CLC Costing

-

Upload

pipestress -

Category

Documents

-

view

233 -

download

0

Transcript of CLC Costing

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 1/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

CLC (Cellular Lightweight Concrete)

The Absolute GREEN Cellular Lightweight Concrete by NEOPOR®

Al Ruwad LeycoChem LEYDE - Iraq

00964 7708748222, 00964 7809245690, 00964 7809245685

www.leyde.com

2014

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 2/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

What is CLC?

CLC is convenonal concrete, where natural gravel is replaced by air embedded in an organic, s/stable and

bio-degradable foam which causes no chemical reacon but solely serves as a “ wrapping “ material for the air

embedded in the concrete.

NEOPOR® Cellular Lightweight Concrete (CLC) is being applied successfully for more than 40 years,

construcng more than 700,000 buildings, using it in densies below 350 kg/m³ for sheer thermal insulaon

or void llings and in density of 800 kg/m³ for blocks and for structural, steel/ber reinforced CLC to produce

prefab and cast in - situ of one oor buildings at the rate of one building each day with every set of vercal

formwork, which is also supplied by NEOPOR® , including doors and windows ( or voids therefore) cast in the

same as empty pipes and tubes for power and sanitary installaons in over 50 dierent countries. Many

public and private buildings, even an increasing number of complete towns are being constructed completely

using CLC.

NEOPOR® CLC had been successfully applied already since more than 30 years ago in Iraq, when a leading

German construcon company built (16) agricultural schools with dormitories in Baghdad, produced in a local

operang prefab plant (brochure available), as well as by our company, LeycoChem LEYDE – Iraq, which was

selected as NEOPOR® Sole Representave in Iraq.

NEOPOR® CLC is the only air-cured cellular concrete system worldwide that has an approval to produce

structural steel-/ber reinforced applicaons/ products . Such approvals are under GB Standards,

German/EU-Norms and ICC/IAPMO (US) Standards.1

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 3/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

How to produce CLC

Except for the NEOPOR® foam processor to produce and dose the foam by exact volume, and for the

necessary foaming agent, CLC is produced like regular concrete- which in fact, it is by idencal raw materials

used, namely, sand, cement and water.

CLC also hardens like regular concrete increasing its strength innitely as long as exposed to humidity in the

atmosphere. It hardens by hydraon as regular concrete and can be accelerated by either high early strength

cement, using warm water in the mix , by applying steam, or by using an addive which has to be tested on

its compability with the foam.

CLC is readily integrated into exisng prefab and concrete works - even produced in truck mixers by installing

NEOPOR® fully automac foam processor in less than an hour. Although CLC does not require vibraon - at

least not to increase the density of the mix which is liquid anyhow- vibraon of horizontally produced panels

will show an even beer surface, drawing the cement slurry to the mold side.

Vibraon of vercal walls is possible when pumping CLC through the boom of the mold to the top in

accordance with NEOPOR’s newly developed technology

Benets of NEOPOR® CLC – The Genuine GREEN System

As the world leader in Cellular Lightweight Concrete (CLC), NEOPOR® System oers the construcon of

maximum houses by least skilled labor in the shortest period of me with maximum benets to the later

tenants and yet at minimum cost compared to regular concrete, such as:

Opmum thermal insulaon (From 500 % to 700 % over convenonal concrete) *

Substanal weight reducon (dead-load)

Highly increased re rang

Maximum sound absorpon ( no echoes in empty rooms and halls)

Fastest progress in construcon

Saving in raw material (no gravel required)

Savings in steel reinforcement in high rise

Savings in transportaon (double payload by volume)

Savings in craning (less re-locaon, larger panels )

* In hot countries such as Iraq, Thermal Insulaon is a MUST. Walls and roofs should be insulated to

avoid huge energy waste and at the same me to live in a comfortable cool/warm climate.

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 4/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

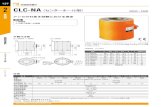

Equipment and Foaming Agent required

NEOPOR®

Fully Automac Foam Processor

Plug & Play Unit (Oponal)

NEOPOR® Foaming Agent: NEOPOR 600

Convenonal mixer or truck mixers & Pumps

Molds

The Plug & Play Unit: A newly launched kit to the CLC producon system. By using the Plug & Play unit,

customers do not have to adjust the foam output and weight anymore as it is set from the factory. It has

a control unit where output is shown either in seconds or in litres .

NEOPOR® Foaming Agent: CLC is an organic and bio-degradable material which has no chemical reacon

but serves solely as wrapping material for the air to be en -capsuled in the concrete. One kilogram of

NEOPOR® foam agent diluted in 40 litres of potable water is sucient to produce 520 litres of foam.

Important Note: Two dierent types of foaming agent are generally used to produce cellular lightweight

concrete: 1) Organic,

2) Synthec

1) Organic Foam : NEOPOR® foaming agent is an organic material and as such bio-degradable. It is delivered

in sealed drums and must not be stored in temperatures above 30˚C, nor exposed to direct sun. Foaming

agent must not be brought into contact with any other product and certainly not with oil, which is known to

inuence the surface tension of the water and thus to the foam to be produced. Any containers, pumps,

funnels used, must therefore be absolute chemically clean. Protein-based NEOPOR® foaming agent is

completely harmless, non-toxic and non-ammable. (Technical Data Sheet & Test Cercate are available on

request).

2) Synthec Foam : There is a large number of synthec foaming agents also used to produce cellular

concrete. None of these however, can match protein based foaming agents in stability. No synthec foam is

known to be used to produce structural (steel-reinforced) cellular concrete. The mechanical and physical

properes of such cellular concrete are not sucient to allow maximum raos of density over strength.

To oer addional stability however, stabilizers, such as chloride are added; a chemical that is harmful to

steel embedded in the concrete and therefore it is not allowed to be used in reinforced concrete.

Foam Generator with Plug & Play Unit

3

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 5/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

Foaming Processor (Generator) : Any foaming agent requires a proper mechanical device to be foamed

correctly. For NEOPOR®

foaming agent, the equipment has been specially designed to suit the specicaon of

this foam agent which if foamed in other generators, the stability will not oer the same consistency.

NEOPOR®

Fully Automac Foam Equipment allows the consistency (sness) of the foam to be set, suing

each applicaon.

The Equipment consists of:

A) Foam Processor

B) Plug & Play unit with a Siemens control system

The Foam Processor is an independent equipment and therefore, it can be used independently , if required,

and in this case, it can be easily removed from the Plug & Play unit.

The complete unit has the following features:

Air compressor with capacity of 850 litre input and 600 litre output per minute and water pump with

capacity of more than 80 litre/min.

