Color Fastness

-

Upload

saurabh-singh-rajput -

Category

Documents

-

view

704 -

download

60

description

Transcript of Color Fastness

COLOUR FASTNESSAssignment

-4Faculty:Prof. Shivalingam

Submitted By:Abhinit KanthArumit KayasthaShashank TrivediSaurabh Singh Rajput

Property of a pigment or dye to retain its original hue, especially without fading, running, or changing when wetted, washed, cleaned; or stored under normal conditions when exposed to light, heat, or other influences.

COLOR FASTNESS

Fiber TypeClass of Dye UsedDyeing or Printing Process usedTypes of Finishing Treatments UsedAction Of Laundering Detergents

FACTORS AFFECTING COLOR FASTNESS

A special individual needed who: Possesses a knowledge of dyes and pigments. Knows why color change Is skilled in colorfastness tests and knows their limitations. Has the ability to evaluate and report color changes.

QUALITIES OF THE COLOR EVALUATOR

Color fastness in Paper: fadeometer, Cloth: launderometer.

MEASURED USING:

Arrangement of Achromatic gray chips in a scale from light to dark.

Nine pairs of non-glossy neutral grey coloured chips, which illustrate the perceived colour differences.

Give a corresponding fastness rating of 5, 4-5, 4, 3-4, 3, 2-3, 2, 1-2, and 1)

GRAY SCALE

Uses a class 5-4-3-2-1 rating system. Class 5 best, Class 1 worst. Half Rating, such as 3-4 also used. 5-Excellent, 4-good, 3-fair, 2-poor, 1- very poor. Specimens of a given hue are matched against these

gray chips. They equate differences in lightness with differences

in color.

USING A GRAY SCALE:

A control fabric is used, usually white or un-dyed; also assessed for the staining which results from contact with the test material.

Results assessed by grading against standard A04/A05 greyscales.

Grade of 5: no change in colour, staining.

Grade of 1: substantially different.

METHODOLOGY OF TESTING:

Usually only one specimen of fabric used.Usually only one specimen of fabric used.

If material dyed or printed uniformly throughout the fabric, If material dyed or printed uniformly throughout the fabric, then specimen chosen should be representative of entire lot.then specimen chosen should be representative of entire lot.

For multi –colored printed fabric, each color should be tested For multi –colored printed fabric, each color should be tested in order to evaluate every color.in order to evaluate every color.

Used to evaluate a fabric’s resistance to staining.

Normally a multi-fibre strip of 6 fibre components used for staining test: Acetate, Cotton, Acrylic, Polyamide, Polyester and Wool.

Same as the other gray scale, except for the chip in each pair that remains the same is a standard white.

GRAY SCALE FOR STAINING:

Various contrasting pair of chips are given numerical color fastness ratings, from class 5 to class 1.

Utilizes samples of undyed fabric to determine if a colored fabric will stain an adjacent fabric.

GRAY SCALE FOR STAINING:

MULTIFIBRE FABRIC STRIP

GREY SCALES FOR STAINING

GREY SCALES FOR COLORING

Disagreement when bright colors are used.

Works well with most colors otherwise.

LIMITATIONS OF GREY SCALE

Used to evaluate fabrics resistance to crocking.

Six sets of color chips.

Each set is graduated from light to dark with different rating.

CHROMATIC TRANSFERENCE SCALE

When visually evaluating or comparing, standardized light source should be used.

COLOR MATCHING BOOTH frequently used for color checking.

LIGHTING USED FOR EVALUATION

Contains 4 different standardized lights:Daylight

Incandescent LightCool White Fluorescent LightUltraviolet Light

Each used to view specimens by pushing a switch.

Daylight used when evaluating colorfastness as color appears closer to way usually seen.

COLOR MATCHING BOOTH

Washing Light Crocking Abrasion Gases in Atmosphere Frosting Perspiration Heat

TYPES OF COLORFASTNESS

Ability of the fabric to with stand the effect of laundering.

Launder-ometer is used to evaluate colour fastness to washing with the help of grey scales.

The washing of fabric results in the removal of dye, therefore staining can occur, inorder to determine the staining, a white multifiber strip is attached to the specimen being tested for CF to washing.

COLORFASTNESS TO WASHING

The staining effect on each fiber in the multifiber test fabric should be rated using the grey scale for evaluating staining.

It is checked afterwards for the effects of bleeding or colour migration.

AATCC standard detergent 124 used.

