CLEERS 2013 Zeolite HC Traps: Experiments and …Manish Sharma Cold Start NMHC on PZEV 150K-mi w/...

Transcript of CLEERS 2013 Zeolite HC Traps: Experiments and …Manish Sharma Cold Start NMHC on PZEV 150K-mi w/...

p. 1 Chemical Engineering Department Manish Sharma

Zeolite HC Traps: Experiments and Simulations

April 10, 2013

Presenter - Manish Sharma

Ford Motor Company

CLEERS 2013

p. 2 Chemical Engineering Department Manish Sharma

Outline

-Introduction -Mathematical model development and simulation -Detailed Analysis

-Zeolite Adsorption, HC adsorption and competitive adsorption between HC and water. -Water Condensation. -TWC Layer Optimization (work in progress).

-Optimizing trap design and future work.

p. 3 Chemical Engineering Department Manish Sharma

Introduction

p. 4 Chemical Engineering Department Manish Sharma

1. Adsorption - Zeolite allows hydrocarbon molecules smaller than the pore diameter to enter channels and adsorb

2. Retention - Zeolite pore structure holds hydrocarbon molecules while precious metal catalyst in washcoat warms up to activation temperature

3. Release - Adsorption bonds are cleaved as a function of temperature, bond type and hydrocarbon characteristics

4. Conversion – The released hydrocarbons are oxidized over the TWC layer.

Square channels on front face of HC Trap brick

Catalyst

Zeolite

Monolith

Catalyzed HC trap washcoats on ceramic honeycomb monolith

Square channels on front face of HC Trap brick

Catalyst

Zeolite

Monolith

Catalyzed HC trap washcoats on ceramic honeycomb monolith

Three WayCatalyst WashcoatZeoliteMonolith

HEAT CO2+ H2OCO2+ H2OCxHyOz

CxHyOz

+ O2

2.

3.

4.

1.

Introduction: Traditional Hydrocarbon Traps

p. 5 Chemical Engineering Department Manish Sharma

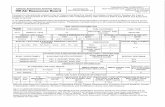

Cold Start NMHC on PZEV 150K-mi w/ E85 Through Catalyzed HC Traps (C&D)

0

0.002

0.004

0.006

0.008

0.01

0.012

0.014

0.016

0 25 50 75 100 125 150 175 200 225 250 275 300Time [s]

NM

HC

Em

issi

ons

[g]

0

100

200

300

400

500

600

700

800

Tem

pera

ture

[C]

Trap Inlet NMHC [g]Trap Outlet NMHC [g]Cat C midbed Temp.Cat D midbed Temp.

Trapping

A B C D

Hydrocarbon (HC) Traps

HC Traps are needed to trap the HCs from engine exhaust during the cold start. The results from this work are also applicable in enabling to meet emission standards for lean burn and diesel engines.

T plateau at about 40 degree C.

p. 6 Chemical Engineering Department Manish Sharma

Background: In-Line HC Trap Systems

Passive In-Line HC Trap PZEVs • 2000MY Nissan Sentra CA*

[SAE 2000-01-1583] • 2003MY Nissan Sentra CA*

[SAE 2003-01-1861] • 2003MY Toyota Camry*

[SAE 2003-01-0817] • 2009 Mitsubishi Lancer*

• Passive In-Line HC Traps are in the exhaust stream all of the time like typical catalytic converters (no exhaust valves or air pumps)

• Zeolite activity for HC storage and retention is not as durable as typical catalytic converter activity so care must be made regarding placement in the exhaust system

• All production passive in-line HC traps are located in the underbody position where maximum mid-brick temperatures should be below 800°C during demanding in-use operation or rapid dynamometer aging cycles.

