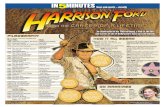

Complexity in engineering design and manufacturing · – Henry Ford's minimum complexity approach...

Transcript of Complexity in engineering design and manufacturing · – Henry Ford's minimum complexity approach...

Complexity in engineering design and manufacturing

W. ElMaraghy, H. ElMaraghy, T. Tomiyama, L. Monostori

Special thanks to: E. Abele, M. Abramovici, P. Butala, G. Chryssolouris, S. J. Hu, S-G. Kim, Y. Koren, S. C-Y Lu, D.

Mourtzis, G. Schuh, K. Ueda, H. Van Brussel, H-P. Wiendahl

2012 STC O keynote paper

International Academy for Production Engineering

Paris Meeting – France 26 January 2012

• The changed environment – Manufacturing is facing unprecedented challenges:

o market volatility, variety in customer demands

o distributed global manufacturing, fierce competition

o faster response time, and shorter life-cycles

• The response – Agile business strategies to respond to changing market conditions

– Market demand satisfied with complex products and design methods

– Complexity of products and response time dictate IMS, FMS, RMS

– New business paradigms: competition/collaboration

– Adaptive, changeable and co-evolutionary design, manufacturing and management systems

Motivation

2 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

• The main challenge

– Increasing complexity continues to be one of the biggest challenge facing manufacturing today.

– Increase in complexity of the manufacturing, technological, business, social systems, and the environment

• Additional challenges – Product imitations and plagiarism

– Fragile economy, etc...

Motivation - Challenges

3

Soci

al

Technology

Environment

Busi

ness

26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

• Past practice during the development of industrialization – Henry Ford's minimum complexity approach to auto production

– Other clever engineering technological innovations

– Reductionist approaches: critically successful in stable times

• The present and future directions – In the age of uncertainty we must accept that complexity is the norm

– Past methods of eliminating complexity have reached their limit

– Useful when uncertainty was limited and complexity manageable

– Complexity of markets should be exploited as “opportunities”

– To manage complexity, need to understand types, sources and ways to manage the increasing complexity in design and manufacturing.

Motivation – The future

4 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Objectives • Problem statement, clarification

– Review the breadth of complexity in engineering design, manufacturing and business

– Clear statements on academic and industrial aims • Survey & results

– Investigate, summarize the types and sources of complexity – List the main complexity metrics – Review different methods to manage complexity in both the

functional and the physical domains, including operational issues – Highlight the new sources of complexity such as multidisciplinary – Give results of industrial surveys and research achievements – Examples and case studies

• Future directions – Trends and roadmap for future research – Promising directions and importance of foresight

5 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Sources & Drivers of complexity

6

Customer Requirements

Social and Environmental Pressures: Government Legislation,

Standards

Complexity of Market Forces: Global Competition,

Turbulence, Variety, Short Delivery, Zero Defect, etc...

Sources of Complexity

Product Structure

Product Features

Product Variety & Number of Parts

Coupling (Functional & Physical)

Paradigm and Technologies

Modules & Configuration

Planning & Scheduling

Human Cognitive Ergonomics

Global Supply Chain

Prod

ucts

Proc

ess

and

Sys

tem

s

26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

• Functional & • Physical Domains

Static & Dynamic

Complexity

Scope

7

Design & Product

Development Complexity

● Number of parts ● Multidisciplinarity ● Manufacturability ● Size, Geometry ● Variety

Mfg. & Manufacturing

Systems Complexity

Changeability ● Responsiveness ● Volume, Speed ● Operational ● Flexibility ●

Business and Market Complexity

● Supply Chain Dynamics ● Global Competition ● Market Turbulence ● Foresight

Qua

lity

Design Manufacturing Business (global supply chain)

26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Scope - Perspectives

8

Process Complexity

Product Complexity

Production & Operational Complexity

Adapted from: ElMaraghy, W., & Urbanic, J., Modelling of Manufacturing Systems Complexity.., CIRP Annals 2003

Strategic Functional, Logical Physical, Technological Tactical and Operational

And from different perspectives and domains: e.g. Complexity due to Multi-disciplines & Different perspectives

Logistics & Global Supply Chain

26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Scope – Size / Scale

9

“Nano-manufacturing complex products”

“Machines to global supply chains”

26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Literature – Books ~ 20

10 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Literature – Dissertations ~ 50

