Combustion Phenomena -Candle

Transcript of Combustion Phenomena -Candle

00MBU$il011PHT]IOMTNA

Selected Mechanisms of Flame Formation,Propagation, and Extinction

Edited by

JOZEF JAROSINSKIBERNARD VEYSSIERE

CRC PressTaylor & Francis GroupBocaRaton London NewYork

CRC Press is an imprint of theTaylor & Francis Group, an Informa business

Other Interesting Examples of Combustion and Flame Formation

CONTENTS

8.1 Candle and Jet Diffusion Flames: Mechanisms of Combustionunder Gravity and Microgravity Conditions ........... ............170

8.2.2 Homogeneous-Charge Spark-Ignition Engines .......178

8.2.3 Stratified-Charge Spark-Ignition Engines ................. 181

8.2.4 Spark-Assisted Compression Ignition .................. ..... 183

8.3 Combustion in Compression-Ignition Engines .................... 186

8.3.2 Conventional Compression-Ignition Engine ............187

8.3.3 High-Speed Compression-Ignition Engines ..,.,........1928.3.4 Premixed CI Engine: An Ultra-Low Emission Concept ......,....,...194

8.4.2.2 Historical Review of DDT Studies in Smooth Tubes .......... ................2008.4.2.3 Experimental DDT Distances .......................201

8.4.3.3 Transition from Deflagration to Detonation .................. ......................204

L69

170 Combustion Phenomenn

8.5.5 Cellular Structure and Detonation Init iation.................. ................211

8.1 Candle and jet Di f fus ion Flames:

Mechanisms of Combust ion

under Gravity and Microgravity

Condi t ions

Fumiaki Takahashi

8 .1 .1 I n t roduc t i on

In flames formed by the condensed or gaseous fuelsources burning in the atmosphere, the combustion pro-cess is controlled by the mixing process rather than therate of chemical reaction. The most familiar example is acandle flame, where the flow field is laminar and mixingoccurs by molecular diffusion. Burke and Schumann [1]developed a theory of simplest laminar diffusion flames,where a gaseous fuel jet was issued into air flowing atthe same velocity in a wider duct, with an infinitely thinflame-sheet model. In diffusion flames, however, theflame structure (i.e., spatial variations of velocity, tem-perature, and species concentrations) determines variouscharacteristics, such as flame stabilization and pollutantformation. A detailed understanding of the structure,particularly the chemical aspect, of diffusion flames isonly being achieved recently. Today, it is common to calcu-late the coupled time-varying fluid dynamics, heat trans-fer, and mass transfer with numerous elementary reactionsthroughout the flame. These results are then comparedwith the detailed, nonintrusive laser-based measurementsof velocity, temperature, and species concentrations, evenwithin the finite-thickness reaction zone itself.

Despite the differences, there are striking similari-ties in the physicochemical structure of the candle-likelaminar diffusion flames of various hydrocarbons.Typically, the high-temperature reducing environmentin the interior of the flame cracks the original fuel to thesame smaller, unsaturated fragments that consequentlydiffuse to the oxidation region of the flame. Hence, thestudy of diffusion flames of much simpler fuels shedslight on many of the important phenomena present withflames of larger fuel molecules. Furthermore, experi-ments in the absence of gravity uncovered previouslyunknown phenomena and helped to validate analyticaland numerical models.

This Chapter highlights the physical and chemicalmechanisms of combustion of candle-like laminar diffu-sion flames: candles, gas jets, and liquid- or gas-fueledcup burners. First, a brief history on the understandingof candle-like flames is outlined, then general features ofa burning candle are described, and finally, recent exper-imental and computational results of (methane, ethane,and propane) gas-jet and (n-heptane) cup-burner flamesare presented. Particular emphasis is placed on theeffects of the type of fuel and gravity on the structure ofthe flame-stabilizing region (base) and the trailing dif-fusion flame.

8. '1 .2 Histor ica l Sketch

For thousands of Earth-years, candle-like flames werea leading lighting technology. Apart from providinglight, the candle flame has been an object of fascina-tion for centuries, inviting speculation on the nature offire and the natural world. Several historical accountsof the study of flames, fire, or combustion can be seenin the literature [2-8]. Investigation of fires or flames,among other natural phenomena, was intensified dur-ing the scientific revolution in the seventeenth century.Francis Bacon l7l Q567-1626) postulated, with respectto the structure of a candle flame, that space is requiredfor the fire to move, and if its motion is suppressed, forexample, by a snuffer, it is instantly extinguished. Ottovon Guericke (7602-7686) and Robert Boyle (7627-7691)independently demonstrated that a candle or charcoaldid not burn in vessels exhausted of air, although itinflamed as soon as air was readmitted. By the early1660s, Robert Hooke [B] (1635-1703) developed a conceptof combustion, in which air possessed two quite sepa-rate components: reactive and inert parts. By insertingthin plates of glass and mica in a lamp or candle flame,he noticed that (1) the point of combustion appearedto be at the bottom part of the conical flame, where theoil rising up the wick became excited by the heat aboveit, and (2) the interior of the flame did not emit light.He also used powerful sunlight to project an image ofa candle flame onto a whitewashed wall, whereby hecould discern the dark interior and heat zones in theresulting shadow ]ohn Mayow (7643-7679) observedthat air is diminished in bulk by combustion and that

