Class: ECE 7366 “Advanced Process Integration” Instructor: Dr. W. Zagozdzon-Wosik.

-

Upload

doris-mccarthy -

Category

Documents

-

view

245 -

download

12

Transcript of Class: ECE 7366 “Advanced Process Integration” Instructor: Dr. W. Zagozdzon-Wosik.

INTRODUCTION

• This course is about the requirements for silicon chip fabrication and the technologies used to meet to thee specific needs of MOS and bipolar devices for current and future generations of ICs. Integration of the current processes and new processes/materials for further scaled down devices will be covered.• We will place a special emphasis on computer simulation tools to help understand these processes and as design tools. • These simulation tools are more sophisticated in some technology areas than in others, but in all areas they have made tremendous progress in recent years.

• 1960 and 1990 integrated circuits. • Progress due to: Feature size reduction - 0.7X/3 years (Moore’s Law).

Increasing chip size - ≈ 16% per year. “Creativity” in implementing functions.

Evolution of the Silicon Integrated Circuits since 1960s

Increasing: circuit complexity, packing density, chip size, speed, and reliability

Decreasing: feature size, price per bit, power (delay) product

1960s1990s

• The era of “easy” scaling is over. We are now in a period where technology and device innovations are required. Beyond 2020, new currently unknown inventions will be required.

Cell dimensions

Atomic dimensions

Device Scaling Over Time

0.1nm

1nm

10nm

1µm

10µm

100µm

1960 1980 2000 2020 2040

Transition Region

Quantum Effects Dominate

Atomic Dimensions

Feature Size

Year

0.1µm130 nm in 2002

18 nm in 2018

Era of Simple Scaling

Scaling + Innovation(ITRS)

Invention

~16% increase in complexity each year (now:6.3% for µP, 12% for DRAM)

~13% decrease in feature size each year (now: ~10%)

0.25µm in 1997

• 1990 IBM demo of Å scale “lithography”. • Technology appears to be capable of making structures much smaller than currently known device limits.

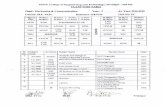

Year of Production 1998 2000 2002 2004 2007 2010 2013 2016 2018

Technology Node (half pitch) 250 nm 180 nm 130 nm 90 nm 65 nm 45 nm 32 nm 22 nm 18 nm

MPU Printed Gate Length 100 nm 70 nm 53 nm 35 nm 25 nm 18 nm 13 nm 10 nm

DRAM Bits/Chip (Sampling) 256M 512M 1G 4G 16G 32G 64G 128G 128G

MPU Transistors/Chip (x106) 550 1100 2200 4400 8800 14,000

Min Supply Voltage (volts) 1.8-2.5 1.5-1.8 1.2-1.5 0.9-1.2 0.8-1.1 0.7-1-0 06-0.9 0.5-0.8 0.5-0.7

ITRS at http://public.itrs.net/ (2003 version + 2004 update) – on class website.

• Assumes that CMOS technology dominates over the entire roadmap.• 2 year cycle moving to 3 years (scaling + innovation now required).

Trends in Increasing Integration Scale of CircuitsPast, Present, and Future ICs

Evolution of the Fabrication Process: The Planar Design of Bipolar Transistors

Implementation of a masking oxide to protect junctions at the Si surface

Boron diffusionSiO2

Mask

Oxidation possible for Si not good for Ge

Oxidation and outdiffusion

Lithography to open window in SiO2

Phosphorus diffusion through the oxide mask

Beginning of the Silicon Technology and the End of Ge devices

P

N

N

N

P

N

Si O 2

N

P

N

The planar process of Hoerni and Fairchild (1950s)

Photolithography used for Pattern Formation

Beginning of Integrated Circuits in 1959Kilby (TI) and Noyce (Fairchild Semiconductors)

Substrate

Film deposition Photoresist application

Deposited Film Photoresist

Exposure

Development Etching Resist removal

Mask

Etch mask

Light

• Basic lithography process which is central to today’s chip fabrication.

