

amplifier, using a small amount of sound energy to produce a larger amount of electrical

energy. Carbon microphones found use as early telephone repeaters, making long distance

phone calls possible in the era before vacuum tubes. These repeaters worked by mechanically

coupling a magnetic telephone receiver to a carbon microphone: the faint signal from the

receiver was transferred to the microphone, with a resulting stronger electrical signal to send

down the line. (One illustration of this amplifier effect was the oscillation caused by

feedback, resulting in an audible squeal from the old "candlestick" telephone if its earphone

was placed near the carbon microphone.

44 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Piezoelectric microphone

A crystal microphone uses the phenomenon of piezoelectricity — the ability of some

materials to produce a voltage when subjected to pressure — to convert vibrations into an

electrical signal. An example of this is Rochelle salt (potassium sodium tartrate), which is a

piezoelectric crystal that works as a transducer, both as a microphone and as a slimline

loudspeaker component. Crystal microphones were once commonly supplied with vacuum

tube (valve) equipment, such as domestic tape recorders. Their high output impedance

matched the high input impedance (typically about 10 megohms) of the vacuum tube input

stage well. They were difficult to match to early transistor equipment, and were quickly

supplanted by dynamic microphones for a time, and later small electret condenser devices.

The high impedance of the crystal microphone made it very susceptible to handling noise,

both from the microphone itself and from the connecting cable.

Piezoelectric transducers are often used as contact microphones to amplify sound

from acoustic musical instruments, to sense drum hits, for triggering electronic samples, and

to record sound in challenging environments, such as underwater under high pressure.

Saddle-mounted pickups on acoustic guitars are generally piezoelectric devices that contact

the strings passing over the saddle. This type of microphone is different from magnetic coil

pickups commonly visible on typical electric guitars, which use magnetic induction, rather

than mechanical coupling, to pick up vibration.

Fiber optic microphone

45 | P a g e

COMPUTER INPUT OUTPUT DEVICES

The Optoacoustics 1140 fiber optic microphone

A fiber optic microphone converts acoustic waves into electrical signals by sensing changes

in light intensity, instead of sensing changes in capacitance or magnetic fields as with

conventional microphones.

During operation, light from a laser source travels through an optical fiber to

illuminate the surface of a tiny, sound-sensitive reflective diaphragm. Sound causes the

diaphragm to vibrate, thereby minutely changing the intensity of the light it reflects. The

modulated light is then transmitted over a second optical fiber to a photo detector, which

transforms the intensity-modulated light into analog or digital audio for transmission or

recording. Fiber optic microphones possess high dynamic and frequency range, similar to the

best high fidelity conventional microphones.

Fiber optic microphones do not react to or influence any electrical, magnetic,

electrostatic or radioactive fields (this is called EMI/RFI immunity). The fiber optic

microphone design is therefore ideal for use in areas where conventional microphones are

ineffective or dangerous, such as inside industrial turbines or in magnetic resonance imaging

(MRI) equipment environments.

Fiber optic microphones are robust, resistant to environmental changes in heat and

moisture, and can be produced for any directionality or impedance matching. The distance

between the microphone's light source and its photo detector may be up to several kilometers

without need for any preamplifier and/or other electrical device, making fiber optic

microphones suitable for industrial and surveillance acoustic monitoring.

Fiber optic microphones are used in very specific application areas such as for infrasound

monitoring and noise-canceling. They have proven especially useful in medical applications,

such as allowing radiologists, staff and patients within the powerful and noisy magnetic field

to converse normally, inside the MRI suites as well as in remote control rooms.) Other uses

include industrial equipment monitoring and sensing, audio calibration and measurement,

high-fidelity recording and law enforcement.

Laser microphone

46 | P a g e

COMPUTER INPUT OUTPUT DEVICES

Laser microphones are often portrayed in movies as spy gadgets. A laser beam is aimed at the

surface of a window or other plane surface that is affected by sound. The slight vibrations of

this surface displace the returned beam, causing it to trace the sound wave. The vibrating