COMMONWEALTH OF PENNSYLVANIA DEPARTMENT OF … · beam haunch detail shall conform to standard...

Transcript of COMMONWEALTH OF PENNSYLVANIA DEPARTMENT OF … · beam haunch detail shall conform to standard...

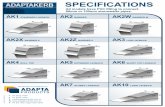

BD-601M

COMMONWEALTH OF PENNSYLVANIADEPARTMENT OF TRANSPORTATION

S

S3 BOTTOM

C PANELLS1

S2

TT

OT

AL

SL

AB

2

1

1

DE

SI

GN

SL

AB

THI

CK

NE

SS

S

C PANELLS1

S2 A

TT

OT

AL

SL

AB

2

DE

SI

GN

SL

AB

THI

CK

NE

SS

COMPOSITE POSITIVE MOMENT REGIONS

NEGATIVE MOMENT REGIONS

CONTINUOUS COMPOSITE

LAP

LAP

1

1

1

SIMPLE AND CONTINUOUS

2

S3 BOTTOM

3

3

4

T

HI

CK

NE

SS

5

T

HI

CK

NE

SS

5

5

1. DESIGN SPECIFICATIONS:

MODULAR RATIO (E /E ) N = 8

S1, S2, S5, AND S6 BARS

S4, S3, S3', AND S7 BARS

8. DETAIL ALL BARS ON THE CONTRACT DRAWINGS.

11. FOR SKEW ANGLES 75° AND MORE, PLACE TRANSVERSE REINFORCEMENT IN DECK SLAB PARALLEL TO CENTERLINE OF BEARINGS.

14. DESIGN IS BASED ON DECKS SUPPORTED ON 3 OR MORE BEAMS.

18. FACTORED MOMENT =

19. DYNAMIC LOAD ALLOWANCE (IM) = 50%

c

s c

2

NOTES:

2

3

3

STANDARD

CONCRETE DECK SLAB

DESIGN & DETAILS

FOR BEAM BRIDGES

MINIMUM BAR SIZE:

c

TYPICAL SLAB PANEL 1

SPLICE WITH S4 BARS

TYPICAL SLAB PANEL 2

AL

(S

EE

TA

BL

E 1

ON

SH

EE

T

NO. 8)

REFERENCE DRAWINGS

BC-732M

BC-788M

BC-767M

BC-762M

BC-739M

4

BAR SIZE: MAXIMUM BAR SIZE

SHEET 8 FOR MINIMUM HAUNCH REQUIREMENTS.

PROVIDE HAUNCH TO COMPENSATE FOR IRREGULARITIES IN CAMBER. SEE TABLE 1,

THE BEAM HAUNCH MAY BE CONSIDERED AS EFFECTIVE IN CONTRIBUTING TO THIS THICKNESS FOR THE OVERHANG DESIGN ONLY.

23. DRAWINGS ARE NOT TO SCALE.

66

66

1 SPACE BARS S3, S3', S4, S5 AND S6 SYMMETRICALLY ABOUT THE PANEL CENTERLINE.

12. SEE BC-767M AND BD-656M FOR ADDITIONAL REINFORCEMENT AT END OF DECK.

LIMITATIONS

DECK DESIGN PROCEDURE

BC-720M

BC-716M

BC-711M

ALUMINUM PEDESTRIAN RAILING

ALUMINUM PROTECTIVE BARRIER

BC-701M PROTECTIVE FENCE

ALUMINUM OR STEEL BRIDGE HAND RAILING

BRIDGE BARRIER TO GUIDE RAIL TRANSITION

TOOTH EXPANSION DAM

BD-656M

BD-662M

TYP. LONGITUDINAL SECTIONS I-BEAM AND

BOX BEAM BRIDGES

3 FOR PRESTRESSED CONCRETE BRIDGES MADE CONTINUOUS, DESIGN

5. USE ONLY FUSION BONDED EPOXY COATED REINFORCEMENT IN ACCORDANCE WITH PUBLICATION 408, SECTION 709.

BD-661M

BC-719M BRIDGE DECK TEMPORARY BARRIERS

24. FOR BARRIER REINFORCEMENT DETAILS, SEE SHEETS 6 AND 7.

LEGEND:

10. FOR HAUNCH DETAILS, SEE SHEET 8.

25. OVERHANG LENGTH MUST NOT EXCEED THE REQUIREMENTS OF DESIGN MANUAL PART 4, SECTION D9.7.1.5.1P.

BC-752M

BC-734M ANCHOR SYSTEMS

BC-718M ALTERNATE RAILING DETAILS

BC-751M BRIDGE DRAINAGE

CONCRETE DECK SLAB DETAILS

SUCH AS LIGHT POLES AND SIGN STRUCTURES ARE USED. SEE NOTE 27 FOR MODIFICATIONS REQUIRED WHEN SOUND BARRIERS ARE USED.

CONCRETE VERTICAL WALL BRIDGE BARRIERS AND BARRIERS WITH FENCES AND HANDRAILS. REDESIGN OF THE DECK IS REQUIRED WHEN OTHER ATTACHMENTS

WHERE CONDITIONS EXCEED THE ABOVE LIMITATIONS, PERFORM SPECIAL DECK DESIGN.

BARRIER AS DETAILED ON SHEET 4. STANDARD REINFORCEMENT MAY BE USED AS FOLLOWS:

16. THE TYPICAL BARRIER AND DECK SLABS, INCLUDING OVERHANGS, ARE DESIGNED TO RESIST A VEHICULAR COLLISION FORCE AT TEST LEVEL 5.

9. ALL DETAILS SHOWN ALSO APPLY TO P/S I-BEAMS, PA BULB-TEE AND P/S SPREAD BOX BEAMS EXCEPT AS NOTED.

I-BEAM AND PA BULB-TEE BEAM REINFORCEMENT DETAILS

BD-660M

BOX BEAM REINFORCEMENT DETAILS

DECK SLAB AND STEEL REINFORCEMENT PLACEMENT

BAR LENGTH ON CENTER OF NEGATIVE MOMENT AREA. STAGGER SPLICES AS PER BD-660M.

7 SPLICES SHOULD BE OUTSIDE OF NEGATIVE MOMENT AREA IF POSSIBLE, IF NOT, CENTER.

7

7

BD-679M STRUCTURE MOUNTED SOUND BARRIER WALLS

BC-779M STRUCTURE MOUNTED SOUND BARRIER WALLS

27. CONCRETE SOUND BARRIER SHOWN ON BC-779M AND BD-679M MAY BE MOUNTED ON THE TOP OF

7. DESIGN TABLES ARE VALID FOR NORMAL WEIGHT CONCRETE DECKS. FOR LIGHTWEIGHT CONCRETE DECKS, INCREASE THE LENGTH L LISTED IN

BC-775M MISCELLANEOUS PRESTRESS DETAILS

4

BD-609M

CHIEF BRIDGE ENGINEER

RECOMMENDEDRECOMMENDED

PA STRUCTURE MOUNTED GUIDE RAIL

21. FOR DECK SLAB AND BARRIER DETAILS AND REINFORCEMENT FOR ADJACENT PRESTRESSED CONCRETE BOX BEAMS, SEE BD-660M AND BD-661M.

BEAM HAUNCH DETAIL SHALL CONFORM TO STANDARD DRAWING BC-732M.

IS VERTICAL WHEN PERMANENT METAL DECK FORMS ARE USED IN PLACING THE DECK.

USE BEAM HAUNCH DETAILS SHOWN WITH REMOVABLE DECK FORMS. FACE OF HAUNCH

RC-65M CONCRETE MOUNTABLE CURBS

AASHTO LRFD BRIDGE DESIGN SPECIFICATIONS AND COMMENTARY

13. FOR TRANSITION OF LONGITUDINAL REINFORCEMENT FROM POSITIVE MOMENT AREA TO NEGATIVE MOMENT AREA, USE AASHTO ARTICLES

17. DECK DESIGN TABLES ARE BASED ON THE EQUIVALENT STRIP METHOD AS PER AASHTO, ARTICLE 4.6.2.1.

PERMANENT METAL DECK FORMS

TYPICAL WATERPROOFING AND EXPANSION DETAILS

SEE DESIGN MANUAL PART 4, SECTION D 5.4.3.1.

NEOPRENE STRIP SEAL DAM

SHEET 1 OF 10

BUREAU OF PROJECT DELIVERY

ACTING DIR, BUR. OF PROJECT DELIVERY

2. MATERIAL STRENGTH: REINFORCEMENT STEEL fy = 60 KSI

= 150 LB./FT

= 115 LB./FT

= 15 LB./FT

= 30 LB./FT

4. DESIGN CONTROLS: CONCRETE COVER: DECK TOTAL TOP COVER = 2•"

DECK BOTTOM COVER = 1"

BARRIER = 2"

SIDEWALK TOP COVER = 2•"

ALTERNATE SIDEWALK DETAIL BARRIER = 2"

MIN. CLEAR DISTANCE BETWEEN REINFORCEMENT MATS = 2", EXCEPT AS PERMITTED IN ALTERNATE CONTINUITY REINF. DETAIL, SHEET 8.

: #6, EXCEPT FOR BARS DESIGNED TO MEET 3

: #5

: #4

BAR SPACINGS: MAXIMUM SPACING = 12" SLAB

12" BARRIER

MINIMUM SPACING = 5•"

SPACING INCREMENTS = •"

THE TOP •" OF THE SLAB IS CONSIDERED TO BE AN INTEGRAL WEARING SURFACE.

THICKNESS INCREMENTS = •"

Z FACTOR FOR CRACK CONTROL = 130 KIPS/IN.

15. THE STRENGTH DESIGN OF THE OVERHANG IS BASED ON THE ASSUMPTION THAT THE ENTIRE OVERHANG HAS A MINIMUM THICKNESS OF T + 1".

BARRIER, MEDIAN BARRIER AND THE GLARE SCREEN MEDIAN BARRIER ARE DESIGNED TO RESIST VEHICULAR COLLISION AT TEST LEVEL 4.

