color expert - OWL a Bagoly · 2 colorexpert Editorial There’s no doubt about it: The job of...

Transcript of color expert - OWL a Bagoly · 2 colorexpert Editorial There’s no doubt about it: The job of...

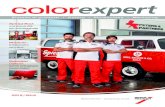

colorexpert

Spies Hecker – simply closer.

ProductsHi-TECPainting in a new dimension.

ColorProfessionalcolor management.

ManagementBenefits of “Lean Thinking”.

WorldwidePassion for colors.

2011

Service • Trends • Training • Management

Efficient, versatile and easy to apply,Permahyd® Hi-TEC 480 is blazing thetrail into the future. Refinishers benefitparticularly from short process timesand the reliable results facilitated by theinnovative system. Specifically, the manyadvantages for the user can be found infive areas:

1. Simple and quickapplication.

Thanks to its exceptional surface wetting,Hi-TEC waterborne base coat can beapplied quickly and easily in just a singlespray pass. A specially developed addi-tive optimizes adjustment of the mate-rial’s viscosity.

2. Results you can rely on.

The bodyshop can depend on the qual-ity and opacity of the product system.Color reproduction is outstanding – afact made possible among other thingsby the uniform effect of all metallic andpearl effect colors. Experience has alsoshown that different refinishers with entirely different spraying techniquesachieve virtually identical paint resultswith Hi-TEC.

3. Easy to blend in.

Permahyd® Hi-TEC reveals its strengthsparticularly during blending-in. A spe-cial blending additive creates gentle,uniform fade-out zones. This way the refinisher achieves a smooth transitionto the original paintwork.

4. Short process times.

Its good flash-off behavior enables re-finishers to dust off the repair directly orimmediately remedy any defects bysanding. On multicolor finishes, thepaint film can be masked and recoatedstraight after flash-off.

5. Many possible uses.

The new Hi-TEC product generationfrom Spies Hecker also has all the rightanswers to current trends on the pro-duction line, because interior coatings aswell as 3-stage and multicolor finishescan be flexibly applied with just this onesystem. Optimal hard drying and excel-lent chemical and mechanical strengthare achieved with the aid of a specialhardener.

Easy, quick, reliable and flexible – any-one painting with Hi-TEC improves hisprocesses and refinish paint applica-tion. The core of the new product sys-tem, incidentally, is an innovative hybridtechnology that unites the positive prop-erties of different paint components.Spies Hecker is thus setting new stand-ards once again.

Internationally successful!

On the market in many countries sincethe beginning of 2010, Hi-TEC has firmlyestablished itself in international body-shops. On the following pages, pilot busi-nesses report on their experience withthe new paint system.

3

Hi-TEC

2 colorexpert

Editorial

There’s no doubt about it: The job of refinishing has changed. Still essentialtoday are craftsmanship, a trained eyeand plenty of experience when it comesto color identification and paint appli-cation. However, what counts more thanever today are efficient product systemsand the use of hypermodern equipmentand technologies.

Matching solutions.

Today, technical and technologicalinnovations are capable of creating anall-important competitive edge. And thisapplies particularly to second-genera-tion waterborne base coat. A good yearafter the successful introduction ofPermahyd® Hi-TEC 480, many countrieshave long discovered conclusively forthemselves that the new product systemdelivers even greater process securityand flexibility and opens up new oppor-tunities.

The development of novel pigments isexpanding the spectrum of colors. Andonly those capable of grasping color inits vast complexity are able to profession-ally remedy paint damage. It’s a questionof reconciling highly exacting processeswith ever tighter deadlines and the pres-sure to succeed. The matching solution

colorexpert – tips and information for bodyshops • © SPIES HECKER GMBH / 50858 Köln, Germany • Horbeller Str. 17 • E-mail: [email protected] • Internet:www.spieshecker.com • Responsible under the German Press Act: Karsten Jürs • Editors: Silke Gursch, Christian Simmert • Layout: Adfactory GmbH, Düsseldorf • Text: Mediaservice GmbH,Neuss • Reader: LLINGUA, Gelsenkirchen • Translation: Tim Chafer, ExperTeam, Düsseldorf • Source of illustrations: Spies Hecker, Adfactory, Mediaservice, Freudenberg, Volker Gehrt,Geza Lorincze • Cover illustration: Sigrid Bakker, Metalak B.V., Netherlands • Reproduction, even in part, only by permission of the editors. The data and information on the suitabilityand usage of our products are not binding and do not release the user from his responsibility to carry out his own tests on their suitability for the intended purposes and processes.The product names mentioned in the articles are predominantly registered trademarks.

Thomas Melzer, Brand Manager Spies Hecker GmbH.

Equipment and technology.Dear Reader,

Welcome to a new dimension.Spies Hecker Hi-TEC waterborne base coat sets new standards in vehicle refinishing.

is provided here by digital color identi-fication with the ColorDialog spectro,which offers so much more in combina-tion with the formula software CRplus –such as electronic color comparison atthe monitor and electronically generatedpaint quantity suggestions.

To put it succinctly: The demands placedon refinishers are becoming consistent-ly tougher. The keys to success now andin the future include openness to inno-vation, technical expertise and an unin-hibited approach to the latest comput-erized systems. And we’ve long gearedourselves to this at Spies Hecker. In ourpractical training, we offer you the tech-nical knowledge necessary for efficientutilization of innovative products, equip-ment and technologies in the bodyshop.Seize this chance to give your body-shop a clear competitive advantage –because we’d like to welcome you to a new dimension!

And now I’d like to wish you plenty of funreading this new issue!

54 colorexpert

Hi-TEC

“Consistency and speed – good news for the bodyshop!”“The new Spies Hecker system is good news for the bodyshop,” say the refinishers of Road and Race Restorations Ltd in the United Kingdom.

Talk to John Bradshaw, owner of Roadand Race Restorations, and his paintersJoe Grant and Dean Snape about theirexperience with Permahyd® Hi-TEC andthey soon run out of superlatives: “Greatsuccess, fantastic products – more thanwe could ever have hoped for!”

