Comparison of Wear and Mechanical Properties of Copper Alloys … · 2019-01-10 · High copper...

Transcript of Comparison of Wear and Mechanical Properties of Copper Alloys … · 2019-01-10 · High copper...

UCTEA Chamber of Metallurgical & Materials Engineers’s Training Center Proceedings Book

248 IMMC 2018 | 19th International Metallurgy & Materials Congress

Comparison of Wear and Mechanical Properties of Copper Alloys Used as Welding Electrodes and Plunger Tips

Tuba Özeren, Taner Yenigün, Nebi Akgün, Erkan Artut, Feriha Birol

Sağlam Metal A.Ş., Department of R&D, Kocaeli, Turkey

Abstract

CuCoNiBe and CuNiSi copper alloys are widely used as welding electrodes and molding applications due to their high wear resistance and good electrical conductivity properties. In this study, wear properties of two CuNiSi alloys and a CuCoNiBe alloy were compared at room and

Additionally, mechanical properties, hardness and electrical conductivity values of the alloys were determined and evaluated.

1. Introduction

High copper alloys are widely used for resistance welding electrodes and molding tool applications due to their properties such as high strength and wear properties, good electrical and thermal conductivity. Among high copper alloys, Cu-Be alloys have attracted much attention for such applications. However, their higher cost due to expensive Be content have always led to searching cheaper alternative copper alloys. Cu-Ni-Si alloys are considered as a promising copper alloy group alternative to Cu-Be alloys for such applications. CuNiSi alloys, also called Corson alloys, are age hardening alloys. They are used either without addition of alloying element or their various properties can be improved adding alloying elements such as Cr, Zr, Mg. [1-7].

Higher wear resistance and mechanical properties are important properties for resistance welding electrode and molding tool applications. The alloys could be classified by measuring mechanical properties and wear resistance.

In this study, wear properties of a Be containing CuCoNiBe (CCNB) and two Ni, Si containing CuNiSiCr (NSH) and CuNiSiCrZr (NSS) alloys prepared in acco

alternative alloy to Be containing copper alloy. Wear tests

and under a load of 10 N. Weight loss and friction coefficients of the alloys were compared in order to

specifies alternatives. Additionally microstructure and mechanical properties of the alloys were determined and evaluated with their wear test results.

2. Experimental

2.1. Materials

Three alloys were cast in permanent mould. Their chemical analysis after casting are given Table 1-2. The samples taken from the ingots were submitted to heat treatments of solutionizing and ageing following hot

onditions were applied. The specimens were prepared in the dimensions of 46*46mm cutting from the forged rods.

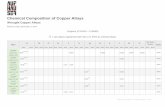

Table 1. Chemical Composition of NSH and NSSAlloys.

Material

Cu%

Ni%

Si% Cr% Fe% Zr%

NSH 95,3 3,15 0,799

0,477

0,123

NSS 95,9 2,49 0,748

0,394

0,0461

0,3

Table 2. Chemical Composition of CCNB Alloy. Material Cu% Ni% Co% Be% Fe% CCNB 97,3 1,05 1,06 0,459 0,0581

2.2. Metallography

Microstructure of the aged samples after heat treatments were examined using a Nikon Eclipse MA 100 model light microscope after metallographic preparation. The samples were grounded with first coarse and then fine sand papers and final surfaces were polisdiamond solution. The samples were etched with a chemical solution of 50 mL HCl + 10 mL + 10 g

+ 100 mL to determine the phases.

TMMOB Metalurj i ve Malzeme Mühendisleri Odas ı Eğ i t im MerkeziBildir i ler Kitab ı

24919. Uluslararas ı Metalurj i ve Malzeme Kongresi | IMMC 2018

2.3. Mechanical tests and conductivity measurements

Mechanical tests and conductivity measurements were made on the prepared samples. Hardness measurements were made by using Vickers hardness tester of Struers Duramin under 0,5 kgf load at room temparature and after wear tests at . Hardness values were determined by taking average of multiple measurements. Tensile tests were performed according to ASTM E8/E8M using MTS C45.504 universal test machine. Dimensions of the tensile test samples are shown in Figure 1. Electrical conductivity was measured using a GE Inspection Tech Auto Sigma 3000 instrument.

Figure 1. Dimension of the tensile test samples.