THE SPLIT GLARE SCREEN MEDIAN BARRIERS, 32" ALTERNATE SIDEWALK DETAIL, THE ALTERNATE SPLIT MEDIAN BARRIER, ALTERNATE

HEIGHT OF SOUND BARRIER (ABOVE TOP OF BARRIER) 10'

THICKNESS ACROSS FULL WIDTH OF BRIDGE

INCREASE THE DESIGNATED DECK THICKNESS BY •", AND USE THIS

DECREASE THE DESIGNATED MAXIMUM ALLOWABLE OVERHANG LENGTH, So, BY 7"

INCREASE THE LENGTH OF S7 BARS BY 9"

ALTERNATE SIDEWALK, VERTICAL WALL BARRIER (WITHOUT RAILING) 530 LB./FT

CONCRETE DIVISOR TYPE A 260 LB./FT, TYPE B 280 LB./FT

SPLIT CONCRETE DIVISOR TYPE A 130 LB./FT, TYPE B 140 LB./FT

CONCRETE GLARE SCREEN MEDIAN BARRIER 960 LB./FT

CONCRETE MEDIAN BARRIER 700 LB./FT

ALTERNATE SPLIT CONCRETE MEDIAN BARRIER 520 LB./FT

SPLIT CONCRETE GLARE SCREEN MEDIAN BARRIER 750 LB./FT

ALTERNATE CONCRETE BARRIER 520 LB./FT

TYPICAL CONCRETE BARRIER 650 LB./FT

3'-1" #6 BARS

LIGHTWEIGHT CONCRETE: 3'-5" #5 BARS

4'-1" #6 BARS 20. SEE TABLES ON SHEET 9 FOR VALUES OF S, T, S1, S2, S3, S3', S6, S7, So, AND L.

WHERE THE BARRIER EXISTS, AT LEAST EQUAL TO THE OVERHANG TOP REINFORCEMENT AREA AS SHOWN ON SHEET 9.

26. THE SLAB REINFORCEMENT SHOWN ON SHEET 9 IS APPLICABLE FOR THE BARRIERS SHOWN ON SHEET 2, 3 AND 4, THE PA HT, TYPE 10M AND

LENGTH BASED ON THE BEAM SPACING, S

THICKNESS, REINFORCEMENT AND THE DESIGNATED MAXIMUM ALLOWANCE OVERHANG

USING THE TABLES AND NOTES ON SHEET 9, ESTABLISH STANDARD DECK

(SEE SHEET 9)

(SEE SHEET 9)

2•" CLR.

1" CLR.

S6 @ 12" MAX.-TOP

CLR.

2•"MAX.

6"

MAX.

6"

1" CLR.

REINFORCEMENT TABLES ON SHEET 9, BY 13".

6. FOR ALL BARRIER REINFORCEMENT AND FOR HOOKED OR BENT BARS IN THE DECK SLAB, DO NOT USE RAIL STEEL (A 996).

DECK THICKNESS: MINIMUM THICKNESS INCLUDING •" INTEGRAL WEARING SURFACE = ((DISTANCE BETWEEN DESIGN SECTIONS

NOV. 21, 2014NOV. 21, 2014

•" I

NT

EG

RA

L

#4 - S4 @ 12" MAX.-TOP

#5 - S5 @ 12" MAX.-TOP

A

@

C

BE

AM

S

•" I

NT

EG

RA

L

WE

ARI

NG

SU

RF

AC

E

S5 AND S6 BARS IN ACCORDANCE WITH DM-4 ARTICLE D5.14.1.4.

DECK SLAB LAP SPLICE LENGTH: NORMAL WEIGHT CONCRETE: 2'-7" #5 BARS

SPREAD BOX BEAM BRIDGE.

SEE SHEET 8. S3 AND S3' BARS DO NOT NEED TO BE PLACED OVER THE BEAM FOR

6 BEGIN S3 AND S3' BARS AT LOCATION OF DESIGN SECTION FOR NEGATIVE MOMENT,

PENNDOT DESIGN MANUAL PART 4

3. DEAD LOAD: NORMAL WEIGHT CONCRETE

LIGHTWEIGHT CONCRETE

PERMANENT METAL DECK FORMS

FUTURE WEARING SURFACE

FOR NEGATIVE MOMENT + 120") / 30 + •") 8",

5.14.1.4 AND 6.10.1.7 AS MODIFIED BY DESIGN MANUAL PART 4, SECTIONS D5.14.1.4 AND D6.10.1.7.

1.25 (SLAB AND BARRIER MOMENT) + 1.5 (FWS MOMENT) + 1.75 (1+IM/100)(L.L. MOMENT)

22. WHEN A TRAFFIC BARRIER IS MOUNTED ON THE DECK BETWEEN TWO GIRDERS, PROVIDE TOP AND BOTTOM REINFORCEMENT AREA IN THE DECK IN THE BAY

THE TYPICAL BARRIER 600 LB. PER FOOT OF LENGTH

WEIGHT OF SOUND BARRIER PLUS THE WEIGHT OF BARRIER AND DECK SLAB IN EXCESS OF

28. FOR DEAD LOAD CALCULATIONS, THE WEIGHT OF BARRIERS/DIVISORS SHOWN ON BD-601M ARE AS FOLLOWS:

L

(S

EE

TA

BL

E 1

ON

SH

EE

T

NO. 8)

A

@

C

BE

AM

S

WE

ARI

NG

SU

RF

AC

E

BC-706M PA STRUCTURE MOUNTED GUIDE RAIL BARRIER

MISCELLANEOUS DETAILS

BC-722M LIGHTING POLE ANCHORAGE

AND RAISED OR ALTERNATE SIDEWALKS.

CONCRETE f = 4 KSI (CLASS AAAP CONCRETE) FOR DECK SLABS AND INTEGRAL SIDEWALKS AND f = 3.5 KSI (CLASS AA CONCRETE) FOR BARRIERS

BD-601M

COMMONWEALTH OF PENNSYLVANIADEPARTMENT OF TRANSPORTATION

STANDARD

CONCRETE DECK SLAB

DESIGN & DETAILS

FOR BEAM BRIDGES

T

S7 3

LS2

So

2S1NOTCH

S3 (TYP.)

DRIP

S3 (TYP.)

S1

So

L

DRIP

NOTCH

1

S7 3 S2

T

2

3S7

So

DRIP NOTCH

1

1

L

S1

2

S2

T

*

NOTES:

* UNDERSIDE OF DECK SLAB MAY BE CONSTRUCTED LEVEL.

(SEE BC-788M FOR OPEN JOINT DETAIL)

T

S7 3

LS2

So

2S1

NOTCH

S3 (TYP.)

DRIP

(SEE BC-788M FOR OPEN JOINT DETAIL)

CHAMFER (TYP.)

CHAMFER (TYP.)

1

BARRIER DETAIL

SPECIFIED IN APPROACH ROADWAY.

TO BE USED WHEN CONCRETE MEDIAN BARRIER IS

MEDIAN BARRIER DETAIL

(TYP.)

CHAMFER

SPECIFIED IN APPROACH ROADWAY.

TO BE USED WHEN CONCRETE GLARE SCREEN IS

2 EXTEND ONE HALF OF THE S1, BOTTOM TRANSVERSE BARS, ACROSS THE FULL

WIDTH OF THE OVERHANG. THE ALTERNATE BARS WHICH DO NOT EXTEND INTO THE

3 BUNDLE THE BARS LISTED AS S7 IN THE REINFORCEMENT TABLES TO EACH S2 BAR.

4

0"

4

4

4

(SEE SHEET 8 FOR LOCATIONS)

FLANGE OF THE FASCIA BEAM.

S3 (TYP.)

LEGEND:

1

1

1

LEVEL (TYP.)

DRIP NOTCH

I-BEAM OR

BOX BEAM

OVERHANG REINFORCEMENT

TOP OF BEAM

TYPICAL CONCRETE BARRIER DETAIL

ALTERNATE CONCRETE BARRIER DETAIL

SPLIT CONCRETE GLARE SCREEN

ALTERNATE SPLIT CONCRETE MEDIAN

REINFORCEMENT BARS TO HALF THE SHOWN SPACING.

BARRIER AND AT THE END OF THE BRIDGE BARRIER, REDUCE SPACING OF

TYPICAL

(RAKED FINISH)

CONSTR. JT.

1

5

5

(RAKED FINISH)

& V-NOTCH

CONSTR. JT.

(RAKED FINISH)

& V-NOTCH

CONSTR. JT.

5

(RAKED FINISH)

CONSTR. JT.

5

5 FOR EMBEDMENT INTO THE CONCRETE BARRIER, SEE SHEET 6.

CHIEF BRIDGE ENGINEER

RECOMMENDEDRECOMMENDED

*

* *

**

6

66

6

6 FOR DRIP NOTCH DETAILS, SEE BC-775M.

6

SHEET 2 OF 10

BUREAU OF PROJECT DELIVERY

ACTING DIR, BUR. OF PROJECT DELIVERY

(SEE SHEET 9)

(SEE SHEET 9)

(SEE SHEET 9)

(SEE SHEET 9)

1'-8‚"

1'-0"

3…"

4‡"

5•"

ƒ"xƒ"

3…"

MAX. 6"

2" CLR. (TYP.)

#6

#5

MAX.

#4 @ 12"

#4 @ 12" MAX.

2" CLR. (TYP.)

2'-8"

3'-6"

7"

3"R=9‡

"

R=1" (TYP.

)

2"

0"

T+1" MIN.

2" MIN. COVER

4"

2" CLR.

1" CLR.

0"

11„"

4‚"

4‡"1'-8‚"

1"

4†"

#6

#5

ƒ"xƒ"

3…"

MAX. 6"

2" CLR. (TYP.)

3'-4"

4'-2"

7"

R=9‡

"

R=1" (TYP.

)

#4 @ 12" MAX.

#4 @ 12" MAX.

2" CLR. (TYP.)

3"

2"

0"

2" CLR.

2" MIN. COVER

4"

1" CLR.

0"

0"

1'-1"

2…"

4‡"1'-8‚"

1"

2" CLR. (TYP.)

ƒ"xƒ"

3…"

MAX. 6"

#6

#4 @ 12" MAX.

2" CLR. (TYP.)

R=9‡"

2"

R=1" (TYP.)

#5

#4 @ 12" MAX.

1'-10"

2'-8"

6•"

3"

0"

7"

2" CLR.