Other Interesting Examples of Combustion and Flame Formstion

the residual air is inactive, through an experiment witha burning candle in a bell-jar of air enclosed over water.Although these early investigators may have been onthe verge of the discovery of the gas now called oxy-gen, they could not make it. Unfortunately, the phlogis-ton theory 12,5,6], which postulated that the essence offire is a substance called phlogiston, dominated chem-istry during the greater part of the eighteenth century.Finally, Antoine Lavoisier (1743-7794) overthrew thephlogiston theory and established his oxygen theory ofcombustion, after Scheele and Priestley independentlydiscovered oxygen.

In the nineteenth century, Humphry Davy (7778-7829)speculated that the luminosity of flames is caused bythe production and ignition of solid particles of carbonas a result of the decomposition of a part of the gas.fcins Jakob Berzelius (7779-1848) is said to be the firstto describe an ordinary candle flame as consisting offour distinct zones. Davy's prot6g6, Michael Faraday

[9] (1791-1867) gave his Christmas lectures and accom-panying demonstrations to a juvenile audience on "TheChemical History of a Candle" in 1848 and 1860. Aroundthe turn of the century, modern combustion science wasestablished based on the increased understanding ofchemistry, physics, and thermodynamics.

[n1928, Burke and Schumann [1] gave a classic theoryof circular and flat gaseous fuel, jet diffusion flames in

an air duct with an infinitely thin flame-sheet model.

|ost [10] pointed out that some of Burke and Schumann'sresults could be derived without solving the differen-tial equation to predict the height of flames [11]. A newera began in combustion research after \zVWII; signifi-cant studies 172-761were made of jet diffusion flamesthrough improved measuring techniques. The pictureof the Burke-Schumann flame was substantiated for ahydrogen flame by the gas composition data of Hotteland Hawthorne [12], obtained via gas chromatography.The detailed structure of a flat diffusion flame was inves-tigated spectroscopically by Wolfhard and Parker [15],who showed that local states of chemical equilibriummay exist in a flame zone of a distinctly finite thickness.Parker and Wolfhard [16] made schlieren observationsof candle flames. Gaydon and Wolflrard [11] used thermo-couples to study the temperature field and revealed thatthe heat transfer to the wick is equal to the amount of heatrequired to heat up and vaporize the paraffin. Smith andGordon [17] analyzed the gaseous products from a candleusing a small quartz probe and a mass spectrometer. Theyfound that the mechanism of precombustion reactionsinvolved mainly the cracking of hydrocarbons predomi-nantly to unsaturated compounds before the fuel-specieshad contact with oxygen. More recently, candles have beenused to study various aspects of combustion phenom-ena: spontaneous near-extinction flame oscillations [18],

flame flickering [19], electric-field effects [20], elevatedgravitational effects 1211, fire safety 1221, and smoke-pointmeasurements [23].

The original Burke-Schumann theory was laterrefined [24-26]. Roper [26] developed a new theory, byrelaxing the requirement of a single constant velocity,and estimated the reasonable flame lengths for bothcircular and noncircular nozzles. Numerical analysesof laminar diffusion flames have advanced over thelast three decades, based on progresses in the reactionmechanisms and computer technologies [27-30]. It isnow feasible to simulate, with reasonable accuracy, thetransient flame phenomena with full chemistry in sim-ple configurations (burner geometry, flow, and fuel).

In normal earth gravity (19), buoyancy causes the hotgaseous products to rise, entraining air at the base of theflame. This air entrainment is of particular importancein the flame structure and stabilization [31-33]. In micro-gravity (pg), because of lack ofbuoyancy, the hot gaseousproducts tend to accumulate, and the flame enlarges andproduces soot more readily B4-411. The behavior of pgcandle flames was investigated in the drop tower andaboard the spacecra ft 136,39,411.

8.1.3 Candle Burning Processes

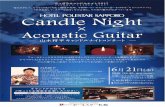

A well-balanced candle burns itself in a clean, steady-state, self-controlled flame. Figure 8.1.1 shows a pho-tograph of a burning paraffin (typically 20-30 carbonatoms) candle in 19, exhibiting an elongated flame

FICURE 8 .1 .1Photograph of a 21mm diameter paraffin candle flame in 13

171,

172

shape as a result of a rising flow. A (flat) wick curls itselfsideways to burn out as it is exposed to the flame zone,and thereby, the wick length is kept constant to con-trol the fuel vaporization rate and, in turn, the flameheight. Allan et al. [23] found that soot emission wasnot possible for 13 different waxes tested when thewick size was below thresholds (diameter<1.8mm orlength <6mm) and thus the flame height did not reachthe smoke point [42].

