Compressed Sheet Gasket Materials - afgco.com Reinz Materials.pdf · Automotive original equipment...

Transcript of Compressed Sheet Gasket Materials - afgco.com Reinz Materials.pdf · Automotive original equipment...

CompressedSheet Gasket Materials

Premium Sealing Technology for Industrial Applications

Available from Acurate Felt & Gasket Mfg. Co., Inc. T: 708-780-9000 E: [email protected]

¬ 2

Available from : Accurate Felt & Gasket 708-780-9000

Reliable sealing with premium sealing technology»Made in Germany«

Use tomorrow's gasket materials todayThe German manufacturer VICTOR REINZis a pioneer and world leader for top-quality, aramide fiber based gasketmaterials for industrial and automotiveapplications. Starting immediately, the entire VICTOR REINZ range of innova-tive gasket materials »Made in Germa-ny« is available in North America fromTarget Marketing Inc., Pennsylvania.

Target Marketing Inc.: 24-hour delivery, service, and support„Superior customer service and high-est quality of sealing products forcompressors, chemical industry, re-fineries, heating and plumbing, powerplants, gas suppliers, shipbuilders andoperators, plus many others at themost reasonable prices.“ That is theassurance given by Target MarketingInc. to customers searching for gasketmaterials for the highest demands inindustrial applications.The specialists at Target Marketing

Inc. are backed by some 30 years ofsealing experience, and are membersof Independent Sealing Distributors aswell as the Association of Iron andSteel Engineers. The marketing andlogistic activities for VICTOR REINZquality products are headquarterednear Pittsburgh, Pennsylvania. Fromhere, Target Marketing Inc. guaranteesshipment of VICTOR REINZ premiummaterials from stock within 24 hours.In addition, customers can benefitfrom competent consultation, technical support, detailed information material,and training courses on VICTOR REINZproducts.

Premium sealing technology fromVICTOR REINZ – the best thing thatcan happen to your applicationVia Target Marketing Inc. the trend-setting sealing technology from Ger-many is now also easily available fordesigners and users of plant andmachinery in the USA.In other regions of the world, these

gasket materials already play a keyrole in the daily business of whole-salers and industrial purchasers due totheir vastly superior physical and che-mical properties. Moreover, the pro-duct ranges benefit from ongoingdevelopments and innovations at theresearch laboratories of REINZ-Dich-tungs-GmbH in Neu-Ulm, Germany.It is also in Neu-Ulm, where the VICTOR REINZ success story beganmore than 80 years ago, that the spec-ialists from Target Marketing Inc. willbe trained.With high-tech gasket materials fromVICTOR REINZ you can rest assuredthat also tomorrow your gaskets willbelong to the best that is available forindustrial plants, machines, and equip-ment.

Available from Accurate Felt & Gasket

¬ 4

Your advantage: Strict testing methods,international certificates, worldwide references

International certification for more than 20 years of successful practical use

Worldwide references areproof of utmost quality

RPM: Testing-methodsfor increased safety

The problemClassical testing methods to DIN andASTM standards only permit a limitedevaluation, because the measurementsare made selectively. Therefore, charac-teristics determined by these testingmethods can only serve as a guide.

Practice-oriented testing methodsThe lack of application-oriented test-ing methods compelled VICTOR REINZto develop their own realistic testingprocedures, thus giving users moresecurity in the application of asbestos-free gasket materials.

RPM – your advantageThe Reinz testing methods (RPM) haveenabled specific values to be deter-mined for maximum continuous opera-ting temperature, permissible surfacepressure, internal pressure loading,

compressibility, and conformability ofasbestos-free gasket materials.Because the testing methods are ori-ented on specific applications, theygive you the following advantages:

¬ Higher confidence when selectingthe correct gasket material

¬ Reduction of cost-intensive troubleshooting to a minimum

¬ Fast conversion to asbestos-freematerials

RPM 505 – Determination of gastightness from the helium leakagerateTest method RPM 505 measures thegas tightness (sealability with helium)as a function of surface pressure,internal pressure, surface roughness,and gasket geometry. The method isalso suitable for measuring sealabilitywith reduced surface pressures.

RPM 510 – Determination of thermalresistance (hot compression test)

Test method RPM 510 measures thethermal resistance as a function oftemperature, surface pressure, time,surface roughness, and gasket geome-try.