11

Abbasi, Maisam, 2008. Perspectives of Complexity and Intelligence on Logistics and Supply Chain Management. M.Sc. Thesis, University of Borås. Adamsson, Niklas, 2008. Interdisciplinary integration in complex product development - Managerial implications of embedding software in manufactured goods. Doctoral Thesis, Royal Institute of Technology (KTH). Arafa, Amir Taher Abd-Allah, 2011. Dynamic Analysis for Enterprise Strategic Flexibility using System Engineering Methodology. Ph.D. Dissertation, University of Windsor. Badrous, Sameh Nozhy Samy, 2011. Complexity of Products and their Assembly Systems. Ph.D. Dissertation, University of Windsor. D’Amelio, Valentina, 2010. Design Interference Detection for Multi-Disciplinary Product Development. Ph.D. Dissertation, Delft University. Deif, Ahmed Mahmoud, 2007. Dynamic Analysis of Agile Manufacturing Planning and Control (MPC) Systems using Control Theory. Ph.D. Dissertation, University of Windsor. Dickmann, John Q. Jr., 2009. Operational Flexibility in Complex Enterprises: Case Studies from Recent Military Operations. Ph.D. Dissertation, MIT. Kreimeyer, Matthias F., 2009. A Structural Measurement System for Engineering Design Processes. Doktor-Ingenieurs genehmigten Dissertation, Technische Universität München. Wang, Hui, 2010. Product Variety Induced Complexity and its Impact on Mixed-Model Assembly Systems and Supply Chains. Ph.D. Dissertation, the University of Michigan. Alamoudi, Rami Hussain, 2008. Interaction Based Measure of Manufacturing Systems Complexity and Supply Chain Systems Vulnerability using Information Entropy. Ph.D. Dissertation, University of Miami.

26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

12

Literature – Journals > 400

CIRP Keywords Complexity in engineering

papers – “Compendex” 26/01/2012, CIRP Paris Meeting STC O Kn:

“Complexity in engineering design and manufacturing”

14 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Complexity in engineering : CIRP Track 3 “Complexity” Related Topics

RMS Reconfigurable

DC Dynamics & Control

Modeling

M Multi-Disciplinarity

RE Release Engineering

DTM Design Theory & Methodology

C Changeability

ECN: Collaborative Negotiation ADC: Axiomatic Design Complexity Theory

EEC: Emergence, Evolution , Co-evolution

15 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Method: nature of complexity Complexity is about Relationships Systems Engineering View

Quantitative Complexity Computational Complexity

Qualitative Complexity Complexity Results from Unknowingness, In science,

and Uncertainty in Applied Science Qualitative Complexity Comes from Uncertainty If We Can Foresee and Enumerate All Possible

Situations, Uncertainty Can Be Evaluated Statistically, Probabilistically or Stochastically

If Not, Uncertainty Cannot Be Quantified that way.

16 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Complexity metrics • Systems complexity [Calinescu et al., 2000]

– Entropic measures of information (amount of information required to predict state of the system).

• Design, Manufacturing Process and Operational Complexity [ElMaraghy W. & Urbanic, 2003 and 2004] – Function of number of parts and their interactions. – Physical and cognitive Factors.

• Manufacturing Systems Complexity [ElMaraghy H. et al., 2005] – New Classification & Coding System “Complexity Coding System”

used to evaluate the complexity of manufacturing systems. – Beneficial property, given reduction of complicatedness.

• Axiomatic design [Nam Suh, 2005] – Time independent (imaginary and real complexity). – Time dependent (uncertainty of future events).

17 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Complexity in manufacturing system Complex manufacturing systems that comprise large

number of different resources, and are designed to respond dynamically to changing requirements represent an expanded space of of alternatives and choices.

The dynamic nature of the manufacturing environment greatly increases the number of decisions that need to be made.

The integration of many software and hardware functions makes it difficult to predict the effect of a decision on the system performance.

The cost of added complexity must be balanced against improved performance, Hence, the need to assess both structural and operational complexity.

18 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Manufacturing complexity Product Complexity Environment Volume

Process Complexity

Operational Complexity

Procedures and Tasks

Production Control

Features and Tools

Information

Effort

Physical Cognitive

Metrics

ElMaraghy, W., & Urbanic, J., Modelling of Manufacturing Systems Complexity.., CIRP Annals 2003

26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

19

IEE Spectrum: by Robert N. Charette / February 2009

Imag

e: D

aim

ler Electronics in Cars today:

50 to 100 CPUs 100 Million line of code ! The Boeing new 787 “Dreamliner”

has about 6.5 million line of software code to operate its avionics and onboard support systems.

In 2005, Toyota voluntarily recalled 160,000 of 2004 and 2005 Prius hybrids because of a software issues. More recently, more problems ! Last year alone, there were several automotive recall notices related to software problems: Chrysler (Jeep Commanders ); Volkswagen recalled about 4,000 of its 2008 Passats and Passat Wagons; and GM’s Cadillac CTS.