The complex physical and chemical processes in aburning candle are reasonably well known. Figure 8.1.2shows a conceptual sketch of a steady-state burning can-dle, showing various regions, major physical and chemi-cal processes (right), and specific transport phenomenawith arrows (left). The origin of the color of the dark-blueregion at the base is chemiluminescence from the excitedCH radicals in the reaction zone [11]. Heat transfer fromthe flame, by conduction and radiation, forms a pool ofthe melted wax at the top of the candle. The melting frontmoves steadily down the candle as the flame consumesthe wax. The melted wax ascends through the wick bycapillary action and vaporizes from the heat of the flametransferred primarily by conduction. Buoyancy inducesan accelerating, ascending flow, thereby entraining thesurrounding air into the lower part of the flame. Thevaporized fuel ascends by convection and diffuses out-wardly, while the fuel cracking (pyrolysis) reactions takeplace at high temperatures. The fuel fragments react withthe oxygen from the surrounding air to form the diffu-sion flame. There are heat losses by radiation (primarily

Products, heat Luminous zonesoot oxidation

Stoichiometriccontour (gas)

Soot formation

Dark zonecracking

Vaporization

Flame zoneoxidation

Capillary action

FIGURE 8 .1 .2Physical and chemical processes in a candle in 19

Combustion Phenomena

from CO2 and HrO vapor, and soot) from the flame zoneto the surroundings. The convective flow immediatelyremoves the combustion products and heat away fromthe flame zone.

Soot is formed on the fuel side of the flame zone owingto cracking and pyrolysis of the vaporized fuel at hightemperatures. The soot particles are convected upwardand eventually penetrate the flame zone, where theyburn out by the reaction with oxygen that is diffusedin from the surrounding air. Recent laser-diagnosticmeasurements in laminar diffusion flames revealedthat soot is formed in a limited range of temperatures(approximately between 1300 and 1600K) on the fuelside of the flame zone and that the soot volume frac-tion peaks in the middle heights of the flame [42]. Theluminous part of the flame by soot incandescence mayextend downstream beyond (i.e., higher than) the localstoichiometry contour for gaseous species. The heat andthe major combustion products (HrO vapor and CO)leave the flame primarily by convection at the tip.

In the absence of gravity, the properties of a candleflame change dramatica\ly 136,39,41). Figure 8.1.3 showsa candle flame on the Mir space station, in which themelt layer was hemispherical and much thicker thanthat in normal gravlty, and the flame was smaller,spherical, and less sooty, uncovering the blue flamezone. There was significant circulation in the liquidphase (as a result of surface-tension-driven flow caused

F ICURE 8 .1 .310mm diameter candle flame in pLg on the Mir. (From Ross, H.D.,Micrograaity Combustion: Fire in Free Fall, Ross, H.D., Ed., AcademicPress, San Diego, 2001.)

o2

Soot

lncandescence

Fuel,02, products, heat

02, fuel

ChemiluminescenceHeat

Other lnteresting Examples of Combustion and Flame Formation

by the temperature difference between the liquid waxnear the flame and wax at the candleholder). Aftersometime, the molten ball of wax collapsed suddenlyand the liquid mass moved back along the candleholder.The blue flame zone is much farther away from the wickcompared with those in the normal gravity. In addition,it was observed that aerosol (condensed paraffin) wasstreaming out underneath the flame base and movingin the boundary layer produced by the liquid flow. Thelong life of the Mir candle flame (up to 45min) burn-ing in the oxygen-enriched atmosphere (mole fraction of0.22-0.25) suggests that a steady microgravity flame canbe achieved even in a quiescent environment. An effortto model candle flames in low gravity continues [43].

8.1.4 f e t Di f fus ion Flame Structure

Insight into the behavior of candle flames in normaland low gravity can be obtained from experiments and

173

modeling of jet diffusion flames with simpler gaseousfuels. The NASA Glenn 2.2-Second Drop Tower has pro-vided pg data 144,451for gaseous hydrocarbon flamesfor comparison with 19 conditions. Figure 8.1.4 showsvideo images of methane (top row), ethane (middle), andpropane (bottom)jet diffusion flames in 1.q (left column)and p.q (middle and right), formed on a circular fuel tube(2.87mm i.d.) in still air in a vented combustion cham-ber (255mm i.d. x 533mm length). The fuel tube imageis superimposed. The flames with "high" (left two col-umns) and "low" (right) fuel flow-rate levels are shown,in which the ratios of the flow rates of different fuelsare maintained to achieve a constant oxygen require-ment for each flow level, based on the molar stoichio-metric expression. The luminous zone of soot in the 19and "high" flow-rate propane flames (Figure 8.1..4d, g,and h) extended beyond and covered the tip of the blueflame zone. The base of the flame was <1 mm away fromthe tip of the fuel tube in 19, while in pg, it was 3-4mm

FIGURE 8 .1 .4Video images of methane (top), ethane (middle), and propane (bottom) jet diffusion flames (2.87mm i.d.) in still air in 19 (left) and pg (middleand right). The mean fuel jet velocity: (a, b) 13.5cm/s, (c) 5.3cm/s, (d, e) 7.7 cm/s, (f) 3.3cm/s, (g, h) 5.6cm/s, (i) 2.2cm/s.

