Company Profile - ELB Group Limited · 2017-03-12 · Hidromek Motor Graders The Hidromek motor...

Transcript of Company Profile - ELB Group Limited · 2017-03-12 · Hidromek Motor Graders The Hidromek motor...

Earthmoving, Construction, Mining, Quarrying & Recycling Equipment

Company Profile

ELB — A Company of Substance Supplying World-class Equipment

Page 2

ELB EQUIPMENT HOLDINGS LIMITED

A Journey to Success …..

The enthusiasm and foresight of a father-and-son team has ultimately resulted in the development of

one of South Africa's most dynamic and reputable international companies involved in the

design, manufacture and delivery of engineered products to the infrastructure, mining, processing and

construction industries.

A young American mechanical engineer, Edward L Bateman, was relocated to South Africa in

1903 by Allis Chalmers to assist their South African representative, Herbert Ainsworth, in selling

equipment to the mines.

The representative died in 1919 and Edward L Bateman bought the business and operated it as a very

effective and dynamic one-man operation until 1925 when his eldest son, Glen L. Bateman

joined the company.

As South Africa developed, so too, did Bateman, and in order to keep on growing, the Group had

established offices on all the continents. This expansion resulted in circumstances changing within

the Bateman Group and the Bateman family culminating in a portion of the company, Bateman

Project Holdings Limited, being sold to an international consortium of high nett-worth individuals in

February, 2002.

As part of the restructure, the Edward L Bateman Group of Companies reverted to its former

well-established trade name of ELB. However, the name-change in no way affects the

day-to-day business of the company as the management style and culture remains unchanged.

Just as the Group founder, Edward L. Bateman, relied on world-leading products for its success in the

early 1900's, so too, today, this continues to be the market strategy which the ELB Group

depends on to carry it forward profitably and successfully into a new era.

Page 3

ELB EQUIPMENT

A Company of Substance

Under the Bateman umbrella of companies, construction products were introduced in 1981. In

mid-1987, an autonomous division with responsibility for earthmoving and construction equipment

was established under the trade name of Bateman Earthmoving Equipment (BEE). In line with the

Group name change, Bateman Earthmoving Equipment became ELB Equipment Limited,

positioning itself as one of the most respected names in the earthmoving, construction mining

equipment supply industry. During 2013 the company changed its trade name to ELB Equipment - a

division of ELB Equipment Holdings (Pty) Limited.

Aim

As a supplier of world-renown earthmoving, construction, mining and quarrying products, our aim is

to match the needs of our customers with ultimate productivity by:

• Providing our customers with specialist solutions that will enhance their profitability;

• Reacting quickly to the customers' needs and wants by either sourcing non-standard

equipment from abroad or in supplying local, custom-built equipment as our customers

diversify into new market sectors; and

• Striving for Service Excellence in After-sales Service on the full range of products that

we distribute.

Vision Statement

Our vision is to be alert and ready to meet the requirements of our customers, our shareholders, our

employees and business associates.

To our customers we commit ourselves to excellence in product distribution and

aftermarket service.

To our shareholders we pledge to contribute to their expected long-term growth, earnings and

profitability.

To our employees we pledge the continual development of our people to ensure professionalism,

personal advancement and security.

Page 4

Meeting World Standards

ELB Equipment represents a number of world-renowned manufacturers whose products are

designed to meet the strict emission and safety control regulations that apply to the industrialized

first-world countries. Since South Africa closely follows global standards, customers can rest

assured that the products we supply meet local safety standards. Benefits derived from such high

safety standards incorporate: enhanced ergonomics; improved productivity; conformance to quality

standards; reduced operating cost and ultimately, client satisfaction.

CHOOSING THE RIGHT PARTNERS

Finance

In acknowledgement of the industry's need for financial support and in pursuance of its policy of

adding value to its service to customers, the company is able to provide financial assistance through

ELB Equipment Finance and/or ELB Leasing. This facility has been established in conjunction with

one of the leading financial institutions.

Overseas Principals

Overseas principals regularly visit South Africa to provide ongoing support and to update and train

local sales, technical service and repair staff on the latest technological developments and

international market trends. Overseas personnel also pay visits to our customers to offer expert advice

in maximizing the productivity of equipment in the field.

Branch and Dealer Network

In order to effectively service its client base, ELB Equipment has branches in Brits, Cape Town,

Durban, East London, George, Kathu, Kimberley, Middelburg in addition to well-established

dealers throughout the South Africa and southern Africa (Botswana, Mozambique, Lesotho,

Namibia, Swaziland, Zambia, DRC and Zimbabwe).

