Collapsed Culvert: INDOT I-465 InfraSteel Stormwater Culvert Repair

-

Upload

cullom-walker -

Category

Engineering

-

view

48 -

download

5

Transcript of Collapsed Culvert: INDOT I-465 InfraSteel Stormwater Culvert Repair

Collapsed Culvert: INDOT I-465 InfraSteel Stormwater Culvert Repair

By Cullom Walker on April 21, 2016 Features/Storm Water/Culvert Rehabilitation

In October 2012, the Indiana Department of Transportation (INDOT) Bridge Inspectors determined a large CMP Arch Pipe culvert, with a span of 16 ft 7 in. and a rise of 10 ft 1 in., was failing under I-465 near Indianapolis. I-465 is a heavily used interstate bypass around Indianapolis, carrying up to 150,000 vehicles per day, of which 15 percent are commercial vehicles.

Originally noted for replacement, INDOT engineers determined that because of the cost and the effect on the traveling public, replacement was not an option.

After evaluating all known options for repair of the structure, INDOT determined that InfraSteel’s smooth-wall carbon steel liner

would provide a cost-effective and environmental-friendly repair.

Precision Pipe first inspected the failing structure in the spring 2013 to determine if its InfraSteel smooth wall carbon steel liner would be a good solution for repair. Other options considered by INDOT were round HDPE, spray-on poly, spray-on concrete, and a spiral-wound coil, which would act as a form for a grout liner reinforced with steel mats. Sliplining with HDPE would have reduced the hydraulic capacity to the extent that an additional bore adjacent to the original structure would have been necessary. There were also concerns about the structural value of the other materials considered.

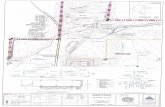

The site of the existing structure came with challenges. A laydown yard was not possible due to concerns of the adjacent property owners, who also own Castleway Drive, which runs perpendicular to I-465 at the location. INDOT officials met with the property owners’ attorneys and condemnation was considered. Additionally, the property owners owned the pond, which provides the primary flow under Castleway Drive into the existing culvert. After evaluating all known options for repair of the structure, INDOT determined that InfraSteel’s smooth-wall carbon steel liner would provide a cost-effective and environmental-friendly repair that was both structurally and hydraulically superior to the other methods considered. “We wanted something proven and you know what you are getting with steel,” said Douglas Dagley, INDOT engineer and project manager. Dagley also wanted a product that could be easily inspected and monitored over time, and InfraSteel required no lay-down yard.

In trying to determine the shape of the existing structure, Dagley was unable to find a match in any recent design manuals and he was informed by the CMP manufacturer that the host pipe was an odd shape that was only made for a couple of years in the 1970s. Unexpectedly, on April 9, 2015, the existing CMP collapsed between the guardrail and Castleway Drive, two months before the job was scheduled to bid. A sinkhole quickly developed and a concrete barrier and shoring were installed, as a temporary fix until the project could be bid and InfraSteel could be installed.

The best determined solution for the project was a 15 ft 4 in X 9 ft 3 in. X 0.875 in. InfraSteel liner with an area of flow of 110 sq ft, a liner with the maximum area of flow that could be sliplined into the host structure. Precision Pipe and Products worked with D.H. Charles Engineering of Santa Rosa, Calif., to determine that an InfraSteel liner, with a thickness of 0.875 in., satisfied HS-20-44 highway loadings with an assumed worst-case scenario of 7 ft for soil-loading and 6 ft for traffic loading.

The best determined solution for the project was a 15 ft 4 in X 9 ft 3 in. X 0.875 in. InfraSteel liner with an area of

flow of 110 sq ft, a liner with the maximum area of flow that could be sliplined into the host structure.

Also, it was decided that InfraSteel would be used to replace the collapsed section as a direct-bury installation, between the shoulder of I-465 and Castleway Drive.

On June 19, 2015, the job was let and Temple & Temple Excavating & Paving, Inc. of Salem, Ind., submitted the low bid of $896,000. Temple and Temple is an experienced contractor, whose subsidiary company T&T Pipe Renovations specializes in culvert rehabilitation. Eric Kennedy with Precision Pipe and Products, Inc. worked hand-in-hand with Temple & Temple project manager Patrick Howser to acquire the host structure measurements. In order for the InfraSteel liner to be made with the exact matching radii of the host pipe, detailed measurements were of the utmost importance. Precision Pipe and Products Inc. has developed an intricate method of measuring and gathering information about the host pipe, which is provided to plant engineers so that they can convert the information into a matching liner. The plant engineers converted the measurements and provided drawings back to Temple & Temple who signed off on them so that production could begin.

Temple & Temple ordered the pipe in 8- to 10-ft lengths with inverted bevels so that all the welding could be done from inside the InfraSteel liner. The first load of the InfraSteel liner was delivered on Sept. 29, 2015, to the I-465 right of way and offloaded from the trucks directly into the pit (that was created by the collapse and subsequent shoring and bracing) with a crane. No laydown yard was required. Temple & Temple’s ground crew used a telescoping forklift and operator to set the InfraSteel liner inside host structure in four days. Next up came a crew of experienced welders who welded up the liner in 21 days, averaging one joint per day. Vertical drainage pipes from the I-465 median were cut and welded into the top of the InfraSteel liner to allow the median to drain inside the rehabilitated structure. The grouting process took three days to complete as 180 yards of grout was pumped into the annular space through grout tubes. The annular space was pressure-pumped in stages with the predetermined calculated volume of grout to ensure there were no voids between the new liner, the existing host pipe and the road.

Due to the collapse that took place in April 2015, an extension of 30 to 40 ft toward Castleway Drive was necessary. Temple & Temple chose to use a flowable-fill grout poured up past the spring line, to give the direct-bury section a solid, stable base. The wood shoring had to be removed and the I Beams were left in place, but were cut down to 30 ft below grade. A headwall was constructed at the inlet end of the extension and 150 yards of rock and dirt was then used as fill for the area between the shoulder and the headwall.

The Indiana Department of Transportation Bridge Inspectors determined a large CMP Arch Pipe culvert, with a span of

16 ft 7 in. and a rise of 10 ft 1 in., was failing under I-465 near Indianapolis. I-465 is a heavily used interstate bypass around Indianapolis,

carrying up to 150,000 vehicles per day, of which 15 percent are commercial vehicles

Failing CMP culverts typically are attacked by abrasion and corrosion. Additionally, they often fail at joints. Each culvert location is different due to the conditions of the specific site. The I-465 site was immediately downstream from a pond and the culvert was being fed from the overflow of the pond. Assuming that the dam stays in good repair and the pond continues to function in its current state, abrasion wear will be minimum, as the pond should retain most of the sediment. Also, California DOT’s destructive testing of culvert products proved carbon steel plate out performs all other culvert products in abrasion resistance testing (re: Caltrans’ “Evaluation of Abrasion Resistance of Pipe and Pipe and Pipe Lining Materials- Final Report” by Glenn DeCou, P.E. and Paul Davies, P.E. September 2007). InfraSteel liners have added copper for corrosion resistance and equations done with the added copper show a loss of mass due to corrosion of 12.5 percent over 50 years (re: “Effect of Alloy Composition on the Atmospheric Corrosion Behavior of Steels Based on a Statistical Analysis of the Larrabee-Coburn Data Set” by Legault and Leckie). There is no possibility of joint failure since the InfraSteel joints were welded and the annular space was completely grouted. The completed I-465 project has a life expectancy of 50 to 100 years.

Cullom Walker is a partner at Precision Pipe and Products and co-founder of InfraSteel Culvert Rehabilitation.