Comparison 59 x 686 x ISO13485

-

Upload

christiane-licinio -

Category

Documents

-

view

225 -

download

0

Transcript of Comparison 59 x 686 x ISO13485

-

7/27/2019 Comparison 59 x 686 x ISO13485

1/126

ABIMED ABRAIDI CBDL

COMPARATIVE STUDY BETWEEN

NBR ISO 13485:2004

RDC 59:2000

ORDINANCE 686:1998

RDC 167:2004

-

7/27/2019 Comparison 59 x 686 x ISO13485

2/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 2

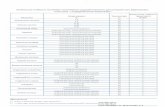

Summary

FOREWORD ........................................................................................................................... 5

OBJECTIVE .............................................................................................................................. 5

METHODOLOGY USED ON COMPARISON .............................................................................. 5

NOTES RELATED TO THE COMPARATIVE STUDY .................................................................... 6

Introduction ................................................................................................................................ 7

0.1 General ............................................................................................................................. 7

0.2 Process Approach ........................................................................................................... 10

0.3 Relation to other Rules ................................................................................................... 11

0.4 Compatibility to other Management Systems ................................................................ 12

1 Objective ................................................................................................................................. 13

1.1 Fundamentals ................................................................................................................. 13

1.2 Application ...................................................................................................................... 15

2 Normative Reference .............................................................................................................. 17

3 Terms and Definitions ............................................................................................................. 18

4 Quality Management System ................................................................................................. 28

4.1 General Requirements ................................................................................................... 28

4.2 Documentation Requirements ....................................................................................... 30

4.2.1 Fundamentals ........................................................................................................ 30

4.2.2 Quality Manual ......................................................................................................... 33

4.2.3 Document Control .................................................................................................... 34

4.2.4 Record Control ......................................................................................................... 36

5 Board Responsibility ............................................................................................................... 40

5.1 Board Commitment ....................................................................................................... 40

5.2 Focus on Customer ........................................................................................................ 41

5.3 Quality Policy ................................................................................................................. 42

5.4 Planning ......................................................................................................................... 43

5.4.1 Quality Objectives .................................................................................................... 43

5.4.2 Planning of the Quality Management System ........................................................ 43

5.5 Responsibility, Authority and Communication ............................................................... 44

5.5.1 Responsibility and Authority ..................................................................................... 44

-

7/27/2019 Comparison 59 x 686 x ISO13485

3/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 3

5.5.2 Board Representative .............................................................................................. 45

5.5.3 Internal Communication .......................................................................................... 45

5.6 Critical Analysis by the Board ......................................................................................... 46

5.6.1 Fundamentals ........................................................................................................... 46

5.6.2 Entries for Critical Analysis ........................................................................................ 46

5.6.3 Exits for Critical Analysis ........................................................................................... 47

6 Resource Management ........................................................................................................ 48

6.1 Resource Provision ............................................................................................................ 48

6.2 Human Resources ............................................................................................................. 48

6.2.1 Fundamentals ........................................................................................................... 48

6.2.2 Competency, Awareness and Training ...................................................................... 486.3 Infrastructure .................................................................................................................... 50

6.4 Work Environment ............................................................................................................ 52

7 Product Manufacture ........................................................................................................... 55

7.1 Planning of the Product Manufacture ............................................................................... 55

7.2 Processes Related to Customers ....................................................................................... 57

7.2.1 Determination of Requirements Related to the Product .. 57

7.2.2 Critical Analysis of the Requirements Related to the Product ....................... 57

7.2.3 Communication to Customer .................................................................................... 59

7.3 Project and Development ................................................................................................. 59

7.3.1 Project Planning and Development .......................................................................... 59

7.3.2 Project and Development Entries ............................................................................. 61

7.3.3 Project and Development Exit .................................................................................. 61

7.3.4 Project and Development Critical Analysis ............................................................... 64

7.3.5 Project and Development Verification ..................................................................... 64

7.3.6 Project and Development Validation ....................................................................... 65

7.3.7 Project and Development Change Control ............................................................... 65

7.4 Acquisition ........................................................................................................................ 69

7.4.1 Acquisition Processes ................................................................................................ 69

7.4.2 Acquisition Information ............................................................................................ 69

7.4.3 Acquired Product Verification .................................................................................. 71

7.5 Production and Service Provision ..................................................................................... 73

7.5.1 Production and Service Provision Control ................................................................ 73

7.5.2 Validation of the Production and Service Provision Processes ................................. 79

-

7/27/2019 Comparison 59 x 686 x ISO13485

4/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 4

7.5.3 Identification and Traceability .................................................................................. 80

7.5.4 Customer Property .................................................................................................... 82

7.5.5 Product Preservation .............................................................................................. 82

7.6 Measurement and Monitoring Device Control ................................................................. 86

8 Measurement, Analysis and Improvement ............................................................................... 88

8.1 Fundamentals .................................................................................................................... 88

8.2 Measurement and Monitoring .......................................................................................... 92

8.2.1 Customer Return ......................................................................................................... 92

8.2.2 Internal Audit ............................................................................................................... 95

8.2.3 Processes Measurement and Monitoring ................................................................... 96

8.2.4 Product Measurement and Monitoring ...................................................................... 98

8.3 Non-Compliant Product Control ..................................................................................... 100

8.4 Data Analysis ................................................................................................................... 103

8.5 Improvements ................................................................................................................. 103

8.5.1 Fundamentals ............................................................................................................ 103

8.5.2 Corrective Measure ................................................................................................... 105

8.5.3 Preventive Measure .................................................................................................. 106

VERIFICATION ITEMS FOR AUDIT ............................................................................................... 108

-

7/27/2019 Comparison 59 x 686 x ISO13485

5/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 5

FOREWORD

OBJECTIVE

This paper is aimed at establishing a comparative study between an ISO rule andtwo sanitary legislations for Good Manufacturing Practices and Control, as well as Storage

and Distribution of Products for Health and establishing a basis for adoption at the ISO rule.

NBR ISO 13485:2004 Health Products Quality management systems

Requirements for regulating purposes;

Resolution RDC 59:2000 Determines to all medical product suppliers, compliance

with the requirements set forth by the Good Medical Product Manufacturing

Practices.

Ordinance 686:1998 Determines to all establishments which manufacture products

for in vitro use diagnosis, compliance with the guidelines set forth by the Good

Manufacturing Practices and Control in In Vitro Use Diagnostic Products

Establishments.

RDC 167:2004 Determines an Inspection Guide for verification of compliance with

Good Manufacturing Practices for Establishments which Manufacture or Trade

Products for In Vitro Use Diagnosis, to be abided by the Sanitary Surveillance

agencies in the whole national territory.

METHODOLOGY USED IN THE COMPARISON

The comparison used the quality management principles as tool for accomplishing

the comparison between the rule and the Good Manufacture Practices legislations. A

quality management principle is a belief or fundamental and extensive rule to conduct and

operate an organization, aimed at continuously improving its performance in the long term,

by focusing on customers and, at the same time, sending the needs from all stakeholders.

Upon growth of the globalization, quality management became fundamental for

leadership and continuous improvement of all organizations. By applying the eight quality

management principles, the organizations will produce benefits to customers, shareholders,

suppliers, local communities, i.e., for the society in general.