Specimen placed in a metal cylinder containing water, detergent, steel balls, and chlorine.

Rotating action of these cylinders produces the same effect as textile products being laundered.

THE LAUNDER-O-METER

The specimen is placed in a metal cylinder in which water, detergent, metal balls and chlorine are placed.

The amount of detergent ,temperature, agitation and bleach can be controlled.

TESTING PROCEDURE: OVERVIEW

SPECIMEN PREPERATION: Cut the specimen 2 x 6 inches, stapled with the multi fiber fabric.

PROCEDURE: Place the sample in the container along with the steel balls and detergent.

Run the machine for 45 minute.

After taking the specimen rinse it with water and soak it in acetic solution and rinse it again with water.

TEST PROCEDURE

Remove the excess solution.

Dry the specimen and test fabric together using an hand iron.

Remove the test fabric and compare it with the gray scale to find the fastness.

PROCESS DIAGRAM

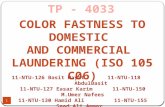

AATCC TEST METHOD 61-2010

This refers to the ability of the fabric to withstand the sun light.

The resistance of the sunlight depends on:

The intensity of the light

Inherent properties of the fabric.

Season

Altitude

Distance from the equator.

COLORFASTNESS TO LIGHT

Original standard method: Sunlight method samples are placed in a glass cabinet and exposed to sun light

from 9 am-3 pm. It is time consumable process.

Weather-o-meter and Fade-o-meter most widely used instruments.

Both this instruments use different light source and the temperature and humidity are controlled with in the machine.

Specimens placed around the light source , and remain there until the end of test.

MEASUREMENT METHOD

Then evaluated as to changes in color resulting from radiation.

Weather-o-meter is a newer and more versatile machine

It enables specimen to be sprayed with water during the test, if desired.

It also is able to alternate light and dark periods if continuous light exposure is not desired.

These conditions are used in the Weather-o-meter to test fabric for such end uses as outdoor furniture, tents or rainwear.

Both machines have either a carbon-arc lamp or a xenon-arc lamp as the light source.

The degree of fastness required depends on end use.

For example, a coat material should have more color fastness than a colored dress shirt. Similarly clothes not intended to worn outside should also have certain color fastness to enable drying in sunlight.

INSTRUMENTS AND FASTNESS

Newer, versatile. It enables the specimen to be

sprayed with water if needed. It also manipulates the light

and dark period if continuous exposure is not needed.

These make it most suitable for testing fabrics for end uses like outdoor furniture, tenting or rainwear.

WEATHER-O-METER

Two testing methods are used:

Time methodStandard fading method

USING WEATHER-O-METER

The specimen is exposed to light for a particular amount of time.

After the termination of time the specimen is taken out and evaluated.

Disadvantage:Specimen is not exposed to the same amount of light each time

the test is performed.

TIME METHOD

Specimen PreparationCut the specimen 2.5” x 8” with the longer dimension in lengthwise.

Test Procedure

Mount the specimen in the cardboard holder and remove the perforated strips so that half of the specimen area will be uncovered.

Insert the cardboard holder into the metal holder and place in to the machine.

TEST PROCEDURE

Expose the specimen for 20 hours.

At the end of the desired exposure time period, remove the specimen and allow it to relax in the dark at room temperature for atleast 2 hours in order to regain moisture from the air.

Using the grey scale for evaluating colour change, determine the colour fastness rating for the test fabric.

AATCC TEST METHOD 16-2004

The rubbing off of colors is called as crocking.

Fabrics with large amount of surface dyes like dark color cotton fabric tend to have poor colorfastness to crocking, pigment dyed or printed fabrics also face the same problem.

Some time in order to increase the depth of the colors the surface dyes are not washed off which also results in crocking.

COLORFASTNESS TO CROCKING

The crock meter is used to find the color fastness to crocking.

This instrument has a finger covered by a white cotton fabric which would rub against the specimen.

This test should be performed both as wet and dry test.

The wet test is an severe test since moisture helps in removal of dyes

CROCK METER

Specimen PreparationCut two specimens on the bias, 8”x8” and place the test

specimen on the crock meter so it will be rubbed in the bias direction.

TEST PROCEDURE

Test Procedure

Mount a dry, white crock test cloth over the finger section of the crock meter so that it will be rubbed in the bias direction.

Lower the covered finger, causing the crock test cloth to slide over the coloured specimen for 10 complete cycles.