The reason for their enthusiasm is thatthe business specializes in the accidentrepair of luxury vehicles of Porsche and similar brands. “Application ofPermahyd® Hi-TEC 480,” says John,“has proved to be much quicker no matter whether a big or small repair.”And he ought to know, because the racecar enthusiast and former karting cham-pion knows all about speed. “Coverage

“Undoubted advantages!”In Jutland in Denmark, the Sundsholmens bodyshop goes all out for progress.

Sundsholmens Autolakering ApS inNørresundby has been using the refinishproducts and service of Danish SpiesHecker distributor Baden-Jensen formany years. However, business ownerRalph Makholm was initially scepticalabout the new Permahyd® Hi-TEC 480waterborne base coat. “When Baden-Jensen introduced the new Spies Heckerbase coat, we thought hard about whether we wanted to change to thisnew technology,” he recalls. “In the end,however, Baden-Jensen convinced usof the modern waterborne base coat – it was simply more efficient.”

Ralph Makholm is now more than gladto have taken the plunge in changing to the new technology. “The base coathas undoubted advantages. It is easy toapply and the results are always thesame – regardless of the person wieldingthe spray gun. Outstanding results havebeen achieved even by our youngesttrainee,” the businessman reports with a smile. At the same time, blending-in is much easier with the new system.Minor flaws like runs in the wet paint cannow be corrected without touching up.“This saves us both time and money,”says Ralph Makholm summing up.

“We’re impressed!”Over a year’s experience with Hi-TEC in Germany.

Senior refinisher Mike Buhl organizesthe work processes in the refinishingdepartment at the BMW Müller dealer-ship in Leipzig. Here, damaged paint-work has been refinished with the newSpies Hecker Permahyd® Hi-TEC 480Base Coat for over a year now.“More than anything else, the new prod-uct system has made our processeseasier. And this in turn makes the resultseven more reliable,” the 39-year-oldstresses. Each refinisher has his ownstyle of paint application or uses differ-ent spray guns – and yet they all achievethe same finish.

The changeover to Hi-TEC 480 in Leipzigwas child’s play and was quickly accom-plished. “The product blends in well,and the transitions are smooth and freeof boundary marks,” is the unanimousanalysis. Mike Buhl: “The new water-

borne base coat dries hard quickly, canbe sanded directly and has flash-offbehavior similar to that of solvent-basedmaterial.” Color reproducibility, he hasfound, is very precise. “There’s a per-fect match between the sample paneland the painted repair. What’s more, theproduct is versatile in its application. Byadding hardener to the waterborne

“The right decision!”Two Austrian bodyshops and their assessment of the system’s reliable results, flexible application and savings.

For over a year now, paint repairs at the Austrian bodyshops of IDENTICApartners Lietz in Wolfern and Ofer inWachsenberg have been carried out withthe Spies Hecker Permahyd® Hi-TEC 480Base Coat. Robert Lietz is particularlyhappy with the reliability of the resultsthanks to the uniformity of the metallicand pearl effects. “Since we’ve beenusing the new Hi-TEC system, mottlingand shading have ceased to be a prob-lem,” the managing director stresses.

Günter Wernig, senior refinisher and old hand at Ofer, emphasizes the relia-bility of the results too. Also useful is theproduct’s flexible use for interior, multi-stage and multicolor finishes with added

hardener. And he finds in particular thatthe silver colors display high opacity.“This is where we can save considerablequantities of material,” he concludes.Robert Lietz is quick to chime in: “Withthe new product system, we’ve achievedtotal savings of about ten percent.” Bothbodyshops are very happy with theirswitch to the waterborne base coat: “It was definitely the right decision!”

is excellent requiring just 1.5 coats, and drying times are not ‘fickle’ but ex-actly as stated,” is his observation.

The verdict from the UK: “Consistentapplication and consistent color meansthat we as a company can remain in aleading position and meet the needs ofour customers and ensure continuingmanufacturer approvals and support.”

Dave Yoeman, Bodyshop Manager, Spies Hecker’s Andy Baxter, and owner ofCUI member Road and Race Restorations, John Bradshaw.

base coat, it’s possible to quickly paintsuch areas as the car interior and en-gine compartments with the matchingcolor.” His verdict: “We’re impressed!”

Mike Buhl of Autohaus Müller, Hi-TEC pilot bodyshop, Germany.

Spies Hecker importer Finn Baden-Jensenand Ralph Makholm of SundsholmensAutolakering, Denmark.

Hi-TEC pilot bodyshop IDENTICA Lietz, Austria.

Hi-TEC pilot bodyshop IDENTICA Ofer, Austria.

Günter Wernig.

76 colorexpert

Hi-TEC

“Simply better!”Two trailblazers from the Netherlands give their answers to the question: “Does Hi-TEC really do what it claims to do?”

Mathijs van Leeuwen of Schadenet vanLeeuwen in Kesteren says it does. “Wecompletely changed over to Permahyd®

Hi-TEC 480 within a day. This was pre-ceded by two days of training – and afterthis, everything went smoothly from theword go.” Dennis Hulzentop, refinisherat Schadenet van Eeden in Cuijk, con-firms the ease of working with Hi-TEC:“Obviously, we had to get used to it onthe first day, but since then we’ve gotalong really well with the new system.”

“Permahyd® Hi-TEC flashes off reallyquickly,” stresses Mathijs van Leeuwen.“Any paint flaws can be corrected imme-diately. And blending-in is also quick andeasy. In addition, Permahyd® Hi-TEC isexcellent for minor repairs as well.” ForDennis Hulzentop, the system’s opacity,corrigibility and flow are the outstandingpluses: “The paint dries very quickly.This way we can remove dust particlesearlier and mask the surface straight-away for further processing.”

The two businesses openly agree: “Our previous products from Metalak,our Spies Hecker supplier, were alreadyvery good. But this system is simply better!”

“Excellently equipped for the future!”By launching Hi-TEC 480, Spies Hecker has struck a chord with the trade in Switzerland as well.