In accordance with ABNT/CB-25, the eight quality management principles are as

follows:

Focus on Customer; Leadership;

-

7/27/2019 Comparison 59 x 686 x ISO13485

6/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 6

People Commitment;

Process Approach;

Systemic Approach for Management;

Continuous Improvement;

Factual Approach for Decision Making;

Mutual Benefits in the Relationship with Suppliers.

The following Technical Rules and Legislations were used in this comparative study:

NBR ISO 13485:2004 Health Products Quality management systems

Requirements for regulating purposes;

ANSI/AAMI/ISO TIR14969:2004 Medical devices Quality management systems

Guidance on the application of ISO 13485:2003;

NBR ISO 9000:2005 Quality Management Systems Fundamentals and vocabulary;

NBR ISO 9001:2000 Quality Management Systems Requirements;

NBR ISSO 19011:2002 Guidelines for quality and/or environmental management

system audits.

The comparison is followed by commentaries related to the requirements that are being

analyzed and ends with the verification items to be used in first, second and/or third parties

audits.

NOTES RELATED TO THE COMPARATIVE STUDY

The rule ISO 13485 complies, at least, with 80% of the sanitary requirements in effect in the

Mercosul for health products and adds important requirements which are not comprised as

focus on customer, risk management, planning, development and project control and entries

and exits of critical analysis.

Sanitary requirements such as rejected materials; sample returns and retentions are implicit

in the non-compliant product control, data analysis and continuous improvements items of

ISO 13485, aimed at safety of the patients health. Thus, even more significant

convergences are verified between the rules MERCOSUL and those international.

The comparative study also shows an inspection guide, applicable to any Quality

Management System, as a proposal to cover all sanitary requirements applicable in health

products.

-

7/27/2019 Comparison 59 x 686 x ISO13485

7/126

-

7/27/2019 Comparison 59 x 686 x ISO13485

8/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 8

specific requirements of this Rule apply only to groupsnamed as health products. These groups are defined insection 3.

Paragraph 1 Establishments which store, distribute ortrade medical products shall equally comply with theprovisions of Attachment I of this Resolution, asapplicable.Paragraph 2 Other products of interest for the riskcontrol to peoples health, met by the NationalSanitary Surveillance System SNVS and pointed outby the National Sanitary Surveillance Agency ANVS,

are equal to the medical products referred to herein,and are subject to the provisions of this Resolution.

Art. 2 Inspection of the medical product suppliers shallbe carried out by sanitary surveillance inspectors fromthe SNVS, who shall use the items for Verification ofCompliance with the Good Manufacturing Practices ofMedical Products, set forth in Attachment II of thisResolution.

Art. 3 Non-compliance with the requirements of theGood Manufacturing Practices of Medical Productsshall subject suppliers of such products to thesanctions and penalties envisaged in the current law.

Art. 4 This Collegiate Board Resolution shall enter intoeffect as of the date of its publication.

GONZALO VECINA NETO

provisions cothose requiredfacilities and qnuclear mater

Art. 4 Non-Ordinance andand penalties

Art. 5 This Orits publicatiocontrary.

GONZALO VE

-

7/27/2019 Comparison 59 x 686 x ISO13485

9/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 9

Comments (Differences between NBR ISO 9001:2000 and NBR ISO 13485:2004): Except for the contents of paragraph 4, Section 0.1 of ABNT NBR ISO 13485, any changes to the t

9001:2000 are solely intended to adjust this text for application in the health product sector.

Comments (General): NBR ISO 13485:2004 specifies the requirements of a Quality Management System of health products for Note that NBR ISO 13485:2004 focuses on improvement of the customers requirements, on process ap

Management System and analysis of the data as an entry for maintenance and improvement of the quality When judging applicability of the requirements of this Rule, the nature of the health product(s) must be co

the associated risk and the applicable regulating requirements. Regulating requirement is construed as Resolution, or any other legislation whether Federal, State or Local, applicable to any Quality Managerelated services.

-

7/27/2019 Comparison 59 x 686 x ISO13485

10/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 10

0.2Process Approach

This Rule is based upon a process approach for thequality management.

Any activity receiving entries and converting them into

exits may be considered as a process.

So that an organization can function efficiently, it has toidentify and manage several related processes.

Usually the exit of a process is the entry for the followingprocess.

Application of a process system in an organization,together with the identification, interaction of theseprocesses and their management, may be consideredas process approach.

No Equivalent at RDC 59:2000 No Equiv

Comments (Differences between NBR ISO 9001:2000 and NBR ISO 13485:2004):

Many of the guidelines contained in section 0.2 of ABNT NBR ISO 9001 are being considered for inclusReport which intends to provide guidance for implementation of the requirements of ABNT NBR ISO 1348subsection of ABNT NBR ISO 9001 because there is no guidance document such as ISO/TR 14969.

Comments (General): NBR ISO 13485:2004 promotes adoption of the process approach in development, implementation and

Quality Management System, for the purpose of satisfying the customers and regulating requirements. Sconsidered by Resolution RDC 59:2000 and Ordinance 686:1998.

The process approach aims to benefit the regulated sector and the regulating sector as a universal referen

-

7/27/2019 Comparison 59 x 686 x ISO13485

11/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 11

0.3 Relation to other Rules

0.3.1 Relation to ABNT NBR ISO 9001Although this is an independent rule, it is based onABNT NBR ISO 9001.

Sections or subsections directly referred to and keptunchanged of ABNT NBR ISO 9001 are in a normalsource. The reasons for which these subsections areshown unchanged are described in attachment B.

Where the text of this Rule is not identical to the text ofABNT NBR ISO 9001, the beginning, the sentence orthe part of the text is shown in italic. The nature andreasons for changes in the text are described inattachment B.

0.3.2 Relation to ISO/TR 14969ISO/TR 14969 is a Technical Report intended to provide

guidance for application of ABNT NBR ISO 13485.

No Equivalent at RDC 59:2000 No Equiv

Comments (Differences between NBR ISO 9001:2000 and NBR ISO 13485:2004): There is no significant relation between ABNT NBR ISO 13485 and ABNT NBR ISO 9004. The key relati

in this introductory subsection are those between ABNT NBR ISO 13485 and ABNT NBR ISO 9001 and IS

Comments (General): Resolution RDC 59:2000 was based upon the Quality System Regulation QSR, Part 820, of the U.S. F

which in turn is agreed with ISO 13485:1996, in which is based on ISO 9001:1994. ISO 13485:1996 cproduct manufacturers added to the general requirements of the Quality Management System found in Iand NBR ISO 13485:2004 replaced, respectively, NBR ISO 9001:1994 and NBR ISO 13485:1996.

Resolution RDC 59:2000 and Ordinance 686:1998 are not agreed to NBR ISO 9001:2000 or NBR ISO 13

-

7/27/2019 Comparison 59 x 686 x ISO13485

12/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 12

0.4 Compatibility to other Management

Systems

This Rule follows the format of ABNT NBR ISO 9001 forthe convenience of the users of the health product

community.

This Rule does not include specific requirements fromother management systems, such as thoseenvironmental management specific, occupationalhealth, safety or financial management.