In October 2013, ELB Equipment established a subsidiary, ELB East Africa Limited, in Nairobi,

Kenya.

Page 5

AFTERMARKET CARE

ELB Equipment's pledge is to offer superior back-up service to all users of its equipment.

Parts Supply

A comprehensive Parts department, offering round-the-clock service, ensures that users have ready

access to a comprehensive range of parts and service exchange components, thereby limiting

downtime of equipment.

Aftermarket Service

A 24-hour call-out service reflects the company's commitment in ensuring the trouble-free operation

of all its equipment in the field. Units are maintained on site on a regular basis. A field service and

workshop facility enables bigger jobs to be dealt with quickly and professionally under controlled

conditions.

The workshops are well equipped to attend to design changes and modifications - be it minor or

major - and do so under the guidance of its principal companies in order to maintain the highest

quality standards.

Refurbishing

A large, centralized and fully equipped refurbishing facility is available for the rebuilding and

refurbishing of ELB's products.

Pre-delivery Inspection Centre (PDI)

All machines are inspected and prepared to meet customers’ specifications at ELB’s PDI Centre

prior to delivery to the customer.

Page 6

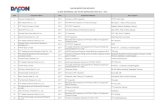

PRODUCT PROFILE

ELB Equipment is one of a few South African companies that can offer the southern African (and

East African) industries a wide selection of products from a single supplier.

Three specialized divisions, each with responsibility for specific products, provide a streamlined and

professional service:

CONSTRUCTION EQUIPMENT DIVISION

Ammann Compaction & Paving Equipment

Ditch Witch®Trenching & Directional Drilling Equipment

HammerHead Mole® Pneumatic Piercing Tools

Hidromek Motor Graders

MST Backhoe Loaders

Mustang Skid Steer Loaders

Terex Backhoe Loaders

EARTHMOVING EQUIPMENT DIVISION

Dressta Bulldozers

Kawasaki Wheel Loaders

Sumitomo Tracked Excavators

MINING/QUARRYING & RECYCLING EQUIPMENT DIVISION

Furukawa Hydraulic Breakers

FRD Excavator Attachments

Furukawa Rock Drills

Kiverco Recycling Systems

McGirr Blockmakers

Powerscreen Mobile Screens

Powerscreen Mobile Crushing Plants

Taurus Heavy Duty Rotary Barrel Screens

Telestack Telescopic and Tracked Conveyor Belts

Terex Mineral Processing Systems—Static & Modular Crushing & Screening Plants

Terex Washing Systems

Page 7

CONSTRUCTION EQUIPMENT DIVISION

Ammann Compaction & Paving Equipment

The Ammann Group is a Swiss company that are proven global compaction Roller

Specialists with over 100 years’ of history. Providing a comprehensive range of

Compaction equipment with a unique design which not only offers machines at a very

competitive price, but with superior running costs, lower maintenance costs and

enhanced compaction performance.

Apart from a full range of compaction equipment, Ammann provide world-leading asphalt pavers and

pavers to suit the demands of almost every road construction project—from start to finish.

Ditch Witch® Chain Trenchers

Ditchwitch Chain Trenchers offer many solutions to both large and small contractors

alike. Versatile adjustability of digging width and depth allow trenches to be dug from as

narrow as 85mm to as wide as 610mm, at a variable depth of up to 2100mm.

The units have proved most popular because of their high performance, ruggedness,

power and ease of operation. For heavy construction digging the larger models can be

fitted with backhoe attachments, heavy duty roller booms or earth saws.

Ditch-Witch® Trenchless Technology Ditchwitch Trenchless Technology is the only effective alternative when job site

restrictions make traditional open excavation methods impractical. Available in the

form of guidable boring systems, guidable boring devices or piercing tools, the

equipment bores to distances of up to 200 metres through a variety of soils, including

solid rock. It can be monitored to depths of up to 3 metres using the Ditch Witch®

Subsite electronic locating equipment.

HammerHead Mole ® Pneumatic Piercing Tools

HammerHead Mole® pneumatic piercing tools create a compact hole for almost

any underground installation with minimal disruption to landscapes, buildings or

normal traffic flow. Whether you’re boring a hole under a sidewalk or under a

highway, HammerHead® delivers the productivity and reliability needed to keep

you on the job.

HammerHead® is the new “must have” tool for municipalities, electrical, cable/telecom, sewer, plumbing

or irrigation contractors.

Page 8

Hidromek Motor Graders

The Hidromek motor grader range is designed to blend high productivity with

uncomplicated maintenance, ensuring reliability under the toughest conditions.