DC

A

B

HEGO

HEGOHC Trap Catalysts 2.3L PFI

Engine

TWCs

* Production vehicles

p. 7 Chemical Engineering Department Manish Sharma

Challenges for HC Traps with High Temperature Aging

• Retention of Stored HC - A fresh HC trap may retain 70% of stored HC emissions above 150°C in the zeolite layer for potential oxidation, but exposure to high temperature exhaust weakens the retention strength and more HC is released at lower temperature.

• Low Temperature Oxidation – A fresh TWC needs about 140°C to convert 50% of inlet CO emissions (Light-off), but exposure to high temperature exhaust sinters the precious metal and support, and a higher inlet temperature is required for light-off.

• The overlapped area below the curves correlates to the HC trap performance metric of Adsorbed HC Conversion and the vehicle tailpipe emissions benefit over a conventional TWC.

0

0.2

0.4

0.6

0.8

1

0 50 100 150 200 250 300

Sample Inlet Temperature [C]

CO

Con

vers

ion/

Sto

red

HC

COHC

AGEDAging

Effects

0

0.2

0.4

0.6

0.8

1

0 50 100 150 200 250 300

Sample Inlet Temperature [C]

CO

Con

vers

ion/

Sto

red

HC

COHC

FRESH

p. 8 Chemical Engineering Department Manish Sharma

Mathematical Model Development

p. 9 Chemical Engineering Department Manish Sharma

Model Development

• 1-D mathematical model, includes mass and energy balances. • Kinetic model considers the following steps: - HC adsorption/desorption on zeolite layer. - Reactions in the TWC layer. - Predicts HC slip and zeolite temperature.

• Input required - FG concentrations of reactants and FG temperature, along with initial

conditions in the catalyst. - Input for trap dimensions

. Cell density with wall thickness . Volume and length . Washcoat loading.

p. 10 Chemical Engineering Department Manish Sharma

• The washcoat is divided into radial elements, the top elements represent TWC layer, the bottom elements are for zeolites. The number of elements is a model parameter. • Diffusivities of gases are different in the two layers (since TWC and zeolite washcoats have different pore sizes/tortuosity etc). • TWC layer is the site for HC/CO oxidation, oxygen storage, NOx reactions.

• Gases have to diffuse through the TWC layer to reach the zeolite layer. Adsorption and storage of HCs occurs in the zeolite layer. • Model accounts for both radial and axial pore diffusion in the washcoat.

• Solid temperature is assumed to be uniform in the washcoat elements. The model does not differentiate between the temperatures in the two washcoat layers.

Model Development

p. 11 Chemical Engineering Department Manish Sharma

Adsorption Model

HC adsorption is assumed to follow langmuir kinetics

Ø For single species, Ratead=kad.pA.ӨV, Ratede=kde.ӨA

Ø For single species, At equilibrium, ӨA=KA.pA/(1+KA.pA)

Ø For competitive adsorptions of species A and B, at equilibrium ӨA=KA.pA/(1+KA.pA+KB.pB) ӨB=KB.pB/(1+KA.pA+KB.pB) ӨA+ ӨB+ ӨV=1

Ø Similar analytical results can be derived for multiple

species competitive adsorption.

p. 12 Chemical Engineering Department Manish Sharma

)( sggg

iningg TTCpGSAh

xT

utT

−−∂

∂−=

∂

∂

ρε

( )∑ Δ−

−−−

−−−

+∂∂

=∂∂

jjss

loadingambs

ss

outoutsg

ss

inins

ss

conds HRCpGSAW

TTCp

GSAhTTCp

GSAhxT

Cpk

tT

ρερερερ )1()(

)1()(

)1(2

2

Tamb

(Exotherm)