RPM 511 – Determination of com-pressibilityTest method RPM 511 measures thematerial's compressibility as a functionof surface pressure.

Premium gasket materials made byVICTOR REINZ – composite gaskets with/without a metal core – have foundworldwide acceptance and applicationfor more than two decades. That iswhy they have been awarded all of theimportant international certificates andapprovals such as ISO/TS 16949 or

DIN EN ISO 14001. Just two examplesof the numerous awards that reflectthe high levels of acceptance andcustomer satisfaction are the acknow-ledgement by the Steinbeis Initiative«Customers evaluate suppliers» andthe «Environmental Award» from Volks-wagen AG.

More than 1000 important industrial andautomotive customers in over 120 coun-tries, covering an enormous applicationrange from food & beverage manufactu-rer to the chemical industry, rely on thehigh-tech gasket materials from VICTORREINZ.

Industrial gasketsBASF_(D) Bayer_(D) Bosch_(D) Bitzer_(D)Dow_(D,NL) Dupont_(USA) John Deere_(D)Enichem_(I) Thermo King_(USA) Shell_(UK)Stihl_(D) Thyssen_(D) and many others.

Automotive original equipmentAudi_(D) BMW_(D) Ford_(D) Porsche_(D) and many others.

Available from Accurate Felt & Gasket [email protected]

Latest fiber composites forexcellent sealing properties

Calender roller Calender for gasket sheet

Helium leakage rate measurement

Asbestos-free gasket materialsToday's gasket materials consist main-ly of a composition of different fibersand inorganic, high-temperature resis-tant materials, which are bound to-gether with synthetic rubbers.It is not possible to simply replace thechemical and physical properties ofasbestos with other fiber materials.However, the alternative gasket mate-rials exhibit a whole range of outstand-ing properties that provide numerousadvantages for gasket design and construction.

Properties and constructionaladvantagesGas tightness: VICTOR REINZ com-pressed sheet materials exhibit farbetter gas tightness than asbestos-based materials – in some cases bymore than a factor of 10.Chemical resistance: In practically allcases, and for operating temperaturesup to 150 °C (partially 200 °C), thechemical resistance is better than withasbestos-based gaskets.Corrosion: The chloride content of as-bestos-free gasket materials is consid-erably lower. This prevents corrosiondamage to the sealed surfaces, andincreases the reliability of the sealedjoint.

Conformability: The material's com-paratively high compressibility resultsin good conformability to rough/unevensealing surfaces. This means a consid-erable improvement in micro & macrosealing of irregularities in the sealedjoint.

Production of compressedsheet materials Composite materials: Composite gas-ket material is produced in the form ofhigh-pressure gasket sheets on speci-al calenders with one heated and onecooled roller. For this, the raw compo-site mix of fibers, filling materials, andbinders is first blended in kneaders oragitators before it is applied to theheated roller in thin layers of approx.0.05 mm until the required materialthickness has been achieved.The calender rolls compress, dry, andvulcanize the material. Consequently,the quality of an asbestos-free mate-rial not only depends on its compo-sition, but also on the manufacturingprocess to a large extent.Duration and intensity of the initialmixing process, and in particular theroller temperature and pressure aswell as the rolling speed have a deci-sive influence on the physical andchemical properties of the asbestos-free composite gasket material.

Available from Accurate Felt & Gasket [email protected]

High mechanical stability

- Aramid fiber- Nitrile binder- reinforcement:

galvanized steel mesh

- High chemical resistance- Very homogeneous structure- High shear resistance- Superior mechanical strength- Good cutting properties

- Chemical plants, refineries,shipbuilding

- Flanges, valves, tanks, radia-tors, compressors, pumps, heatexchangers

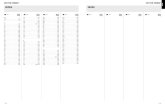

Technical data (typical values refer to 1/16" material unless otherwise specified)

Tensile strength, transverse ASTM F 152

Creep relaxation (1/32") ASTM F 38 B

Sealability (1/32") ASTM F 37 B

Gas permeability DIN 3535/6

Compressibility ASTM F 36 J

Recovery ASTM F 36 J

VR-Hot compression test (@7250psi):

Thickness decrease 68°F (20°C)