“What we’ve clearly found is that thenew product system makes the pro-cess more dependable,” affirms BennoSchütze, in charge of the refinishingdepartment at Carrosserie Zumbrunn inSissach. The bodyshops in Biel-Benkenand Füllinsdorf have also switched tothe innovation from Spies Hecker.“We’ve opted for the new system be-cause we, like Spies Hecker, are in favorof technical developments that makeprocesses in the bodyshop easier,” sayAngelo Grasso and Erwin Leu explainingtheir motives for introducing the newpaint system. Managing Director RogerSteimann of CS R. Steimann AG inBachenbülach found familiarization real-ly easy: “The changeover to Hi-TEC 480went off quickly and without a hitch.”

Erwin Leu, Volker Wistorf, Selcuk Özgül, Roger Steimann and Angelo Grasso.

greater flexibility than ever in the allo-cation of jobs to different painters,” is theverdict from Laufental, for instance. Inconclusion, the Swiss pilot bodyshopsall agree: “Impressive in practice – andwe’re excellently equipped for the future!”

Like in Baselbiet – as well as at all thebodyshops we questioned, as it hap-pens – the professionals in the Cantonof Zurich appreciate the staggeringlyuniform paint results. “The process se-curity afforded by the system gives us

Hi-TEC pilot bodyshops Schadenet van Leeuwen and Schadenet van Eeden, Netherlands.

Approval

Star effects.For the painting of rims and add-on parts, new Spies Hecker Permahyd® Silver StarBase Coat conjures superfine silver onto vehicle parts.Whether used for tuning, rims or accessories, Permahyd® Silver Star Base Coat yieldsa smooth, aluminum-like gloss with its microscopic metal pigments. Its preferredfield of application is the repair and original finishing of rims and add-on parts suchas mirror housings. “Such vehicle parts are usually coated in extremely fine shadesof silver,” explains Frank Barduna, Technical Manager at Spies Hecker.

Refinishers achieve the brightest effects if they spray a film of clear coat straight ontothe surfacer before base coat application and then lightly sand the surface to preventthe effect from being marred by variations in substrate texture. The VOC-compliantbase coat can be recoated with any Permasolid® clear coat applied in 1.5 coats.

A sign of trust.Manufacturer approvals stand for tested quality and reliable repair solutions.

To obtain a repair approval from a ve-hicle manufacturer, the products con-cerned have to satisfy a multitude of criteria and pass numerous tests. Themanufacturer tests whether the refinishpaints meet the standards of the OEMfinish and can be used for warranty work.

Spies Hecker has been cultivating closepartnership with the automotive industryfor years. Worldwide, the company hasbeen awarded over 100 approvals by 40 vehicle manufacturers. These are anassurance that the various vehicle spec-ifications are complied with when abodyshop repairs accident damage withSpies Hecker products. Along with thetechnical requirements, certain servicesare also a permanent feature of theagreements with the various automobilebrands.

Making targeted use ofbrand approvals.

Consumers are attaching growing im-portance to manufacturer informationand verifications of product quality. In business with private customers, thebodyshop can therefore make targeteduse of manufacturer approvals. “This isa convincing argument, particularly forworkshops that mainly repair premiumbrands,” stresses Karsten Jürs, SpiesHecker Marketing Manager. “The body-shop can thus reinforce the customer’strust in its work and in the quality of therepair.”

Recognized repair quality: Car manufacturers rely on Spies Hecker.

9

Technology

8 colorexpert

Products

Filter out of kilter?

Punctual filter replacement in the spraybooth is something refinishers cannotafford to forget. Often, however, cloggedceiling and floor filters are only noticedwhen defects, dust inclusions and blisters have already got of hand. “The ceiling filter should be replaced at leastonce a year,” Jürgen Becker, Head ofFilter Service at Freudenberg FiltrationTechnologies, advises. “And, given asteady flow of work, the floor filters arereplaced on a weekly basis.”

Preparation.

Maintenance work should be carried outat the weekend, as it puts the booth outof operation for several hours. “Whenchanging the ceiling filter, the holding

With its wide-ranging applications and rapid drying of 10 to 35 minutes at 60°C metal temperature, the new Permasolid® HS Optimum Plus Clear Coat 8650 from Spies Hecker makes a big impression.Varied uses – for everything from standard repairs to Speed Repair. “In the development of the product, we set ourselves the target of making the application process for clear coat even more efficient,” says Jörg Sandner of Technical Service at Spies Hecker. “Thanks to its rapid drying, Permasolid® HS Optimum PlusClear Coat 8650 can be quickly and easily polished. This boosts bodyshop productivity.”Good results are achieved even in less favorable conditions in the spray booth. This innovative high solids product thus contributes greatly to optimization of the overall work process. The clear coat can be used forpartial and full vehicle resprays. The VOC-compliant clear coat from Spies Hecker is best of all for busi-nesses that frequently carry out Speed Repairs to remedy minor damage.

A fast finish.New Spies Hecker Permasolid® HS Optimum Plus Clear Coat 8650 permits simple application and extra-fast drying.

frame has to be thoroughly cleaned,”the expert explains. Vacuuming andwiping it with a damp cloth are indispen-sable. “What’s more, the new cut-to-sizeelements have to be carefully insertedwithout folding.” The right clothing forthis is disposable overalls, goggles, gloves and a dust mask.

Ceiling filters.

“The dust and fiber particles respon-sible for paint defects enter via the air,”Jürgen Becker stresses. This is why efficient filtration of the incoming airinvolves not only the ceiling filters, butalso the prefilters. This is where pocketfilters are mostly used. Just how oftenpocket filters have to be replaceddepends ultimately also on the location.“Air contamination in towns is of coursemuch higher than in rural areas. Thepressure difference at the filter shouldbe monitored and not exceed 250 Pa.”When changing prefilters, the dirty andclean air sides should be cleaned.Vacuuming is usually sufficient for this.Jürgen Becker: “When fitting the new filter, see to it that the printing is on thedownstream side and that there is anairtight seal.”

Dust inclusions are a nightmare for any refinisher. So if you want to prevent such paint defects, it’s all the more important to change the filters in the spray booth correctly and in good time.