174

away. As the overall oxygen-consumption rate was keptconstant for different fuels, the size (height and width)of the blue flame zone at each fuel flow level in 19 or

lrg was nearly identical. The flames in 19 were muchthinner (-5.5mm width) than their counterparts in prg(=17mm width), because the buoyancy-induced con-vection moved the flame zone inward and resulted inhigher oxygen transport rates per unit flame area. In the"low" flow-rate-level trrg flames (right), the soot, formedinitially at ignition transienf seemed to disappear evenfor propane, and their shape and size were comparablewith those of the Mir flame (Figure 8.1.3).

Transient computations of methane, ethane, and pro-pane gas-jet diffusion flames in 19 and 0g have beenperformed using the numerical code developed by Katta

[30,46], with a detailed reaction mechanism [47,48] (33species and 772 elementary steps) for these fuels and asimple radiation heat-loss model 1491, for the high fuel-flow condition. The results for methane and ethane canbe obtained from earlier studies [44,45]. For propane,Figure 8.1.5 shows the calculated flame structure in 1gand 09. The variables on the right half include, velocityvectors (v), isotherms (T), total heat-release rate (ri), andthe local equivalence ratio (@ro.o); while on the left half:the total molar flux vectors of atomic hydrogen (M*,),oxygen mole fractio^ (Xo, ), oxygen consumption rate(-6o), and mixture fractiori (0, including stoichiometry(4., = 0.06). General features of the propane flame aresimilar to those of methane and ethane flames [44,45].Although soot formation is excluded in the model, theshape and size of the simulated flame match very wellwith the lower soot-free part of the observed flame(Figure 8.1.4g and h).

Combustion Phenomena

In 19 (Figure 8.1.5a), the velocity vectors show the lon-gitudinal acceleration in the hot zone owing to buoy-ancy, and surrounding air is entrained into the lowerpart of the flame. The heat-release rate and the oxygen-consumption rate contours show a peak reactivity spot(called the reaction kernel) 144,45,501at the flame base.The values at the reaction kernel were rio = 1961/cm3s,- 6or,u = 0.000648 mol/cmts, laol = 0.250 m/s , Tu=1483K,Xo.,r. = 0.031, @lucal.k = 0.99, and 6r = 0.060. Hydrogen atomsanii other chain radicals diffused onto both sides of theflame zone and in every downward direction aroundthe flame base against the incoming flow with higheroxygen concentrations and gradients. Consequently, thechain-branching reaction, H+O, -+ OH+O and otherchain reactions were enhanced to maximize the reac-tivity at the reaction kernel. Thus, the reaction kernelsustained stationary combustion processes within aresidence time available in the flow, thereby holding thetrailing diffusion flame (which had both lower reactiv-ity and higher velocities) 144,45,501. The thickness of theflammable (0.5 < @ <2.551) fud./air mixture layer nearbythe base of the attnched flame was much lesser than theminimum quenching distance of the propane/air mix-ture (2mm) [51], and not sufficiently thick to form acombustion-wave reminiscent of the triple flame struc-ture of lifted flames.

In 0g (Figure 8.1.5b), unlike in the 19 case, the fueljet momentum dispersed and the centerline veloc-ity decayed rapidly owing to the lack of buoyancy.As a result, the fuel molecules diffused in every direc-tion and formed a quasi-spherical flame. The slow dif-fusion processes (1) limited the transport rates of thefuel and oxygen into the flame zone and (2) decreased

5 0 5(a) r (mm)

1 0 5 0(b) r (mm)

FICURE 8 ,1 ,5Calculated structure of propane jet diffusion flames (3 mm i.d., fuel velocity: 4.8 cm/s) in "stil1" air in (a) 19 and (b) 0g

Other Interesting Examples of Combustion and Flame Formqtion 175

>d 10-

1000

500

0

the inner region. For methane 144,501, the CH.+O -+

CHrO+H reaction was a dominant contributor to theheat-release rate peak. The exothermic final-productformation reactions, CO+OH + CO, and Hr+OH-+ H,O+H, took place in a wide rage over the flamezone. On the air side, the Or+H+M -+ HOr+M and thesubsequent HOr+OH -+ HrO+O, reactions were verymuch exothermic, thus contributing to a secondaryheat-release rate hump in the outer region. In 0g, therelative contributions of these HO, reactions with nullactivation energies became more significant, because ofthe lower flame temperature and total heat-release ratethan those in 19.