2" MIN. COVER

4"

1" CLR.

0"

0"

1'-8‚"

2…"

4‡"

CHAMFER (TYP.)

ƒ"xƒ"

3…"

MAX. 6"

2" CLR. (TYP.)

#4 @ 12" MAX.

2" CLR. (TYP.)

2"

6•"

#6

#4 @

12"

MAX.

#5

R=9‡

"

R=1" (TYP.

)3"

0"

1'-1"

1'-10"

2'-8"

7"

T+1" MIN.

2" MIN. COVER

4"0"

2" CLR.

0"

1" CLR.

(TO BE USED WHEN THE OVERHANG IS 3" OR MORE IN DEPTH)

2-#4 #4 @ 18"

3" OR MORE

4"

1 WITHIN 10' ON BOTH SIDES OF AN EXPANSION JOINT IN THE

OVERHANG SHALL EXTEND 6" MINIMUM BEYOND THE INTERIOR EDGE OF THE

3'-5•"

3'-5•"

NOV. 21, 2014NOV. 21, 2014

4 BEGIN S3 AND S3' BARS AT LOCATION OF DESIGN SECTION FOR NEGATIVE MOMENT.

4'-4" #6 BARS

2. BARRIER LAP SPLICE LENGTH: 3'-7" #5 BARS

1. FOR ADDITIONAL NOTES, SEE SHEET 1.

BD-601M

COMMONWEALTH OF PENNSYLVANIADEPARTMENT OF TRANSPORTATION

STANDARD

CONCRETE DECK SLAB

DESIGN & DETAILS

FOR BEAM BRIDGES

CONCRETE MEDIAN

CHAMFER (TYP.)

CHAMFER (TYP.)

R=9‡"

BARRIER DETAIL

R=9‡"

MEDIAN BARRIER DETAIL

CONCRETE GLARE SCREEN

2 EXTEND ONE HALF OF THE S1, BOTTOM TRANSVERSE BARS, ACROSS THE FULL

WIDTH OF THE OVERHANG. THE ALTERNATE BARS WHICH DO NOT EXTEND INTO THE

3 BUNDLE THE BARS LISTED AS S7 IN THE REINFORCEMENT TABLES TO EACH S2 BAR.

(SEE SHEET 8 FOR LOCATIONS)

FLANGE OF THE FASCIA BEAM.

SPLIT CONCRETE DIVISOR DETAILCONCRETE DIVISOR DETAIL

TO BE USED ONLY FOR BRIDGES WITHOUT LONGITUDINAL JOINTS.

1

1

1

1

S3 (TYP.)

S1

So

DRIP

NOTCH

S7

T

2

*

4

L JOINTC

T

2.0% 2.0%

LEGEND:

FOR TYPE A AND B DIVISORS, SET CROSS SLOPE AT 2.0%.

WIDTH AND SET CROSS SLOPE BETWEEN 1.0% AND 2.0%.

WHERE WIDER THAN SHOWN DIVISORS ARE USED, PROVIDE

S23

L

NOTES:

1. FOR ADDITIONAL NOTES, SEE SHEET 1.

TO BE USED ONLY FOR BRIDGES WITHOUT LONGITUDINAL JOINTS AND WHEN

CONCRETE GLARE SCREEN IS SPECIFIED IN APPROACH ROADWAY.

TO BE USED ONLY FOR BRIDGES WITHOUT LONGITUDINAL JOINTS AND

WHEN CONCRETE MEDIAN BARRIER IS SPECIFIED IN APPROACH ROADWAY.

REINFORCEMENT BARS TO HALF THE SHOWN SPACING.

BARRIER AND AT THE END OF THE BRIDGE BARRIER, REDUCE SPACING OF

(RAKED FINISH)

CONSTR. JT.

(RAKED FINISH)

CONSTR. JT.

(RAKED FINISH)

CONSTR. JT.

5

(RAKED FINISH)

CONSTR. JT.

5 FOR EMBEDMENT INTO THE CONCRETE BARRIER, SEE SHEET 6.

5

L 6 L 6

ON SHT.1.

S7 SEE NOTE 22ON SHT.1.

S7 SEE NOTE 22

*

UNDERSIDE OF DECK SLAB MAY BE CONSTRUCTED LEVEL.*

S2S2

77L 6 7 L 6 7

EXTEND THE DISTANCE "L" BEYOND THE ADJACENT BEAMS ON EACH SIDE.

6 IF THE BARRIER IS POSITIONED DIRECTLY ABOVE A GIRDER THE S7 BAR, IF REQUIRED MUST

7

SEE BC-788M FOR OPEN JOINT DETAIL

NOT FOR USE AS A MEDIAN BARRIER, SEE RC-65M.

NOT FOR USE AS A MEDIAN BARRIER, SEE RC-65M.

FOR DECK SLAB REINFORCEMENT, SEE TYPICAL SLAB PANEL DETAILS, SHEET 1.

CHIEF BRIDGE ENGINEER

RECOMMENDEDRECOMMENDED

NOTE 2)

(SEE

2. FOR DRIP NOTCH DETAILS, SEE BC-775M.

FOR DECK SLAB REINFORCEMENT, SEE TYPICAL SLAB PANEL DETAILS, SHT.1.

S1S1

FOR DECK SLAB REINFORCEMENT, SEE TYPICAL SLAB PANEL DETAILS, SHT.1.

FOR DECK SLAB REINFORCEMENT, SEE TYPICAL SLAB PANEL DETAILS, SHEET 1.

SHEET 3 OF 10

BUREAU OF PROJECT DELIVERY

ACTING DIR, BUR. OF PROJECT DELIVERY

(SEE SHEET 9)

2'-6‚"

4‡"

2…"

1'-3ƒ"

9•"

ƒ"xƒ"

2'-8"

1'-1

0"

7"

3"

#5

3…"

6" MAX.

#6

#4 @ 12"

#4 @ 12"

#5

2"

2"

R=1" (TYP.)

(TYP.)

2" CLR.

0"

2'-6‚"

4‡"

4‚"

1'-0"

5•"

ƒ"xƒ"

(TYP.)

2" CLR.

4'-2"

3'-4"

#5

3"

R=1" (TYP.)

3…"

6" MAX.

#6

#4 @ 12"

#4 @ 12"

#5

2"

2"

0"

7"

4'-0"

1'-0" TYPE A DIVISOR

1'-3" TYPE B DIVISOR

4" TYPE A DIVISOR

5" TYPE B DIVISOR

2"

0"

1'-0" TYPE A DIVISOR

9" TYPE B DIVISOR

#4 @ 12"

5-#5

2" CLR. (TYP.)

2"

2'-0"

1'-0" TYPE A DIVISOR

1'-3" TYPE B DIVISOR

4" TYPE A DIVISOR

5" TYPE B DIVISOR

2"

1'-0" TYPE A DIVISOR

9" TYPE B DIVISOR

#4 @ 12"

3-#5

2" CLR. (TYP.)

2"

0"

COVER

2" MIN.

4" (TYP.)

0"

1"

1 WITHIN 10' ON BOTH SIDES OF AN EXPANSION JOINT IN THE

OVERHANG SHALL EXTEND 6" MINIMUM BEYOND THE INTERIOR EDGE OF THE

3'-1" #6 BARS

LIGHTWEIGHT CONCRETE: 3'-5" #5 BARS

4'-1" #6 BARSNOV. 21, 2014NOV. 21, 2014

4'-4" #6 BARS

3. BARRIER LAP SPLICE LENGTH: 3'-7" #5 BARS

4 BEGIN S3 AND S3' BARS AT LOCATION OF DESIGN SECTION FOR NEGATIVE MOMENT.

DECK SLAB LAP SPLICE LENGTH: NORMAL WEIGHT CONCRETE: 2'-7" #5 BARS

BD-601M

COMMONWEALTH OF PENNSYLVANIADEPARTMENT OF TRANSPORTATION

STANDARD

CONCRETE DECK SLAB

DESIGN & DETAILS

FOR BEAM BRIDGES

VEHICULARCONCRETE

BARRIER

PEDESTRIAN RAILING, SIDEWALK

PROTECTIVE FENCE OR BARRIER

FOR ADDITIONAL DETAILS,

SEE BC-701M, BC-711M OR BC-716M

5

2 S1

LAP

S3 (TYP.)

WI

TH

OU

T

RAI

LI

NG

1

T

RAILING TO BE USED ONLY

WHEN AUTHORIZED BY THE

SIDEWALK WIDTH

S2

ALTERNATE SIDEWALK DETAIL

FOR DETAILS, SEE BC-720M

DISTRICT TRAFFIC ENGINEER

SIDEWALK WIDTH

RAILING TO BE USED ONLY

WHEN AUTHORIZED BY THE

FOR DETAILS, SEE BC-720M

DISTRICT TRAFFIC ENGINEER

ROADWAY)

(OVER UNDERPASS

(OTHER CONDITIONS)

FROM CONC.BARRIER

NOTCH

DRIP

T

S3 (TYP.)

S1

So

L

DRIP

NOTCH

1

S7 3 S2

2

CHAMFER (TYP.)

1

4

CONCRETE BARRIER WITH STRUCTURE

MOUNTED SOUND BARRIER DETAIL

WIDTH AS REQ'D.TO

ACCOMMODATE ANCHOR BOLTS

WITHIN BARRIER REINFORCEMENT

CAGE. SEE BC-779M

BARRIER DETAILS

2 EXTEND ONE HALF OF THE S1, BOTTOM TRANSVERSE BARS, ACROSS THE FULL

WIDTH OF THE OVERHANG. THE ALTERNATE BARS WHICH DO NOT EXTEND INTO THE

3 BUNDLE THE BARS LISTED AS S7 IN THE REINFORCEMENT TABLES TO EACH S2 BAR.

(SEE SHEET 8 FOR LOCATIONS)

5

WIDTH

FOR REINFORCING IN SIDEWALK

5 LAP

4

3S7

L

REAR FACE

DRAIN RUNOFF WITH CURB DRAINS THROUGH

IN SIDEWALK SLAB. WHERE CURB DRAINS

CONC. BARRIER OR WITH TYPE 2 SCUPPERS

ARE USED, SET SIDEWALK ELEVATION AT

GUTTERLINE ELEVATION. THIS MAY RESULT

IN INCREASED COVER FOR S2 & S7 BARS.