Tg

Ts Q

- Gas temperature

- Solid temperature

Model Overview

Energy Balance Equations

p. 13 Chemical Engineering Department Manish Sharma

)( ,,,,

isigmigig CCkGSA

xC

utC

−−∂

∂−=

∂

∂

ε

,exp, , viss

adadad C

TREkRatealso θ⎟⎟

⎠

⎞⎜⎜⎝

⎛−= i

s

desdesdes TR

EkRate θ⎟⎟⎠

⎞⎜⎜⎝

⎛−= exp

∑−∂

∂+

∂

∂=

∂

∂jwc

ise

ise

isw R

xC

DwC

DtC

ρε 2,

2

2,

2,

- Gas phase

- Washcoat Equations

Model Overview

Mass Balance Equations

Different reactions in the two washcoat layers. Also the washcoat loadings are proportional to the ratio of elements for TWC vs zeolite layer.

p. 14 Chemical Engineering Department Manish Sharma

Modeling Results The model was calibrated using lab data. HC species were binned into three categories based on Bag1 FTP data. C2-C3 data was represented by propylene, C4-C5 data was represented by Isopentane, and C6+ data was represented by Toluene. The individual HC results from the model are combined to give cumulative gms.

-0.010

0.010.020.030.040.050.060.070.080.09

0.1

0 50 100 150 200 250 300 350time (s)

cum

u. g

ms

(NM

HC)

FG TP (exp) TP (model)

p. 15 Chemical Engineering Department Manish Sharma

Adsorption in Zeolites

p. 16 Chemical Engineering Department Manish Sharma

- The diffusion of molecules in zeolites is intra-crystalline or configurational diffusion. - For most zeolite adsorptions, the shape of the isotherm is adequately represented by the Langmuir equation. - Qualitatively, diffusion in zeolites is bound by knudsen and solid state diffusion. - In ZSM-5, bulky molecules (aromatics and branched paraffins) sit at channel intersections, while small molecules sit in the channels. Polar molecules like water and alcohol, are adsorbed very strongly. -Bulk Diffusion α T1.5 (not activated)

Knudsen Diffusion α T0.5 (not activated)

Zeolite Diffusion α T0.5. exp(-Ea/RT) - Ea varies from 2-15 Kcal/mol.

Diffusion in zeolites

p. 17 Chemical Engineering Department Manish Sharma

Diffusion in zeolites

- Since organic molecules can rotate and vibrate, and zeolite (thermal) lattice vibrations on the order of tenths of angstroms can occur, effective pore sizes for adsorption or catalytic reaction may appear somewhat larger than crystallographic dimensions. - Thus even structurally complex molecules such as the triglyceride C57, which might appear excessively bulky, can enter into the pores of ZSM-5, since, given adequate energy of activation, conformational/configurational adaptations can be made. - The vertical (configurational) segment of the plot

spans about ten orders of magnitude in diffusion coefficient and reflects only the modest range of pore sizes shown in 4-8 A. - Interaction of adsorbate polar functional groups with lattice polarity near the pore mouth can be the dominant factor, rather than steric effects .

p. 18 Chemical Engineering Department Manish Sharma

Lab Results (High Zeolite Loading)

1min HC adsorption followed by TPD on beta zeolite. Propylene converts into other HCs (next slide)

HC 1 min adsorption, N2 desorption

0

100

200

300

400

500

600

700

800

900

1000

100 150 200 250 300 350 400 450 500 550 600time (s)

ppm

2-Methybutane 150c 0 Propylene 150C Toluene 150C T_out [ーC] T_in [ーC]

p. 19 Chemical Engineering Department Manish Sharma

Propylene converts to Methylbutane and 2-Methylpropene

Lab Results (High Zeolite Loading)

Propylene 1 min adsorption, N2 desorption

0

200

400

600

800

1000

1200

1400

100 150 200 250 300 350 400 450 500 550 600

time (s)

ppm

Propylene 150C Ethylene 150C CO ppm 150C T_out [ーC]T_in [ーC] Toluene 150C 2-Methybutane 150c 2-Methylpropene 150C

p. 20 Chemical Engineering Department Manish Sharma

Lab experiments were conducted on Beta and ZSM5 catalysts to understand the effect of water on HC adsorption. The results showed that-