8.1.5 Cup-Burner F lame Structure

By examining the experimental and computationalresults obtained [52] for r-heptane flames inlg, afurtherattempt was made to extract a general trend in the struc-ture of higher aliphatic hydrocarbon flames. Figure 8.1.7shows a photograph and the calculated fields of tem-perature (left half) and soot mass fraction (right half) ofn-heptane diffusion flames in the coflowing air in thecup-burner apparatus (-30mm diameter). In the experi-ment (Figure 8.7.7a), in which liquid r-heptane wasused, the blue flame base was anchored at the burnerrim with an inward inclination as a result of the incom-ing buoyancy-induced flow. The color of the flame zoneturned bright-yellow downstream owing to consider-able soot formation. The computation (Figurc 8.7.7b)of the gaseous n-heptane flame with a full-chemistrymodel [53] (197 species and 2757 elementary reactionsteps), including global soot formation, captured wellthe transient flame flickering behavior, and the generaltrend in the soot field observed in the liquid-fuel flame(Figure 8.7.7a).

10-1

>{ to-z

10-3

the molar flux of hydrogen atoms by an order ofmagnitude as a result of lower concentration gradients,so that the reactivity in the reaction kernel decreasedby an order of magnitude. The reaction kernel loca-tion is closely coupled with the local flow velocityand mixture reactivity [44]. The values of variousvariables at the reaction kernel were 4u=1,4.8J/cm3s,-6er,r.=0.000042mo1/ cm3s, I ar | =0.0045m/ s,Tu=!299y,Xo",y=0.077, fro.u1.1=0.51, and 6r=0.058. The reactionkemel temperature in 0g was almost 300K lower thanin 19.

Figure 8.1.6 shows the variations of the species molefractions (X,), temperature, and total heat-release rateacross the propane flame in 19 and 0g at a height fromthe jet exit of 3mm (i.e., in the trailing diffusion flame).The thickness of the flame zone, determined from thelocus of positive values for the total heat-release rate,was approximately 2mm in 19 and 3mm in 0g. Hence,the flame zone was far from an infinitesimally thinflame-sheet model by Burke and Schumann [1]. In both19 and 09, general trends in the species mole fractionswere typical of diffusion flames, i.e., chain radicals wereformed on the air side at high temperatures, diffusedonto the fuel side and dissociated the fuel into frag-mental hydrocarbons, and finally CO and H, were oxi-dized to products. A distinct feature of both 0g and 19flames, not accounted for any of the analytical modelsof diffusion flame shape, was that oxygen from the airpenetrated into the fuel side of the flame zone throughthe quenched space between the flame base and theburner rim. Furthermore, for ethane [45] and propane,major hydrocarbon fragments and oxygenates burningin the reaction zone were C2H2,CH4, CrFt, and CHCqand thus the C, species oxidation reactions, CHCO+O -+ CO+CO+H and CrHr+O --> CH'+CO weremajor contributors to the total heat-release rate peak in

2000

1500

r000

500

X

\

c

X.s.

Fl

(aJ r (mm) (b)4 6 8 1 0

r (mm.)

FtcuRE 8.1.5Calculated species mole fractions, temperature, and heat-release rate across propane jet diffusion flames in "stifl" ai,r at a height of 3mm in(a) 1.9 and (b) 0g

176

F ICURE 8 .1 .7(a) Phobgraph of a l iquic l r r -heptane cup-b111nsr f larne in 1,g(b) Calculatecl f ie lc ls of temperatLrrc [ef t hal f l and soot mass f rac-t ior-r [ r ig l r t hal f ] of a gaseous rr -heptane di f f t rs ion f lame in 1rr Burnerdiamc' ter = 30 mm.

Figure 8.1.8 shows the calculated structure of a gas-eous n-heptane flame in 19 at a height of 10.8 mm (in thetrail ing diffusion flame). Because of the negligibly smallgaseous fuel velocity (0.1cmls), which modeled the l iq-uid pool flame, a near-stagnant recirculation zone wasformed near the exit of the burner. As a result of hightemperatures (>1000 K) and relatively long residencetime, n-heptane pyrolyzed and disappeared by the flow

Combustion Phenomena

arrival time at this height. A greater variety of predomi-nantly unsaturated hydrocarbon fragments formed inthe core region before the heat-release rate started torise, when compared with the ethane [45] and propane(Figure 8.1.6a) flames. Nevertheless, there were strikingsimilarities among these hydrocarbon flames. The com-mon hydrocarbon fragments present in the flame zonewere C2H2, CFt, and CrFt. Moreover, the calculated spe-cies and their concentration levels for heptane flameswere qualitatively consistent with the expeiimental spe-cies data obtained from the study of a paraffin candleflame by Smith and Gordon [17].