FLANGE OF THE FASCIA BEAM.

DRIP NOTCH

BARRIER DETAIL

SEE TYPICAL CONC.

OF CONC. BARRIER,

AND REINFORCING

FOR DIMENSIONS

LEGEND:

NOTES:

1. FOR ADDITIONAL NOTES, SEE SHEET 1.

BC-STANDARD FOR THE BARRIER TOP WIDTH.

BARRIER AND RAILINGS. SEE THE APPROPRIATE

DETAILS SIMILAR FOR PROTECTIVE FENCE, PROTECTIVE

MI

N.

5

2 S1

S3 (TYP.)

T

SIDEWALK WIDTH

S2

MA

X.

5 LAP

4

S2

DRIP NOTCH

MI

N.

RAISED SIDEWALK DETAIL

REAR FACE

RAILING. FOR DETAILS,

SEE BC-720M

LAP 5

PEDESTRIAN RAILING, SIDEWALK

PROTECTIVE FENCE OR BARRIER

FOR ADDITIONAL DETAILS,

SEE BC-701M, BC-711M OR BC-716M

6

6

6

7

6

7

6

CONC.BARRIER

UNDERSIDE OF DECK SLAB MAY BE

BEVEL DRAINS AS PER BC-751M.

CONSTRUCTED LEVEL

SEALER

APPROVED

SEAL WITH

ALTERNATE BARRIER REINFORCEMENT)

(SEE SHEET 2 FOR TYPICAL OR

REINFORCEMENT BARS TO HALF THE SHOWN SPACING.

BARRIER AND AT THE END OF THE BRIDGE BARRIER, REDUCE SPACING OF

(RAKED FINISH)

& V-NOTCH

CONSTR. JT.

CONSTR. JT. (RAKED FINISH)

JT. & V-NOTCH

(LEVEL) CONSTR.

(RAKED FINISH)

& V-NOTCH

CONSTR. JT.

(RAKED FINISH)

& V-NOTCH

CONSTR. JT.

ALTERNATE RAILING, BC-718M

ALTERNATE BARRIER REQUIRES

NOTE:

(SEE BC-751M)

CURB DRAIN

L

S7 3

8

LAP

8

BD-679M FOR SOUND

SEE BC-779M AND

SIDEWALK DETAIL.

DECK SLAB, SEE RAISED

L

CHIEF BRIDGE ENGINEER

RECOMMENDEDRECOMMENDED

2. FOR DRIP NOTCH DETAILS, SEE BC-775M.

T

1.5%, SLOPED AWAY

1.5%, SLOPED TOWARD

ROADWAY)(OVER UNDERPASS

(OTHER CONDITIONS)

FROM CONC.BARRIER

7CONC.BARRIER

1.5%, SLOPED AWAY

1.5%, SLOPED TOWARD

1.5%

SHEET 4 OF 10

BUREAU OF PROJECT DELIVERY

ACTING DIR, BUR. OF PROJECT DELIVERY

(1'-6" MIN.)

(SEE SHEET 9)

ƒ"xƒ"

3…"

4‡"

3…"

6" MAX.

(TYP.)

2" CLR.

#4 @ 12" MAX.

2" CLR. (TYP.)

2"

T+1" MIN.

2" MIN. COVER

4"

2'-8"

3'-6"

7"

#6

#5

MAX.

#4 @ 12"

3"R=9

‡"

R=1" (TYP)

0"

1" CLR.

0"0"

2" CLR.

T+1"

MI

N.

2"

3'-6" #4 @ 12"

CLR.

2•"

#5 @ 12" MAX.

2"

T+ 1"

2" MIN. COVER

4"

0"0"

#5 @ 12" MAX.

8"

MI

N.

3'-6"

1'-0"

5…"

CHAMFER (TYP.)

ƒ"xƒ"

3'-6"

WI

TH

OR

#4 BARS @ 12" MAX.

#5 BARS @ 12" MAX.

#4 @ 12"

CLR.

2•"

1"

1" R

AD.

8"

#5 BARS @ 12" MAX.

0"0"

4"

2" MIN. COVER

T+ 1"

2" 2" CLR. (TYP.)

1'-4" MIN.

2" CLR. (TYP.)

9"

6"#6

3…

"

#5

1 WITHIN 10' ON BOTH SIDES OF AN EXPANSION JOINT IN THE

OVERHANG SHALL EXTEND 6" MINIMUM BEYOND THE INTERIOR EDGE OF THE

3'-1" #6 BARS

LIGHTWEIGHT CONCRETE: 3'-5" #5 BARS

4'-1" #6 BARS

REAR FACE OF BARRIER 1" ABOVE

2'-2‚"

3'-6"

NOV. 21, 2014NOV. 21, 2014

MIN.

4'-4" #6 BARS

3. BARRIER LAP SPLICE LENGTH: 3'-7" #5 BARS

INTEGRAL SIDEWALK DETAIL

PROTECTED SIDEWALKS

4 BEGIN S3 AND S3' BARS AT LOCATION OF DESIGN SECTION FOR NEGATIVE MOMENT.

DECK SLAB LAP SPLICE LENGTH: NORMAL WEIGHT CONCRETE: 2'-7" #5 BARS

LESS THAN OR EQUAL TO 200 FEET (SEE DM-4 DC2.3.2.2.2).

LESS THAN OR EQUAL TO 45 MPH AND A STRUCTURE LENGTH

PERMITTED FOR BRIDGES WITH A POSTED VEHICULAR SPEED

(SEE DM-4 DC2.3.2.2.2).

THAN 200 FEET, UNLESS WAIVED BY THE DEPARTMENT

GREATER THAN 45 MPH OR A STRUCTURE LENGTH LONGER

REQUIRED FOR BRIDGES WITH A POSTED VEHICULAR SPEED

FRONT SIDE OF BARRIER.

REQUIRED MUST EXTEND A DISTANCE "L" BEYOND THE ADJACENT BEAMS ON

IF THE BARRIER IS POSITIONED DIRECTLY ABOVE A GIRDER THE S7 BAR IF

BD-601M

COMMONWEALTH OF PENNSYLVANIADEPARTMENT OF TRANSPORTATION

STANDARD

CONCRETE DECK SLAB

FOR BEAM BRIDGES

PLAN

ELEVATION

L POSTCL POSTCL POSTCL POSTC

2 SPA.@ 2 SPA.@ 2 SPA.@ 2 SPA.@ 2 SPA.@ 2 SPA.@ 2 SPA.@ 2 SPA.@ 2 SPA.@

A

A

T

SECTION A-AANCHOR BOLTS SHALL BE INSTALLED WITH

ANCHOR BOLT ALIGNMENT & PLACEMENT

W/BASEPLATE INSTALLED TO ENSURE PROPER

EITHER A TEMPLATE OR ACTUAL POST

PRIOR TO CONSTRUCTING CURB AND DECK,

NOTE:

S2 BARS (TYP.)

S7 BARS BUNDLED TO

RUB RAIL

MECHANICAL SPLICE

FEMALE END

VERTICAL REINFORCEMENT

REINFORCEMENT BAR DETAILS

MECHANICAL SPLICE

FEMALE END

ANCHOR BOLT BAR DETAIL

MECHANICAL SPLICE AS PER BULLETIN 15

MECHANICAL SPLICE AS PER BULLETIN 15

BOLT BARS

ANCHOR

CURB REINFORCEMENT SHOWN FOR CLARITY

THI

CK

NE

SS

DE

CK

S7

S2VERTICAL BARS

S1

S3

GUIDE RAIL

NOTES:

CHIEF BRIDGE ENGINEER

RECOMMENDEDRECOMMENDED

(TYP.)

CLR.

PA STRUCTURE MOUNTED

2. FOR PA STRUCTURE MOUNTED GUIDE RAIL DETAILS SEE BD-609M.

DESIGNATION BY FHWA.

1. MODIFIED STRUCTURE MOUNTED GUIDE RAIL BARRIER GRANTED TL3

3. FOR DRIP NOTCH DETAILS, SEE BC-775M.

(SEE NOTE 3)

DRIP NOTCH

SHEET 1.

BAR DETAILS ON BD-609M,

SEE CURB REINFORCEMENT

SHEET 5 OF 10

BUREAU OF PROJECT DELIVERY

ACTING DIR, BUR. OF PROJECT DELIVERY

3"

1'-

6"

3"

2" R

8•" 25"

2" R

(-)

2"

T

MI

NU

S

(-)

2"

T

MI

NU

S

ALL VERTICAL REINFORCEMENT #4

SEE SHT. 9, TABLES 1 THRU 4.

FOR SLAB AND OVERHANG REINFORCEMENT

6'-3"6'-3"

4"

9"15•"

6'-3"

15•"15•" 9"9"9"9"9"

9"2"

4"4"4"4"4"4"

8•

"8"

1'-

11"

10ƒ

"

1'-6ƒ"

(TYP.)

2" CLR.

5" 8" 5"

8"

1'-10" 1'-10"

1'-6"

2" R

8•"

T MINUS (-) 2"

NOV. 21, 2014NOV. 21, 2014

BD-601M

COMMONWEALTH OF PENNSYLVANIADEPARTMENT OF TRANSPORTATION

STANDARD

CONCRETE DECK SLAB

DESIGN & DETAILS

FOR BEAM BRIDGES

B

C

(FOR DIMENSIONS "B" AND "C", SEE TABLE 1)

T

B AND C DIMENSIONS

TABLE 1

9.0"

9.5"

8.5"

8.0"

B C

10.0"

10.5"

1'-9"

1'-9•"

1'-10"

11.0"

C

NOTE

0.44 C 0.44 C

REINFORCEMENT BAR NOTES

ALONG THE OUTSIDE EDGE.