However, this Rule makes it possible for an organizationto align or integrate its quality management system toother related management system requirements. It ispossible for an organization to adapt its existingmanagement systems to establish a qualitymanagement system which complies with therequirements of this Rule.

No Equivalent at RDC 59:2000 No Equiv

Comments (Differences between NBR ISO 9001:2000 and NBR ISO 13485:2004): The first paragraph of section 0.4 of ABNT NBR ISO 13485 emphasizes the alignment of ABNT NBR ISO Risk management is an essential requirement in many activities and requirements associated with the qu

product organizations.

Comments (General): Compliance with the Quality Management System requirements of NBR ISO 13485:2004 does not com

Federal, State or Local regulating requirements. The organization is responsible for identifying and establrequirements.

-

7/27/2019 Comparison 59 x 686 x ISO13485

13/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 13

1 Objective

1.1 FundamentalsThis Rule specifies requirements for a qualitymanagement system where an organizationneeds to show its abilities to supply healthproducts and related services which consistentlymeet the customer and regulating requirementsapplicable for health products and relatedservices.

The main purpose of this Rule is making it easyfor the agreement of the health productregulating requirements for the qualitymanagement systems. As a result, it includessome specific requirements for health products

and excludes some of the requirements ofABNT NBR ISO 9001 that are not appropriateas regulating requirements. Due to suchexclusions, the organizations which qualitymanagement system is in compliance with thisRule cannot claim compliance with ABNT NBRISO 9001, unless their quality managementsystems are in compliance with all therequirements of ABNT NBR ISO 9001 (seeattachment B).

Part A General Provisions

1. Scope

(a) Applicability.(1) This rule sets forth requirements applicableto manufacturing of medical products. Theserequirements describe the good manufacturingpractices (BPF) for methods and controls usedin the project, purchase, manufacture,packaging, labeling, storage, installation andtechnical assistance of all medical products.The requirements of this rule are intended toassure that the medical products are safe andefficient.

(2) The requirements of this Rule are applicableto any medical product that is manufactured orimported for commercialization in the Country.

ATTACHM

INTRODUC

This regulapractices acommerciaapplied to acontrols useproducts fappropriate

-

7/27/2019 Comparison 59 x 686 x ISO13485

14/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 14

Comments (Differences between NBR ISO 9001:2000 and NBR ISO 13485:2004): This subsection uses and explains terms that are appropriate for the health product sector. In addition, t

continuous improvement were taken off because they are not relevant for a rule which objective is faproduct regulations for quality management systems around the globe.

Paragraph 2 intends to clarify that intention of ABNT NBR ISO 13485 is making it easy the harmonization

quality management system around the globe; for points out of such purpose it is needed to add some the ABNT NBR ISO 9001 and exclude some requirements found there, and to clarify the fact that adhereresult in the claim for adherence to ABNT NBR ISO 9001.

The term and related services was added twice to modify the term health products, because health pits definition. This is in contrast to ABNT NBR ISO 9001, where the term product does not include servic

Comments (General): The objective of the Quality Management System must be based on the nature of the organizations pro

processes, on the result of the risk assessment, on the commercial, statutory, and contractual considerarequirements.

-

7/27/2019 Comparison 59 x 686 x ISO13485

15/126

-

7/27/2019 Comparison 59 x 686 x ISO13485

16/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 16

Comments (Differences between NBR ISO 9001:2000 and NBR ISO 13485:2004): The text clarifies the fact that requirements from ABNT NBR ISO 13485 are specific for the health produ

relation between exclusions for project and development that may have a regulating impact in cerdistinguishes the requirements of section 7, in which an organization may, with regulating justifications, esystem (limited to 7.3), even if they can carry out activities for which those requirements are related, and

with justification, not include on its quality management system because they are related to activities not c

Comments (General):

Some requirements in section 7 Product Manufacture, of NBR ISO 13485:2004 may be legitimately ombe excluded, or can be not applicable. However, it is important to note that any exclusion or non-applicabthe organizations Quality Manual. Non-applicability relates to the nature of the health product. E.g.: Sinneed to be included in the elements of the Quality Management System related to the installation or seorganization providing non-sterile product does not need to include the elements related to sterilization.

For application of NBR ISO 13485:2004 in replacement to Resolution RDC 59:2000 and for the Ordinanrequired that the possibilities of exclusions of the requirements of section 7 Product Manufacture,differentiate between the requirements applicable to manufacturers and importers/distributors and ju

exclusion be made by the System Certification Agency, the applicable health authority or whom it determi

-

7/27/2019 Comparison 59 x 686 x ISO13485

17/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 17

2 Normative Reference

The rule listed as follows contains provisions

that, when being mentioned herein, constituteprescriptions for this Rule. The edition referredto was in effect by the time of this publication.Since every rule is subject to revision, thosewho enter into agreements based on it arerecommended to verify the convenience ofusing the most recent edition of the rulementioned as follows. ABNT has theinformation of the rules in effect at a giventime.

ABNT NBR ISO 9000:2000 Quality

management systems Fundamentals andvocabulary.

Law no. 6360, dated September 23

rd

,1976; Decree no. 79094 dated January 5th,

1977; Resolution Mercosul/GMC/Res. no.

04/95 Resolution Mercosul/GMC/Res. no.

131/96 Resolution RDC no. 331, dated

November 29th, 2002

Law197 Dec

197 Res

Manfor use

Res2nd,

-

7/27/2019 Comparison 59 x 686 x ISO13485

18/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 18

3 Terms and Definitions

For the purposes of this document, the terms anddefinitions of ABNT NBR ISO 9000 are applied, togetherwith those that follow.

The following terms, used in this edition of ABNT NBRISO 13485 to describe the supply chain, were changedin order to reflect the currently used vocabulary:

Supplier --------Organization -------- Customer

The term organization replaces the term supplierused in ABNT NBR ISO 13485:2000, and refers to theunit to which this Rule applies. Equally, the termsupplier now replaces the term subcontractor.

Throughout the text of this Rule, where the termproduct appears, it may also mean service.

Whenever requirements are specified as applicable forhealth products, they apply equally to related servicesas provided by the organization.

The following definitions are recommended to beconsidered as generic, since definitions provided innational regulations may differ slightly and shall prevail.

Part A General Provisions

2. Definitions

DEFINITIO

The followinthis Regulat

in other cont

3.1 Implantable Active Health Product

Active health product which is intended to be total orpartially introduced, surgically or clinically, into thehuman body, or by means of medical intervention in a

natural hole and which is intended to remain in thelocation after the procedure.

No Equivalent at RDC 59:2000 Not Appl

-

7/27/2019 Comparison 59 x 686 x ISO13485

19/126

-

7/27/2019 Comparison 59 x 686 x ISO13485

20/126

-

7/27/2019 Comparison 59 x 686 x ISO13485

21/126

-

7/27/2019 Comparison 59 x 686 x ISO13485

22/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 22

No Equivalent at NBR ISO 13485:2004

(d) Project Entry Data list of the physical andperformance requirements of a medical product that areused as basis of its project. No Equi

No Equivalent at NBR ISO 13485:2004

(e) Project Exit Data - result of the work at each phaseof the project and the total effort for finalization. Thefinalized project exit data consists of the product, itspackage and labels, the related specifications, designs,production and the quality system specifications that areinserted in the master product record (RMP).