8 .1 .6 Conc lus ions

The advancement in research tools has increased theunderstanding of candle and gas-jet diffusion flames.Notable insights were gleaned from the Burke-Schumanntheory and refinements, a surge in the experimental workafter WWII, nonintrusive laser diagnostics, progress indetailed computation, and low-gravity experiments.Similarities among diffusion flames of various hydrocar-bons, including paraffin candles, arise from the crackingof the original fuel predominantly to unsaturated com-pounds on the fuel side of the flame zone. For higher(>Cr) hydrocarbons, the common species burning in theflame zone, besides major intermediates (CO and Hr),are C2H2, CH,,, and CrH, in the inner region, and HO,in the outer region. Although lack of buoyancy-inducedflow acceleration in 0g enlarges the flame and makes therates of flame processes an order-of-magnitude lowerthan in 1.q, the general trend in the chemical kineticstructure typical of diffusion flames is maintained.

t " 0 1 2 3 4 5 6 7r (mm/

F IGURE 8 .1 .8Calculated species mole fractions, tenlperature, and heat-release rateacross a gaseous n-heptane diffusiorr flame (18mm o.d., fuel vclocity:0.1 cm/s) in coflowing air (velocity: 107 cm/s) at a hcight of l0.Bmmin 1.9.

Acknowledgments

This work was supported by the National Aeronauticsand Space Agency, Washington, D.C. The author thanksDrs. V. R. Katta and C. T. Linteris for their assistance inrefining the manuscript as well as for their long-termresearch partnership and contributions.

References

1. Burke, S.P. and Schumann, T.E.W, Diffusion flames,I rr t|. En g. Chem., 20, 998, 1928.

2. Bone, W.A. and Townend, D.T.A., FInnrc and Confuustiottin Cases, Longmans, Green and Co. Ltd., London, 1927,Chapter 1.

1500 -'E

C

rooo R

Y500 -

Other Interesting Examples of Combustion and Flame Formation

3. Fristrom, R.M., Flame Structure and Processes, OxfordUniversity Press, New York, 1995, Chapter 1.

4. Weinberg, F.J., The first half-million years of combustionresearch and today's burning problems, Proc. Combust.Inst . ,1 .5,11975.

5. Williams, F.A., The role of theory in combustion science,Proc. Combust. Inst., 24, l, 1992.

6. Lyons, J.W., Fire, Scientific American Books, New York,1985.

7. Bacon,F.,TheNezu Organon, Jardine, L. and Silverthorne,M., Eds., Cambridge University Press, Cambridge, UK,2000, p.124.

8. Chapman, A., England's Leonardo: Robert Hooke (1635-1703) and the art of experiment in restoration England,Proc. R. Inst. Great Britain, 67,239,1996.

9. Faraday, M., A Course of Six Lectures on the ChemicalHistory of a Candle, Crookes, W., Ed., Harper & Brothers,New York, 1861.

10. Jost, rN., Explosion and Combustion Processes in Gases,McGraw-Hill, New York, 1946.

11. Gaydon, A.G. and Wolflr ard, H.G., F lames, Their S truc ture,Radiation and Temperature, 4th ed., Chapman and Hall,London, 1979, Chapter 6.

12. Hottel, H.C. and Hawthorne, W.R., Diffusion in laminarflame iets, Proc. Combust. Inst., 3, 254, 1949.

13. Wohl, K., GazIey, C., and Kapp, N., Diffusion flames,Proc. Combust. Inst., 3, 288, 1949.

14. Scholefield, D.A. and Garside, 1.E., The structure and sta-bility of diffusion flames, Proc. Combust. lnst.,3,102,1949.

15. Wolfhard, H.G. and Parket W.G., A spectroscopic inves-tigation into the structure of diffusion flames, Proc. Plrys.Soc., A65,2,1952.

16. Parker, W.G. and Wolfhard, H.G., Carbon formation inflames, I. Chem. 9oc.,2038, 1950.

17. Smith, S.R. and Gordon, A.S., Precombustion reactions inhydrocarbon diffusion flames: The paraffin candle flame,I. Chem. Phys., 22, 1150, 1954.

18. Chan, W.Y. and T'ien, J.S., An experiment on spontane-ous oscillation prior to extinction, Combust. Sci. Technol.,1 .8, r39,1.978.

19. Buckmaster, J. and Peters, N., The infinite candle andits stability-a paradigm for flickering diffusion flames,Proc. Combust. Inst., 2'1., 1.829, 1.988.

20. Carleton, F. and Weinberg, F., Electric field-inducedflame convection in the absence of gravity, Nature,330,635,1989.

