Cleaning tests of central Illinois coal

-

Upload

thomas-fraser -

Category

Documents

-

view

217 -

download

0

Transcript of Cleaning tests of central Illinois coal

256 U . S . BUREAU OF MINES NOTES. [J.F.I.

gas flows and gas pressures, but is not flexible enough to burn efficiently under widely varying gas flows and gas pressures; (3) the heater is properly designed by the manufacturer, and is very flexible in operation, but users can too easily change the adjust- ments, so that the primary air-gas ratio is reduced or the gas flow increased beyond the safe capacity of the heater.

Formation of incomplete combustion products is primarily caused by restricting the air supply to the burning gas either because of faulty construction of the heater or because adjust- ments are so made that enough oxygen does not reach the flame to give complete combustion. Further details are given in Technical Paper 362 of the Bureau of Mines, which was recently published.

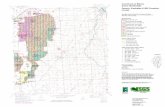

CLEANING TESTS OF CENTRAL ILLINOIS COAL.

By Thomas Fraser and H. F. Yancey.

IN .recent years higher freight rates have been largely respon- sible for a growing demand for cleaner coal, especially from out- lying markets. So far as Illinois coal is concerned this demand comes for the most part from the northwest states. A condition more conducive to profitable washery operation is resulting, and is revi~cing the interest of Illinois operators in coal-cleaning pro- cesses. For this reason much of the Bureau of Mines experi- mental work on the beneficiation of the coals of the eastern and interior fields has been done in Illinois.

As an integral part of this experimental work, the bureau, in co6peration with certain Illinois operators, has studied the problem of cleaning the No. 6 coal mined in Central Illinois.

Raw screenings from this district generally carry 13 to I6 per cent. and occasionally up to 20 per cent. of ash. Specifically, there- fore, the problem is to produce a dependably uniform washed coal product containing about IO per cent. ash from a raw coal that averages probably between 14 and 15 per cent. ash but fluctuates between 13 and 20 per cent., and to obtain this reduction in ash content with not more than 20 per cent. shrinkage.

The results indicate that cleaning the screenings and nut-coal sizes is practicable at mines of this field working the No. 6 seam, and that a cleaned coal product containing IO to I I per cent. ash may be expected. This ash content is approximately that of the

Feb., I926. ] U . S . BUREAU OF MINES NOTES. 257

average face sample, excluding all segregated impurities that it is practicable to pick out in cutting a face sample.

A fuller description of the tests will be found in Technical Paper 361 of the bureau.

SILICOSIS AMONG MINERS. By R. R. Sayers.

SILICOSIS, or miners' phthisis, has been known to occur among miners in certain districts for centuries. This disease is found among metal miners in New Zealand, Australia, South Africa, Great Britain, and in many of the states of the United States. Silicosis is due to breathing very fine rock dust. Rock dust high in free silica is found to be most injurious.

Some physicians have thought that silica dust by its sharp- edged and needle-like particles injures the lung tissue mechani- cally. Another belief is that the silica, being soluble in water and weakly alkaline liquids, injures lung tissue by its poisonous action.

The rate of development of silicosis depends upon the charac- ter of the dust, the amount breathed, length of exposure, past illness (especially tuberculosis), and physical fitness of the men.

Among gold miners in South Africa the average length of exposure to silica dust before silicosis develops is seven and a half years, the shortest period of exposure for like results is two and a half years.

Silicosis is usually divided into three stages: The first shows symptoms and physical signs of damage to lung tissue caused bv exposure to dust, but capacity for work is not impaired. The second stage shows definite signs of silicosis and capacity for work is impaired, although not seriously or permanently. The third stage shows that specific signs of silicosis are or have been present and the capacity for work has been seriously and perma- nently impaired by the disease.

The cardinal symptom of silicosis is shortness of breath, espe- cially on exertion. The cardinal sign is diminished expansion of the chest. Both .are slight in the early stages and increase grad- ually with development of the disease. Other symptoms and signs, as coughing, frequent colds, pains in the chest, and X-ray findings, are very important in making a diagnosis.

Men having silicosis are more susceptible to tuberculosis than normal men.