Really Complex Products: “This Car Runs on Code”

20 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Complexity resulting from multi-disciplinarity

Multi-Disciplinarity as Combinations of (Well-Known) Disciplines Multi-Disciplinarity Causes Cross-Disciplinary Problems

Example: Troubles During Integration of Subsystems

Subsystems Are Well-Understood

When Subsystems Are Integrated, Unforeseen or Unidentified Problems Are Detected: Printers (Valentina D’Amelio et al. 2010)

AGV (Tomiyama, ElMaraghy et al. CIRP Annals 2007)

26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

21

Cross-Disciplinary Problems Strategy No Uncertainty = No Complexity

Risk Analysis with Causality

If Uncertainties Unavoidable, Reduce “Unknowns” Convert It to a Probabilistic Problem by

Enumerating Possibilities Information Content/Entropy Minimum Approach Discover “Interferences”

Design Interference Detector If Impossible, Mitigation Through Being Prepared

for the Worst Cases

Risk Analysis without Causality

App

licat

ion

or C

onte

xt

Method 1 Method 2

22 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Multi-disciplinary complexity design:

Most products are multi-domain systems, e.g. mechatronics systems, are multi- and inter- disciplinary devices exist, but there is no unified methods, or common language among engineers from the various disciplines, to deal with that.

These unpredictable problems are the consequence of insufficient integration of domain knowledge and methods.

Building a physical prototype and “test benches”, is often essential to develop those multi-disciplinary products.

Mechatronics is not only the constructive coupling of domains that enable a system to work but also the destructive coupling of domains that generates unpredicted problems.

Products & Assembly Systems Complexity

Product Assembly Complexity Samy S.N., ElMaraghy H. (2010b)

Code-based assembly system structural complexity ElMaraghy H. (2006), Samy S.N., ElMaraghy H.(2010c)

24 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Structural Complexity Coding System

Tomiyama T, D'Amelio V, Urbanic J, ElMaraghy W (2007) Complexity of multi-disciplinary design. CIRP Annals-Manufacturing Technology. 56(1): 185-188.

Systems Structural Code (ElMaraghy, H. 2006)

System Capabilities

25 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Manufacturing Systems Structural Complexity

0.00

5.00

10.00

15.00

20.00

25.00

30.00

DedicatedMilling M/Cs

(M1+M2+M3)

Broach CNC ParallelLine

Sy

ste

m S

tru

ctu

ral C

om

ple

xit

y In

de

x

BuffersIndex

MaterialHandlingIndexEquipmentIndex

Heavy Material Removal V6 Cylinder Block Manufacturing System Complexity Breakdown

Using The SCC Code

Piston Assembly

26

27

Models and potential complexity measures

26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

L. Monostori, et al. 41st CIRP ISMS, Tokyo, Japan, May 26 – 28, 2008

(1) Environment model: sequence of random variables (time series X1,

X2, …, Xt, ..., Xn) Potential complexity measure: Information complexity (entropy)

(2) Collaboration model: complex adaptive systems Potential complexity measure: computational complexity (measure of applied resources)

(3) Enterprise network model: network and graph theory Potential complexity measure: topological (graph) complexity (adjacency, components, walks)

Figure 21 Conceptual model structure (Arafa and ElMaraghy

2011b)

28

Figure 29 Volume flexibility sub model

29

Volume Flexibility

Fixed Cost

<Capacity>

+

<Unit Fixed Cost>

+

Unit Variable Cost <Initial Unit

Variable Cost> +

<Learning>

-

Price

<Change in Price>

+

Contribution Margin +

+

-

+

Managing the Different Aspects of Manufacturing Complexity

Goals and

Strategy

Environm

ent

Technology; Infratsructure

Operational Complexity Compliance

Product/Process/ Service Complexity

Global Competition, Complex Supply Chains

Customer Demand, Product Variety

Time-to-Market Pressures

Responsiveness Ability Turbulent Market Demands

Trained Workforce and Educated Management 30

Increased Complexity

Applications of engineering design and manufacturing to complex challenges

31 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Adapted from: Presidential Address by Prof. Dr. Ing. F. Klocke, Manchester, August 2008 And the US NAE: “The Grand Challenges for Engineering” – The Engineer 2020 Report

Energy Environment, Global warming, Fresh water shortages

Health, New diseases

Mobility

Communication Safety, Security Aging infrastructure

Applications of engineering design and manufacturing to complex challenges

32 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Acatech, oct. 2007 Presidential Address by Prof. Dr. Ing. F. Klocke, Manchester, August 2008