21. Villermaux, E. and Durox, D., On the physics of jet diffu-sion flames, Combust. Sci. Teclmol., 84, 279, 1992.

22. Hamins, A., Bundy, M., and Sillon, S.E., Characterizationof candle flames, l. F ire Prot. Eng., 15, 265, 2005.

23. Allan, K.M., Kaminski, J.R., Bertrand, J.C., Head, J.,and Sunderland, P.8., Laminar smoke points of candleflames, presented at 5th US Combustion Meeting of theCombustion Institute, Paper No. D32, San Diego, CA,March 25-28, 2007 .

24. Barr, J., Length of cylindrical laminar diffusion flames,Fue\,33,51,7954.

25. Fay, J.A., The distributions of concentration and temper-ature in a laminar jet diffusion flame, /. Aeronaut. \ci.,21,687, 1954.

t77

26. Roper, F.G., The prediction of laminar jet diffusion flamesizes: Part I. theoretical model, Combust. Flame,29,2L9,1977.

27. Mlller, j.A. and Kee, R.J., Chemical nonequilibriumeffects in hydrogen-air laminar jet diffusion flames,l. Phys. Chem., 81, 2534, 1977.

28. Mitchell, R.E., Sarofim, A.F., and Clomburg, L.A.,Experimental and numerical investigation of confinedlaminar diffusion flames, Combttst. F lame, 37, 227, 1980.

29. Smooke, M.D., Lin, P., Lam, J.K., and Long, M.B.,Computational and experimental study of a laminar axi-symmetric methane-air diffusion flame, Proc. Combust.Inst.,23,575,1990.

30. Katta, V.R., Goss, L.P., and Roquemore, W.M., Numericalinvestigations of transitional H2lN2 jet diffusion flames,ArAA 1.,32,84,1994.

31. Robson, K. and Wilson, M.J.G., The stabil ity of lami-nar diffusion flames of methane, Combust. Flame, 13,626,1.969.

32. Kawamura, T., Asato, K., and Mazaki, T., Structure ofthe stabilizing region of plane, laminar fuel-jet flames,Co mbust. S ci. Technol., 22, 211, 1980.

33. Takahashi, F., Mizomoto, M., and Ikai, S., Structure of thestabilizing region of a laminar jet diffusion flame,l. HeatTransfer, 110, 1,82, 7988.

34. Edelman, R.B., Fortune, O.F., Weilerstein, G., Cochran,T.H., and Haggard, J.B. ,Jr., An analytical and experimen-tal investigation of gravity effects upon laminar gas jet-diffusion fl ames, Pro c. Combust. Inst., 1,4, 399, 1,973.

35. Bahadori, M.Y., Edelman, R.B., Stocket D.P., and Olson,S.L., Ignition and behavior of laminar gas-jet diffusionflames in microgravity, AIAA 1., 28, 236, 1990.

36. Ross, H.D., Sotos, R.G., and T'ien, J.S., Observations ofcandle flames under various atmospheres in micrograv-ity, Combust. Sci. Technol., 75, 155, 1991.

37. Walsh, K.T., Fielding, J., Smooke, M.D., and Long, M.8.,Experimental and computational study of temperature,species, and soot in buoyant and non-buoyant coflowlaminar diffusion flames, Proc. Combust. Inst., 28, L973,2000.

38. Lin, K.-C., Faeth, G.M., Sunderland, P.B., Urban, D.L.,and Yuan, Z.-G., Shapes of nonbuoyant round luminoushydrocarbon/air laminar jet diffusion flames, Combust.Flame, 116, 415 , 1999 .

39. Dietrich, D.L., Ross, H.D., Shu, Y., Chang, P., and T'ien,J.S., Candle fl ames in non-buoyant atmospheres, Combust.Sci. Technol., 156, 1,2000.

40. Urban, D.L., Yuan, Z.-G., Sunderland, P.B., Lin, K.-C.,Dai, 2., and Faeth, G.M., Smoke-point properties ofnon-buoyant round laminar jet diffusion flames, Proc.Combust. Inst ., 28, 1965, 2000.

41. Ross, H.D., Basics of microgravity combustion,Micrograaity Combustion: Fire in Free Fall, Ross, H.D. Ed.,Academic Press, San Diego, CA,2001, Chapter 1.

42. Glassman, 1., Combustion, 3rd ed., Academic Press, SanDiego,CA,1996.

43. Alsairafi, A., Lee, S.T., and T'ien, J.S., Modeling gravityeffects on diffusion flames stabilized around a cylindri-cal wick saturated with liquid fuel, Combust. Sci. Technol.,t76,2165.2004.

t78

44,

45.

Takahashi, F. and Katta, V.R., Reaction kernel structureand stabilizing mechanisms of jet diffusion flames inmicrogravity, P r o c. Comb ust. Inst., 29, 2509, 2002.Takahashi, F. and Katta, V.R., Further studies of the reac-tion kernel structure and stabilization of jet diffusionflames, Proc. Combust. Inst., 30, 383, 2005.