No Equi

No Equivalent at NBR ISO 13485:2004

(f) Specifications documents that prescribe therequirements to which a product, component, productionor technical assistance activity or a quality system needto be in compliance.

SPECIFICATmust meet thand materials

No Equivalent at NBR ISO 13485:2004(g) Establish define, document and implement.

No Equi

No Equivalent at NBR ISO 13485:2004

(h) Manufacturer any person who designs,

manufactures, assemblies or processes a finishedproduct, including third parties that are authorized orqualified to sterilize, label and/or package andimporters.

No Equi

No Equivalent at NBR ISO 13485:2004

(i) Executive management means themanufacturers graduated employees who have theauthority to establish or effect changes to the qualitypolicy, quality system requirements or effect changes tothe products project procedures or its production,distribution, technical assistance, maintenance orinstallation.

No Equi

No Equivalent at NBR ISO 13485:2004

(j) Law Countrys regulation to be prepared as from

this rule. No Equi

-

7/27/2019 Comparison 59 x 686 x ISO13485

23/126

-

7/27/2019 Comparison 59 x 686 x ISO13485

24/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 24

No Equivalent at NBR ISO 13485:2004

(v) Record written or automated document, includingspecifications, procedures, protocols, standards,methods, instructions, plans, files, notes, revisions,analyses and reports.

RECORDS:history of eacexecution omanufacture

No Equivalent at NBR ISO 13485:2004

(w) Product Historic Record compilation of records

containing the full production history of a finishedproduct. No Equ

No Equivalent at NBR ISO 13485:2004(x) Project Historic Record compilation of recordscontaining the full project history for a finished product. No Equ

No Equivalent at NBR ISO 13485:2004

(y) Master Product Record (RMP) compilation ofrecords containing the full product designs, its formulaand specifications, the manufacturing and purchaseprocedures and specifications, the quality systemprocedures and requirements and the finished productprocedures related to packaging, labeling, technicalassistance, maintenance and installation.

No Equ

No Equivalent at NBR ISO 13485:2004

(z) Reprocessing part or all the manufacturingoperation intended to correct the non-compliance of acomponent or a finished product.

REPROCESSunacceptableso that its quof one or mor

No Equivalent at NBR ISO 13485:2004

(aa) Project Revision systematic and full examinationof the project in order to assess adequacy of the productto its requirements for the purpose of assessingcapacity of the project in satisfying such requirements,identifying problems with the project in relation to therequirements and proposing solutions for suchproblems.

No Equ

-

7/27/2019 Comparison 59 x 686 x ISO13485

25/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 25

No Equivalent at NBR ISO 13485:2004

(bb) Quality System organizational structure,responsibilities, procedures, specifications,processes and resources needed to implement thequality management.

No Equi

No Equivalent at NBR ISO 13485:2004

(cc) Validation in relation to a product, meansestablishing and documenting evidence that the

product is ready for the intended usage. In relationto a process, means establishing and documentingevidence that the process will consistently producea result that meets the predeterminedspecifications and the quality characteristics.

VALIDATION: Doprocess, equipme

the expected resu

No Equivalent at NBR ISO 13485:2004

(dd) Verification confirmation anddocumentation, when valid, of the objectiveevidence that the specified requirements were met.Verification includes the process of examiningresults of an activity to determine compliance withthe specifications set forth for that activity andassuring that the product is appropriate to theintended usage.

No Equi

No Equivalent at NBR ISO 13485:2004 No Equivalent at RDC 59:2000

CALIBRATION:greatest exactitudecorrespondence measurement insreference material

No Equivalent at NBR ISO 13485:2004 No Equivalent at RDC 59:2000CROSS CONTAMa product, with oth

No Equivalent at NBR ISO 13485:2004 No Equivalent at RDC 59:2000

QUALITY CONTRprepared in orderproduction lots com

No Equivalent at NBR ISO 13485:2004 No Equivalent at RDC 59:2000

PROCESS COproduction for thadjusting the promeets its specifcontrol may be al

-

7/27/2019 Comparison 59 x 686 x ISO13485

26/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 26

No Equivalent at NBR ISO 13485:2004 No Equivalent at RDC 59:2000

RETURNS: Retproduct, becausecommercial cond

No Equivalent at NBR ISO 13485:2004 No Equivalent at RDC 59:2000 STERILE: Lack o

No Equivalent at NBR ISO 13485:2004 No Equivalent at RDC 59:2000

FINAL STAGES:process, such as

grinding, sieving,

No Equivalent at NBR ISO 13485:2004 No Equivalent at RDC 59:2000

REANALYSIS Tintermediate or rdue previous rean

No Equivalent at NBR ISO 13485:2004 No Equivalent at RDC 59:2000

FRAGMENTATIOtransformation oincluding packagi

No Equivalent at NBR ISO 13485:2004 No Equivalent at RDC 59:2000

PRODUCTION Mwhich specify threspective amoun

procedures and pa determined amcontrols that mus

No Equivalent at NBR ISO 13485:2004 No Equivalent at RDC 59:2000

PACKAGING fragmentation andiagnosis. The pprimary (get into d(do not get into di

No Equivalent at NBR ISO 13485:2004 No Equivalent at RDC 59:2000TERM OF VALIDbe used as such.

No Equivalent at NBR ISO 13485:2004 No Equivalent at RDC 59:2000AUTHORIZED PEresponsibility to c

-

7/27/2019 Comparison 59 x 686 x ISO13485

27/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 27

No Equivalent at NBR ISO 13485:2004 No Equivalent at RDC 59:2000

PROCEDURcarried out, measures applied, in product.

No Equivalent at NBR ISO 13485:2004 No Equivalent at RDC 59:2000 BULK PRO

fragmentatioNo Equivalent at NBR ISO 13485:2004 No Equivalent at RDC 59:2000 APPROVED

the requirem

No Equivalent at NBR ISO 13485:2004 No Equivalent at RDC 59:2000

INTERMEDPRODUCT:which must stages befor

No Equivalent at NBR ISO 13485:2004 No Equivalent at RDC 59:2000REJECTEDmeet one specification

No Equivalent at NBR ISO 13485:2004 No Equivalent at RDC 59:2000RECOVERYlots with attstage of the

Comments (Differences between NBR ISO 9001:2000 and NBR ISO 13485:2004): The text is adjusted to use in the health product sector and also includes a warning related to the fact that loca

superpose to that contained or referred to at ABNT NBR ISO 13485. Definitions from 3.1 to 3.8 are specific to t

Comments (General): For application of NBR ISO 13485:2004 in replacement to Resolution RDC 59:2000 and Ordinance 686:19

found at NBR ISO 9000:2005, NBR ISO 13485:2004 and NBR ISO 19011:2002 jointly with other Federal, State

-

7/27/2019 Comparison 59 x 686 x ISO13485

28/126

-

7/27/2019 Comparison 59 x 686 x ISO13485

29/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 29

system (see 8.5.1).

NOTE It is convenient that the processes required forthe quality management system mentioned aboveinclude processes for the management activities,resource provision, preparation of the product andmeasurement.

of a producRegulation.