Thickness decrease additional, at maximum continous application temperature

Increase in thickness after immersion in ASTM F 146

IRM 903 Oil (replaces ASTM Oil No.3), 5h, 300°F

ASTM Fuel B, 5h, 73°F

Water/antifreeze 1:1, 5h, 212°F

Increase in weight after immersion in ASTM F 146

IRM 903 Oil (replaces ASTM Oil No.3), 5h, 300°F

ASTM Fuel B, 5h, 73°F

Water/antifreeze (50:50), 5h, 212°F

Density

ASTM F 104 "line call-out" ASTM F 104

Application temperature, max.1) continuous

temporary

Operating pressure1) maximum

Thickness

Characteristics

Material construction

Properties

Application

Material VR 90 VR 98

> 2900 psi / > 20 N/mm2

2)

2)

< 2.5 ml/min

> 5%

> 60%

7%

7% (480ºF / 250ºC)

0 - 10%

0 - 10%

0 - 5%

10% Maximum

10% Maximum

5% Maximum

131-144 lb/ft3 / 2.1-2.3 g/cm3

F711119B9E12M7

480°F / 250°C

750°F / 400°C

2460 psi / 170 bar

0.031in - 0.125in, 1/32" - 1/8"

> 2610 psi / > 18 N/mm2

2)

2)

~0.2 ml/min

5 - 8%

> 55%

6%

8% (480ºF / 250ºC)

0 - 7%

0 - 10%

0- 10%

7% Maximum

10% Maximum

10% Maximum

112-125 lb/ft3 / 1.8-2 g/cm3

F711119B9E12K7M6

480°F / 250°C

750°F / 400°C

2170 psi / 150 bar

0.016in - 0.125in, 1/64" - 1/8"

Best chemical and mechanicalresistance

- Aramid fiber- Nitrile binder

- Physiologically harmless- Very homogeneous structure- High shear resistance- Particularly gas tight- Universal application- Superior steam sheet3)

- Chemical plants, refineries, foodprocessing, shipbuilding, powergeneration, beverage, air condi-tioning, heating and refrigera-tion, gas and water installations

- Flanges, valves, tanks, radiators,compressors, pumps, plate heatexchangers

- Approval: API 607 Applied for

1)Maximum operating pressure and maximum operating temperature should not arise concurrently. 2)Testing in progress 3)For saturated steam applications consult Target Marketing Inc.

Available from Accurate Felt & Gasket [email protected]

Controlled swelling sheet

- Aramid fiber- SBR binder

- Purposely made to swell inmineral oils and many biodeg-radable oils, such as biodiesel,bio-oils etc.

- High mechanical strengthdespite swelling properties

- Mechanical engineering,automobile production

- Oil pans, valve covers, casings,transmissions

Economical sheet

- Aramid and synthetic fiber- Nitrile binder

- Good conformability- Well suited for applications with

low to moderate mechanicalload

- Mechanical engineering, ship-building, apparatus and engineproduction

- Flanges, casings, oil pans,transmission covers

HVAC, water and foodsafeapplications

- Aramid fiber- Nitrile binder

- Physiologically harmless- Very adaptable- Soft- Gas tight- Well suited for applications with

low to medium thermal andmechanical load

- Food industry, beverage, airconditioning, heating and refri-geration, HVAC installations,mechanical engineering, appa-ratus construction, drinkingwater supply, hot water boilers

- Flanges, pumps, transmissions,containers

Standard quality, cost-effective

- Aramid fiber- Nitrile binder

- Well suited for applicationswith thermal and mechanicalrequirements load

- Mechanical engineering, ship-building, apparatus and trans-former construction, chemicalplants

- Flanges, compressors, pumps,casings

Multiple-use application

- Aramid fiber- Nitrile binder

- Good conformability- Excellent gas tight- Well suited for applications with

high thermal and mechanicalload

- Mechanical engineering, ship-building, automobile produc-tion, power generation

- Flanges, pumps, casings, com-pressors, gas meters, plateheat exchangers, oil pans,transmission covers

VR 80 VR 70 VR 60 VR 50 VR 30 CS

> 1740 psi / > 12 N/mm2

2)

2)

< 1 ml/min

7 - 15%

> 50%

11%

8% (480ºF / 250ºC)