2.4. Wear tests

Wear tests were conducted under the load of 10N at room

T30M-HT (Figure 2). Aluminium oxide balls were forced against copper alloy disc samples. Wear samples were of

friction coefficient for both temperatures were determined to evaluate wear resistance of the alloys.

Figure 2. Pin on disc wear test parameters.

3. Results and Discussion

3.1. Microstructural characterization of aged condition

Microstructure of three alloys NSH (CuNiSiCr), NSS (CuNiSiCrZr), and CCNB (CuCoNiBe) are given in Figure 3a, b and c respectively. .

Figure 3. Optical light microscope images of the aged alloys a) NSH, b) NSS, c) CCNB.

CuNiSi alloys, also called Corson alloys, are age hardening alloys. They can be used without any alloying element or their various properties can be improved adding alloying elements such as Cr, Zr, Mg. The resulting precipitates and their formation mechanism are reported in various studies [4]. The precipitation reaction can not only improve strength but also enhance the electrical conductivity of the alloy by depletion of the solute elements from the matrix. Age hardening in this system was first investigated by Corson and the precipitating

--binary section of the Cu-Ni-Si

a

b

c

UCTEA Chamber of Metallurgical & Materials Engineers’s Training Center Proceedings Book

250 IMMC 2018 | 19th International Metallurgy & Materials Congress

ternary diagram [5]. In Cr containing Cu-Ni-Si alloys, Cr2Si3 -

-Cu matrix [2]. Optical micrographs of the NSS and NSH alloys show that very small partical distribution at aged conditions, whi -

In the solidification of Cu- -Cu and resemblingChinese scripts primary beryllides are crystallized from the liquid phase. T -phase peritectic reaction occurs with decrease in temperature. This phase transforms into

beryllides phase that occurs during solidification is best observed as a blue-gray color in the polished state. The secondary beryllium phase is seen in a certain crystallographic orientation and in plaques morphology.

-precipitates with aging [8]. The microstructure images of the CCNB alloy, it is observed that the (Ni,Co) beryllides reprecipitate in the copper phase by aging (Figure 3c).

3.2. Hardness, conductivity and mechanical properties of alloys

Table 3. shows hardness and electrical conductivity of the aged alloys. The alloy of CCNB has the highest hardness, tensile and yield strength and electrical conductivity while NSS has the lowest ones as expected.

hardness of the alloys increases likely due to progression of aging at higher temperatures.

Table 3.Hardness values of the alloys after wear tests at room and 400 C and electrical conductivity measurements.

Hardness (HV-0.5 kgf)

Electrical Conductivity

(MS/m)

Material Room Temperatur

400

NSS 21,5

NSH 23,7

CCNB 26,4

Table 4. Mechanical properties of the alloys.

Material

Tensile Strength (MPa)

Yield Strength (MPa) % Elongation

NSS 589,6 498,7 12,3 NSH 764,1 662,7 7,8

CCNB 809,7 668,3 14,9

3.3. Wear resistance and friction coefficient Mass loses (mg) of there alloys after wear tests at room temperature and are shown in Figure 4 and Table 5.

Mass loss results of room temperatures experiments reveal that CCNB has the highest wear loss (27,5 mg) while NSS has the lowest one (9,1 mg) (Table 5). On the other hand, all of the alloys have lower mass loss (NSS, NSH and CCNB 7; 8,8 and 8,6 mg respectively) at 400compared to room temperature and their mass loss values were close to each other.

It is expected that the harder the alloy is the higher wear resistance according to Archard wear equation [9,10]. However, the hardest alloy CCNB shows the higher mass loss at room temperature indicating lower wear resistance. Explanation of this result needs to more examination of the worn surfaces by using SEM and 3D profilometer.

Figure 4. Mass loss in specimens as a result of wear tests. Table 5. Values of mass losses (mg).

Mass Loss (mg) NSS NSH CCNB

Room Temperature (22)

9,1 17,3 27,5

400 7 8,8 8,6

The behavior of the friction coefficient of three alloys was similar at both test temperatures (Fig 5, 6 and 7 and Table

TMMOB Metalurj i ve Malzeme Mühendisleri Odas ı Eğ i t im MerkeziBildir i ler Kitab ı

25119. Uluslararas ı Metalurj i ve Malzeme Kongresi | IMMC 2018

6). All the alloys have lower friction coefficient values at the beginning of the wear test at room temperature. Then, it reached to higher values with large scatterings after from a distance changing depending on alloy (300 m for NSS and NSH, 100 m for CCNB). At high test temperature

stable and lower along all wear test.