1.5 The pracapplied to pro

Comments (Differences between NBR ISO 9001:2000 and NBR ISO 13485:2004): The resulting text is consistent to the purposes of reflecting the current regulations and making harmonization

easy around the world. The current regulations are aimed at efficiency of the quality management system in oefficient products.

Comments (General):The following guidelines should be complied with in order to maintain efficacy of a Quality Management System

include definition and promotion of processes that lead to the attainment of compliance with the regulating requ acquire and use process data and information on a continuous basis; determine and provide resources, including human resources and information systems;

guide changes required to the Quality Management System; use satisfactory assessment methods such as internal audits and critical analyses by the board.

-

7/27/2019 Comparison 59 x 686 x ISO13485

30/126

-

7/27/2019 Comparison 59 x 686 x ISO13485

31/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 31

c) to the personnel competency.

NOTE 2 The documentation may be in any format ortype of communication means.

Comments (Differences between NBR ISO 9001:2000 and NBR ISO 13485:2004):

The text in 4.2.1 of ABNT NBR ISO 13485 includes all requirements contained in the corresponding subsaddition of a general statement related to the regulations that may contain documentation requirements containing documents specified for each type/model of health product. In addition, the text includes the doactivities and measures. The resulting text is consistent to the objectives of reflecting the current regulations anproduct regulations easy around the globe.

Comments (General):

The documented procedures of the Quality Management System are needed for the applicable requirements

consistent to the organizations quality policy. It is important knowing that the structure and level of detail requirto the organizations needs.

Procedures or instructions may be presented in text, graphic, or audiovisual format. Usually, a simple serunderstanding of the procedure more precisely than a detailed and long description.

The table below shows the documented procedures required by NBR ISO 13485:2004.

-

7/27/2019 Comparison 59 x 686 x ISO13485

32/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 32

Requirements Required Documented Procedures

4.2.2 Quality Manual

4.2.3 Document Control

4.2.4 Record Control

6.4 Work Environment

7.3.1 Project Planning and Development

7.4.1 Acquisition Processes

7.5.1.2.3 Service Activities

7.5.2.1 Validation of the Production Processes and Service Provision General R

7.5.2.2 Specific Requirements for Sterile Health Products

7.5.3.1 Identification and Traceability Identification

7.5.3.2.1 Identification and Traceability Traceability

7.5.5 Product Preservation

7.6 Measurement Device Control and Monitoring

8.2.1 Measurement and Monitoring Customer Return

8.2.2 Internal Audit

8.3 Non-Compliant Product Control

8.4 Data Analysis

8.5.1 Improvements Fundamentals

8.5.2 Corrective Measure

8.5.3 Preventive Measure

-

7/27/2019 Comparison 59 x 686 x ISO13485

33/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 33

4.2.2 Quality Manual

The organization must establish and keep a qualitymanual which includes

a) scope of the quality management system, includingdetails and justifications for any exclusion and/or non-applicability (see 1.2),

b) documented procedures set forth for the qualitymanagement system, or reference to them, and

c) description of the interaction between the qualitymanagement system processes.

The quality manual must describe structure of thedocumentation used in the quality management system.

No Reference at RDC 59:2000Note: Equivalent is the Good Practice Manual

No RefNote: Equi

Comments (General): Implementation of a Quality Management System by an organization is very effective when individu

its intention, function, relevance for their own activities, and the interface to other parties of the syimportant role in this regard, for both internal and external parties.

The manual format is a decision by each organization, and shall depend upon the organizations siexample, a quality manual may be a document in levels increasingly detailed with detailed documglobal manual, one or more specific manuals, work instructions and reference documents. Togeorganizations Quality Management System.

RDC 59:2000 does not refer, in its requirements, to a Quality Manual, but does so in the ItemsOrdinance 686:1998 makes no reference as well.

-

7/27/2019 Comparison 59 x 686 x ISO13485

34/126

-

7/27/2019 Comparison 59 x 686 x ISO13485

35/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 35

documents related to manufacture and health producttests are available at least during the useful life of thehealth product, defined by the organization, but notlower than the period for retention of any resultingrecord (see 4.2.4), or as specified by applicableregulating requirements.

(d) Document Alteration Records. Each manufacturershall keep records of changes to documents. Thedocument alteration records shall include a descriptionof the change, identification of the changed documents,signature of the person responsible, approval date anddate in which the changes entered in effect. A list, indexor equivalent procedures for document control must be

established and kept in order to identify the currentstatus of the documents, for the purpose of assuringthat only current and approved documents are in use.

-

7/27/2019 Comparison 59 x 686 x ISO13485

36/126

-

7/27/2019 Comparison 59 x 686 x ISO13485

37/126

-

7/27/2019 Comparison 59 x 686 x ISO13485

38/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 38

No Equivalent at NBR ISO 13485:2004

Part M Records

1. General Requirements

(a) Confidentiality. The records considered asconfidential by manufacturer may be initialed in order to

warn the applicable health authority.

No Equ

Comments (General):

The table below shows the records required by NBR ISO 13485:2004.

-

7/27/2019 Comparison 59 x 686 x ISO13485

39/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 39

Requirements Required Records

5.6.1 Critical Analysis by the Board

6.2.2 (e) Education, Training, Ability and Experience

6.3 Infrastructure

7.1 (d) Evidence that manufacturing procedures and resulting product meet the requireme

7.1 risk management

7.2.2 Critical Analysis of the requirements related to the product

7.3.2 Project Entries and Development

7.3.3 Project Exit and Development

7.3.4 Project Critical Analysis and Development

7.3.5 Project Verification and Development

7.3.6 Project Validation and Development

7.3.7 Project Change Control and Development

7.4.1 Acquisition Process

7.4.2 Acquisition Information

7.4.3 Acquired Product Verification

7.5.1.1 Health Products Lot

7.5.1.2.2 Installation and Verification7.5.1.2.3 Service Activities

7.5.1.3 Process Parameters for Sterilization Process

7.5.2 Process Validation

7.5.3 Traceability

7.5.4 Customer Property

7.5.5 Product Preservation

7.6 Measurement and Monitoring Device Control

8.2.2 Internal Audit Results

8.2.4 Product Measurement and Monitoring

8.3 Non-Compliant Product Control

8.4 Data Analysis

8.5.1 Customer Complaint Investigation8.5.2 Corrective Measure

8.5.3 Preventive Measure

-

7/27/2019 Comparison 59 x 686 x ISO13485

40/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 40

5 Board Responsibility

5.1 Board Commitment

The Senior Board must provide evidence of itscommitment to development and implementation of thequality management system and keep its efficacy upon

a) communication to the organization of the importancein complying with the customers requirements, as wellas with the regulating and statutory requirements,b) establishment of the quality policy,c) assurance that the quality objectives are established,d) conduction of critical analyses by the Senior Board,ande) assurance of the resource availability.

NOTE For the purposes of this Rule, the statutory

requirements are only limited to safety and performanceof the health product.

No Direct Reference at RDC 59:2000,but implicit and mentioned at RDC 59:2000

No Directbut imp

Comments (Differences between NBR ISO 9001:2000 and NBR ISO 13485:2004): This text is consistent to the goal of reflecting the current regulations and making harmonization of n

around the globe. The current regulations are aimed at efficacy of the quality management system inand efficient products.