Output minimum 10 litres/sec at 80 grams/litre

Rinsing buon for cleaning of foam processor

Output can be seen either in seconds or in litres

Unit checks automacally whether electricity circuit is correct and will show it on the display

Plug & Play Unit cuts o automacally in case any material is missing and will record the amount of foam

that is needed to complete mix with the rest of foam needed.

CLC Blocks used in mul -storey buildings

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 6/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

Cellular Concrete Mixer BM1000 NEW

1100 l horizontal sha posive-acon mixer with special agitator. This can be removed by opening the

lid on the side.

Centered and borne by robust studs. Gear box and mixer sha bearing are protected by well-proven

mixer bearing seal.

Mixer outlet with adjustable mixer ap – opens downwards into the agitator hopper.

Agitator hopper, 1100l, is built in steel frame. The worm pump 2L8 is assembled into the front side of

the hopper.

The pump drive sha is equipped with mixing paddles and prevents eecvely mortar from seling.

The Mixer is driven by a 15 kW electric gear motor. The pump is also driven by a 15 kW electric motor .

The total unit is assembled on a rigid axle with res.

5

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 7/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

BM1000 Technical Specifications

Mixer Capacity 1100 litre

Agitator Capacity 1100 litre

Dosage System

3 WOLF Dosage device ( TEKNO Product)

WOLF 1 – Sand , Cement

WOLF 2 – Water ( Pulse meter)

WOLF 3 – NEOPOR® foaming agent ( Pulse meter)

5 INPUTS , 7 OUTPUTS

Dosage Control for 4 Bins

Communication in between

255 Recipe , Recipe can be designed for all devices together.

You can start production from one device by selecting recipe and total m³,

it prepares production batch by batch according to your mixer capacity.

And then it makes continuous production in automatic mode.

Mixer Weighing System 3 pcs load-cell

Pump Drive 15kW, 400V, 50Hz

Mixer Drive

15kW, 400V, 50Hz

Power Supply Connector Type CEE-coupling, 63A, 400V, 50Hz

Mixing Platform 19m³/h max dependent upon time needed for feeding dry mix

Aggregate Diameter 0-8mm

Built-on Water metre: electromagnetic flow meter adjustable rage 10 - 215 l/min

Worm Pump 2L8

Pumping Distance max. 60m

BM1000 Dimensions

Length 4770 mm

Width 1600 mm

Height 2330 mm

Weight approx. 2840 kg

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 8/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

CBX30 Technical Specifications

Producon Capacity:

Blender Capacity:

30 m³/h

1.5 cubic meter

Mixer Capacity 1500 litre

Agitator Capacity 1500 litre

Cement Silo Capacity 24 Tons Capacity

Sand Bunker Capacity 8 m³ /Loaded by loader

Mixer Motor 18.5 kW, 400V, 50Hz

Vibrators On Cement Silo and Sand Bunker

OLI MVE 100/3 90 W IP67 vibrator

Pump / Pump Drive Peristaltic Pump / 11kW, 400V, 50Hz

Power Supply

Connector Type CEE

-coupling, 63A, 400V, 50Hz

Aggregate Diameter 0-8mm

Built-on

Water metre: Electromagnetic flow meter adjustable rate 10 - 215 l/min

Built-on

Water metre For Foam

Agent Water Content

Electromagnetic flow meter adjustable rate 5 -110 l/min

Pumping Distance max. 60m

Truck Towed Mobile Cellular Concrete Machine

N E W

7

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 9/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

NEOPOR® Fibre Meter Automacally dosage Neopor bre up to the mix design.

Automaon Completely automac system run on Windows OS.

Unlimited Reports Capability

Stock, weighing and Mixing Results Track ability

Unlimited Mix Design

Fully Parametric Machine Opons

MS SQL Database

Possibility to be integrated Central Soware to track all results

and reports over Internet.

Power Generator Type Diesel

Power Generator Capacity

100 kW

Water Cooling System There is water cooling system to decrease temperature of

water for producon

CBX30 Dimensions

Length 12800 mm

Width

3000 mm

Height 4300 mm

Weight approx. 12480 kg

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 10/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

CBX 30 Machine is one component. Fully Transportable by a truck.

Start to work within 1 hour aer reaching the job site.

100 kW Diesel Power Generator

1500 l horizontal sha posive-acon mixer with special agitator. This can be removed by opening the lid

on the side. Centred and borne by robust studs. Gear box and mixer sha bearing are protected by well-

proven mixer bearing seal.

Mixer Gate Opens Pneumacally downwards.

Mixer outlet with adjustable mixer ap – opens downwards into the agitator hopper

Central, large-sized lling opening

Agitator hopper, 1500l, is built in steel frame. Peristalc pump is connected to agitator hopper.

The pump drive sha is equipped with mixing paddles and prevents eecvely mortar from seling.

The Mixer is driven by a 18.5 kW electric gear motor. The pump can be start by a hand operated clutch

while the motor is sll running.

The Peristalc pump is driven by speed control unit to adjust speed.

9

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 11/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

Major Products and Applicaons of NEOPOR® CLC

Void lling & Thermal insulaon

Floor & Roof slabs prefab and cast in- situ

Floor Screed

Parons precast and cast in- situ

Vercal walls cast in- situ or by NEOPOR®

blocks

Hollow core walls in prefab

Facades prefab and cast in- situ

Dierent Methods of Producing & Casng NEOPOR® CLC Blocks:

1. One mold – One block 2. Cung by wire 3. Cung by saw

Blocks on Tsunami project in Thailand Manhandling and sawing blocks ….. Easy applicaon & proper masonry work

Simple NEOPOR® molds can be

produced locally to desired

dimensions. No screws used, hence

fast manual assembly strip pin g, easy

clean ing and mulple cycles

every 24 hours.

Large “cakes” of CLC are poured in molds to be cut to the desired

dimensions by (2) wires in a so state and (3) by saw blades in hardened

state. Molds for the large cake are oiled for easy stripping. The skin facing

the oily molds is cut away to safeguard proper adhesion of paint or

plaster. No waste as all cut-away is recycled 100 % !

School Building in South Africa Bazar in Istanbul built with

6 Million blocks of CLC

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 12/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

Recommended Mix Design to Produce (1 m³) of NEOPOR® CLC

Achieved strength at the lab with opmum sand and cement qualies. More cement will increase strength.

General Remarks

Recommended weight of foam: Minimum 80 g/litre.