Experiment Beta ZSM5 Beta ZSM5 Beta ZSM5 Beta ZSM5

Water and HC simul. 0.196 0.198 0.006 0.013 0.0028 0.0042 0.007 0.0064

Water First (1min) 0.3 0.31 0.003 0.01 0.004 0.0047 0.0078 0.0072

HC First (1min) 0.147 0.174 0.01 0.02 0.0072 0.0051 0.01 0.011

Water First (1min), cooling on 0.284 0.3 0.002 0.01 0.0067 0.005 0.0072 0.0077

HC First (1min), cooling on 0.188 0.2 0.008 0.021 0.0088 0.0055 0.01 0.011

Water First (5min) 1.65 1.32 0.002 0.011 0.017 0.0122 0.019 0.017

HC First (5min) 0.62 0.66 0.022 0.04 0.027 0.017 0.033 0.027

Water and HC Storage

Water Stored (g) Propylene Stored (g) 2-M, butane Stored (g) Toluene Stored (g)

-Water adsorption remains same for Beta and ZSM5. In experiments where water is fed first, more water gets adsorbed. -ZSM5 leads to more propylene adsorption, HC first experiments result in more propylene adsorption. -M-butane and toluene have similar adsorptions on ZSM5 and Beta zeolite. HC first experiments lead to more M-butane and toluene adsorption. -Water and propylene may be competing for bronsted acid sites.

Lab Results (High Zeolite Loading)

p. 21 Chemical Engineering Department Manish Sharma

Water Condensation on Zeolites

p. 22 Chemical Engineering Department Manish Sharma

0

100

200

300

400

500

600

0 50 100 150 200 250 300 350

time (s)

T (d

eg C

)

TempFG TempTP (exp)

High Zeolite Loading Traps High Zeolite loading monoliths with TWC layer on it. These monoliths have more HC Storage capacity.

HC Trap on Vehicle

When high zeolite loading traps are used on the vehicle, the water condensation plateau is observed at close to 100 degree C. This was modeled by raising the Dew Point (plateau temperature) to 100 degree C. We do not understand the phenomena clearly right now.

T plateau at 100 deg C.

p. 23 Chemical Engineering Department Manish Sharma

Effect of water condensation - HC release shifts (delayed) because of the T plateau, and there may be a small improvement in the trap conversion efficiency.

Water Condensation Modeling k

• A logistic function is used to approximate step changes in rate constants at the dew point:

( )01 TTmc ekk

−+=

( )01 TTme ekk

−−+=

ck ek

T0T

where T and T0 are the gas and dew point temperatures, and m controls the sharpness of the transition.

k

0TT

k

0TT

k

0T

k

0TT

0T0T0T

(SAE-2010-01-0885)

0

100

200

300

400

500

600

0 50 100 150 200 250 300 350

time (s)T_

out (

oC)

T, FG (measured) T, TP (measured)Model without Condensation Model with Condensation

p. 24 Chemical Engineering Department Manish Sharma

Lab Experiments (Water Condensation)

Beta Zeolite Substrate

0

100

200

300

400

500

600

700

800

0 100 200 300 400 500 600

Time (s)

T (d

eg C

)

0

2

4

6

8

10

12

14

wat

er (%

)

T_out [°C] 2% T_in [°C] 2% T_out [°C] 4% T_in [°C] 4% T_out [°C] 10%T_in [°C] 10% H2O (%) 2% H2O% 4% H2O% 10%

p. 25 Chemical Engineering Department Manish Sharma

Lab Experiments (Water Condensation)

Higher water fraction leads to Tout reaching the plateau temperature faster, but the plateau temperature itself remains unaffected.