Comments (General): It is important noting the emphasis given to Senior Board through this requirement. It is the in

Management System is efficient as a result of the commitment by the management of the higher leve

The Senior Board commitment is best shown by its actions.

-

7/27/2019 Comparison 59 x 686 x ISO13485

41/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 41

5.2 Focus on Customer

The Senior Board must assure that the customersrequirements are determined and met (see 7.2.1 and

8.2.1).

No Equivalent at RDC 59:2000 No Equ

Comments (Differences between NBR ISO 9001:2000 and NBR ISO 13485:2004): The text revision is consistent to the stand that customer satisfaction is not an appropriate regulatin

result, this text is consistent to the goal of ABNT NBR ISO 13485 of making harmonization ofregulations easy around the globe.

Comments (General):

This requirement intends to emphasize the Senior Board responsibility to cause the customer requithe resources needed are available to satisfy these requirements.

-

7/27/2019 Comparison 59 x 686 x ISO13485

42/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 42

5.3 Quality Policy

The Senior Board must assure that the quality policy

a) is appropriate to the organizations purpose,

b) includes a commitment to compliance with therequirements and to maintenance of the efficacy of thequality management system,

c) provides a structure for establishing and criticallyanalyzing the quality goals,

d) is communicated and understood by the entireorganization, and

e) is critically analyzed for maintenance of its adequacy.

Part B Quality System Requirements

1. Managerial Responsibility

(a) Quality Policy. Executive management of eachmanufacturer shall set forth its policy and objectives forcommitment to quality. Executive management shallkeep the policy in all levels of the organization.Executive management shall assure that such policy isunderstood by all employees who may affect orinfluence quality of a product. No Equ

Comments (Differences between NBR ISO 9001:2000 and NBR ISO 13485:2004):

The text of subsection 5.3, ABNT NBR ISO 13485 eliminates from item b) commitment to contimanagement system efficacy and replaces by commitment to maintaining efficacy of the qureplacement is consistent to the objective of the current regulations and its intent is to make harmonsystem regulations easy around the globe.

Comments (General): All employees need to understand the quality policy and how it affects them. The Senior Board

decides the methods that shall be used to reach such understanding. The quality policy also needs to be revised from time to time in order to determine whether it precisel

to the goals and objectives of the organization.

-

7/27/2019 Comparison 59 x 686 x ISO13485

43/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 43

5.4 Planning

5.4.1 Quality Objectives

The Senior Board must assure that the qualityobjectives, including those needed to meet the product

requirements [see 7.1 (a)], are set forth in the applicablefunctions and levels of the organization. The qualityobjectives are measurable and coherent to the qualitypolicy.

No Equivalent at RDC 59:2000

Chapter 1.11.1 Manufactway that mapurpose they predefined poquality, idencompliance w

The quality concepts of GSuch conceprelations and control of the

5.4.2 Quality Management System Planning

The Senior Board must assure that

a) planning of the quality management system is carriedout so as to satisfy the requirements referred to in 4.1,as well as the quality objectives, and

b) integrity of the quality management system is keptwhen changes to the quality management system areplanned and implemented.

Part A ProvisionsPart A.33. Quality systemEach manufacturer shall set forth and keep a qualitysystem in order to assure that the requirements of thisrule are attained and that the manufactured productsare safe, efficient and, generally, appropriate to theintended use. As part of its activities in the qualitysystem, each manufacturer shall:(a) Establish efficient instructions and procedures of thequality system according to the requirements of thisrule; and(b) Keep the instructions and procedures established forthe quality system in an efficient manner.

No Equ

Comments (General):

Groups within the organization set forth their objectives and must follow the organizations global objectives. The quality oQuality Management System Planning.

Typical entries to the Quality Management System Planning may include: quality policy, quality objectives, regulatinManagement System.

-

7/27/2019 Comparison 59 x 686 x ISO13485

44/126

-

7/27/2019 Comparison 59 x 686 x ISO13485

45/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 45

5.5.2 Board Representative

The Senior Board must appoint one member of theorganization who, regardless of other responsibilities,must have responsibility and authority to

a) assure that the required processes for the quality

management system are established, implemented andkept,

b) report to the Senior Board performance of the qualitymanagement system and any need for improvement(see 8.5), and

c) assure promotion of awareness on the regulatingrequirements and the customer in the entireorganization.

NOTE Responsibility of a board representative mayinclude relationship with external parties in affairsrelated to the quality management system.

Part B Quality System Requirements

1. Managerial Responsibility

(b) Organization.

(3) Management Representative. The executive

management of each manufacturer shall appoint anindividual from such executive management who,regardless of other functions, shall have authority andresponsibility to:

(i) Assure that the quality system requirements areestablished and kept in compliance with this rule; and

(ii) Report performance of the quality system to theexecutive management for revision and provideinformation on improvement of the quality system.Appointment of such employee shall be documented.

No Equ

5.5.3 Internal Communication

The Senior Board must assure that the appropriatecommunication processes are established in theorganization and that communication related toefficiency of the quality management system is carriedout. No Equivalent at RDC 59:2000 No Equ

-

7/27/2019 Comparison 59 x 686 x ISO13485

46/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 46

5.6 Critical Analysis by the Board

5.6.1 Fundamentals

The Senior Board must critically analyze the quality

management system of the organization, at plannedintervals, in order to assure its continuous applicability,adequacy and efficiency. Such critical analysis mustinclude assessment of opportunities for improvementand need for changes to the quality managementsystem, including the quality policy and qualityobjectives.

Records of the critical analyses must be kept by theSenior Board (see 4.2.4).

Part B Quality System Requirements

1. Managerial Responsibility

(c) Managerial Revision.

The executive management of each manufacturer shallrevise adequacy and efficacy of the quality system atdefined intervals and with a sufficient frequency toassure that the quality system satisfies the requirementsof this rule and that it attains the objectives of the qualitypolicy established. Revision by the management shallbe conducted according to the revision procedures setforth and the results of each revision of the qualitysystem shall be documented.

No Equ

5.6.2 Entries for Critical Analysis

Entries for critical analysis by the board must includeinformation on

a) audit results,b) customer feedback,c) process performance and product compliance,d) preventive and corrective measure status,e) follow-up of the measures deriving from previouscritical analyses by the board,f) changes that may affect the quality managementsystem,g) suggestions for improvement, and

h) new or revised regulating requirements.

No Equivalent at RDC 59:2000 No Equ

-

7/27/2019 Comparison 59 x 686 x ISO13485

47/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 47

5.6.3 Exits of the Critical Analysis

Exits of the critical analysis by the board must includeany decisions and measures related to

a) improvements needed to keep efficacy of qualitymanagement system and its processes,

b) improvement of the product in relation to thecustomer requirements, and

c) need for resources.

No Equivalent at RDC 59:2000 No Equ

-

7/27/2019 Comparison 59 x 686 x ISO13485

48/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 48

6 Resource Management

6.1 Resource Provision

The organization must determine and provide resourcesneeded to

a) implement the quality management system and keepits efficacy, and

b) meet the regulating requirements and that ofcustomers.