2. DIMENSIONS ALONG CURVED PORTIONS OF BAR ARE MEASURED

1. REINFORCEMENT BAR DIMENSIONS ARE OUT TO OUT OF BAR.

2'-2‚"

** ****

REINFORCEMENT DETAILS

BARRIERS, SPILT GLARE SCREEN

AND SPLIT MEDIAN BARRIERS

G

M

S

Q

N

P

BARRIERS, SPLIT GLARE SCREEN

AND SPLIT MEDIAN BARRIER

(FOR DIMENSIONS M, N, P, Q AND S, SEE TABLE 2)

2'-0•"

2'-1‚"

2'-1ƒ"

MEDIAN BARRIERS

AND SPLIT GLARE SCREEN

BARRIERS,SPLIT MEDIAN

TABLE 2

M N P Q

BARRIER

TYPICAL

BARRIER

MEDIAN

SCREEN

GLARE

SPLIT

S

BARRIER

MEDIAN

AND SPLIT

BARRIER

ALTERNATE

6ƒ"

6ƒ"

4„" 6ƒ"

3…"

2‚"

2'-9•"

1'-11•"

3'-5•"

2'-7ƒ"

1'-9ƒ"

3'-3ƒ"

11.5" 2'-2ƒ"2'-0•"

(FOR DIMENSIONS "B" AND "C", SEE TABLE 1)

DIMENSION G TO BE

DETERMINED BY THE DESIGNERALTERNATE SIDEWALK

NOTES:FOR NOTES, SEE SHEET 1.

PROVIDE NECESSARY DIMENSIONS.

SLOPE LEG TO MATCH DECK CROSS-SLOPE. DESIGNER TO

WHEN THE DECK IS SLOPED AWAY FROM THE GUTTERLINE**

**

3…"

4•"

2•"

WITH SOUND BARRIER)

(DETERMINE DIMENSIONS N AND S FOR BARRIER

1'-10•"

1'-11"

1'-11•"

2'-0"

1'-11"

1'-11•"

2'-0"

BARRIERS WITH SOUND BARRIERS

AND ALUMINUM PROTECTIVE BARRIER

(AT CURB)

TOP OF DECK

(AT CURB)

TOP OF DECK

CHIEF BRIDGE ENGINEER

RECOMMENDEDRECOMMENDED SHEET 6 OF 10

BUREAU OF PROJECT DELIVERY

ACTING DIR, BUR. OF PROJECT DELIVERY

4"

4"

2ƒ"

1'-4•

"

2ƒ"

CONCRETE

NORMAL WEIGHT

1'-0"

CONCRETE

LIGHT WEIGHT

1'-3"

4"2ƒ"

1'-4•

"

2ƒ"

4"

4"

B -2•

"

CONCRETE

NORMAL WEIGHT

1'-0"

CONCRETE

LIGHT WEIGHT

1'-3"

CONCRETE

WEIGHT

5" NORMAL

CONCRETE

WEIGHT

9" LIGHT

4"

4„"

(T

YP.)

IN

SI

DE

RA

D.

=2"

(T

YP.)

IN

SI

DE

RA

D.

=2"

(T

YP.)

IN

SI

DE

RA

D.

=2"

4"3†"

4" (TYP.)

3"

T

+1'-8"*

OF 8'-0" AND LESS

DETAILED FOR SIDEWALK WIDTHS*

T

+1'-1

0•

"*

2" (

TY

P.)

IN

SI

DE

RA

D.

=

CONCRETE

NORMAL WEIGHT

1'-0"

CONCRETE

LIGHT WEIGHT

1'-3"

2" (

TY

P.)

IN

SI

DE

RA

D.

=

2'-9"

3"

5•"

4" (TYP.)

3"

NOV. 21, 2014NOV. 21, 2014

M, N, P, Q AND S DIMENSIONS

BD-601M

COMMONWEALTH OF PENNSYLVANIADEPARTMENT OF TRANSPORTATION

STANDARD

CONCRETE DECK SLAB

DESIGN & DETAILS

FOR BEAM BRIDGES

REINFORCEMENT BAR NOTES

ALONG THE OUTSIDE EDGE.

2. DIMENSIONS ALONG CURVED PORTIONS OF BAR ARE MEASURED

1. REINFORCEMENT BAR DIMENSIONS ARE OUT TO OUT OF BAR.

MEDIAN BARRIER GLARE SCREEN

MEDIAN BARRIER

REINFORCEMENT DETAILS

**

NOTES:FOR NOTES, SEE SHEET 1.

(TYP.)

** (TYP.)

(TYP.)

(T

YP.)

4‚" (TYP.)

TABLE 4

B CA D

TYPE A

TYPE B

DIVISORS

SPLIT CONCRETE DIVISOR

CONCRETE DIVISOR

**

19•"

T

+D

TABLE 3

B C

15"

A DDIVISORS

SPLIT

TYPE A

TYPE B

E

3•"

3…"

†"

R

R

R

B

(AT CURB)

TOP OF DECK

(T

YP.)

(AT CURB)

TOP OF DECK

15‚"

19ƒ"

20‚"

C

**

C

R

R

B

A

15ƒ" 15‚" 4‚" 1•"

E

F

E F

3‚"

A, B, C, D, E AND F DIMENSIONS

3•" 4‚"

4•"

(FOR DIMENSIONS A, B, C, D, E AND F, SEE TABLE 3)

(FOR DIMENSIONS A, B, C, D, AND E, SEE TABLE 4)

D

E

A

A, B, C, D, AND E DIMENSIONS

PROVIDE WIDTH AND A, B, AND C DIMENSIONS)

(WHERE WIDER THAN SHOWN DIVISIORS ARE USED,

•"

4‚"

5‚"20"

3"

•"

CHIEF BRIDGE ENGINEER

RECOMMENDEDRECOMMENDED SHEET 7 OF 10

BUREAU OF PROJECT DELIVERY

ACTING DIR, BUR. OF PROJECT DELIVERY

PROVIDE NECESSARY DIMENSIONS.

SLOPE LEG TO MATCH DECK CROSS-SLOPE. DESIGNER TO

WHEN THE DECK IS SLOPED AWAY FROM THE GUTTERLINE**

WEIGHT CONC.

1'-0" NORMAL

WEIGHT CONC.

1'-3" LIGHT

4"

T -4

ƒ"

INSIDE R= 2" (TYP.)

(T

YP.)

R=2"

IN

SI

DE1'-9" (

TY

P.)

WEIGHT CONC.

9" LIGHT

WEIGHT CONC.

5" NORMAL

8•"

2‚" (TYP.)

4„"12‚"4„"

3†" (TYP.)

3†" (TYP.)4"

(T

YP.)

R=2"

IN

SI

DE

3'-3" (

TY

P.)

WEIGHT CONC.

9" LIGHT

WEIGHT CONC.

5" NORMAL

4„" 4„"12‚"

4ƒ"

1'-

6•

"

1'-7"

T -1ƒ"

(TYP.)

WEIGHT CONC.

1'-3" LIGHT

WEIGHT CONC.

1'-0" NORMAL

10†"

(TYP.)

1•"

(TYP.)

4"

(TYP.)

(TYP.)

R= 2"

INSIDE

10†"4ƒ"

1'-7"

T -1ƒ"

(TYP.)

4"

1•"

1'-

6•

"

WEIGHT CONC.

1'-3" LIGHT

WEIGHT CONC.

1'-0" NORMAL

T -4ƒ

"

4"

INSIDE R= 2" (TYP.)

WEIGHT CONC.

1'-0" NORMAL

WEIGHT CONC.

1'-3" LIGHT

(TYP.)

R= 2"

INSIDE

NOV. 21, 2014NOV. 21, 2014

PROVIDE WIDTH AND A, B, C AND D DIMENSIONS)

(WHERE WIDER THAN SHOWN DIVISORS ARE USED,

H

1"

CL

R.

DESIGN SECTION

FOR NEGATIVE MOMENT

DESIGN SECTION

FOR NEGATIVE MOMENT

DESIGN SECTION

FOR NEGATIVE MOMENT

FLANGE

W1

4

FLANGE

FLANGE

1W

3

W W

BOX BEAMS

STEEL BEAMS

T

W

2

1W

DESIGN SECTION

FOR NEGATIVE MOMENT

TREAT EACH WEB OF A BOX BEAM AS

A SEPARATE RECTANGULAR BEAM.

W2

1

CL

CLCL

*

CL WEB

A

BD-601M

COMMONWEALTH OF PENNSYLVANIADEPARTMENT OF TRANSPORTATION

STANDARD

CONCRETE DECK SLAB

DESIGN & DETAILS

FOR BEAM BRIDGES

HAUNCH

P/S CONCRETE I BEAMSP/S CONCRETE

LOCATION OF DESIGN SECTION FOR NEGATIVE MOMENT IN DECK SLABS

A

*

DESIGN

COMPOSITE

ANYWHERE ACROSS WIDTH OF HAUNCH

LOCATION OF

LOCATION OF

LOCATION OF

LOCATION OF

STEEL I-BEAMS AND PLATE GIRDERS

PLAN CAMBER

HPLAN CAMBER

ALL

STEEL BEAMS

DESIGN

NON-COMPOSITE

TABLE 1: MINIMUM HAUNCH THICKNESSES

T

HAUNCH

ANYWHERE ACROSS WIDTH OF HAUNCH

(P/S SPREAD BOX BEAM SIMILAR)

P/S BEAM

SEE BD-662M

STANDARD P/S BEAM REINF.

T

HAUNCH

P/S BEAM

CLR.

T

TRANSVERSE REINF.

INSTRUCTIONS FOR DETAILING HAUNCH

REINFORCEMENT ON CONSTRUCTION PLANS

WHEN HAUNCH REINFORCEMENT IS REQUIRED

WHEN HAUNCH REINFORCEMENT IS NOT REQUIRED BASED ON COMPUTED BEAM CAMBERS

HAUNCH REINFORCEMENT DETAILS

NOTES:FOR NOTES, SEE SHEET 1.

CLR.

FLANGE

SHEETS 1, 2, 3 AND 4.

1. "T" IS THE DECK THICKNESS AS INDICATED ON

FOLLOWING WHEN DETERMINING DIMENSION "A":

BEAM AT THE CENTERLINE OF BEAM. INCLUDE THE

3. "A" IS THE DIMENSION FROM TOP OF DECK TO TOP OF

DECK THICKNESS, "T"

MINIMUM HAUNCH THICKNESS, "H"

EFFECT OF DECK CROSS SLOPE

T

STEEL BEAM/GIRDER

H

T

H

P/S CONCRETE BEAM

PLATE REGIONS OF STEEL BEAM BRIDGES.