The popular long-life turbocharged engines performs exceptionally well in other

equipment supplied by ELB Equipment. A large number of these popular

graders are operating in difficult circumstances all over Africa. A fully trained

service and parts staff provide after-market support of the quality demanded by both Mitsubishi

Heavy Industries Ltd. and our customers.

MST Backhoe Loaders

The performance of the MST M5 series is rated tops in the category of backhoe loaders

currently in the international market and sets a new industry standard in terms of durability,

performance and value for its production capability.

These backhoe loaders are guaranteed in terms of quality and safety since they are

designed and manufactured to meet the ISO9001, CE and TŰV standards, whilst the ROPS

and FOBS also meet international safety regulations.

Mustang Skid-steer Loaders

The versatile and cost-effective Mustang skid steer loaders are designed and built

to excel in a wide range of working environments including agriculture,

construction and mining industries. It is ideally suited to work in confined areas,

inside buildings, or anywhere else where it would not be cost-effective to use a

bigger machine. A choice of over 50 different attachments is available to ensure the

versatility of this compact machine.

Terex® Backhoe Loaders

Terex® backhoe loaders are known in the industry for their outstanding quality,

performance and affordability. With proven attributes of low maintenance costs and high

efficiency ratings, Terex® TLBs are a firm favourite with owners and operators.

Superior traction force under all working conditions is provided by the larger front and

rear wheels resulting in increased production, tyre life and better flotation. The Terex®

backhoe loader is produced in a high specification as standard, including a 74.5kW engine, 30" rear wheels,

20" front wheels and air conditioner fitted as standard and meets international ISO9001, CE and TŰV

standards.

Page 9

EARTHMOVING EQUIPMENT DIVISION

Dressta Bulldozers

Dressta Dozers are designed to be easily controlled, no matter the skill level of the

operator. Their machines feature a left hand joystick control, right foot pedal for

engine deceleration and a left pedal for braking. The M-series dozers are designed

with a power train that combines a torque converter with clutch-brake steering.

This powertrain outperforms competitors that use hydrostatic power trains in

addition to having lower repair and maintenance costs. It provides good shock absorption, minimizes

engine lugging, and allows operators excellent control over machine power.

Kawasaki Wheel Loaders

The range of Kawasaki wheel loaders and LHDs is designed to meet the demands

of the larger mining operations.

Kawasaki is one of the biggest wheel loader manufacturers in the world and, in

fact, a leader in their field when considering that the first articulated loader was designed and

manufactured by Kawasaki.

Meeting, and in many instances surpassing international competition, the reliability and durability of

the Kawasaki product range is well proven and established throughout the world.

Sumitomo Excavators

Sumitomo presents the world with an excavator that combines the latest

technology with increased productivity, lower running costs and increased

environmental protection.

With fuel savings up to and exceeding 20%, the latest Sumitomo LEGEST series

hydraulic excavator won the prestigious Japanese “Energy Conservation Award” in 2008 and the

“Good Design” Award for 2007 - 2008. These awards puts Sumitomo’s advanced technology on the

same level as the Toyota Prius, a world-renowned hybrid car. The integration of the newly-developed

“SPACE 5” Isuzu 4HK1X engine and the new Sumitomo intelligent hydraulic system (SIH:S)

improves fuel efficiency, engine output and torque.

Page 10

MINING EQUIPMENT DIVISION

Furukawa Hydraulic Hammers

With the range of Mini-excavators rapidly expanding, some 17 sub-divisions of bucket

capacities (from 0.5 to 5 tons) are now recognized. To match this increased range, the

new small F-series breakers are available in five models, each designed to match specific

needs. The new Furukawa maintenance-free breaker models, F1 to F5 offer a clear

distinction from combined hydraulic/gas ones. The F6 and F9 breakers are of the

combined hydraulic/gas design.

Furukawa Hydraulic Hammers can be fitted to any type of excavators, mini excavators, skid steer

loaders or backhoe loaders that are on the market.

FRD Excavator Attachments

A complete range of Furukawa excavator attachments is available - from

hydraulic crushers and cutters to compactors, demolition and sorting grabs for use in

rock breaking and demolition applications.

Furukawa Rock Drills

Furukawa Rock Drill products include the well-proven, rugged pneumatic

crawler drills, a full range of hydraulic and down-the-hole (DTH) crawler drills

available ex stock for small to medium surface blast-hole needs.

A wide range of underground drill rigs can be supplied to suit any underground

installation as well as a selection of pneumatic hand tools.