0 - 10%

0 - 10%

0 - 5%

10% Maximum

10% Maximum

10% Maximum

109-122 lb/ft3 / 1.75-1.95 g/cm3

F712119B9E12M5

480°F / 250°C

750°F / 400°C

1450 psi / 100 bar

0.016in - 0.125in, 1/64" - 1/8"

> 1160 psi / > 8N/mm2

2)

2)

< 1 ml/min

7 - 15 %

> 50%

10%

17% (480ºF / 250ºC)

0 - 10%

0 - 10%

0 - 5%

15% Maximum

10% Maximum

10% Maximum

119-131 lb/ft3 / 1.9-2.1 g/cm3

F712119B9E12M4

480°F / 250°C

750°F / 400°C

1450 psi / 100 bar

0.016in - 0.125in, 1/64" - 1/8"

> 1010 psi / > 7N/mm2

2)

2)

~0.5 ml/min

9 - 18%

> 55%

12%

22% (430ºF / 220ºC)

10 - 25%

10 - 25%

-

20% Maximum

20% Maximum

-

112-125 lb/ft3 / 1.8-2 g/cm3

F712339B9E35M4

430°F / 220°C

570°F / 300°C

870 psi / 60 bar

0.016in - 0.125in, 1/64" - 1/8"

> 1010 psi / > 7 N/mm2

2)

2)

< 1 ml/min

8 - 15%

> 50%

14%

24% (390ºF / 200ºC)

0 - 15%

0 - 15%

0 - 10%

20% Maximum

15% Maximum

15% Maximum

106-119 lb/ft3 / 1.7-1.9 g/cm3

F712139B9E23M4

390°F / 200°C

570°F / 300°C

1160 psi / 80 bar

0.016in - 0.125in, 1/64" - 1/8"

> 2030 psi / > 14N/mm2

2)

2)

< 1 ml/min

8 - 15%

> 55%

11%

10% (390ºF / 200ºC)

10 - 30%

10 - 30%

-

30% Maximum

30% Maximum

-

97-109 lb/ft3 / 1.55-1.75 g/cm3

F712449B9E35M6

390°F / 200°C

750°F / 400°C

1740 psi / 120 bar

0.016in - 0.125in, 1/64" - 1/8"

Available from Accurate Felt & Gasket [email protected]

¬ 8

Acetaldehyde

Acetic acid

Acetic acid anhydride

Acetone

Acetylene

Aluminium salts1)

Alums

Ammonia

Ammonium salts1)

Aniline

Asphalt

Benzaldehyde

Benzene

Bleaching alkaline, dilute

Borax

Boric acid

Butane

Butanol

Butylacetate

Butyric acid

Calcium hydroxide

Calcium salts1)

Carbon disulphide

Carbon tetrachloride

Chlorine water

Chloroacetic acid

Chlorobenzene

Chlorodiphenyl

Chloroform

Chromic acid

Chromium salts1)

Citric acid

Cresol

Cyclohexane

VR 90

, VR

98VR

80VR

70VR

60VR

50

VR 30

CS

Cyclohexanol

Cyclohexanone

Dibutyl phthalate

Diesel oil

Diethyl amine

Diethyl ether

Diethyl glycol

Dimethylether

Dimethyl formamide

Dioxane

Diphenyl methane

Ethane

Ethanol

Ethanolamine

Ether

Ethyl acetate

Ethyl benzene

Ethylene

Ethylene glycol

Fatty acids from C 10

Fluoric acid

Formaldehyde

Formic acid

Freons, CFC’s

Gelatine

Glycols

Heating oil

Heat conducting oils, synth.

Hexane

Hydraulic fluids (Mineral oil based)

Hydraulic fluids (Ester based)

● Resistant●● Partly resistant: testing under operational conditions recommended▲ Not resistant

1) Salts are: nitrates, nitrites, sulphates, sulphides, chlorides, acetates, tartrates,cyanides, phosphates, oxalates, etc.