Versatile hardeners.You can only achieve outstanding paint-ing results if the hardener is adaptedcorrectly to the working environment. A number of points have to be borne inmind.It is always important to consider theprevailing ambient conditions and ob-ject size. If, for instance, an excessivelyfast-drying hardener is used in highsummer temperatures, solvent poppingor matting may occur. The choice of hardener also depends on whether acomplete or partial respray is involved.

The Spies Hecker system poster indi-cates which hardeners should be usedin which conditions. The poster is avail-able for downloading free of charge atwww.spieshecker.com.

Floor filters.

If the pressure in the booth rises andextraction performance deteriorates,it’s time for a floor filter change. Carehas to be taken particularly when re-placing the overspray arrestor. Replace-ment should not be carried out imme-diately after spraying, because the sep-arated paint still has a high proportion of solvent in it. After removal, don’t store it in a closed container on any account,because of the serious risk of explosion.“Ensure an unhindered exchange of airso that the residual solvent can evap-orate,” is Jürgen Becker’s urgent rec-ommendation. Depending on the paintmaterial applied, the floor filters canusually be finally disposed of with theother commercial waste.

In a nutshell, paint defects of all kindscan be minimized with regular filtermaintenance. “You then have extremelyclean conditions for your work andachieve flawless results.”

Checklist for filter maintenance.

• Regularly replace floor filters• Change ceiling filters at least once a year• Clean holding frames• Insert cut-to-size elements without folding• Monitor pressure differences at the filter• Clean prefilters on the dirty and clean air sides• Check the airtightness of the fitted filters• Dispose of filters correctly• Maintenance work is best carried out at weekends

Spray booth filtration concept.

Air supplyCeiling filter

Floor filter Prefiltration with pocket filter

1110 colorexpert

Creative job.For refinishers, effect colors mean new challenges and exacting processes.

Let’s take a look back in time. 20 yearsago, solid colors still dominated work in the bodyshop. Since then, the job ofthe refinisher has undoubtedly becomemuch more sophisticated and varied.Because matt finishes, numerous spe-cial effects, tinted clear coat and 3-stagefinishes have brought much more diver-sity into everyday work.

Special effects.

“The huge diversity of colors calls, on theone hand, for greater knowledge fromusers and, on the other hand, for prac-tical product solutions from paint man-ufacturers,” explains Dietmar Wegener,Spies Hecker coloristic expert. “Newcars with some 1,000 new colors comeonto the market each year.” And, unlike20 years ago, special finishes now alsogo into series production. “This confrontsthe refinisher with two key challenges:firstly, selecting the right refinish colorby digital color measurement with theColorDialog spectro and, secondly, preparing properly for the job in order to achieve immaculate results.” This ishardly feasible these days without digitalcolor management, Dietmar Wegenerbelieves.

While Nissan, for example, catches theeye with its KAB Ultimate Metal Silver,Ford pins its faith on a powerful Hot Magenta. Toyota, Porsche, Opel, Renaultand other manufacturers, for their part,boost their brand impact with effectpaints containing special Colorstream®

pigments.

Solutions for paint repairs.

Quick to respond to this trend, SpiesHecker has long been offering repairsolutions perfectly attuned to specialeffects. “For instance, for the repair ofnumerous special effect finishes, we’vegot special additives and ready-mixcolors,” Dietmar Wegener explains. “Wecan thus supply our customers with atinted clear coat geared to OEM paint-work. It contains the same pigmentationas the production-line paint material.This makes it possible to re-create theoriginal appearance.” Another example:For paint repairs to the Nissan GTR colorKAB Ultimate Metal Silver, a ready-mixcolor of the Permahyd® Base CoatSeries 280 and Permahyd® SpecialAdditive 9016 are employed.

Special knowledge is also, of course,demanded. In this case, contrasting withthe usual sequence of coats, a clear coatis applied straight onto the sanded sur-facer or sanded original paintwork oncompletion of substrate pretreatment.You can find out which application-relatedrequirements are important for the vari-ous products and effect finishes on theinternet at www.spieshecker.com/tds.

Color

Dietmar Wegener, Color Project Manager.

Progress in paint repairs almost knowsno bounds! With the “Result com-parison” function in the Spies HeckerCRplus formula software, the refinishercan now view digitally measured colorsat the monitor and, if necessary, correctthem. The precise quantities of materialrequired can now be calculated at thecomputer as well.

Result comparison at the monitor.

First of all, the color is measured at thevehicle with the ColorDialog spectrospectrophotometer and transferred tothe PC (e.g. ColorTint PC DesktopSystem). After this, the CRplus softwaresearches for matching colors in the formula database. The measured colorand the suggested formula are then displayed side by side on the screen. Ifdesired, the system even automaticallysuggests a correction to the formula.Once the refinisher is satisfied with theresult comparison, the data of the colorformula can be transferred to the elec-tronic scales for immediate mixing.

“The formula and proposed formula cor-rections are immediately visualized andcan be checked much better and fasterby the refinisher,” explains enthusiasticcolor specialist Dietmar Wegener. Thismakes the choice of color more accurateeven before a sample panel is sprayed.

More efficient calculation.

But this is by no means everything theCRplus software can do, as it also cal-culates the required quantity of paint.“The ‘Volume suggestion’ tells the userhow much base coat he needs for therepair,” Dietmar Wegener continues.How does this work? After selecting thematching color, the refinisher selectsthe repair location on the vehicle and theprogram suggests the required quantity.

The steps in detail: 1. Selecting one ofthree vehicle sizes (small, medium andlarge). 2. Marking the damaged parts.

Dietmar Wegener: “This is where the en-visaged process can be entered, e.g.exterior painting, interior painting orblending-in.” As a result, the refinisher istold which quantity of color has to bemixed. A useful feature here: “Users caninput their own personal experience inthe settings, i.e. to the effect that more

or less material tends to be used thansuggested. This stored information canthen be applied to future suggestedquantities.”

The two functions optimize materialusage in the bodyshop and thus ulti-mately benefit the environment. “Therefinisher is concerned with selectingthe matching color and the requiredquantity of material before the color ismixed,” says Dietmar Wegener, sum-ming up the huge advantages.