Table 6. Approximate values of friction coefficient of the

Temperature Coefficient of Friction NSS NSH CCNB

Room Temperature

0.5 to 0.7-0.95 (after

300 m)

0.5 to 0.8-1.0 (after 300 m)

0.5 to 0.8-0.9 (after 100 m)

400 0.6 0.55 0.4

Figure 5. Friction coefficient graphs of NSH sample obtained during wear test a) room temperature and b) at

.

Figure 6. Friction coefficient graphs of NSS samples obtained during wear test a) room temperature and b) at

Although mass loss results and hardness values of the alloys at room temperature wear test are contradictory and require further investigation, high temperature results appears to be more meaningful and consistent. Furthermore, since both applications are high temperature application, high temperature wear results appear to be more suitable in terms of determining alternative alloy for electrode and mold application.

a)

b)

a)

b)

a)

b)

UCTEA Chamber of Metallurgical & Materials Engineers’s Training Center Proceedings Book

252 IMMC 2018 | 19th International Metallurgy & Materials Congress

Figure 7. Friction coefficient graphs of CCNB sample obtained during wear test a) room temperature and b) at

1. Conclusions

Among investigated three alloys NSS (CuNiSiCrZr), NSH (CuNiSiCr), and CCNB (CuCoNiBe), Be containing CCNB alloy has the highest hardness, electrical conductivity and mechanical properties.

NSS and NSH alloys revealed lower mass loss while the CCNB had the highest mass loss at room temperature

alloys was similiar. It was low at the beginning of wear test, then increased with large scattering.

at room temperature wear tests. Friction coefficient values were small and stable along all wear test.

Altough mass loss results and hardness values of the alloys at room temperature wear test are contradictory and require further investigation, high temperature results appears to be more meaningful and consistent. Furthermore, since both applications are high temperature application, high temperature wear results appear to be more suitable in terms of determining alternative alloy for electrode and mold application.

As a result, both NSS and NSH alloy could be offered as electrode and mold materials alternative to CCNB alloy.

References

-step increase in hardness of precipitation hardened CuCoNiBe alloys and characterization of precipitates, Journal of Alloys and Compounds 701 (2017) 116-121. [2] W. Wang, H. Kang, Z. Chen, Z. Chen, C. Zou, R. Li, G. Yin, T. Wang, Effects of Cr and Zr additions on microstructure and properties of Cu-Ni-Si alloys, Material Science& Engineering A 673 (2016) 378-390. [3] D. Zhao, Q.M. Dong, P. Liu, B.X. Kang, J.L. Huang, Z.H. Jin, Aging behavior of Cu Ni Si alloy, Materials Science and Engineering A361 (2003) 93 99. [4] M. Gholami, J. Vesely, I. Altenberger, H.-A. Kuhn, M. Janecek, M. Wollmann, L. Wagner, Effects of microstructure on mechanical properties of CuNiSi alloys, Journal of Alloys and Compounds 696 (2017) 201e212. [5] X.P. Xiao, B.Q. Xiong, Q.S. Wang, G.L. Xie, L.J. Peng,G.X.Huang, Microstructure and properties of CuNi Si Zr alloy after thermomechanical treatments, Rare Met. (2013) 32(2):144 149. [6] S. Suzuki, N. Shibutani, K. Mimura, M. Isshiki, Y. Waseda, Improvement in strength and electrical

conductivity of Cu-Ni-Si alloys by aging and cold rolling, Journal of Alloys, and Compounds, 417 (2006) 116-120. [7] S. Lee, H. Matsunaga, X. Sauvage, Z. Horita, Strengthening of Cu-Ni-Si alloy using high-pressure torsion and aging, Material Characterization 90(2014) 62-70.

M.Sc. Thesis, Kocaeli University, 2014, Kocaeli, Turkey.

Behaviour of Nickel-Aluminum Bronzes Produced With

-.

[10] ASM Handbook, Vol. 18, Friction, Lubrication and Wear Technology, ASM International Publications, 1992.