Medium Tables1)

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

▲

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

▲

●

●

●●

●

●

●

●

●

●

●●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

▲

●

●

●

●

●

●●

●

●

●

●

●

●

●

●●

●

●

●

●

●

●

●

●

●

●

●

●

●●

●

●

▲

●●

●

●

▲

●

●

▲

●

●

●●

●

●

●

●

●

●

●

●●

●

●

●

●

●

●

●

●

●

●

●

●

●●

●

●

▲

●●

●

●

▲

●

●

▲

●

●

●●

●●

●

●

●

●

●

●

▲

●

●

▲

●

●

●

●

●

●

●

●

●

●●

●

●

▲

▲

●●

●

▲

●

●

●●

●

VR 90

, VR

98VR

80VR

70VR

60VR

50VR

30 C

S

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

▲

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

▲

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

▲

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●●

●

●

●

●●

●

●

●

●

●

●

●

●

●

●

●

▲

●

▲

●

●

●

●

●

●

●

●●

●

●

●

●

▲

●

●

●

▲

●

●

●

●

●

●

●

●

●

●

●

▲

●

▲

●

●

●

●

●

●

●

●●

●

●

●

●

●

●

●

●

▲

●

●

●

●

●

●

●

●

●

●

●

▲

●

●

●

●

●

●

▲

●

●

●

Available from Accurate Felt & Gasket [email protected]

Hydrochloric acid, conc.

Hydrochloric acid, dilute

Hydrogen

Hydrogen peroxide, dilute

Hydrogen sulphide

Isopropyl alcohol

Iron salts1)

Kerosene (Petroleum)

Lead salts1)

Lubricating oils

Machine oils RT

Machine oils 100°C

Magnesium hydroxide

Methane

Methyl alcohol

Methyl chloride

Methylene chloride

Methylethylketone (Butanone)

Motor oils RT

Motor oils 100°C

Naphtha

Natural gas

Nickel salts1)

Nitric acid, conc.

Nitric acid, dilute

Nitrobenzenes

Oxalic acid

Oxygen

VR 90

, VR

98VR

80VR

70VR

60VR

50

VR 30

CS

Perchloroethylene

Petrol

Petroleum ether

Petroleum oil

Phenol

Phenylether

Phenylhydrazine

Phosphoric acid

Phthalic acid anhydride

Potassium hydroxide

Potassium salts1)

Pyridine

Salicylic acid

Sea water

Steam 130°C

Styrene

Sulphuric acid, conc.

Sulphuric acid, dilute

Sulphurous acid

Sodium hydroxide (Caustic soda sol.)

Terpentine

Toluene

Transformer oils

Transmission oil

Trichloroethylene

Triethanolamine

Vegetable oils

Water

Zinc salts1)

Choice of suitable sealing materialsThe Medium Tables are designed to simplify your choice of a suitable sealing material.These recommendations are based on the current status of our knowledge.

Determination of chemical resistanceTo determine chemical resistance, the gasket materials were suspended freely in therespective media for 70 hours (if not specified otherwise).A 10 % solution was used for diluted acids, lyes, and salts, whereas saturated solutionswere used for media with lower solubility.

Please note:Mixtures or non-aqueous solutions could produce a different result for the chemical resi-stance evaluation. The thermo-mechanical operating conditions should also be taken intoaccount when selecting a sealing material, as these also influence the resistance of a material to a medium.

For this reason, the recommendations in the Medium Tables are to be considered as aguideline. No warranty can be granted for the use of any material. In case of doubt please consult us and give exact details of the operating conditions.

●●

●●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

▲

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●●

●

●

●

●

●

●

●

▲

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●●

●

●

●

●

●

●

●

▲

●

●

●

▲

▲

●●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

▲

●●

●●

●

▲

▲

▲

●

●

●

●

●

●

●

●

●

●

●

●

●

●●

●

●

●

●

●

●

●

▲

▲

▲

●

▲

●

●

●

●

●

●

●

●●

●

●

●

●

●

●

●

●●

●

●

●

●

●●

●

●

▲

●

▲

●

▲

VR 90

, VR

98VR

80VR

70VR

60VR

50VR

30 C

S

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

▲

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

▲

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

▲

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

▲

●

●●

●

●

▲

●

●●

●

●

●●

●

▲

●●

●

▲

●

●

●

●

●

●

●

●

●

●

●

●

●

▲

●

●●

●

●

▲

●

▲

●

●

●●

●

▲

▲

●

▲

●

●

●

●

●

●

●

●

●

●

●●

●●

●

●●

●

●

●

●

●

●

▲

●

●

●

▲

▲

●

●

●

●

▲

●

●

●

●

●

●

●

Available from Accurate Felt & Gasket [email protected]

¬ 10

Recommendations for flat gasketsCorrect installation is an essential pre-requisite for reliable gasket operation.Sealing surfaces and clamping boltsmust be selected according to the mini-mum required and maximum permittedsurface pressures for the respectivegasket. Please make sure that:

¬ Only new, undamaged and dry gas-kets are used. Also pay attention tothe storage conditions (see below).