Efficient, quick and fast!The Spies Hecker CRplus formula software not only takes the effort out of color management, but also facilitates more efficient material usage.

CRplus: comparison of formula and measured data.

CRplus: volume suggestion.

Professional Color Management.

Absolutely essential for a good refinish is correctly identifying the color.

The future for refinishers involves craftsmanship aided by digital equipment. With the ColorDialog spectro spectrophotometer and the CRplus Spies Hecker formula software, you benefit from professional color management – for reliability throughout the process and efficiency for your business.

Spies Hecker – simply closer.

© Spies Hecker GmbH, 07/2011

Place the ColorDialog spectro on the cleaned surface and carry out three measurements in slightly offset positions.

Record and assess the damage. Spray a sample panel.

Sample panel.5

The function “Volume suggestion”calculates the required paint quantity for the repair of vehicle parts in a chosen process, e.g. exterior or interior paintwork or blending-in.

Color mixing.4

Polish and clean the measurement area close to the damage.

Measuring the color.2

Find the color code on the type plate or in the vehicle’s service booklet.

Archive the sample panel.

Apply the mixed paint to the vehicle.

Print out the manufacturer andcolor formula with a barcode onthe label and stick it onto theback of the sample panel.

Compare the panel at the vehicle in daylight or under a daylight lamp.

The scale function on the screenaids color mixing and automat-ically corrects the formula in theevent of weighing errors.

The function “Result comparison”displays the measured color and the formula from the database on the screen.

Enter the vehicle manufacturerand color code to narrow downthe formula suggestions.

The color formulas with the closest match to the color are listed.

For effect paintwork, determinethe coarseness of the metallicpaint with the Effect Index.

With the CRplus formula software,read the measured color data into the PC.

Formula search.3

The function “Shaded effect color”adapts the database formula to the measured color values. Store the corrected formula.

Job acceptance.1

Painting & final tasks.6

1514 colorexpert

Practice

A legend comes back to life! The Audi Sport quattro S1 ranks amongthe most exciting and ground-breakingrally cars of motor racing history. Itsdrive concept, its primordial power andof course the successes of its drivers – the likes of Walter Röhrl, Stig Blomqvist,Michèle Mouton and Hannu Mikkola –have indelibly imprinted the Audi quattroon the memories of rally fans.From 0 to 100 km/h in only 2.6 seconds.The first rally car with permanently active four-wheel drive. It was an icon.Technology that still inspires today. “I saw the Audi Sport quattro S1 for thefirst time on television 25 years ago,” a moved 51-year-old bodyshop ownerVolker Gehrt tells us. To mark his firm’s25th anniversary he set himself a thor-oughly ambitious goal – that of con-structing a replica of this legendarysports car.

A race track mind.

An audacious project, because all tracesof the winning car of yore have sincevanished. No one knows anything aboutthe Audi’s whereabouts. Undaunted,Volker Gehrt embarked on his en-deavor together with Roland Gumpert, former manager of the Audi team.With passion and expertise, the wholeteam of the paint- and bodyshop inGermany got down to work. Three yearsof planning and a year of hard graft.“The main challenge involved gettingthe Audi back on the road as true to the original as possible,” Volker Gehrt stresses. “Numerous components wereno longer available – no amount ofmoney or smooth talking made any difference.”

Reliving sporting history.

Instinct, perseverance and good con-tacts were necessary in tracking downplans and parts. To construct the S1body, Audi resorted in 1985 to parts fromstandard production. “We needed threewhole Audi quattro bodies from thatyear. On top of this, we had to machinea whole host of components ourselvesentirely from scratch,” Volker Gehrtexplains. To rebuild the gearbox, it wasright back to the drawing board for former design engineer Werner Kugler.

Retro with Hi-TEC.

The painting of the Audi Sport quattro S1replica posed an entirely new challengefor Volker Gehrt: Alpine white and HByellow – how is it possible to replicatethe old colors accurately with moderntechnology? A question to which SpiesHecker had the only fitting answer: “We put together our own special painthistory,” explains Dietmar Wegener ofSpies Hecker Color Management. Afterexhaustive searches, the specialistmanaged to pinpoint the original colors.

“With the digital ColorDialog spectrospectrophotometer and the CRplusformula software, we came up with thecolors for the ground color and logostrip in new Permahyd® Hi-TEC quality.”The entire Audi Sport quattro S1 replicawas then painted with Hi-TEC water-borne base coat in just two days. “Thenew system lent itself particularly well toquick and neat application of the multi-color paintwork,” Heiko Pätz, VolkerGehrt’s senior refinisher, confirms.

In short, this is a happy marriage of his-tory and technology. Thanks to modernpaint technology, the retro paintwork isvirtually indistinguishable from the orig-inal. Dietmar Wegener: “By affixing bar-codes to the sample panels, the formu-las can be quickly read off at any time.”This will facilitate touch-ups on the body.Because the Audi Sport quattro S1 isnot destined for the museum. Racingdriver Walter Röhrl has already taken itout for a spin on the Sachsenring racecircuit. Races at the Nürburgring and in San Marino are scheduled to follow. And then there are Monte Carlo and San Remo. This is a success story thathas impressively brought a legend backto life.

Rekindling memories of its glory days, the legendary Audi Sport quattro S1 is back!25 years on, Volker Gehrt rebuilds a detailed replica of the rally car – with craftsmanship, modern technology and a passion for motor racing.

Technical data Audi Sport quattro S1 replica.

• Engine: five-cylinder, 2100 cc displacement• Output: 330 kW (560 hp) at 7500 rpm• Dead weight: 1085-1195 kg• Top speed: 220 km/h• Price: priceless and not for sale

True-to-original finish with Permahyd® Hi-TEC 480.

“Accurately reconstructing the Audi S1 was a brilliant idea.When I saw the car for the first time, it was like being trans-ported 25 years back in time. The amount of work that goesinto building such a replica is incredible.”

(Walter Röhrl, German racing driver who drove to World Championship victory in San Remo on October 4, 1985.)

“A rally car with permanently active four-wheel drive –something that had been previously inconceivable. But theimpressive track record speaks volumes. A masterly achieve-ment by the Audi engineers!”