Water to process foam:

Potable, if possible below 25° C

Recommended Cement: Portland CEM I 32,5R or higher grade

Recommended Sand: Washed river sand, Density/Sieve: Up to 1000/ up to 2 mm

Up to 1200/ up to 4 mm

Up to 1400/ up to 5 mm

Up to 1600/ up to 6 mm

Crushed Sand might mechanically destroy part of the foam.

Oven Density in kg/m³ 400 600 800 1000 1200 1400 1600 2350

Convenonal

Concrete

Sand kg ₋ 210 400 560 750 950 1100

1950

(gravel+sand)

Cement kg ₊ 300 310 320 350 360 380 400 320

Water in Mortar kg ₊ 110 110 120 120 140 150 160 180

Quanty in Foam Ltrs 800 715 630 560 460 370 290 ₋

Water in Foam kg ₊ 64 57 50 45 37 30 23 ₋

Wet Density kg/m³ 474 687 890 1075 1287 1510 1683 2400

Foaming Agent kg 1.5 1.4 1.2 1.1 0.9 0.7 0.6 ₋

Water/Cement Rao 0.58 0.54 0.53 0.47 0.49 0.47 0.46 0.56

Maximum Strength N/mm² 1̃ 2̃ 3̃ 4̃ 8̃ 1̃2 1̃8 25 +

Average Lambda W/m. K 0.096 0.18 0.21 0.32 0.405 0.45 0.55 2.1

11

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 13/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

CLC and Thermostone Blocks

There is a substanal dierence between the AAC (Autoclaved Aerated Concrete) - also known as

(Thermostone) - and the CLC (Cellular Lightweight Concrete). To avoid any possible confusion, we would like

to highlight the major dierences between both products for the benet of our valued customers:

AAC -Autoclaved Aerated Concrete is cellular concrete where the air-bubbles embedded are caused by a

chemical reacon, namely when aluminum powder or aluminum paste expands like bread, when adding

yeast to dough to expand it in its process of producing bread. Please note the following addional informaon

about AAC :

Special sand (above 95% SiO2 content) has to be grinded to micro size while used to produce AAC.

In AAC producon, the degree of expansion cannot be precisely controlled and therefore expands

beyond the mold used, therefore, AAC has to be cut to the required dimensions.

Relavely, large bubbles allow only lower densies up to maximum 800 kg/m3 to be produced. As the

bubbles between the matrixes are connected with each other, the consequence being, that water has

easy access to the concrete produced, which has to be thoroughly protected against the laer by an

extensive protecon plaster.

To lend AAC sucient strength, it has to be autoclaved in a pressure-vessel. Unfortunately this

treatment completely destroys the ongoing hydraon process of the cement used.

AAC must also be thoroughly protected against humidity.

Low density and the crumbly composion make it necessary to use screw plugs when xing nails or

screws into AAC concrete.

Sound insulaon therefore is not as successful when compared to air-cured cellular lightweight

concrete (CLC) of idencal density.

The enre process of producing AAC is dierent from CLC and calls for sophiscated plant and

equipment, with an admiedly high output of perhaps 300 or more cubic meter each day. Due to the

above described, it is not possible to produce AAC on site, nor to produce prefab panels of desired

shape and size. A high skilled team of experts are essenal to operate such a plant and produce the

product.

Steel-reinforcement used has to be thoroughly protected against corrosion.

CLC – Cellular Lightweight Concrete is convenonal concrete, where coarse aggregate (gravel) is replaced by

air, which we embed in NEOPOR® very stable organic foam that causes no chemical reacon, but solely serves

as wrapping medium for the air to be embedded. Authenc plant and equipment is used to produce CLC,

therefore the producon is easily integrated into exisng concrete and prefab plants for convenonal

concrete.

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 14/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

Only sand, cement and water are used with NEOPOR® highly stable foam, to produce air-cured cellular

concrete in densies ranging from as low as 350 to as much as 1800 kg/m3 and strengths achievable from

as low as 1.5 to more than 30 N/mm2. Washed river sand, if available, up to 2, 4, 6 and 8 mm is

recommended depending on the density desired. Portland cement oers opmum performance but most

other types of cement are also suitable. As the density can be precisely re-produced, any size and shape

of prefab can be produced. Above densies of 1200 kg /m3 (half the weight of convenonal concrete) for

structural steel reinforced applicaon, the bubbles produced are completely separated from each other,

therefore, water absorpon is much less and thus, steel does not need to be protected against corrosion,

which also means, that the concrete in densies of 1200 kg/mᶾ and above, does not require any plaster,

as in the case of AAC, but painng the surface is sucient. Water absorpon is substanally lower than

in AAC and favorably compares to convenonal concrete.

As in convenonal concrete, CLC increases strength praccally innitely as long as it is exposed to the

humidity of the atmosphere. Although not as much as in AAC, CLC nevertheless, oers substanal weight

reducon compared to convenonal concrete and 500% higher thermal insulaon and also has a much

beer re-

rang.

Nails and screws can be easily driven into CLC and hold without the use of dowels. Due to the absence of

gravel however, CLC may also be cut or sawed. For the same reason, it oers high consistency to the

concrete; therefore, no vibraon is required. This allows complete houses to be cast in one pour.

There is no other type of concrete, dense or lightweight, that oers that much scope of applicaon

ranging from roof -insulaon in the lowest possible density of 350 kg/m3 up to the producon of columns

and slabs in density 1800 kg/m3. Floor-screeds, blocks, parons and void-lls are some of the many

applicaons as menoned above. Using vercal molds for houses for instance, allows one complete

house to be cast each day with each set of molds, openings or frames for doors and windows to be cast in

place, the same as empty tubes and pipes for sanitary and power installaons.

CLC is comparable to convenonal concrete; it is produced by the same equipment and oers innite

increase of its mechanical and physical properes over me as the laer. Astonishing behavior of CLC is

becoming evident when used in conjuncon with other materials, such as expanded clay/shale, bers and

others. CLC, like convenonal concrete ages well increasing its strength by as much as 50% between

28 and 90 days aer pouring. As long as CLC draws humidity from the atmosphere it will keep on

increasing its mechanical properes. 13

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 15/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

*CLC uses the same raw material as in convenonal concrete; hence it ages well and oers many advantages also over

convenonal concrete. CLC cures within the same period as convenonal concrete. CLC is most successfully used to cast

complete houses in situ, but also as prefab. Note: The structural savings in the cost of steel and concrete due to reduced

weight of walls would be addional advantage, as well as savings in transportaon, foundaon, piling and crane handling.