46. Roquemore, WM. and Katta, V.R., Role of flow visualiza-tion in the development of UNICORN, J. Vis.,2,257,2000.

47. Peters, N., Reduced Kinetic Mechanisms for Applicationsin Combustion Systems, N. Peters and B. Rogg, Eds.,Springer-Verlag, Berlin, Germany, 1993, p. 3.

48. Vlarnatz, J., Combustion Chcmistry, W.C. Gardiner, Ed.,Springer-Verlag, New York, 1984, p.197.

49. Barlow, R.S., Karpetis, A.N., and Frank, J.H., Scalar pro-files and NO formation in laminar opposed-flow par-tially premixed methane/air flames, Combust. Flame,127,2102,2001..

50. Takahashi, F. and Katta, V.R., Chemical kinetic structureof the reaction kernel of methane jet diffusion flames,Comb ust. S ci. Tcc h nol., 1 55, 243, 2000.

51. Lewis, B. and von Elbe, G., Combustion, Flames and Explo-siotrs of Gnses,3rd ed., Academic Press, New York,1987.

52. Takahashi, F., Linteris, G., and Katta, V.R., Further studiesof cup-burner flame extinguishment, 16th Annual HalonOptions Technical Working Conference (HOTWC),Albuquerque, NM, May 2006.

53. Tsang, W Progress in the development of combus-tion kinetics databases for l iquid fuels, Data Sci. [.,3,1,2004.

8.2 Combust ion in Spark- Igni ted Engines

lames D. Smith and Volker Sick

8.2.1 Int roduct ion

Spark-ignited internal-combustion engines have beenin existence for well over 100 years, with the first exam-ple being presented by Nikolaus Otto in 1876. However,age should not be deceiving in this case, as significantresearch and development efforts are still being appliedto this concept to achieve more powet better efficiency,and lower emissions. Fuel charge preparation and in-cylinder motion are the two main parameters affectingignition and combustion, and therefore, have a largedegree of influence on the aforementioned quantities.Depending on the method used for preparing the fuel/air mixture, the combustion regime ranges from nearperfectly premixed to highly heterogeneous diffusionburning in a multiphase, Iiquid /vapor environment.In-cylinder motion is also crucial to engine opera-tion at various speeds. As engine speed increases, sodo in-cylinder turbulence levels, yielding faster burn-ing velocities, without which engines cannot operate

Combustion Phenomena

on normal speed scales of the thousands of cycles perminute. Fuel charge preparation and in-cylinder floware invariably intertwined, as certain preparation strat-egies rely on the directed flows to achieve reliable igni-tion, in addition to having a large degree of influenceon the motion itself.

This chapter will treat the three modes of combus-tion in spark-ignited IC engines: homogeneous-chargespark-ignition (HCSI, premixed-turbulent combus-tion), stratified-charge spark-ignition (SCSI, partiallypremixed-turbulent combustion), and homogeneous-charge compression-ignition with spark assist (SACI,premixed-turbulent combustion). This range of fuelpreparation and in-cylinder motion strategies coversthe time span from the basic incarnation of the SIengine to future engine concepts that will probablyplay a major role in the future of ground transpor-tation. The highlights and governing characteristicsof each combustion mode wil l be discussed and visualexamples of each case will be presented from a runningengine with optical accesses that were obtained witha high-speed camera (12000 frames/s) that recordedcombustion luminosity. The viewing area within theengine is presented in Figure 8.2.1, which showsprominent features, such as the fuel injector, sparkplug, and intake/exhaust valves. Further details of theengine can be found in the work by Smith and Sick [1].These visual examples wil l help to explain the obser-vations made from pressure-based measurements,such as ignition delay, combustion duration, and heatrelease rates.

8.2.2 Homogeneous-Charge Spark- lgni t ion Engines

HCSI engines are the most common spark-ignitionengines in existence. While methods for mixture prepa-ration have varied from carburetors to port fuel injection,the overall goal is the same: to have a well-mixed fuel/aircharge at all locations in the combustion chamber. Withthis concept, the air/fuel ratio is close to stoichiometricto promote reliable combustion and facilitate emissionsafter treatment. Since the ratio of air and fuel must bekept nearly constant, intake-air throttling is used tocontrol engine power output. At low engine-load con-ditions, high throttling is necessary and has a negativeconsequence on the volumetric efficiency. Conversely, athigh loads, near-ambient intake manifold pressures areused to draw in the maximum possible amount of air/fuel mixture to the combustion chamber.

Once the well-mixed air/fuel charge is inducted intothe combustion chamber, the rising piston compressesand heats the mixture. At a point near the peak travelof the piston (top dead center; TDC), ignition is initiatedthrough a spark plug. Normally, this occurs at a singu-lar poinf however, some instances of using two or more