Beta Zeolite Substrate

0

100

200

300

400

500

600

700

800

0 100 200 300 400 500 600

Time (s)

T (d

eg C

)

T_out [°C] 2% T_in [°C] 2% T_out [°C] 4% T_in [°C] 4% T_out [°C] 10% T_in [°C] 10%

p. 26 Chemical Engineering Department Manish Sharma

Amount of Heat Stored and Water Stored increases with water fraction. At the maximum points, Heat/g 2% = 1580J/g, Heat/g 4% = 1920J/g, and Heat/g 10% = 1190J/g. Latent Heat of Water (Vaporization) = 2260 J/g

Lab Experiments (Water Condensation)

0

50

100

150

200

250

300

0 50 100 150 200 250 300 350 400

time (s)

Heat

(J)

0

0.05

0.1

0.15

0.2

0.25

wat

er s

tore

d (g

)

Cumulative (Heat Out-Heat In) (J) 2% Cumulative (Heat Out-Heat In) (J) 4% Cumulative (Heat Out-Heat In) (J) 10%gms of water 2% gms of water 4% gms of water 10%

p. 27 Chemical Engineering Department Manish Sharma

TWC Layer Optimization

p. 28 Chemical Engineering Department Manish Sharma

-0.010

0.010.020.030.040.050.060.070.080.09

0 50 100 150 200 250 300 350 400

time (s)

cum

u. g

ms

(NM

HC)

FG TP (exp) TP (model) TP (model, Double TWC layer thickness).

-0.010

0.010.020.030.040.050.060.070.080.09

0 50 100 150 200 250 300 350 400

time (s)

cum

u. g

ms

(NM

HC)

FG TP (exp) TP (model) TP (model, 1.5 times TWC layer thickness).

1.5x TWC Layer Thickness Base = 22.1%, New Conversion = 30.86%

2x TWC Layer Thickness Base = 22.1%, New Conversion = 34.2%

p. 29 Chemical Engineering Department Manish Sharma

Design Optimization and Future Work

p. 30 Chemical Engineering Department Manish Sharma

Design of HC Trap • 2 key monolith design parameters affect performance:

1. Cell Density 2. Open Frontal Area [OFA]

(inversely related to wall thickness)

• These parameters produce both positive and negative effects on performance. • Higher loading & higher cell density increase zeolite capacity (+), but also increase thermal mass and diffusion length (-)

- The example above shows model-predicted effects of cell density and OFA on trap performance

Modeling Results (Design)

10

12

14

16

18

20

22

24

100 200 300 400 500 600 700

Cell Density

Trap

Con

vers

ion

42% OFA 47% OFA 52% OFA 62% OFA

p. 31 Chemical Engineering Department Manish Sharma

- Trap performance improves with increasing cell density for a given OFA. This is because the pore diffusional resistance decreases with decreasing zeolite layer thickness (increasing cell density). -A trap with higher OFA gives better performance for a fixed cell density. Thermal mass and pore diffusional resistance both increase with increasing Wall (and zeolite layer) thickness (decreasing OFA, for a fixed cell density). -A 200 cpsi 62%OFA performs better than a 600cpsi 42% OFA trap. - All traps assume a 2 gci layer of TWC washcoat on the zeolite samples.

- Results can be repeated for other zeolite-binder ratios.

Modeling Results

p. 32 Chemical Engineering Department Manish Sharma

Future Work

-Expand and Calibrate the model for other reactions in the zeolite/TWC Layer (Ethanol work).

- The goal is to continue the model development so that it may also be used to guide the chemical characteristics needed to improve trap performance (Si/Al ratio, system architecture).

- Since the model is calibrated using individual HCs, it can be used for simulating active traps, passive traps, CC traps and UB traps. -Calculate Effective Diffusivities in the zeolite layer by performing diffusion experiments on the zeolite samples.

p. 33 Chemical Engineering Department Manish Sharma

Acknowledgements- - Jason Lupescu

- Paul Laing

- Jeff Hepburn

Contact Info- Manish Sharma Email - [email protected], [email protected] Phone-3133224673, 8328654900.

p. 34 Chemical Engineering Department Manish Sharma

?????

Questions?