Comparison between Air- Cured CLC and Autoclaved AAC

Descripon CLC-Air cured AAC- Autoclaved (Thermostone)

Space required Lile Huge plant

Mobile set-up Possible Not possible

On-site applicaon Possible Not possible

Mixing in truck mixer Possible Not possible

Producible in concrete plant Possible Not possible

Autoclaving used

No

Essenal

Primary energy required No

Autoclaving 150-160 kg

Steam + 15 –20 Kw/mᶾ

Expansion (Aluminium powder) No (foaming agent) In one direcon

Organic foam (bio-degradable) Yes No

Ordinary Sand Yes High Silicate, Grinded

Density choice 350 – 1800 kg/m3 400 – 700 kg/m

3

Air bubble structure Round / Closed Flat / interconnected

Dimension/Shape of element Any size and shape Is cut to required dimensions

Water retenon aer curing

5-

10%

For ext. period +20%

Special/expensive plaster required

Paint will do. Will cure

even under water

Yes, to keep water out

from destroying AAC

Thermal insulaon 5 mes beer than concrete Very high (0.1 W/m.K)

Sound insulaon (Air transmission) Sucient Poor

Rao density/strength Good Good

Ageing As concrete (innite) Dissipates when geng wet

Fire Rang Good (beer than concrete) Good (beer than concrete)

Handling nished product Easy Easy

Repair possible Mortar Special grout (dicult)

Water absorpon Acceptable Requires sophiscated coang

Fiber applicaon Possible Gets destroyed in autoclave

Windows/doors/conduits Cast-in Not possible

Nailing Holds nails Requires dowels

Technology standard Semi-skilled labor Experts

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 16/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

Parameters

Lightweight Concrete

Burnt Clay Bricks

Concrete

Hollow Core

Blocks NEOPOR® CLC

AAC

(Hebel, Ytong, Siporex)

Basic

raw material

Cement, sand, water and

foam (oponally y ash)

Cement, lime, specially

grinded sand, high

primary energy input

Top agricultural soil,

primary energy input

Cement, sand and

aggregate

Producon

process

and set-

up

Mobile (on site) or staonary, using

ordinary concrete mixer and foam

generator

Produced only in well-

established plant,

equipped with steam

boiler and high pressure

autoclaves

Processed in specially

erected or central

brick kilns

Mobile or

staonary

Dry density

kg/m³ 400 - 600 800 - 1000 1200 - 1800 400 - 700 1900 1700

Compressive

strength N/mm² 1-2 3-4 8-25 3-6 4-12 3-15

Usage

Thermal

insulaon &

void lling

Parons,

non-load

bearing,

load

bearing

(blocks,

cast-

in-

situ,precast)

Load

bearing

elements

(cast-in-

situ,

precast)

Non-load bearing panels

and blocks

load bearing and

non-load bearing walls

load bearing and

non-load bearing

walls

Block/element

size and shape

Any Any Any

Any size, shape given by

mold/cut Typical shape and size Typical size

Compacon

during

producon

None None None None Yes Yes

Ageing

Gains strength with age

(like convenonal concrete)

No ageing (loses strength,

if not protected against

humidity)

No Yes

Thermal

conducvity

(W/m.K)

0.096-0.550

(depending on density)

0.08-

0.25

0.4

2.1

Sound insulaon Superior Superior Normal Beer

Ease of working

Superior: can be cut, sawn, nailed,

drilled, ordinary mortar/plaster

Special mortar (glue) and

plaster is required

Normal Dicult

Eco friendliness

* Polluon free

* No primary energy consumpon

* Can consume y ash (waste material)

High energy consump-

on

* Creates smoke

* High energy

consumpon

* Wastes agricultural

land

* Soil erosion

Polluon free

Comparison between dierent building materials واد

ن

ر

خا

اء

15

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 17/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

NEOPOR® Recommendaons

Producing CLC in Truck Mixers

To avoid costly waste, inial tests in small quanes of approximately 50 litres should be done.

When producing cellular concrete in a mobile mixer (ready-mix truck) it has to be strictly observed that

the mixing drum is thoroughly cleaned if regular concrete had been produced previously. This is in

parcular true, if any addive had been used prior, as even traces of the same, might tend to be harm for

NEOPOR® foam and consequently destroy some or even all of the foam injected.

As chemicals cannot just be washed out by water, it is necessary to clean the mixing drum by lling about

one cubic meter (mᶾ) of dry sand into it and run the mixer for one or two minutes. The sand, of course,

can aerwards be used again.

Producing CLC Blocks with Fly Ash

Using Fly Ash in CLC blocks can replace up to 25% of cement in the mix. It

should be noted however, that Fly Ash has to be tested to check its

suitability before being used.

The density recommended for blocks is 1000 kg /m3 and 1200 kg/m

3 to

Produce prefab elements and walls cast in-

situ. The typical mix for a1000 kg/m

3 density and 1 m³ CLC to be used in blocks is as follows:

Cement (Portland): 190 kg = 61 litres

Sand (0 - 2 mm or ner): 430 kg = 164 litres

Fly-Ash: 309 kg = 100 litres (approx.)

Water: 250 kg = 250 litres

Neopor Foam: 423 litres

Wet density 1179 kg/m3

Total volume (Submerged in water) 1000 litres (= 1 m3)

Expected (oven-dry) density approx. 1000 kg/m3

Content of air in concrete approx. 43%

Content of Fly Ash in solid material 929 kg (33%)

Content of Fly Ash in oven-dry material: 31 %

Buildings with CLC Blocks

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 18/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

THE IDEAL ROOFING SOLUTION IN IRAQ …… NEOPOR®

CLC FOR FLOOR SCREED and

LEYCO® TILE ROOFING SYSTEM

Heavy Concrete les are being used in Iraq long me ago as a convenonal, simple and economical soluon

for buildings roong. Yet, the praccal experience shows a number of disadvantages related to using the

convenonal Concrete les for roong. Such as:

1. No heat insulaon with high loss of energy.

2. Buildings are exposed to high and connuous humidity.

3. Extra and unnecessary loads on the construcon due to the heavy weight of concrete les and layers

beneath used.

4. Masc is used for the joints and must be replaced annually.

5. High cost on the short term as well as the long term due to the annual maintenance needed for this

type of buildings roong.

Any alternative solution?

Internaonal researches and tests are connuously being conducted on building materials for beer energy

saving, waterproong and sound isolaon in order to eliminate the disadvantages of old systems or

materials. New building materials are being introduced to the wide public.

LEYCO® TILE is one of the newly produced materials used instead of the concrete les as the most ideal

soluon for roong in Iraq and the Middle East where temperature varies extremely.