ALONG THE FULL LENGTH OF BEAMS, INCLUDING SPLICE

2. PROVIDE THE SPECIFIED MINIMUM HAUNCH THICKNESSES

4. INCLUDE ONE OF THE FOLLOWING NOTES ON THE PLANS:

EACH BEAM/GIRDER ON THE SLAB PLAN OR ON ANOTHER APPROPRIATE DETAIL.

3. SHOW THE LIMITS OF HAUNCH REINFORCEMENT ALONG THE LENGTH OF

2. SHOW HAUNCH REINFORCEMENT DETAILS ON THE CONSTRUCTION PLANS.

1. DETAIL HAUNCH REINFORCEMENT ON THE REINFORCEMENT BAR SCHEDULE.

THICKNESSES SPECIFIED IN BC-752M."

BEAM CAMBERS OR OTHER CONSTRUCTION CONDITIONS PROVIDE ACTUAL HAUNCHES THAT EXCEED THE

CAMBERS. HOWEVER, PROVIDE HAUNCH REINFORCEMENT IN ACCORDANCE WITH BC-752M WHERE IRREGULAR

"BEAM HAUNCH REINFORCEMENT WAS NOT DETERMINED TO BE REQUIRED FOR THE COMPUTED BEAM

REINFORCEMENT DETAIL

ALTERNATE CONTINUITY

AASHTO TYPE P/S CONC. I-BEAM

STANDARD P/S BEAM REINF.

SEE BD-662M

P/S CONC. I-BEAMS, PA BULB-TEE AND

SPREAD BOX BEAMS

P/S CONC. PA I-BEAM & PA BULB-TEE BEAMS

& PA BULB-TEE BEAMS

CHIEF BRIDGE ENGINEER

RECOMMENDEDRECOMMENDED SHEET 8 OF 10

BUREAU OF PROJECT DELIVERY

ACTING DIR, BUR. OF PROJECT DELIVERY

UP TO 1•"

OVER 1•" TO 3"

OVER 3"

•"

ƒ"

1"

•"

2-#4

#3 @ 2xS1 SPACING

0"

1"

(TYP.)

1'-0" LAP

1'-3" (P/S I-BEAM)

1'-4" (PA BULB-TEE BEAM)

#3 @ 2xS1 SPACING

2-#4

(TYP.)

1'-0" LAP

1"

0"

(T

YP.)

PROVIDE WHEN HAUNCH THICKNESS IS 3" OR GREATER

PROVIDE WHEN HAUNCH THICKNESS IS 5" OR GREATER

2"

2-#4

LONGITUDINAL REINF. > #6

2" MIN.

MAINTAIN 2" MIN. BETWEEN THE REBAR MATS.

LONGITUDINAL REBARS CAN BE STAGGERED TO

AVOID INCREASE IN DECK SLAB THICKNESS IF

NOV. 21, 2014NOV. 21, 2014

MONOLITHIC

CONSTRUCTION

DESIGN SECTION

FOR NEGATIVE MOMENT

C

LOCATION OF

NEXT BEAMS

6"

(TYP.)

L STEM

** PROVIDE APPROPRIATE SHEET NUMBER(S).

WHERE ACTUAL HAUNCHES EXCEED THE THICKNESSES SPECIFIED IN BC-752M."

ADDITIONAL HAUNCH REINFORCEMENT IN OTHER REGIONS ALONG THE LENGTH OF THE BEAM

PROVIDES THE AMOUNT NECESSARY TO COVER THE LIMITS SHOWN ON SHEET **. PROVIDE

"THE HAUNCH REINFORCEMENT QUANTITY SHOWN ON THE REINFORCEMENT BAR SCHEDULE

OR GREATER ANYWHERE ACROSS WIDTH OF HAUNCH.

SIP FORMS ARE NOT PRESENT AND THE HAUNCH THICKNESS IS 3"

IS 5" OR GREATER ANYWHERE ACROSS WIDTH OF HAUNCH OR WHEN

PROVIDE WHEN SIP FORMS ARE PRESENT AND HAUNCH THICKNESS

BD-601M

COMMONWEALTH OF PENNSYLVANIADEPARTMENT OF TRANSPORTATION

STANDARD

CONCRETE DECK SLAB

DESIGN & DETAILS

FOR BEAM BRIDGES

So

So

So

BOX BEAM

DESIGN NOTES:

L BEAMC

L BEAMCL WEBC

5.

NOTES:

(A) THE OVERHANG LENGTH, So, SHOWN MAY BE INCREASED BY UP TO 5 INCHES IF #5 S7 BARS REPLACE

THE #4 S7 BARS SHOWN. THE LENGTH "L" SHALL BE TAKEN NO LESS THAN 4'-3".

(C) WHEN THE LENGTH OF THE OVERHANG IS INCREASED IN ACCORDANCE WITH NOTE (A) OR (B) ABOVE,

- THE OVERHANG LENGTH, So, DOES NOT EXCEED THE SMALLER OF:

- THE LIMIT DETERMINED IN NOTE "C" ABOVE

- 3'-9" FOR OVERHANGS SUPPORTING BARRIERS OR 3'-8" FOR OVERHANGS SUPPORTING SPLIT

MEDIAN BARRIERS

- S2 BARS SHOWN IN THE TABLES ARE REPLACED WITH:

CONDITIONS ARE SATISFIED:

THE INCREASED OVERHANG LENGTH SHALL NOT EXCEED THE LIMITS STATED IN DESIGN MANUAL PART 4,

SECTION D9.7.1.5.1P.

#6 @ 7" FOR 8" THICK DECKS

#6 @ 7•" FOR 8•" THICK DECKS

(B) THE OVERHANG LENGTH, So, SHOWN MAY BE INCREASED BY UP TO 8 INCHES IF #4 S7 BARS ARE BUNDLED TO

EACH S2 BAR SHOWN. THE OVERHANG LENGTH, So, SHOWN MAY BE INCREASED BY UP TO 13 INCHES IF #5 S7

BARS ARE BUNDLED TO EACH S2 BAR SHOWN. THE LENGTH "L" SHALL BE TAKEN NO LESS THAN 4'-3".

DEFINITION OF So (OVERHANG LENGTH)

TO CENTERLINE OF BEAM = 0 IN.

TABLE 1: DISTANCE FROM DESIGN SECTION FOR NEGATIVE MOMENT

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

S

8

S1 S2 S3 S6

#5

So L

9

9

9

10

10

11

4'-3"

4'-7"

4'-11"

5'-2"

5'-10"

6'-2"

6'-6"

6'-10"

7'-2"

7'-6"

7'-10"

8'-2"

8'-6"

8'-10"

9'-2"

9'-6"

9'-10"

10'-2"

10'-5"

10'-9"

11'-1"

11'-5"

11'-9"

12'-1"

12'-5"

12'-9"

13'-1"

13'-5"

13'-9"

14'-1"

14'-5"

14'-9"

15'-1"

5'-6"

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8-1/2

8-1/2

8-1/2

9-1/2

9-1/2

9-1/2

9-1/2

10-1/2

10-1/2

11-1/2

11-1/2

11-1/2

11-1/2

#5 @9-1/2

#5 @9-1/2

#5 @9

#5 @9

#5 @9

#5 @9

#5 @8-1/2

#5 @8

#5 @8

#5 @7-1/2

#5 @7

#5 @7

#5 @7

#5 @7

#5 @6-1/2

#5 @6-1/2

#5 @6-1/2

#5 @6

#5 @6-1/2

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6-1/2

#5 @6

#5 @6-1/2

#5 @6

#5 @11-1/2

#5 @10

#5 @9

#5 @8

#5 @7

#5 @6

#5 @7-1/2

#5 @6-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#6 @7

#6 @7

#6 @7

#6 @7

#6 @7

#6 @6

#6 @6

#6 @6

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @6-1/2

#6 @6-1/2

#6 @6-1/2

#4 @9

#4 @9

#4 @9

#4 @9

#4 @8-1/2

#4 @8-1/2

#4 @8

#4 @7-1/2

#4 @7-1/2

#5 @11

#5 @11

#5 @10

#5 @10

#5 @10

#5 @9-1/2

#5 @9-1/2

#5 @9-1/2

#5 @9-1/2

#5 @9

#5 @9

#5 @9

#5 @9

#5 @9

#5 @9-1/2

#5 @9-1/2

#5 @9-1/2

#5 @10

#5 @10

#5 @10

#5 @10-1/2

#5 @11

#5 @10-1/2

#5 @11

#5 @11

T(in.) S3'

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#6

S7+

1 #6

1 #5

1 #5

1 #4

1 #4

1 #4

1 #4

1 #4

1 #4

1 #4

1 #4

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

2'-8"

2'-10"

3'-1"

3'-3"

3'-5"

3'-8"

3'-10"

4'-1"

4'-3"

4'-5"

4'-5"

3'-9"

3'-9"

3'-9"

3'-10"

3'-11"

3'-11"

4'-0"

4'-3"

4'-5"

4'-5"

4'-7"

4'-10"

4'-10"

4'-10"

5'-2"

5'-2"

5'-5"

5'-5"

5'-8"

6'-0"

6'-0"

6'-0"

6'-0"

3'-1"

3'-1"

2'-10"

2'-10"

2'-10"

2'-5"

2'-6"

2'-4"

2'-3"

2'-3"

2'-3"

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

TO CENTERLINE OF BEAM = 3 IN.

TABLE 2: DISTANCE FROM DESIGN SECTION FOR NEGATIVE MOMENT

A,C

A,C

A,C

A,C

A,C

A,C

A,C

A,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

* STEEL I-BEAMS WHEN: 12" < TOP FLANGE WIDTH < 24"

* PRECAST PRESTRESSED I-BEAMS WITH TOP FLANGE WIDTH < 18"

USE FOR:

S S1 S2 S3 S6 So L

#5

NOTES NOTES

4'-3"

4'-7"

4'-11"

5'-2"

5'-6"

5'-10"

6'-2"

6'-6"

6'-10"

7'-2"

7'-6"

7'-10"

8'-2"

8'-6"

8'-10"

9'-2"

9'-6"

9'-10"

10'-2"

10'-5"

10'-9"

11'-1"

11'-5"

11'-9"

12'-1"

12'-5"

12'-9"

13'-1"

13'-5"

13'-9"

14'-1"

14'-5"

14'-9"

15'-1"

8

9

9

9

10

11

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8-1/2

8-1/2

9-1/2

9-1/2

9-1/2

9-1/2

10-1/2

10-1/2

11-1/2

T(in.)