Remove the specimen and the white crock test cloth.

Perform a wet crocking test by the same procedure.

Rate the crock test cloths using the colour transference chart.

AATCC TEST METHOD 116-2010

Perspiration can cause a fabric to change color as well as resulting in staining of adjacent material.

The test is attempted to stimulate the actual condition. the specimen is heated for 6 hours at 38°C .

A multifibre test fabric is placed against the specimen, the test is carried out and later evaluated for bleeding or color migration.

After the test is completed ,the specimen is evaluated using the gray scale and the average rating is reported.

COLOR FASTNESS TO PERSPIRATION

Diagram Perspiration tester

SPECIMEN PREPERATION:

Cut the specimen of 2 ¼” x 2 ¼”

Cut the multifiber fabric to 2 x 2 inch

TEST PROCEDURE

PROCEDURE:

Immerse the test sample and the specimen in the acid solution for 15 min.With draw the fabric and remove any excess liquor.Place the specimen in the perspiration tester.Load the tester with 10 pounds of pressure.Place the loaded tester in an oven and heat it to 100*f for 6 hours.Remove the tester from oven and allow the fabric to dry at room temperature.Remove specimen and test cloth and Compare with gray scale.

AATCC TEST METHOD 61-2010

Frosting is the change of color caused by a localized , flat abrasive action.

Fabrics that have poor dye penetration possess poor colorfastness to frosting.

Fabric that are cross dyed also possess poor color fastness (due to differences in the abrasion resistance).

COLOR FASTNESS TO FROSTING

Crocking evaluates the appearance of the specimen.

Frosting only evaluates the rubbing cloth, not the specimen.

DIFFERENCE BETWEEN CROCKING TEST AND FROSTING TEST

The dyes in the textile material are affected to a various degree by atmospheric gases.

The major cause for this is due to the reaction of disperse dye with ozone and oxides of nitrogen.

The disperse dyed with acetate fabric has the maximum effect while nylon, polyester, acrylic has low effect.

COLOR FASTNESS TO GASES IN ATMOSPHERE

Inhibitors are used for this purpose but are not permanent.

Darker, brighter change more dramatically.

Typical changes: Blues turning pinkish, browns turning reddish, greens turning brownish.

GAS FADING CHAMBER:-Tests the effects of oxides of nitrogen.

OZONITER (ozone exposure chamber):-Tests the effect of ozone.

INSTRUMENTS USED

The specimens are placed in the gas filled chamber for a particular time along with the control fabric.

The tests are conducted at 140*F for approximately 2-3 hours.

The relative humidity is normally kept low due to the heating of gases.

Gas fading termination: when blue sample turns a specific purple color.

Ozone fading test: gray sample turns a standard brown color

GENERAL PROCEDURE

GAS FADING CHAMBER

SPECIMEN PREPERATION:

Cut the specimen 2 x 4 inches ,with the long direction length wise

Cut the blue acetate control swatch 2 x 2 inches long

TEST PROCEDURE

TEST PROCEDURE:

Place the specimen(2x4inches)and control sample(2x2inches)in the gas fading chamber.

Heat the chamber to about 140*f by using Bunsen burner.

Leave the specimens in the chamber until the color changes from blue to purple.

Change the control sample and repeat the procedure (only for ozoniter test, sample changes from grey sample turns brown.

Using The Gray Scale Determine The Color Fastness Rating.

Diagram of gas fading chamber

The change in color of the garment due to hot iron and dry heat can be found by Contact Heat Tester.

COLOR FASTNESS DUE TO HOT IRON

The heat contact tester consist of 3 pairs of individually controlled heaters.

Allows simultaneous testing of 3 differing temperatures in the range 100°C to 230°C.

After the allocated time the specimens are taken out and is compared to the gray scale from which the color fastness is found out.

CONTACT HEAT TESTER

SAMPLE PREPERATION: Cut the specimen and the multi fiber specimen of 6 x 6 cm and sew it together.

PROCEDURE:Place the specimen in a Petri dish and add distilled water to a depth of 1.5 cm.Soak the specimen at room temperature for 15 min with occasional agitation.After removing the excess water place the specimen in perspir-o-meter with a load of 10 pounds.Place the total unit in the oven at an temperature of 38*c for 18 hours.Remove he specimen from the oven and dry it at standard atmosphere.Compare the sample with the gray scale to find the fastness.

COLOR FASTNESS TO WATER