Roofing with Heavy Concrete Tiles

LEYCO TILE 17

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 19/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

Leyco® Tile consists of two layers: 1-2 cm topping of high strength special mortar and a lower

layer of 3-5 cm high density extruded Polystyrene. Extruded closed cell Polystyrene is being used

for more than 50 years in construcon. It does not absorb water, does not rot and is ideally used

for inverted roong.

NEOPOR® CLC is the best compleon to this type of roong system if used as a screed layer underneath

the Leyco® Tile system. It saves more than 70% energy in winter and summer seasons.

Advantages of Leyco® Tile Roong System:

1.

Heat Insulaon in hot and cold seasons.

2. High compressive strength: The topping of Leyco® Tile is made of high strength polymeric

concrete laminated to extrude polystyrene foam which accepts a load of 6000 kg/m².

3. Energy Saving: Cool rooms do not need extra air -condioning or heang systems and hence, using

the LEYCO® TILE roong system saves your money.

4. Light weight of Leyco® Tiles to avoid extra loads on the buildings’ roofs.

5. Fast and easy applicaon.

6. Annual maintenance is not required, unlike the convenonal concrete les.

7. Small and appropriate size of Leyco® Tile.

8. Leyco® Tile protects against UV-radiaon which shortens the life me of other roong materials.

9. Drainage channels in Leyco® Tile allow quick drying and aeraon.

10.

LEYCO® TILE is re and ame resistant.

11. Easy Replacement or removal of LEYCO® TILEs if renovaon is required.

(For more details, please ask for our Leyco® Tile Brochure)

Leyco® Tile

NEOPOR ® CLC

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 20/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

Some of Our Achievements ......ازا

........ اخرى د اجز و ةزجا رشا ن ددا ا فضا

The Waterproofng System

Using cold applied specialy developed highly elasc materialsئا لزا مظ

دد ت و ةزت صئ خ لز داو- درا طت

Placing LEYCO® TILEs

Easy & Fast Applicaon

تط اكو تل - رو وه

LEYCO® TILE System - The Energy Saver

تطح كو تل ا مظ- ط نت

LEYCO® TILE System

Al Ataba Al Husseiniya—Karbala-

تطح كو تل - ا تا

دا - رك

School Project - Erbil

رد تطح عو ر ش - را

19

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 21/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

Agricultural Schools built in Iraq with NEOPOR® CLC

ن خا رخا ما د خت ةد ش ارز سرا د NEOPOR®- ا را

One of Neopor® CLC projects in India

اد

ا

را

رش

اد

Authorizaon Leer from NEOPOR®

تخول بت ك LeycoChem LEYDE -Iraq ير عزو ك NEOPOR®ا را ف

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 22/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

Our Mission

To produce a wide range of Concrete Addives & Modern Building Materials supported by Professional Consultancy &

Technical Supervision adopted from the World Class Standards to be a compeve leader in re-building Iraq

سر

ص كساوضلاسخلااولاثحلابارسااشاولاولالالكل

طلالدااالا

Our Vision

Modern Construcon Products for Healthy and Energy Saving Buildings

ر

دصاو ص أ ى لوصاو طا رفو ثد ء داو

LeycoChem LEYDE - Iraq

ISO 9001-2008 Cered

since 2012

ذ

رش

وا

اودة

2012شدة

21

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 23/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

NEOPORظم اسطح اثل ف اراق..... اخرس خ اوزن® CLCمظ طس ل وا

ان

ا

.د

وأ

وذات

ط

د

رط

اراق

ا

وف

ط

طول

زن

ذ

اشر

ط

دم

:او تا ن ددا طا رطا هذ نا تا ا برا

1..طا ر رد يرارا لزا مادا

2..ارة

ا

وطر

ا

رض

3..و رشا نزو ب يرور رو ا نزو ا ل

4..و هدد ةرورو كا مادا

5..و

ؤارا

اواب

ا

ب

ا

واد

ارب

ادى

ادل

ال

هو

اد رض ا داو لاد د دا ما لود براو ثا ر

دا ا ظا مادا لش يد واو او يرارا لزاو طا ن ل ا لا

و ادام اواد د ا ا ر ان س اوت. ون ذه اث وان ام

ر

طو

ا

دو

اواد

ذه

ز

.طاو

ا

ازل

ظا

دم

د

واد

اد

ا

اول

ل

او

ط

و

ا

ودانLeyco® Tileاودة

اراق

طا

ظا

شر

دل

دم

اذي

.ر

شل

ارارة

درت

ن

ث

اوط

اشرق

:طن

ن

طا

ذه

ون

دا. ونم ن ط ا وري ول ووط وة ل اوزا1-2اط ا ذات ك

ا طا ك3-5 ( ( ا وادم الPolystyreneم و رة ن دة ز ن او رن

.اوت

رور

ن

و

ا

ص

ور

ح

ن

ن

ر

شا

NEOPOR® CLCطا ل وا مظ لا لا وLeyco® Tile Roong System

)رد( ت طت ظم اط ود ان ذاات اربث م ادا ل ط ط

ط ور ار ن .ن اط وش07% اظم

فوائد اسخدام ظم او ل سطح

شو يرارا لزا

ا

ل

اوزان

ل

ث

اط

و6000ر

ر

/م

را

ل

و

اوا

د

/ف

ازة

ادام

د

ا

ط

ر

ور

شا هدو يذا ا فو ا لا ن ل و نزوا ف

او

اذ

رو

و

.رشا مادا د لا و رودا ا ادام ا ا ارا

ط بو ر م

ش

ارا

ار

ن

ل

ا

ا

وق

شا

ن

د و لا ه فر تاو )ل و ط( وي

وا تاوا هذ لو طا ف ر

او ار مو

.طا وا مر ا د تطا ر وا لادا و

رى اطع ى اشرة ا اخص ظم اول سطح زد ن اصل

اسطح شر

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 24/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

®NEOPORشررت ن

(Truck Mixers)ف شت خطCLCاج

)CLCد اج ار اوزن ط تش Truck Mixer)ن و دا وا داوا ف يا بو

ا فNEOPOR®( ت وا جا بر ر ر57.)را

)وب اد ن اد ا ن وت اج Drum ظ اطوا اط ادوارة را ن طا ش )

ؤدي ا اف ن وود ات وان ت ت دا دا را و ت مادا اةد

ن اروري ظف اطو ط ر ازا ن وا داوا نا و . وا ز ةرو ا وراا

)اذي ن ادا1 –2 اط ن طر وا واد ر ب ن ارل اف م ش دة د م ر ن ارل

.)ارار

اي

دون

CLCوت ن اخرس اخف ا(Fly Ash)اسخدام ارد اطر

( ن اور )CLCار اFly Ashدام ارد اطر ج اوت

طا مدا تا 25ل ةدا ص ةار )ر( %

.طا

وت

ن

ادا

ا هذ را ا1777و تو ب ر /م1277 ب ر /م

ب

ر

ج

دا

اط

ب

.و

وا

وادران

ازة

را

اراب

ا

را

ن

واد

1777:

ب

ر

/م

)وردي( = 197ت ر1م

( = 437م او ار و7-2)رل ر14م

( =Fly Ash) 379رد طر )ر177)م ر

257= ر257م

رNEOPOR®423روة

طرا ا 1109ب ر /م

) رو( ا ما 1777= ر

1ر ب

)وا( ا ا 1777)ر( م/ ر ب

را )ر 43%)وى اوا

ا

اواد

اطر

ارد

وى

929(م

33%)

ا داوا رطا درا ىو31%

دة وت ش اCLC

23

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 25/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

اروت

هم

ندول

CLCو

AAC)اثرسون

(

Descripon صاوا CLC-Air cured AAC- Autoclaved (Thermostone)

Space required Lile Huge plant

Mobile set-up Possible Not possible

On-site applicaon Possible Not possible

Mixing in truck mixer Possible Not possible

Producible in concrete plant Possible Not possible

Autoclaving used No Essenal

Primary energy required No

Autoclaving 150-160 kg

Steam + 15 –20 Kw/mᶾ

Expansion (Aluminum powder) No (foaming agent) In one direcon

Organic foam (bio-degradable) Yes No

Ordinary Sand Yes High Silicate, Grinded

Density choice 350 – 1800 kg/m3 400 – 700 kg/m

3

Air bubble structure Round / Closed Flat / interconnected

Dimension/Shape of element Any size and shape Is cut to required dimensions

Water retenon aer curing 5-10% For ext. period +20%

Special/expensive plaster required

Paint will do. Will cure

even under water

Yes, to keep water out

from destroying AAC

Thermal insulaon 5 mes beer than concrete Very high (0.1 W/m.K)

Sound insulaon (Air transmission) Sucient Poor

Rao density/strength Good Good

Ageing As concrete (innite) Dissipates when geng wet

Fire Rang Good (beer than concrete) Good (beer than concrete)

Handling nished product Easy Easy

Repair possible Mortar Special grout (dicult)

Water absorpon Acceptable Requires sophiscated coang

Fiber applicaon Possible Gets destroyed in autoclave

Windows/doors/conduits Cast-in Not possible

Nailing Holds nails Requires dowels

Technology standard Semi-skilled labor Experts

ص ف خا ءا داو ن ر لود ى عطا ن *51

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 26/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

.وطا

وات

اشل

زة

ط

اج

ن

و

د

را

ن

اوع

ذا

وطا

ا

دد

ن

ن

ار

ر

اج

1277(ا

را

ال

اد

ب

ر

/Steel Reinforcedم

Applicaonج و ةر رد ا صا راد ص ا يدؤ ةرو ن اوا تا ل )

ج ا ادام اي وع ن اضم/ ر ب وق1277ا دد ا د ال ان ار ا ت

ادام

د

ال

و

ا

AAC

وب

ا

اص

را

زد

واذي

)ارون

(

نCLCدام اوازل ا ورد ذره .ورم ن ادام ا ا ادام اض ا ار اوزن

. ار ا دة طا ط لا

( زداد و ار ا اوزن دا را لا و CLCوطر ر رار ةدود ر ةرو )ن مرو .

ا

را

ان

CLC(ارون

وزن

ت

AACور

ا

دا

را

ر

وزن

ظو

ا

ا

)

ا دار . %AACن ار اد ا ا و دة را واب ر ـ577زل راري

ا را و راو ارا ت نCLC( وبScrew Plugsدون ا ا در ) ا دوو مد

ر دوو مد( و .وس اب اه رشوا ط ا ن را ن عوا اذ رCLCعوا اذ ز )

ز ذا اوع و ج ا رج د .ل اوات واواد اذر نن ار در ن اك

ـا تادا نو . را ن را عو يا رو ا ةددا اد راCLCماد ن( : ور زل طوح

ر357 مدو )ب ر /م177ط ل ا مدو .فواو ةدا ج ب ر /م

ور ن ادات ارى. ارات ال اش رض ازل اراري طاوا ا تو جا طوح

اوزن

را

ان

اول

وCLCا

ادات

س

ا

وم

ر

اواد

س

ن

ون

ث

دا

ر

ش

ا را كو رظو .دا را توا رور وزاو ا صا س طCLCحوو درا

ادا دناز( ) ( Fibersواد ارى ف ( ورExpanded Clay.اطن ادد

ا

ل

دار

)دا

ر

(ا

را

و

زداد

57ر

%2و

97ا

ون

د

وم

رار ر رطو او.

خا سرخا ن كوCLC

- ا لزا ى و نزو خ-

دا سرخا ن كو

25

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 27/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

)وت خا سرخاCLC)توو( (Thermostoneاثرسون

-(AAC)-Autoclaved Aerated Concreteوار ا اش وا (CLC)ك روت ور ن ار اوزن

ا فر ا: -م ارون. و و م اروت ن اون

AAC– Autoclaved Aerated Concreteرط ن اد اوا تا دو م ر )نورا(يوا لا

ش

ا

وذه

را

اخ

ا

ذه

ن

اوم

ون

او

وق

ا

م

ث

.)اروة

دام

وس

(

:AACاخ از د ا ارة ا .و ض اوت ا طر اج

نوا دوا ىو ( رل ص ( د ط ا ت د دا.د اد95%دم

لا )خا( ث زداد در رة ض ان ار ن م ابAACن ام م ادد

ن اج. ا د وطا دا ا ا توا ط ب و

جا

م

ار

اوا

ت

م

ب

AAC)ارون

(ن

زد

ط

طاو

ت

77وب

.ب

ر

/م

ا

وذه

(دة

ز

واد

دام

طب

و

ا

را

ا

ا

رب

ات

ارط

.)ال

ط

اج

ف

ن

لوAACتا ا رؤ رطا هذ ن فو ب ا دام اط و

ادم.

بAAC .وطرا تار ن ةرو

ر طاوا ا بAAC( د ن ادام ادر ا روScrew Plug). را وا ارا ت

و ر وا لزا AAC)نورا (و ر ر CLC. ا س ادا د كذو

) اس ن اج AACاج د تاد مادا بطو ( ا ا ن ادر ذر ان دل اج ذاCLCدة

(را

ن

اAACاوع

ل

د

)377اج

ن

ادة

ا

و

.)دا

د

(اوم

/ب

وAACر

ن ادا ج اواح اب شل وات اطو .و طب اج ور لACCال وود را

. ص

. ب دد ا ادم ذا اوع ن ار د ال وادأ

روةCLCا اخرس خ اوزن

ا

رط

ن

وا

ا

ادال

ب

ف

وزن

ون

دا

ر

ش

را

اج

ن

.