Kiverco Recycling Systems

Kiverco Recycling Systems is reputed to be a leading manufacturer of

Waste Recycling Systems for Construction and Demolition Waste. This

market-leading supplier provides many customers with its wide range of

equipment for use in the Waste Processing and Recycling industries and

offers superior operating efficiency combined with low level

maintenance requirements.

Page 11

McGirr Blockmakers

The McGirr Multilevel masterblock MkII is the most advanced automated

mobile block-making machine of its kind. Its innovative design enables the

machine to make all types of blocks, bricks and cavity blocks.

On tests the machine can produce in excess of 4500 solid blocks per hour making

it one of the most cost-effective and efficient mobile blockmaking machines on

the market. The unique system for raising and lowering the front end of the machine to facilitate

“any size of block on the market” makes this the most versatile machine available.

Powerscreen Mobile Crushing Plants

ELB Equipment provides a comprehensive range of high performance, high

quality jaw and cone crushers to meet the toughest crushing demands of

quarrying, demolition and recycling industries.

The machinery and plant are designed to give a long and trouble-free

operation.

Powerscreen Mobile Screening Plants

Powerscreen manufactures an extensive range of screening, shredding and washing equipment for

use in material processing industries. This equipment, with its unique screening action, is capable of

being used in a myriad of applications and industries - applications include sludge and ash as well as

aggregates such as: sand, gravel, hard rock, crushed rock, coal, limestone, mineral ores & many

others.

Taurus Heavy Duty Rotary Barrel Screen The Taurus Heavy Duty Rotary Barrel Screen is designed to meet the needs of the many mines, especially open pit mines, opting for in-field screening. It is a unit that is capable of taking the R.O.M. (Run of Mine) materials and separating it at throughput tonnages ranging from 250 to over 1000 tons/hour. The extra heavy duty rotary barrel screen can handle materials of 1 m² or larger and is therefore ideally suited to screen any type of ore.

All barrel screens are locally designed and built by ELB Equipment to suit the client’s specifications and are able to produce many different screened sizes of R.O.M. material from just the one machine. The unit can be installed as a fixed, skid-mounted or mobile unit.

Page 12

Telestack Telescopic and Tracked Conveyor Belts Mobile, track-mounted Telestack Telescopic Conveyor Belts provide ideal bulk materials handling solutions to the Quarrying, Ship loading and Mining industries. The range of products gives the customer total flexibility, efficiency and productivity in any application.

Terex Minerals Processing Systems

Terex Minerals Processing Systems (MPS) offers the most comprehensive crushing and screening lines on the market today. MPS was created to enhance customer satisfaction by providing applications expertise, process equipment, parts, service and complete systems for fixed-site crushing and screening of construction aggregates, industrial minerals, ore and demolition debris.

Terex Washing Systems (TWS)

Terex Washing Systems is a newly-launched product line within the Terex Material Processing segment and supports mines, quarries and aggregate producers globally offering a broad portfolio, including: sand wash and fines recovery plants, log washers, hoppers, feeders, conveyors, de-watering screens, static screens, mobile, static and modular wash plants, as well as the addition of combination plants and water management systems. TWS is committed to providing outstanding

customer support and expertise in the field to meet customers’ individual needs.

Page 13

ELB EQUIPMENT

HEAD OFFICE:

14 Atlas Road, Anderbolt, Boksburg 1459.Tel.: +27 (0)11 306-0700

Website: www.elbequipment.com ● E-mail: [email protected]

BRANCHES:

BRITS: +27 (0)12-250-1565 ● CAPE TOWN +27 (0)21 933-2383

DURBAN +27(0)31 464-6522 • EAST LONDON +27 (0)43 740-4530

GEORGE +27 (0)44 878-0874 • KIMBERLEY +27 (0)53 841-0040

MIDDELBURG +27 (0)13 246-2312

SUBSIDIARY:

ELB EAST AFRICA: NAIROBI, KENYA (+254) (0)20 807-0728

DEALERS:

LESOTHO: (27) 66 2831 3926 • MOZAMBIQUE: +258 2190 0469

NAMIBIA (00) 264 61 234-052

POLOKWANE +27 (0)81 329-8529 • SWAZILAND (00) 268 518-5348

ZAMBIA (+260) 212-210-642 • ZIMBABWE (+263) 4 48-5771/4

![[jaws days 2014]ELB/AutoScaling](https://static.fdocuments.in/doc/165x107/5595a4491a28ab357f8b4698/jaws-days-2014elbautoscaling.jpg)