(Stig Blomqvist, Swedish race driver who clinched the World Championship by winning the Rally Ivory Coast in the Sport quattro in 1984.) Stig Blomqvist, World Champion 1984.

Take part ...

and with a bit of luck you can win one of five Audi Sport quattro S1 model cars: www.spieshecker.com/hitec-s1

Professional color management is essential for efficient processes. Giving you access to over 35,000 Hi-TEC color formulas, the CRplus formula search program delivers rapidresults in your search for colors. We help you to find any color faster.

Spies Hecker – simply closer.

Spies Hecker GmbH · Horbeller Straße 17 · 50858 Köln · www.spieshecker.com

ems-

p.c

om

Our refinishers find formulas faster.

Based on practical requirements, Spies Hecker training is tailored to your particularneeds. At the Training Center, we introduce you to new product systems and paintingtechniques. Together, we optimize your processes and thus boost the efficiency ofyour bodyshop.

Spies Hecker – simply closer.

Spies Hecker GmbH · Horbeller Straße 17 · 50858 Köln · www.spieshecker.com

ems-

p.c

om

Our refinishers aremore knowledgeable.

1716 colorexpert

Worldwide

Heiko Becker, Becker Automobildesign.

Practice

Pure passion.

In the fast lane.Becker Automobildesign has made a name for itself as an international expert in Porsche restoration.

With their unusual shape, inimitablesound and superlative quality, Porscheshave many admirers – one of thembeing Heiko Becker. Fascinated by thesports car brand, he has made his passion his profession. Becker Auto-mobildesign in Germany specializes inthe repair and restoration of Porschemodels.

Formative workshop years.

It all started when the now 40-year-oldwas still a teenager: “When I was 19, I worked at a repair shop that did up old sports cars,” he recalls. “One of thefirst vehicles that I worked on was aPorsche.” His absolute favourite, a 9112.5 GT, as it happens. He had one ofthese rare models for repair at his ownbodyshop only last year.Heiko Becker has been running his ownbodyshop since 2005 – with 14 perma-

nently employed staff, including tensprayers. Business expansion is in thepipeline. Anyone visiting the businesscan’t help noticing how neat and tidyeverything is. “A clean shop for neatwork” is his motto. “My team is a blendof young and old, all of them highly skilled.” The company owner attachesspecial importance to teamwork be-tween the refinishers and body repair-ers. Young and old, experience andenthusiasm – a combination that seemsto work well at Becker Automobildesign.Characteristically, the vehicles in therepair shop are a mix of historic andmore recent. About 50 percent comefrom private owners.

Speeding into action.

The sports cars from Becker’s body-shop are in race action all over Europe –at the Nürburgring, in the Rally Trieste-Vienna or in the Trofeo Baleares. “Four

to five meetings take place per year inGermany alone,” explains the business-man, who goes to many races himself.“This is an excellent opportunity to cultivate existing contacts and establishnew ties.” Two 911 3.0 RS cars are con-stantly on the road in rallies and on racecircuits, sporting the Becker companylogo.

A brand for booming business.

His commitment to Porsche has paid off – business is flourishing. By special-izing, the firm has made itself independ-ent of insurers, dealerships and thestate of the economy. Because classiccars and motor racing are two crisis-resistant sources of business. As far asattracting new customers is concerned,Heiko has been relying for some timenow on others to spread the word.“Almost all of our customers come to uson the strength of personal recommen-dation from friends and acquaintances,”he proudly tells us. Heiko Becker’s bodyshop certainly isn’twary of new technologies – neither ofthe internet, nor of innovative productslike Spies Hecker Permahyd® Hi-TEC 480Base Coat.

And paint supplier Spies Hecker haslong shown an interest in Becker’s suc-cess story and has showcased the busi-ness in a large-scale advertising andcalendar shoot.

Global togetherness.

With its offers of practical training, compact seminars for business owners,supportive marketing measures andface-to-face consultations, Spies Heckermaintains close contacts with its cus-tomers at all times. “Simply closer”,after all, has long been the paint manu-facturer’s guiding principle – and onethat it also acts on. It’s therefore no surprise that the current Spies Heckeradvertising campaign is also stayingtrue to this motto and presenting thebodyshop as the central scene of theaction. Not least thanks to this extremely closepartnership, the Cologne-based paintmanufacturer understands what body-shops need most. “The new ad motifstake up these close relations and pre-sent concrete solutions for processes inthe bodyshop,” explains Peter Wingen ofSpies Hecker Marketing. “The motifs alsostress the advantages for Spies Heckerrefinishers and, together with the text,generate a strong sense of togetherness.We are, after all, a global team.”

Innovative Permahyd® Hi-TEC 480 waterborne base coat brings a new dimension to vehicle refinishing – with easy processing, rapid blending-in and flexibility in its application.We help you achieve greater process security.

Spies Hecker – simply closer.

Spies Hecker GmbH · Horbeller Straße 17 · 50858 Köln · www.spieshecker.com

ems-

p.c

om

Our refinishers work at the highest level.

Preparation for the photo shooting at Becker Automobildesign.

“Passion 2011”: Devoted to the passion for paint, the current Spies Hecker calendarguides us through the year with twelve dynamic pictures of vehicles. “In our choice ofmotifs, we’ve put the emphasis on highly innovative or unusual bodyshops,” explainsPeter Wingen of Spies Hecker Marketing. Repair shops in Austria, the Czech Republic,Germany, the Netherlands, Switzerland, Spain and the USA opened their doors toSpies Hecker this time.The pictorial language of “Passion 2011” differs from that of its predecessors. The images are all printed without a margin, thus creating a special visual tension.There’s a good reason for the ongoing success of the Spies Hecker calendar series,now in its sixth year, Peter Wingen believes: “We’re simply closer to the customer,showcasing him with his skills and enthusiasm.” The refinisher’s craftsmanship andtalent are pure passion – and this is something the viewer senses in all the calendarpictures of the year. The 2011 calendar motifs can be downloaded as screen savers:www.spieshecker.com/passion2011.