رات

اي

اداث

دون

را

دال

اون

وا

ف

ط

ل

را

اط

ا

و

(CLC.ةر رد جا ل تاوداو تادا س مادو دا را خا ل )

( ا ا ال اروي(CLCج ار اوزن ت اص. ود ادام ال ارويج ا ادام رل

رشNEOPOR®ن

راوح

ت

را

ذه

اج

ن

357و

177ن

دأ

و

ب

ر

/م

1.57)دا

د

(ا

37 .)تا ض ا وا( ر ر / )ان ود( NEOPOR®ون 2,4,6 & 8دام رل ري ول

ا تا عاوا ن جا يدرو ت مادا لا نو . وطا ا ادا ما

دم ور اوع اول.

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 28/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

را طا بNEOPOR®ار انوادج ر ب

ا يدؤ طا تا ةدز . م اول اوت اذورة ادول اه دام وت دة ن ات وارل

. وا ةدز

تصو

:رشا

و

اذي

)اوم

(ورا

ادة

وزن

7)دا

د

(ر

/م

ن

ال

رار

رد

ون

ان

ول

)اوم

(ورا

ادة

ج

اشرب

دم

25و

رد

او درت ا ل ورCEM I 32,5Rل ادام ت وردي

ا ل لو ل ادام رل ري

17771277م(2 )ل س

(4ل س ل س)1477(

5 او م(

177()ل س

ورا ةدا ن ب ادام ارل ار و ف ز

Oven Density in kg/m³ 400 600 800 1000 1200 1400 1600 2350

Convenonal

Concrete

Sand kg ₋ 210 400 560 750 950 1100

1950

(gravel+sand)

Cement kg ₊ 300 310 320 350 360 380 400 320

Water in Mortar

kg

₊

110

110

120

120

140

150

160

180

Quanty in Foam Ltrs 800 715 630 560 460 370 290 ₋

Water in Foam kg ₊ 64 57 50 45 37 30 23 ₋

Wet Density kg/m³ 474 687 890 1075 1287 1510 1683 2400

Foaming Agent kg 1.5 1.4 1.2 1.1 0.9 0.7 0.6 ₋

Water/Cement Rao 0.58 0.54 0.53 0.47 0.49 0.47 0.46 0.56

Maximum Strength N/mm² 1̃ 2̃ 3̃ 4̃ 8̃ 1̃2 1̃8 25 +

Average Lambda W/m . K 0.096 0.18 0.21 0.32 0.405 0.45 0.55 2.1

27

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 29/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

NEOPOR® CLC اسخدات

اهم

شتارايرار لز لواو ا

و و وا ةز فوو ترا ج

)در( ل ط ط طوح

و و وا با طاو ج

ج دران ود و و او دام وت

NEOPOR®

ةزا وا ناردا ج

و واوا ةزا ا تاو ج

NEOPORطرق اج وصب وت® CLC

صرة

واب

سخدام سا

سخدام

طا شا

سخدام

طا

رس ف وب د

دة ش

رفا

سخدام

CLC - رفا

-وب

ط

واب

دام

اوت

اج

م

.اطب

ب

ددة

م

ارا مادا ا ا نود باوا هذ و ظو ود ن اذ

ن

.ال

ن

ا

د

رو

.اواد

اوم

رات

دة

ادا

ن

ام

رة

وت

اج

م

NEOPOR® CLC م

ون

واب

) ورة رطا و كا طاو ا بوطا ما ا ط2)

ورة

(

را

ون

د

شر

طاو

او

3د

.)

ال

ورة

اوت

اراج

رض

اواب

زت

م

ام

رة

اوت

اج

زا

اس

ذات

اطت

ن

ص

ب

ا

وا

طا

ط

م

م

را ط )را( و ن اق اغ او ط اورك

ن ادة ادام . د ادام ذه اطر ج اوت ورة ال

ف

اي

رطا

ذه

ود

و

ر

ط

م

ا

اطت

.دا

اواد

سوق ري شد

ام د خس

0666666

CLCوك

- ر-

ا وهستو

CLC - د ف وع ر ش

Pic. 2 Pic. 1 Pic. 3

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 30/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

2): صا يوغرا لار ن ن ك اواع ددة ن اوال ارو ا اد ج ار اوزن

ا عاوا مادا نا ث ا ود ن )يوا( ذ ذذا اوع ن اوال ارو ا وع اول

.

ت

ر

ج

او

وزا

ان

م ا ض ات ا وردات ا ورا لاوا مادا د لا تاو ر لوا ضرو

را ج ا ورا لاوا ماد را مدا ا دد ر وا داوا هذ نا و.ا

.ا ا شا را ج ا ورا لاوا عاوا ن عو يا مادا م م با اذو

)اوم

(ارغوة

ود

:ت

NEOPOR®.

ن

ا

اروي

ال

وات

ب

روة

ود

م

ن اول روة ب اطت®NEOPORد ادام اود اوو ا ب

.اودة

س

ا

اروة

ون

ن

ث

ارى

واع

روة

ودات

ادام

ن

اس

شا

: ف ظو ود اروة ن

ود اروة1 )

)Plug & Play Unitودة ام واطرة2

ن ودة ام واطرة ل و ا د ن و ن ان ل ود اروة ورة ن ودة ام

.در

اد

:

واطرة

ام

ودة

ز

)دال( و 57وود ط وا ار ن77ر ةداوا دا ل )جر( / د7ر ر

جا لد17 دا د /ر7 /مار

ا ا د ةورا دو ل بار دوو

او س ةدد ز ةد ل جا لد وا ر ا جا ار ن

را

شش

ذك

ظر

ل

اي

وود

و

واطرة

ام

ودة

را

ادورة

ن

اد

ا

و ول ص ادة ارو از دا داوا ن يا ص دوو د ووا ةرطاو ما ةدو فو

.طو ةرو جا ل ا بوطا ةورا ا ةرشا ششا رظ

NEOPOR®وول وت ن اواع اطت ار ج ار اوزن دام واد ر اطع

ا(5-9.)