Part B Quality System Requirements

1. Managerial Responsibility

(b) Organization.

(2) Resources and personnel for verification.Each manufacturer shall set forth verification functionsand shall provide appropriate resources and delegationto the trained personnel for performance of theverification activities.

No Equ

6.2 Human Resources

6.2.1 Fundamentals

The personnel carrying out activities that affect productquality must be competent, based on appropriateeducation, training, ability and expertise.

Part B Quality System Requirements

3. Personnel

(a) General Instructions.Each manufacturer shall hire personnel in sufficientnumber with instruction, expertise, training and practiceto assure that all activities envisaged in this rule arecorrectly performed.

CHAPTER 2

Personnel

2.1 Manufactqualification aand quality asmust rely on professional practical expeout.

6.2.2 Competency, Awareness and Training

The organization must

a) determine the required competencies for thepersonnel carrying out works that affectproduct quality,

Part B Quality System Requirements

3. Personnel

(b) Training.

Each manufacturer shall assure that all personnel istrained to appropriately carry out

CHAPTER 2

Personnel

2.2 Manufacrepresented responsibilitie

-

7/27/2019 Comparison 59 x 686 x ISO13485

49/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 49

b) provide training or take other measures in order tosatisfy such needs for competency,

c) assess efficacy of the actions carried out,

d) assure that personnel is aware as to applicability andimportance of their activities and how they contribute

towards attaining the quality objectives, and

e) keep appropriate education, training, ability andexpertise records (see 4.2.4).

NOTE National or regional regulations may require theorganization to establish documented procedures toidentify training needs.

the tasks designated to him/her. The training shall beconducted according to the procedures set forth byqualified people to assure that employees perfectlyunderstand their regular functions and the requirementsof this rule applicable to the functions. As part of theirtraining, all employees shall be made aware of defectsin products that may occur as a result of the incorrect

performance of their specific functions. The employeescarrying out verification activities shall be made awareof errors and defects that may be found as part of theirverification functions. Employee training shall bedocumented.

(c) Advisors.(1) Each manufacturer shall assure that any advisorguiding on methods used or on controls used for theproject, purchase, manufacturing, packaging, labeling,storage, installation or technical assistance of productshas sufficient qualifications (instruction, training andexpertise) to advise on the matters for which he/she washired.

(2) Each manufacturer shall keep records related toeach advisor. Such records must include name,address, qualifications, including copy of the curriculumand a list of previous jobs, as well as a specificdescription of the matters he/she provided advisoryservices.

distributed asfunctions, sosuperpositionbe too extenquality.

2.3 Employe

appropriately designated to

-

7/27/2019 Comparison 59 x 686 x ISO13485

50/126

-

7/27/2019 Comparison 59 x 686 x ISO13485

51/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 51

4.3 As requircontrol must processes for

4.5 Equipmeidentified andas soon as pdocumented.

-

7/27/2019 Comparison 59 x 686 x ISO13485

52/126

-

7/27/2019 Comparison 59 x 686 x ISO13485

53/126

-

7/27/2019 Comparison 59 x 686 x ISO13485

54/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 54

Usually, the maintenance schedule must be affixed, near the equipment, or readily available. The organization must assure that facilities (buildings, warehouses, industrial plants, etc.) used, have a satisfactory lay

cleaning, maintenance and other required operations easy. Facilities must have layout with sufficient space distribution, tomix between entry material, lots under process, rejected, reworked, modified or repaired material, and any other non-compl

-

7/27/2019 Comparison 59 x 686 x ISO13485

55/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 55

7 Product Manufacturing

7.1 Product Manufacturing Planning

The organization must plan and develop the requiredprocesses to manufacture the product. Planning of theproduct manufacturing must be coherent with therequirements of other quality management systemprocesses (see 4.1).

When planning product manufacturing, the organizationmust determine the following, as appropriate:

a) quality objectives and requirements for the product;

b) need to establish processes and documents andprovide specific resources for the product;

c) verification, validation, monitoring, inspection andtesting activities required, specific for the product, aswell as the criteria for product acceptance;

d) records needed to provide evidence that themanufacturing processes and the resulting product meetthe requirements (see 4.2.4).

Exit of this planning must be adequate to theorganizations method of operation.

The organization must establish documentedrequirements for risk management during the productmanufacturing. Records resulting from the riskmanagement must be kept (see 4.2.4).

NOTE 1 A document specifying the quality

management system processes (including productmanufacturing processes) and the resources to beapplied to a product, undertaking or specific contract,may be referenced as a quality plan.

NOTE 2 The organization may also apply therequirements presented in 7.3 when developing the

No Equivalent at RDC 59:2000

CHAPTER 8

Production

8.D Finishe

8.D.1 Each specificationsrespective Pr

8.D.2 Finisheunder the contheir final relstored in theconditions es

-

7/27/2019 Comparison 59 x 686 x ISO13485

56/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 56

product manufacturing processes.

NOTE 3 See ISO 14971 for guidance to the riskmanagement.

Comments (Differences between NBR ISO 9001:2000 and NBR ISO 13485:2004):

Make the resulting text consistent to the objective of reflecting the current regulations and makingproduct regulations easy around the globe. Risk management is a key activity that determines theseveral areas addressed by the quality management system of the health product organization.

Comments (General): Decisions may be taken related to the product useful life, in parts, to control identified residual risks

levels with the extended period of usage of a health product. Organizations are required by NBR ISO 13485:2004 to define the health product useful life for the

and records (see 4.2.3 and 4.2.4). Useful life of a health product may be based on technical, legal, co

-

7/27/2019 Comparison 59 x 686 x ISO13485

57/126

-

7/27/2019 Comparison 59 x 686 x ISO13485

58/126

-

7/27/2019 Comparison 59 x 686 x ISO13485

59/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 59

7.2.3 Communication with Customer

The organization must determine and take efficientmeasures to communicate with the customers in relationto

a) product information,

b) treatment of consultations, contracts or orders,including amendments,

c) customer feedback, including complaints (see 8.2.1),and

d) notices (see 8.5.1).

No Equivalent at RDC 59:2000 No Equ

7.3 Project and Development

7.3.1 Project Planning and Development

The organization must establish documentedprocedures for project and development.

The organization must plan and control the productproject and development.

During the project planning and development theorganization must determine

a) steps of the project and development,

b) critical analysis, verification, validation and project

transfer activities (see NOTE) that are appropriate foreach phase of the project and development, and

c) responsibilities and authorities for project anddevelopment.

Part C Project Controls

(a) General Instructions. (1) Each medical productmanufacturer listed in class II or III (medium risk) or IV(high risk), shall set forth and keep control proceduresand verify the product project in order to ensure that therequirements specified for the project are being abidedby.

(b) Project Planning and Development. Eachmanufacturer shall set forth and keep plans identifyingeach activity of project development and the peopleresponsible for each activity. The plans shall describe orrefer to the project development activities, including anyinteraction between the several organizational andtechnical groups. The plans shall be updated as theproject development evolves.

No Equ

-

7/27/2019 Comparison 59 x 686 x ISO13485

60/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 60

The organization must manage interfaces betweendifferent groups involved in the project anddevelopment, to assure efficient communication andclear designation of responsibilities.