PUR Top Coat Series 570.PUR Matt Top Coat Series 555.PUR Textured Top Coat Series 560.

• High mechanical and chemical resistance• For indoor and outdoor applications• Suitable on primed substrates

Acrylic Plus Top Coat Series 575.

• High UV stability• Special system for window frames

Acrylic Top Coat Series 550.

• For 1-coat application / without primer• Apply direct onto steel, aluminum and zinc• For indoor and outdoor applications

Stone Chip Top Coat Series 515.

• High mechanical strength• Improved for pump application

PUR

1918 colorexpert

Products

The all-important binder.Industrial coating is a multifaceted field of business with constantly growing demands on the refinisher. With the Spies Hecker Permaflex® paint system, a broad range of surface finishes, effects and degrees ofgloss can be achieved. And it is the selected Permaflex® binder that determines the special properties of theproduct in its mixed state.For advice on specific applications, Spies Hecker experts are always willing to help.

Iron Mica Top Coat Series 510.

• High mechanical and chemical strength• Typical iron mica gloss and effect• High weather resistance

Alkyd KH Top Coat Series 530.

• Suitable for indoors and outdoors• Also suitable for rolling and brushing• Accelerator 9011 improves complete drying and

permits faster recoating

Epoxy EP Top Coat Series 540.

• Suitable for special applications in interiors• For objects with extreme surface hardness and

high mechanical and chemical resistance, e.g. floors, machines

Nitrocellulose NC Top Coat Series 520.

• Suitable for indoors• Quick air drying

Acrylic Plus

Acrylic

Stone Chip

Epoxy

Iron Mica

Alkyd

Nitrocellulose

Optimal CV surfacer.If extra-high productivity is called for in the bodyshop, refinishers can now resort toPermafleet® VHS Wet-on-Wet Surfacer 5620 from Spies Hecker. “What makes thenew Surfacer 5620 special are its simple application, excellent sprayability and out-standing gloss and flow,” stresses Arno Steyns, Spies Hecker commercial vehiclepainting expert. “What’s more, its broad range of processing conditions and long potlife create greater leeway during application.” These two factors are of special impor-tance on commercial vehicles, as Surfacer 5620 makes the coating of large surfaceslike those on trailers and buses possible.Permafleet® VHS Wet-on-Wet Surfacer 5620 is approved for all Permahyd® Water-borne Base Coat systems and Permafleet® 2K Top Coat systems. The product is avail-able in dark grey and white in 3.5-liter cans.Sure and fast processing, high quality, and results on large surfaces you can count on:New Spies Hecker Permafleet® VHS Wet-on-Wet Surfacer 5620 yields high-gradepaint finishes and boosts the efficiency of bodyshop operations.

Flexible uses.

Damage to bumpers, scratches on doorsand accident damage – the types ofpossible damage are many. Anyone whowants to repair damaged paintwork professionally has to be flexible – a precondition satisfied by the newPermasolid® HS Clear Coat 8055.Suitable for any kind of repair, it is easyto apply and creates process security.“The VOC-compliant high solids clearcoat is ideal for all kinds of repair – foranything from spot repairs through topartial and full resprays in the spraybooth,” explains Frank Barduna ofTechnical Service International. “What’smore, the new clear coat strikes a perfectbalance between fast drying and gloss.”

Industrial coating.

The new clear coat from Spies Heckerhas been designed for the waterbornePermahyd® Hi-TEC 480 and Permahyd®

Base Coat 280/285 systems. The clearcoat is applied in 1.5 or 2 coats. Themixing ratio is 3:1 with Permasolid® VHSHardeners plus Permasolid® HS ClearCoat Additive 9034. “The additive opti-mizes the clear coat’s flow characteris-tics. For spot repairs, Accelerator 9025or Additive 9026 can be used instead ofAdditive 9034. This way, small areas canbe efficiently processed,” the expertpoints out.

2120 colorexpert

Management

Now you’re talking!Communication expert Thomas Wetzel explains how to achieve greater success in dealings with customers.

Mr Wetzel, what’s the best approachfor the employee at customer recep-tion?He should pay close attention to howthe customer comes across. What’s hereally trying to say? If he only mentionsthe damage and asks for a repairstraight off, a matter-of-fact reaction isabsolutely appropriate. If, on the otherhand, the customer is upset and ventshis feelings, his primary need is for asympathetic response before you getdown to business. More advice or less,comprehensive support or simply a spe-cific, quick solution – in customer serv-ice, a good deal of intuition is called for.Openness, an ability to listen and saythe right thing at the right time – a diffi-cult task, although dealing with peopleis something you can learn. In addition,the after-sales service employee is ofcourse also a seller. Offering extra serv-ices is therefore involved.

Is it true that negotiations with in-surers or claims managers differ fromthe usual meetings in after-salesservice?Yes, because it is here that the onus ison the business owner and particularlyon careful preparation for the meeting.This is the way to avoid any uncertaintythat the other side will immediatelysense. Probably the most difficult meet-ings are price negotiations. It is impor-tant here to accurately calculate prices,feel free to quote them, justify them andexplain them – without becoming de-fensive. My advice is to run throughprice negotiations in advance and try toput yourself in your opposite number’sposition. This way you can develop suc-cessful strategies and respond smartlyto whatever comes up.

Thomas Wetzel, communication expert.

Lean thinking.Boosting profitability: Bodyshops in the UK focus on value and efficiency in cooperation with Colors Unlimited International.

There’s growing demand for processesthat improve efficiency. The SpiesHecker expertise programme ColorsUnlimited International (CUI) has re-sponded to this with the Lean Thinkingbusiness strategy. Together with BritishCUI members, a Lean Academy hasbeen established by drawing on the lean knowledge and experience of UKprogram partner Muradi LLP. “This iswhere bodyshop employees find outhow to focus on value for customers andmake work processes better – and howto effectively combine the two,” explainsGary Steele from Muradi.

Staying competitive.