8

11

9-1/2

9-1/2

8-1/2

#5 @9-1/2

#5 @9-1/2

#5 @9

#5 @9

#5 @9

#5 @9

#5 @8-1/2

#5 @8

#5 @8

#5 @7-1/2

#5 @7

#5 @7

#5 @7

#5 @7

#5 @6-1/2

#5 @6-1/2

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @5-1/2

#5 @6

#5 @6

#5 @5-1/2

#5 @6

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @6

#5 @5-1/2

#5 @5-1/2

#5 @6

#5 @6

#5 @11-1/2

#5 @11

#5 @10

#5 @9

#5 @8

#5 @7

#5 @7

#5 @6

#5 @8-1/2

#5 @7-1/2

#5 @6-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#6 @7

#6 @7

#6 @6

#6 @6-1/2

#6 @6-1/2

#6 @6

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#4 @9

#4 @9

#4 @9

#4 @9

#4 @8-1/2

#4 @8-1/2

#4 @8

#4 @7-1/2

#4 @7-1/2

#5 @11

#5 @11

#5 @10

#5 @10

#5 @10

#5 @9

#5 @9

#5 @10

#5 @9-1/2

#5 @9

#5 @9

#5 @9

#5 @9

#5 @9

#5 @9

#5 @9

#5 @9

#5 @9

#5 @9-1/2

#5 @8-1/2

#5 @9-1/2

#5 @9-1/2

#5 @10-1/2

#5 @9-1/2

#5 @10-1/2

S3'

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

S7+

1 #6

1 #6

1 #5

1 #5

1 #4

1 #4

1 #4

1 #4

1 #4

1 #4

1 #4

1 #4

1 #4

1 #4

1 #4

1 #4

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

2'-8"

2'-10"

3'-1"

3'-3"

3'-5"

3'-8"

3'-10"

4'-1"

4'-2"

4'-4"

4'-6"

4'-8"

4'-8"

4'-8"

4'-8"

4'-8"

4'-2"

4'-4"

4'-6"

4'-8"

4'-11"

5'-2"

5'-2"

5'-2"

5'-2"

4'-8"

5'-6"

5'-9"

5'-9"

6'-0"

6'-0"

6'-0"

3'-0"

3'-2"

2'-10"

2'-11"

3'-0"

2'-9"

2'-8"

2'-8"

2'-8"

2'-6"

2'-6"

2'-6"

2'-6"

2'-6"

2'-4"

2'-4"

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

TO CENTERLINE OF BEAM = 6 IN.

TABLE 3: DISTANCE FROM DESIGN SECTION FOR NEGATIVE MOMENT

A,C

B,C

A,C

A,C

A,C

A,C

A,C

A,C

A,C

A,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

S T(in.) S1 S2 S3 S3' S6 S7+ So L NOTES

8 #5

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

9

9

9

10

10

4'-3"

4'-7"

4'-11"

5'-2"

5'-6"

5'-10"

6'-2"

6'-6"

6'-10"

7'-2"

7'-6"

7'-10"

8'-2"

8'-6"

8'-10"

9'-2"

9'-6"

9'-10"

10'-2"

10'-5"

10'-9"

11'-1"

11'-5"

11'-9"

12'-1"

12'-5"

12'-9"

13'-1"

13'-5"

13'-9"

14'-1"

14'-5"

14'-9"

15'-1"

8-1/2

8-1/2

8-1/2

9-1/2

9-1/2

9-1/2

9-1/2

9-1/2

9-1/2

10-1/2

10-1/2

#5 @9-1/2

#5 @9-1/2

#5 @9

#5 @9

#5 @9

#5 @9

#5 @8-1/2

#5 @8

#5 @8

#5 @7-1/2

#5 @7

#5 @7

#5 @7

#5 @7

#5 @6-1/2

#5 @6

#5 @6

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @11-1/2

#5 @11-1/2

#5 @11-1/2

#5 @11

#5 @10

#5 @9

#5 @9

#5 @8

#5 @7

#5 @7

#5 @7

#5 @6

#6 @7

#5 @8-1/2

#5 @7-1/2

#5 @6-1/2

#5 @6-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#6 @7

#6 @6

#6 @6-1/2

#6 @6-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#6 @5-1/2

#4 @9

#4 @9

#4 @9

#4 @9

#4 @8-1/2

#4 @8-1/2

#4 @8

#4 @7-1/2

#4 @7-1/2

#5 @11

#5 @11

#5 @10

#5 @10

#5 @10

#5 @9-1/2

#5 @9

#5 @9

#5 @8-1/2

#5 @9

#5 @8-1/2

#5 @8-1/2

#5 @8-1/2

#5 @8-1/2

#5 @8-1/2

#5 @8-1/2

#5 @9

#5 @8

#5 @9

#5 @8-1/2

#5 @8-1/2

#5 @9

#5 @9

#5 @9

#5 @9

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

1 #6

1 #6

1 #6

1 #6

1 #5

1 #5

1 #5

1 #4

1 #4

1 #4

1 #4

1 #4

1 #4

1 #4

1 #4

1 #4

1 #4

1 #4

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

2'-8"

2'-10"

3'-1"

3'-3"

3'-5"

3'-8"

3'-10"

4'-0"

4'-2"

4'-3"

4'-5"

4'-5"

4'-5"

4'-7"

4'-10"

5'-0"

5'-0"

4'-3"

4'-3"

4'-5"

4'-7"

4'-9"

4'-9"

5'-3"

5'-6"

5'-6"

5'-6"

5'-6"

5'-6"

4'-7"

5'-10"

5'-10"

6'-0"

6'-0"

3'-3"

3'-3"

3'-4"

3'-6"

3'-2"

3'-2"

3'-2"

3'-1"

3'-0"

3'-0"

3'-0"

3'-0"

2'-11"

2'-9"

2'-11"

2'-9"

2'-9"

2'-9"

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

TO CENTERLINE OF BEAM = 12 IN.

TABLE 4: DISTANCE FROM DESIGN SECTION FOR NEGATIVE MOMENT

S S1 S2 S3 S6 So L

8

#6

9

9

9

10

T(in.) S3' S7+ NOTES

A,C

B,C

A,C

A,C

A,C

A,C

A,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

B,C

4'-3"

4'-7"

4'-11"

5'-2"

5'-6"

5'-10"

6'-2"

6'-6"

6'-10"

7'-2"

7'-6"

7'-10"

8'-2"

8'-6"

8'-10"

9'-2"

9'-6"

9'-10"

10'-2"

10'-5"

10'-9"

11'-1"

11'-5"

11'-9"

12'-1"

12'-5"

12'-9"

13'-1"

13'-5"

13'-9"

14'-1"

14'-5"

14'-9"

15'-1"

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8-1/2

8-1/2

8-1/2

9-1/2

9-1/2

9-1/2

9-1/2

9-1/2

9-1/2

#5 @9-1/2

#5 @9-1/2

#5 @9

#5 @9

#5 @9

#5 @9

#5 @8-1/2

#5 @8

#5 @8

#5 @7-1/2

#5 @7

#5 @7

#5 @7

#5 @7

#5 @6-1/2

#5 @6

#5 @6

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#6 @7

#5 @5-1/2

#5 @5-1/2

#6 @7

#5 @5-1/2

#6 @7

#6 @7

#6 @7

#5 @11-1/2

#5 @11-1/2

#5 @11-1/2

#5 @11-1/2

#5 @11-1/2

#5 @11-1/2

#5 @11-1/2

#5 @11-1/2

#5 @11

#5 @11

#5 @10

#5 @9-1/2

#5 @9

#5 @9

#5 @8-1/2

#5 @8

#5 @7-1/2

#5 @7

#5 @7

#5 @6-1/2

#5 @6

#5 @6

#5 @5-1/2

#5 @5-1/2

#5 @5-1/2

#6 @7

#6 @7

#6 @7

#6 @6

#6 @6

#6 @6

#6 @6

#6 @6-1/2

#6 @5-1/2

#4 @9

#4 @9

#4 @9

#4 @9

#4 @8

#4 @8-1/2

#4 @8-1/2

#4 @7-1/2

#4 @7-1/2

#5 @11

#5 @11

#5 @10

#5 @10

#5 @10

#5 @9-1/2

#5 @9

#5 @9

#5 @8-1/2

#5 @8-1/2

#5 @7-1/2

#5 @7-1/2

#5 @7-1/2

#5 @7-1/2

#5 @7-1/2

#5 @7-1/2

#5 @7-1/2

#5 @7

#5 @8

#5 @8

#5 @7

#5 @8-1/2

#5 @7-1/2

#5 @7-1/2

#5 @7-1/2

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#4 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5 @6

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#5

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

1#6

1#6

1#6

1#6

1#6

1#6

1#6

1#6

1#6

1#6

1#5

1#5

1#5

1#5

1#4

---

---

---

---

---

---

---

---

---

---

---

---

2'-8"

2'-10"

3'-1"

3'-3"

3'-5"

3'-8"

3'-10"

4'-1"

4'-3"

4'-6"

4'-8"

4'-10"

4'-11"

4'-11"

4'-8"

4'-10"

4'-11"

5'-1"

5'-1"

5'-4"

5'-6"

5'-10"

4'-10"

4'-10"

5'-0"

5'-3"

5'-3"

5'-5"

5'-8"

5'-10"

5'-10"

5'-10"

6'-0"

6'-0"

3'-9"

3'-9"

3'-9"

3'-9"

3'-9"

3'-10"

3'-11"

4'-1"

4'-0"

4'-0"

3'-10"

3'-10"

3'-10"

3'-10"

3'-9"

3'-8"

3'-5"

3'-5"

3'-4"

4'-0"

4'-0"

4'-0"

---

---

---

---

---

---

---

---

---

---

---

---

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#6

#5 @6

#5

#5

1#4

1#4

1#4

1#4

1#4

1#4

1#4

USE FOR:

* PRECAST PRESTRESSED PA BULB-TEE AND I-BEAMS WITH TOP FLANGE WIDTH > 36"

* STEEL I-BEAMS OR STEEL CLOSED BOXES WITH TOP FLANGE WIDTH > 48"

4'-0"

4'-0"

* STEEL I-BEAMS WITH TOP FLANGE WIDTH < 12"

* PLANK BEAMS

* PRECAST PRESTRESSED SPREAD BOX BEAMS

USE FOR:

CHIEF BRIDGE ENGINEER

RECOMMENDEDRECOMMENDED

GUTTERLINE

GUTTERLINE

GUTTERLINE

L

L

L

SHEET 9 OF 10

BUREAU OF PROJECT DELIVERY

ACTING DIR, BUR. OF PROJECT DELIVERY

NOV. 21, 2014NOV. 21, 2014

NEXT BEAM

STEEL I-BEAM, P/S I-BEAM AND PA BULB-TEE

<

* NEXT BEAMS

* STEEL I-BEAMS WHEN: 24" < TOP FLANGE WIDTH < 48"

* PRECAST PRESTRESSED I-BEAMS WHEN: 18" < TOP FLANGE WIDTH < 36"

USE FOR:

T

5' STEM SPACING

� STEM

DIMENSION "L", SEE SHEETS 2, 3 AND 4.