Environment, climate, resources

Economy growth welfare

Individual and collective needs

Overall balance

Demographics

Challenges

Economic/societal forces

SoS and Engineering Systems

26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

33

Traditional SE practices, while suitable for some situations, are not sufficient for systems of systems Need to use ES (Engineering Systems)** for socio-technical problems Research is required to evolve new methodologies and tools for performing multi-disciplinary socio-technical engineering studies

Product Systems Engineering

Global Enterprise ES

Systems of Systems

Systems Engineering Management

Com

plex

ity

1950-1960s 1970s 1990s 2010 2000s 1980s

Systems Theory

2020+

** More information about this subject can be found in a new MIT Press book: de Weck OL, Roos D, Magee LC (2011) “Engineering Systems - Meeting Human Needs in a Complex Technological World”

Managing complexity in design & manufacturing

34 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Managing Design & Manufacturing

Complexity in Functional & Physical domains

Reduce the (- ve) effects of complexity Control the (+ ve) aspects of complexity

Decoupling, sub-assemblies Design for Manufacturability Interference detection in multidisciplinary product development Reduce variety, reduce number of parts Apply design methodologies for robustness New product development paradigms (e.g. ECN, concurrent engineering, axiomatics) Use of engineering tools to minimize perceived (imaginary) complexity Minimize information content (entropy) Modularization, standardization & variants Minimize static and dynamic complexity Products and market intelligence and foresight

Use modularity, product platforms Process simplification, clustering Use of Intelligent sensors and control logics to mitigate against complexity Flexible and responsive manufacturing Use robust planning & control systems Apply robust scheduling strategies and team work, quality circles, lean principles, etc. Develop hard and soft technologies to deal operational issues (e.g. Cognitive training Operational processes to reduce “effort” Delayed differentiation & JIT Manufacturing Reconfigurable & changeable manufacturing Global dynamic logistics &SC management

35

Mastering Innovation & Complexity

Source: Deloitte Research [2005]: http://www.deloitte.com/view/en_AU/au/article/eb00a7d2770fb110VgnVCM100000ba42f00aRCRD.htm

26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Contents 1. Introduction

1.1 Sources of complexity

1.2 Perspectives on complex systems

2. The nature of complexity 2.1 Complicatedness, complexity and chaos

2.2 Complexity in engineering 2.3 Complexity of the product development process

2.4 Framework and methodologies for complex product development and architecting

2.5 Complexity in manufacturing processes and systems

36 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Contents (2)

3. Complexity in engineering design and its measures 3.1 Information theory/ uncertainty / entropy

3.2 Types of complexity (functional, static, and dynamic)

3.3 Heuristics measures of complexity metrics

3.4 Statistical complexity metrics

3.5 Products modularity, platforms and complexity 3.5.1 Products modularity and its effect on complexity of

the manufacturing process, the supply chain and the organization

3.5.2 Product platforms

3.6 Multi‐discipline complexity of engineered systems

37 26/01/2012, CIRP Paris Meeting STC O Kn:

“Complexity in engineering design and manufacturing”

Contents (3)

4. Manufacturing systems complexity 4.1 Types of manufacturing systems complexity 4.2 Complexity of engineered products 4.3 Measuring manufacturing systems complexity 4.3.1 Entropy and information content measures 4.3.2 Measuring manufacturing systems complexity in the functional

domain 4.3.3 Measuring manufacturing systems complexity using heuristics

and indices 4.4 Integrating products and assembly systems complexity 4.4.1 Assembled products complexity 4.4.2 Assembly systems complexity 4.5 Manufacturing systems configuration and layout complexity 4.5.1 The structural complexity of systems layout 4.5.2 Layout complexity indices

38 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Contents (4)

5. Business / enterprise complexity 5.1 The global supply chain complexity

5.2 The socio-technical systems

5.3 Managing the dynamic business landscape

5.4 Sustainability and evolution of engineering systems

6. Current directions

6.1 Embracing complexity in engineering and business

6.2 Complex products and engineering systems

6.3 Chaordic manufacturing systems

6.4 Trends in managing the business complexity

Acknowledgements References

39 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”

Schedule Action Due by

Outline presented to STC O at the 61th GA 26/08/2011

Paper ( 24 pages) presented to STC O Chairman 25/01/2012

Presented to STC O - available to interested colleagues 26/01/2012

Final version ready – Approval by the STC Chairman 31/01/2012

Keynote paper submitted on EES for review 22/02/2012

Comments of EC to the responsible author 22/03/2012

Updated version re-submitted on EES 22/04/2012

Final checking and approval by the EC chairman 22/05/2012

CIRP Office gives Publisher the approval to print 01/06/2012

External STC O presentation at the 62nd GA 26/08/2012

40 26/01/2012, CIRP Paris Meeting STC O Kn: “Complexity in engineering design and manufacturing”