So that businesses stay competitive, the CUI partners subject all processesto close scrutiny. Commercial and entrepreneurial specifics are studied,analyzed and assessed with the goal ofachieving better use of staff, reducingtouching-up, preventing unnecessaryvehicle maneuvering, and managingmaterials and spare parts efficiently. The basic idea is that, in a lean business,work flows from one value-generatingactivity to the next proceeds steadily –without interruptions and without round-about routes.

Optimizing processes.

“Disruptions to the work process and theincorrect use of materials can be foundin every facet of the organization and inodd places you might not think of,” saysCharles Williams, owner of CUI partnerC&P Panelcraft. Sometimes it’s thepoorly organized workplace where im-portant tools are missing because theyare scattered about the bodyshop. Allsearching and wasted effort then meansextra – and absolutely avoidable – cost.

Or polishing a whole vehicle althoughonly the newly painted parts ought to bepolished. The office is also often enoughthe scene of redundant activity – forinstance, when far too many office sup-plies have been ordered or a price quotehas to be repeatedly revised.

Transparency on all levels.

“Lean thinking is a slow burning processwhich benefits the whole organizationand carries a real potential to signifi-cantly increase profits,” says a confidentCharles Williams. This is why LeanManagement involves critically exam-ining and rethinking each work area andeach step in the process. Clearly definedtasks and responsibilities and a quickresponse to mistakes yield more stableprocesses in the end – and ultimatelygreater customer satisfaction as well asa thoroughly balanced working atmos-phere.

Let’s move on to complaints. How cannegative incidents be turned intopositive encounters?First of all, the customer must be allowedto let off steam before you discuss thematter in hand. If you can then showsympathy for the customer’s response,you can pick up useful points. Which ofcourse shouldn’t mean making excusesfor the problem itself. Once a construc-tive conversational atmosphere has beenestablished, it should be utilized formaking a good impression with a swift,unbureaucratic handling of the com-plaint. This also gives you an excellentopportunity to present your after-salesservice in its best light. However, avoidadmissions of guilt and always proposeconcrete solutions.

Can greater success be achievedwith communication training?Professional communication certainlyalso needs a certain degree of profes-sional training. With sufficient practice,you gain self-assurance and proficiency –and thus achieve greater success. Theresults will manifest themselves in animprovement in the order situation, a fallin the rate of complaints and growingcustomer satisfaction. In other words, if you can communicate effectively, youcan improve your competitive position.

Mr Wetzel, thank you very much forthe interview.

Gary Steele, Muradi’s Lean expert.

2322 colorexpert

Worldwide

Reflections.

Devilishly good!

Creativity, a sure hand, a delicate touchand fervor – airbrushing is a real challenge for the refinisher. And this is a view endorsed by Michal Slánský,technician of the Czech Spies Heckerdistributor Interaction s.r.o. Airbrush arthas been his all-consuming pursuit forover ten years now.

Just what the refinishing trade is capable of was recentlydemonstrated by the Drews IDENTICA bodyshop in Hannover on a special occasion. Taking part in the “Design Your Car” com-petition organized by the pan-European Spies Hecker IDENTICAbodyshop system, the bodyshop beat all comers with a remark-able devil design created by the vehicle’s owner.Business owner Harri Luze and his team invested over 60 hoursof consummate craftsmanship in the paint finish. “Bringing cus-tomer dreams to life always has its own special appeal,” enthusesthe manager who, in his everyday work, is mainly concernedwith accident repairs, eliminating minor damage and cleaning upvehicles.

This time he’s given a 16.5 kg model airplane with a 3.2 m wing span a spectacular color scheme. However, no less important than the uniquedesign and the quality of the materials isthe final weight, for anything that fliesmustn’t be too heavy.

Using paint to provoke thought: Spies Hecker has supported one of the spectacular projects of Slovakianartist Stanislav Stankoci.The Slovak recently built a sculptureentitled “Pig”. This one-off work of artmade of glass-reinforced plastic wascoated with Permasolid® Premium Sur-facer 5310, Permahyd® Base Coat 285and Permasolid® Clear Coat 8600.“The purpose of my sculpture is to drawattention to the causes and effects ofthe global social crisis – focusing par-ticularly on conditions in Slovakia,”Stanislav Stankoci explains.In his home country, Stanislav Stankocihas a reputation for using his own brandof sarcasm to open the public’s eyes.The sculpture was on show in a gallery inBratislava. “I’m planning further projectsin the near future, and Spies Heckervehicle refinishes will amplify their message,” the artist reports.

Golden age.Nine bridges in Budapest link Buda on one side of the Danube to Pest on the other. A century after its construction, the Liberty Bridge in the Hungarian capital has recently undergone complete renovation.Involved in this project was Alami Kft., the distributor for Spies Hecker paints in Hungary.The job involved repainting the two golden crowns and the four golden balls adorning the iron bridge gate-ways. The substrates were first prepared with an epoxy etch primer so that the gold-colored Spies Heckerbase coat would be able to suitably embellish the bridge for decades to come. To achieve the best-possible UVstability and outstanding gloss, the painters also used Spies Hecker Permasolid® HS Optimum Clear Coat 8600.The golden crowns and balls are now back in place, high up on the time-honored structure.

Flights of fancy.

High-wire act.Architecture and design combined with Austria’s breath-taking Alpine panorama – and right in the middle, all the wayto the top, Spies Hecker. Two of Austria’s architecturallymost spectacular and technically advanced cable cars have been in operation to the Gaislachkogl at 3,058 m sinceDecember 2010. The total of 107 gondolas were painted in Switzerland with “Atlantic Sunset”, one of the Permahyd®

Fascination Colors, by a customer of Spies Hecker distrib-utor CH COATINGS AG.

Photo courtesy of Geza Lorincze owl.hu

With the ColorDialog spectro and CRplus color software, you can identify even sophisticated effect colors in a matter of moments. The Spies Hecker formula database with its weekly updates is available to you online. This way, you can match the latest effect colors with thesame accuracy as standard colors. www.spieshecker.com/colorfinder.

Spies Hecker – simply closer.

ems-

p.c

om

Our refinishers can match any paint effect.

Spies Hecker GmbH • Horbeller Str. 17 • 50858 Köln • Germany • www.spieshecker.com