4. FOR LOCATION OF REINFORCEMENT BARS, SEE SHEETS 1, 2, 3 AND 4. FOR LOCATION OF

SEE NOTES 26, 27 AND 28 ON SHEET 1 FOR ADDITIONAL LIMITATIONS.

BY 1".

FOR SPLIT MEDIAN BARRIERS, REDUCE THE So VALUES LISTED IN THE TABLES

OVERHANG LENGTHS UTILIZING THE SPECIFIED REINFORCEMENT.

THE So VALUES SHOWN IN THE TABLES INDICATE THE MAXIMUM ALLOWABLE

FOR DEFINITION OF "So", SEE DETAILS THIS SHEET.

3. OVERHANG LENGTH, "So"

2. "T" = TOTAL SLAB THICKNESS, INCLUDES •" INTEGRAL WEARING SURFACE.

WHERE S <4'-3", USE S = 4'-3"

S = BEAM SPACING - 6'-0" FOR BEAM SPACING >10'-0" (BEAM WIDTH)

S = 4'-3" FOR BEAM SPACING 10'-0" (BEAM WIDTH)

NEXT BEAMS:

S = MAXIMUM BEAM SPACING - 3'-7" [48" WIDE BEAMS]

S = MAXIMUM BEAM SPACING - 2'-7" [36" WIDE BEAMS]

SPREAD BOX BEAMS:

S = MAXIMUM BEAM SPACING, CENTERLINE TO CENTERLINE OF ADJACENT BEAMS

ALL EXCEPT SPREAD BOX BEAMS AND NEXT BEAMS:

1. BEAM SPACING, "S"

+ FOR BRIDGES WITH TOTAL WIDTH NO MORE THAN 36', THE S7 BARS MAY BE ELIMINATED IF THE FOLLOWING

MOMENT TO THE CENTERLINE OF BEAMS EQUAL TO OR SMALLER THAN THE CALCULATED DISTANCE.

USE THE REINFORCEMENT TABLE WHICH CAPTION SHOWS A DISTANCE FROM THE DESIGN SECTION FOR NEGATIVE

THE DESIGN SECTION FOR NEGATIVE MOMENT TO THE CENTERLINE OF BEAM USING THE SKETCHES ON SHEET 8.

FOR OTHER BEAMS NOT LISTED UNDER THE HEADING OF THE TABLES ABOVE, DETERMINE THE DISTANCE FROM

CONSTR. JOINT

BASE PLATE

ABOVE TOP OF

FOR ANCHOR BOLTS

C LIGHTING POLE

C CONDUITL

L

HANDHOLE

LEVELING NUT (TYP.)

CL LIGHTING POLE

C

CO

ND

UI

TL

ANCHOR ANGLES

1 2 3

B B

R

(T

YP)

R(T

YP)

R(T

YP)

BD-601M

COMMONWEALTH OF PENNSYLVANIADEPARTMENT OF TRANSPORTATION

STANDARD

GUTTER LINE

AB

BASE PLATE

GUTTER LINE

CONCRETE DECK

LIGHTING POLE ANCHORAGE DETAILS

SHEET 2.

BARRIER DETAIL SEE

FOR TYP. CONCRETE

PLAN

SECTION A-AELEVATION

A

A

NOTES:

2. SET ANCHOR BOLTS ACCURATELY BY THE TEMPLATE FURNISHED

BY THE MANUFACTURER, TO THE CORRECT ELEVATION AND

ALIGNMENT AND SECURELY BRACE AGAINST DISPLACEMENT

BEFORE THE SURROUNDING CONCRETE IS PLACED. ANCHOR BOLT

DIAMETER AS REQUIRED BY LIGHTING POLE MANUFACTURER.

(FOR FUTURE LIGHTING PROVISIONS, SEE CHART ON THIS SHEET.)

3. SEAL CONDUIT AND PROTECT THREADS FOR FUTURE LIGHTING

1. PROVIDE MATERIALS AND WORKMANSHIP IN ACCORDANCE WITH

PUBLICATION 408.

FOR CONDUIT.

LEVELING NUTS.

5. SET LIGHTING POLES TRULY VERTICAL WITH BASES LEVEL USING

INSTALLATIONS.

9. PREFERRED LOCATION FOR LIGHTING POLES IS AT PIERS AND

REINFORCEMENT TABLE

MARK NUMBER TYPE

2

SIZE Y Z

PROVISIONS FOR FUTURE LIGHTING

MOUNTING

HEIGHT

ANCHOR BOLT

CIRCLE DIA.ANCHOR BOLT

DIAMETER

REINFORCEMENT BAR NOTES

REINFORCEMENT DETAILS

"A" "B" "C"

TYPICAL

ALTERNATE

C

6

7

4

2

1

3

3

----

----

X

Y

X

X

Y

Z

TYPICAL

LENGTH

ALTERNATE

LENGTH

TYPICALX

ALTERNATEX

"D"

D

X

Y

CONCRETE DECK SLAB

FOR BEAM BRIDGES

CHIEF BRIDGE ENGINEER

RECOMMENDEDRECOMMENDED

TYPEBARRIER

NOT SHOWN, SEE SHEET 2.

8. FOR GEOMETRIC AND REINFORCEMENT DETAILS OF THE BARRIER

SHEET 10 OF 10

BUREAU OF PROJECT DELIVERY

ACTING DIR, BUR. OF PROJECT DELIVERY

(SEE NOTE 9)

LIGHTING POLE SUPPORT, (SEE NOTE 9)

LIGHTING POLE SUPPORT,

404

406

501

502

4

4

5

5

8'-2"

5'-11"

5'-3†"

5'-10†"

7'-4"

5'-11"

4'-7†"

5'-2†"

3'-10"

2'-0"

2'-8"

2'-8"

3'-0"

2'-0"

2'-0"

2'-0"

50'-0" MAX. 15" 1"

3†"5•"

4"

2"2"

OF THE REINFORCEMENT BAR.

FOR #5 BARS, IS MEASURED TO THE INSIDE EDGE

3. RADIUS, R= 2", FOR #4 BARS AND R= 3",

WITH PUBLICATION 408, SECTION 709.1(c).

2. EPOXY COAT ALL REINFORCEMENT STEEL IN ACCORDANCE

MEASURED ALONG THE OUTSIDE EDGE.

1. DIMENSIONS ALONG CURVED PORTIONS OF BAR ARE

PEDESTAL

GROOVE IN

1" DRAIN

406

501

404

502

404404

501

1'-7"

1•

"

1'-0" 1'-0"

1•

"

9•

"1'-

8‚

"

1•"

1'-

9"

406

4x4x•x1'-8"

404

CONDUIT

2" DIA.

REQ'D., TOP ONLY.

SPRING LOCK WASHER AS

501 OR 502

2" PROJECTION

404

406

501501

CONDUIT (TYP.)

2" DIA.

502

1'-0"

1'-1"

11" 3'-6"

2'-8"

3…"

2…"

6. PROVIDE 2" CLEAR ON ALL REINFORCEMENT UNLESS NOTED.

7. PROVIDE A MINIMUM OF 2•" CONCRETE COVER

4'-0"

1'-7"

4•"

11•"

1'-6"

1'-6"

NOV. 21, 2014NOV. 21, 2014

NUTS, 2" DIA. x ‰"

THREAD EACH END, HEX.

4-ANCHOR BOLTS, 4"

SUPPORT DETAIL. LIGHTING POLE SUPPORT, IF NEEDED, TO

BD-658M FOR PIER DETAILS TO HELP DEVELOP LIGHT POLE

ABUTMENTS. REFER TO BD-655M FOR ABUTMENT DETAILS AND

BE DESIGNED BY THE ENGINEER TO DISTRIBUTE LOAD TO BOTH

FASCIA AND FIRST INTERIOR BEAM.

OF 1101.04.

MEETING THE REQUIREMENTS

FULL LENGTH OF COUPLING

NC FREE FIT CLASS 2, THREAD

BOLTS (8 THREADS PER INCH)

4 REQ'D. (TYP.) FOR HEAVY

COUPLING 3" LONG MIN.

EDGES OF PAD. MINIMUM HEIGHT 1".

VERTICAL USING LEVELING NUTS, TOOL

GROUT AFTER SETTING POLE TRULY

POLE BASE PLATE AND CONCRETE WITH

FOR LEVELING PAD, FILL SPACE BETWEEN

ARE PERMITTED TO BE GALVANIZED.

4. CONFORM ANCHOR MATERIALS TO 1101.4 PUB.408, ANCHOR ANGLES

DEFLECTION MUST BE EVALUATED FOR DYNAMIC EFFECTS.

10. FOR LIGHTING POLE LOCATIONS WITHIN A SPAN, THE LUMINIARE

11"