29

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 31/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

ج

د

خ

س

د

و

و

ت

د

NEOPOR® CLC

(اروة

ود

ووا

NEOPOR® Foam Processor)

ةرطاو ما ةدوPlug & Play Unit)يرا (

اروي

ال

(NEOPOR® 600)

ط ش وا د ط(Truck Mixer)

ب باو

ام

ودة

Plug & Play Unitت

:NEOPOR®

ووا

اطرة

رض

اج

وظ

ا

اودة

ذه

دل

ؤرا

ل ةرطاو ما ةدو رط ن ةزا رشا ل ن نازوا دد م ث ا ورا ةدا نزوا

.) او س ةدد ز ةد ل وا ر ا ( ورا ةدا ن وطا

ط(NEOPOR® Foaming Agent)ال ارغوي

ف

ل

ل

ر

اي

س

اوي

ل

و

دة

:

اذي م ار .ور ذه ادة رزة ث اورام اواد د دار اشرب 47وا ن ر

ج

527.)اوم

(ورا

ادة

ن

ر

: : ه ون ن ال ارغوي اسخدم ج اخرس خ اوزن ظ5)وضا عوا 2) صا اوع

NEOPOR®ز ال اروي ا ن شر:ال ارغوي اضوي(5 و وي ل ل. م زه وت

ن

ال

رارة

درت

زن

ا

37اشر

اشس

شا

ا

ر

دم

راة

و

رد

.دم

ا

اه

اروري

ن

رؤ و طا دشا رؤ ا توزا صو ىرا داو يا يوا يورا لا ول س ن

ا داوا را ن جا دا تاودا ن رو تا اوت ظ ن دا ب و ا ةورا ل

رش ن ا يورا لا .ةورا جا ذو اس رو وو ل ن اواد ا ا ر ل®NEOPORاد

اطب

د

ورة

اروي

ل

ا

اص

وشدة

ا

اشرة

(ان

ان

و

و

شل

).

ارغوة ودة ام دو Plug & Play

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 32/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

و ز ن خ خ ر س ج CLC

او

ارل

ت

دا

را

اج

دا

وا

اواد

س

دام

ا

را

اج

وم

اود

اف

ورا

ادة

ود

ص

ز

ور

رورة

NEOPOR® Foamاروي

ال

ا

ا

وذك

Foam Agentج

ازم

.ار اوزن

ا را بCLC(.رد و ةدز ب وا وطر ر رار )دا را لا و

ا

طا

رض

او

طا

دائ

دام

او

ادا

و

ت

دام

ا

اب

اراع

رون

. وا ن ادام ف ر ص راع ب اط د ان م ار دى وا اف ادم ال اروي

( طا تشا ماد لا و ا را جا نTruck Mixersث )ةورا( ( د ب ود اوم

.

ن

ال

ا

اوزنرق

را

CLCوج

ون

ا

طا

زدة

رض

د

رج

ا

دة

ث و طا لوا ن زازا ن ب راد ا ا ةرو ا ا را حاوا ضر ل ا ا

را

ا

دوا

ادران

رج

ن

. )اب

(ال

ا

ا

ا

ب

ا

ازاز

ؤدي

. ®NEOPORاوزن ن ال اب ا ا ع د ت ر ؤرا

س خ د م د ) و و ز ن خ NEOPOR® CLC )- خ ر س س ر خ ض و

NEOPOR®

ر

ل

و

و

ص

و

ت

ن

ز

و

ر

ج

ل

د

ر

ر

ش

ن شر ر ل ر ل ذ ز و و ر ط و ر ن ش ن

.. ...م

س

ل

ز

ر

ن و و ر ر م و م NEOPOR® CLCو

ن حوار يرارا لز % 500-700%* دا ر ر

نزوا

ار و تاذ

)را

وات

ارف

ادى

ظرة

ادام

(اوت

اص

دا

شا

ال

از

ر

را ن عوا اذ ا مد ث ا دا وا داوا ت اور

را ا مدا ا دد ل

داوا ا را هذ ن ف ل ن ث داوا ل زا ةدا را

داوا

ارة

اوت

او

طاوا

ن

ار

دد

ر

ن

ث

ارات

ادام

ص

و * ) ر ق( س و ء د ر ن ر ة د ن ف د ر ر ي ز ل ش ئ ذ ت و د س خ د م ض ر و ر ي د ن

و ء ش ر ص و ش ء ر ط و و ف ر د ر ب و ك و س .

31

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 33/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE – Iraq

Tel: 07708748222, 07809245690; 07809245685, E-mail: [email protected],

www.leyde.com

و ز ن خ خ ر س ه (CLC)

/

و

)وم

(ور

ط

ان

وا

طا

ا

ادال

دا

ر

ش

ا

را

اتة

. ر و را نا ال اوي ث ل ذه اط ف وا

رش

ت

NEOPOR®اوزن

را

ل

ارادة

ا

CLCح

اداو

را

ن

اوع

ذا

اج

طور

ار ن47ر ذ ار ن شا ادا م ث 077,777 وت ار اد ذه ا ال ن

357راري

زل

ا

ادى

ا

ارات

او

شا

ال

را

ن

اوع

ذا

ادام

ان

.ب

ر

/لم

ا تاذ ا را تدا . ا هذ 77 و و لو شا ل جا ب ر / م

رش ن ا ز م ( دو ب باو ماد موا ةداو او داو ط نNEOPOR® باوا ا ا )

ام.57واشك ا ب س طر ب اب ارف ا واب اط وا م ادا ار ن ا ود

ا

را

دام

ل

دش

ري

ا

ادن

ن

ازاد

ادد

ا

ا

او

ا

ا

ن

ادد

اوم

ود

.

NEOPOR® CLCن را ذ قارا د37 تا شا ل ةدار ا رش ت ث 1 ارز رد

ن

ر

شرة

د

ور

(

زر

ط

دام

از

ا

رط

زا

م

داد

د

.)اشروع

ا

وزات

NEOPOR®رش

ل

ن

اراق

وة

وادة

LeycoChem LEYDE- Iraqرش

ري

ل

را

م

ا

NEOPOR® اراق.

NEOPOR® CLCوا وا با ا شا لا ج ادا اوا ت ا ةدوا ا را

وروا /ا را ن تاوا هذ لا مو .و (German/EU– Norms

)را تاوا

Standards)ICC/IAPMO)اوا

اوGB Standard

و ت ش ط و CLCر ج س

- ه د -

7/26/2019 CLC Costing

http://slidepdf.com/reader/full/clc-costing 34/34

عى بة ة و قتصادية

ل

ص و ةقاط رفت ةثيح م د بنا

Modern Construcon Products for Economical, Healthy and Energy Saving Buildings

Al Ruwad LeycoChem LEYDE - Iraq

00964 7708748222, 00964 7809245690, 00964 7809245685

2014

(CLC)ر اوزنا وا وا راNEOPOR®