The planning exits must be appropriately documentedand updated, as the project and development evolve

(see 4.2.3.).

NOTE The project transfer activities during the projectprocess and development, assure that the project anddevelopment exits are verified as appropriate formanufacture before they become final productionspecifications.

-

7/27/2019 Comparison 59 x 686 x ISO13485

61/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 61

7.3.2 Project Entries and Development

Entries related to product requirements must be determinedand records must be kept (see 4.2.4).Such entries must include

a) functioning, performance and safety requirements,according to the intended use,

b) applicable statutory and regulating requirements,

c) where applicable, information originated from previoussimilar projects,

d) other essential project and development requirements, and

e) risk management exit(s) (see 7.1).

Such entries must be critically analyzed as to adequacy andduly approved.

Requirements shall be complete, not ambiguous and non-conflicting among themselves.

Part C Project Controls

(c) Project Entry Data. Each manufacturer shall setforth project entry data requirements related to theproduct. The requirements shall entirely refer to theproducts intended use, including the user needs(patient or operator) and must be revised andapproved by a qualified designated person.Approval of the requirements, including date andapprover, shall be documented.

No Equ

7.3.3 Project and Development Exit

The project and development exits must be presented in sucha way that allows for verification in relation to project anddevelopment entries and must be approved before release.

The project and development exits musta) meet the entry requirements for project and development,

b) provide appropriate information for acquisition, productionand service provision,

Part C Project Controls

(f) Project Exit Data. Each manufacturer shalldefine and document the project exit data so as toallow for appropriate assessment of the projectcompliance with the entry data requirements. Theproject exit data shall satisfy the entry datarequirements and shall include projectcharacteristics essential to the product intendeduse.

No Equ

-

7/27/2019 Comparison 59 x 686 x ISO13485

62/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 62

c) contain or refer to product acceptance criteria, and

d) specify the product characteristics essential for safeand appropriate use.

The project and development exit records shall be kept(see 4.2.4).

NOTE Project and development exit records mayinclude specifications, manufacturing procedures,engineering designs, and engineering records orresearch.

No Equivalent at NBR ISO 13485:2004

Part C Project Controls

(g) Project Transfer. Each manufacturer shall set forthand keep procedures to assure that the project basis fora product and its components is properly translated intoproduction specification terms. The productionspecifications shall be approved by a person appointedby manufacturer. Approval, including projectidentification, date and approver of the specifications

shall be documented. Each manufacturer shall choose asample representing the product of the first three lots orproduction batches and test such samples under real orsimulated conditions. Each manufacturer shall conductsuch testing according to the established proceduresand shall keep records of all tests. Each manufacturershall also conduct such tests when changes to theproduct or to the manufacturing process are made.

No Equ

-

7/27/2019 Comparison 59 x 686 x ISO13485

63/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 63

No Equivalent at NBR ISO13485:2004

Part C Project Controls

(h) Project Release. Each manufacturer shall assurethat the project is not released for production until it isapproved by the people designated for such bymanufacturer. Designated people shall revise all recordsrequired for the project historic record, for the purposeof assuring that it is complete and that the final project iscompatible to the approved plans, before release. Suchrelease, including date and responsible signature, shallbe documented.

No Equ

-

7/27/2019 Comparison 59 x 686 x ISO13485

64/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 64

7.3.4 Project and Development Critical Analysis

In appropriate stages, project and developmentsystematic critical analyses must be carried out, inaccordance with the planned provisions (see 7.3.1) inorder to

a) assess capacity of the project and developmentresults in complying with the requirements, and

b) identify any issue and propose the requiredmeasures.

Such critical analyses must include among itsparticipants representatives of functions involved withthe project and development stage(s) that is(are) beingcritically analyzed, as well as other expert personnel(see 5.5.1 and 6.2.1).

Result records of the critical analyses and of any

needed measures must be kept (see 4.2.4).

Part C Project Controls

(e) Project Revision. Each manufacturer shall performa formal revision of the project exit data according to theestablished requirements. Each manufacturer shalldesignate responsibility for the project revision toqualified people who have direct responsibility for theproject development. Designations shall bedocumented. The project revision results shall bedocumented in the projects historic record.

No Equ

7.3.5 Project and Development Verification

Verification must be carried out as per plannedprovisions (see 7.3.1), in order to assure that the projectand development exits are complying with the projectand development entry requirements.

Records of verification results and of any neededmeasures must be kept (see 4.2.4).

Part C Project Controls

(d) Project Verification. Each manufacturer shall setforth and keep procedures for the product projectverification and designate such functions to competentpersonnel. The project verification shall be performed ona timely manner and shall confirm that the project exitdata satisfies the entry data requirements and that theproject is appropriate for the intended use. The projectverification results, including identification of the verifiedproject, verification methods, date and name of theperson in charge of the verification, shall bedocumented in the project historic record. Whereapplicable, project verification shall include softwarevalidation and risk analysis.

No Equ

-

7/27/2019 Comparison 59 x 686 x ISO13485

65/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 65

7.3.6 Project and Development Validation

The project and development validation must be carriedout according to the planned provisions (see 7.3.1), inorder to assure that the resulting product is capable ofmeeting the requirements for the specified application orintended use. Validation must be concluded before

delivery or implementation of the product (see NOTE 1).

Records of the validation results and of any neededmeasures must be kept (see 4.2.4).

As part of the project and development validation, theorganization must carry out clinical assessments and/orperformance assessment of the health product, asrequired by national or regional regulations (see NOTE2).

NOTE 1 If a health product can be only validated afterassembly and installation at the usage location, deliveryis not considered concluded until the product has been

formally transferred to the customer.

NOTE 2 Health product provision aimed at clinicalassessment and/or performance assessment is notconsidered delivery.

No Equivalent at RDC 59:2000 No Equ

7.3.7 Project and Development Change Control

The project and development changes must beidentified and records must be kept. Changes must becritically analyzed, verified and validated, asappropriate, and approved before implementation. Thecritical analysis of the project and development changes

must include assessment of the effect of changes inparts, components and the already

Part C Project Controls

(i) Project Changes. Each manufacturer shall set forthand keep procedures for identification, documentation,validation, revision and approval of the project changes.

No Equ

-

7/27/2019 Comparison 59 x 686 x ISO13485

66/126

COMPARATIVE STUDY

NBR ISO 13485:2004 RDC 59:2000 ORDINANCE 686:1998

So Paulo, October/2007 Page 66

delivered product.Records of the results of the change critical analysisand of any needed measures must be kept (see 4.2.4)

No Equivalent at NBR ISO 13485:2004

Part C Project Controls

(j) Project Historic Record. Each manufacturer shallset forth and keep a project historic record for each

product. Each of these shall contain or refer to allrecords needed to show that the project was developedaccording to the approved project plans and therequirements of this rule.

No Equ

Comments (Differences between NBR ISO 9001:2000 and NBR ISO 13485:2004):

This text is consistent to the aim of reflecting the current regulations and making harmonization of teasy around the globe. In general, ABNT NBR ISO 13485 contains the same level of documentedNBR ISO 9001:1994, the rule, according to which, most of the local regulations is consistent.

Comments (General):