¬ Clean the sealing surfaces thorough-ly, without scratching them. Dry thesurfaces.

¬ Position the gaskets centrally. Do notapply any additives (grease, releasingagent or sealing compound) to thegasket or the sealing surfaces.

¬ Do not use corroded bolts, nuts, orwashers. Calculated and achievedsurface pressure must coincide,therefore lubricate the bolt threadsand nut faces lightly.

¬ Mount the mating sealing surfaceplane-parallel, and tighten the boltsby hand.

Warning:

Properties/applications shown throughout this brochure are typical. Your specific application should not be implemented with-out independent study and evaluation for suitability. For specific application recommendations please consult Target Marketing.Failure to select the proper sealing products could result in material damage and/or serious personal injury.Performance data published in this brochure is based on field tests, customer field reports and/or in-house testing. Field condi-tions will affect gasket performance.While utmost care has been taken while compiling this brochure, we assume no responsibility for errors. Specifications aresubject to change without notice. We point out that this method for gasket selection is merely a general guide and should notbe the sole means for selecting or rejecting a product.

¬ To ensure an even pressure distribu-tion, torque the bolts «crosswise» tothe specified value in at least 3 steps.Example:1st step: 20% of final torque.2nd step: 60% of final torque.3rd step: 100% of final torque.

¬ All bolts must be torqued to the samespecified value.

¬ Every gasket will set, especially aftera lengthy downtime. Therefore, re-torque the bolts to the 100% valuebefore commissioning.

¬ Fiber-based or PTFE gaskets thathave already been at operating tem-perature should only be retorqued inthe cold condition using great care,and in several steps, as there is aconsiderable risk of destroying thegasket (especially fiber-based gas-kets that have already hardened).

Storage conditions for fiber-basedgaskets and sheet material (FA to DIN 28 091-2) Maximum storagetime is 2 to 3 years under the following

conditions:

¬ Temperature < + 20°C/68ºF¬ Relative humidity 30% to 60%¬ No exposure to direct sunlight¬ No exposure to artificial light with

high UV levels¬ No exposure to ozone¬ Stress-free storage

Large deviations from the above condi-tions will reduce the permissible stor-age time. With critical (e.g. toxic) gases,a storage time of one year should notbe exceeded. If necessary, the gasketsor gasket material should be enclosedin suitable packaging (airtight and pro-tected from light).

Available from Accurate Felt & Gasket [email protected]

Compan y Address

Sys tem

Medium

Concentration

Min./max. pressure

Min./max temp.

Comments

F lange

Size

Pressure

Flange material

Flange surface finish

Flange type

Comments

Bo l t s

Grade

Number

Diameter

Length

Lubrication type

Target Marketing Technical Support

We are here to support our customers any way we can. If you are in need oftechnical advice please photocopy the form below, fill it out and fax it to us.

Contact Person

Phone

Fax

Dimens ions

OD

ID

Number of bolt holes

Hole diameter

OD

ID

Please provide currentgasket material

specifications

1.Full Face

2.Ring

3 .Cus t om

Please provide sketch or drawing.

Reason for change (i.e. problems)

/

/

Please fax form to > Target Marketing · P.O. Box 445 · Glenshaw · PA 15116 · Phone: 412-486-2627 · Fax: 412-486-0914

Available from Accurate Felt & Gasket [email protected]

ACCURATE FELT & GASKET

Fax/email form to: Accurate Felt & Gasket F:708-780-9009 E: [email protected]

REINZ-Dichtungs-GmbH

Reinzstraße 3-7

D-89233 Neu-Ulm

Phone +49 (0) 731-7046-777

Fax +49 (0) 731-7046-399

www.reinz.com

Target Marketing, Inc.

Marketing & Distribution Center USA

P.O. Box 445

Glenshaw, PA 15116

Phone (412) 486-2627

Fax (412) 486-0914

Authorized Distributor:Accurate Felt & Gasket 3239 South 51st AvenueCicero, IL 60804T: 708-780-9000F: 708-780-9009E: [email protected]: www.afgco.com