CLUTCHES

-

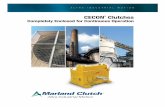

Upload

radhakrishan-pandey -

Category

Engineering

-

view

243 -

download

0

description

Transcript of CLUTCHES

- 1. CLUTCHES

2. INTRODUCTION Purpose Clutch terms Components Construction Of Clutches Clutch Linkage Types of Clutch Clutch Safety Switch Clutch Disk Replacement 3. ClutchClutch is a mechanical device that facilitatestransmission of power and motion from onecomponent (the driving member) to another (thedriven member) when engaged, with a provision fordisengagement whenever required.In the simplest application, clutches connect anddisconnect two rotating coaxial shafts. One shaft isattached to a power unit (the driving member) whilethe other shaft (the driven member) provides outputpower for work. The motions involved are rotary innature. 4. PurposeA clutch is designed with the followingrequirementsAllow the vehicle to come to a stop while thetransmission remains in gearAllow the driver to smoothly take off from adead stopAllow the driver to smoothly change gearsMust be able to transmit power and torquewithout slipping 5. Clutch disengaged (Clutch pedal pressed)The clutch is disengaged whenStarting the engineShifting the gearStopping the vehicle andIdling the engineClutch engagedClutch pedal is released 6. 6 7. ComponentsPrimary componentsFlywheelClutch discPressure plateRelease (Throw out) bearingSecondary componentsPilot bearingRelease forkSlave cylinder 8. 8Coil spring pressure plate(cover and pressure plate) 9. 9Bolted to CrankPilot bushing or bearing in centerof flywheel or crankshaft, supportsthe end of input shaft(friction disk) splined to transmissionInput shaft(throw-out bearingT/O bearing) allowsto push on rotatingclutch fingersBolted to flywheel - Appliesthe spring force to clamp thefriction disk to the flywheel(clutch fork) pushesT/O bearing to releaserotating clutch 10. 10Pivots T/O bearingMoves pressurePlate rightReleases friction diskfrom flywheel 11. Can be very complicated Have the right amount ofmovement and directionwithout too much pedalpressure Wear Motor mounts Spring to pull T/O bearingaway Has to be lubricated11 12. Types of Clutch1.WET CLUTCH : Wet clutch is immersed ina cooling lubricating fluid which alsokeeps the surfaces clean and givessmoother performance and longer life. Wetclutches, however, tend to lose some energyto the liquid.2.DRY CLUTCH : Dry clutch, as the nameimplies, is not bathed in fluid and runs dry. 13. No complicatedlinkageFlexibilityNo motor mountproblems13 14. 14 15. 15 16. The faster the RPM, the harder theclutch disk is squeezed16 17. Uses master cylinder and slave cylinderUses brake fluidMust be bleed17 18. No complicatedlinkageCan easily controlmechanicaladvantage withpiston sizesSelf lubricatingNo motor mountproblems18Service just like you would hydraulicbrakes 19. 19Slave cylinderSome are adjustablefor free-play andsome not 20. Prevents from cranking with clutchengaged Some standard transmissions wont let youtake the key out and lock the steeringcolumn with out the transmission inreverse Prevents steering lock while moving forward20 21. Very wise to: Have flywheel surfaced (even with no run-out orhot spots) Replace pilot bushing or bearing Replace T/O bearing Replace pressure plate (cover, plate springs)21 22. Very wise to inspect & replace asnecessary: Clutch fork & pivot Input shaft bearing retainer on transmission(where T/O bearing slides) Linkage, cable or hydraulic components Motor mounts Flywheel ring gear22