• Sensitive to light• Durable in etching

Alignment of Layers to Fabricate IC Elements

Emitter

Collector

Resistor

P N

N

PNP BaseResistor

• Lithographic process allows integration of multiple devices side by side on a wafer.

• Bipolar Transistor and resistors made in the base region

•Accuracy of placement ~1/4 to 1/3 of the linewidth being printed

Vcc

C

B

E

BJT

0V

Contact to collector

R=L/W•Rs

Schematic Cross-Section of Modern CMOS Integrated Circuit with Two Metal Levels

IC is located at the surface of a Si wafer (~500µm thick)

P

P WellN Well

PNP+ P+ N+ N+PMOS NMOS

Via

Interconnect

SilicideOxide Isolation

M1

M2

OXIDE

TiN

• Actual cross-section of a modern microprocessor chip. Note the multiple levels of metal and planarization. (Intel website).

Computer Simulation Tools (TCAD)

•Most of the basic technologies in silicon chip manufacturing can now be simulated.Simulation is now used for:

• Designing new processes and devices.• Exploring the limits of semiconductor devices and

technology (R&D).• “Centering” manufacturing processes.• Solving manufacturing problems (what-if?)

Semiconductor Devices

Reverse biased diode

Forward biased diode

p-n Diodes

after Kano, Sem. Dev.

n+ for low resistance

p-n Diodes at Thermal Equilibrium

Uncompensated acceptors and donors

At thermal equilibrium charge neutrality qN+

dxn=qN-Axp leads to asymmetrical depletion layers

Electric field only in the depletion layer

Breakdown Voltage of a p-n Diode

after Kano and Streetman

Eg

5-7V

• Ebr field increases with ND but not very much• Wdepl~1/√NDVbr=Ebr•Wdepl so Vbr decreases with ND

Bipolar Transistors

E-B junction is forward biased=injects minority carriers to the baseBase (electrically neutral) is responsible for electron transport via diffusion (or drift also if the build in electric field exist) to collectorC-B diode is reverse biased and collects transported carries

VBE>0 VBC<0

IE=IEn+IEp IC=IE<1

IB=IEp+Irec

IE IC

IB

Bipolar Junction Transistors

minority carriers

Injectedelectrons

Extracted electronsholes

Forwards bias Reverse bias

Bipolar Junction Transistors

Current Gain =

Gummel Plot

Kirk Effect

Recombination in the E-B SCR

IC/IB

MOS Field Effect Transistors (MOSFET)

NMOS and PMOS (used in CMOS circuits)

VG>VT to create strong inversion

depletion

Oxide

Operation of NMOS-FET

Linear Region, Low VD

Saturation Region, Channel Starts to Pinch-Off

Saturation Region, channel shortens beyond pinch-off, L’<L

Operation of MOS-FET

ID(VD)

Channel-Length-Modulation(Shorten by L)

ID=kp[(VG-VT)VD-VD2/2

Device transconductancekp=µnCoxW/L larger for NMOS than PMOSIn CMOS for compensation use Wp>Wn

Modern MOS Transistors

Gate

LDDLDD used to reduce the electric field in the drain depletion region and hot carrier effects

Self aligned contacts decrease the resistance

isolation

Drain

Source

Semiconductor Technology Families

First circuits were based on BJT as a switch because MOS circuits limitations related to large oxide charges

isolation

BL

n-p-n

NMOS and CMOS Technologies

Enhancement NMOS Depletion NMOS

1970s

NMOS PMOS1980s and beyond Smaller power consumption

Challenges For The Future• Having a “roadmap” suggests that the future is well defined and there are few challenges to making it happen.

• The truth is that there are enormous technical hurdles to actually achieving the forecasts of the roadmap. Scaling is no longer enough.

• 3 stages for future development:

Materials/process innovationsNOW

Device innovationsIN 5-15 YEARS

Beyond Si CMOSIN 15 YEARS??

“Technology Performance Boosters” InventionSilicide

PolyGate

Substrate

Silicide

SidewallSpacer

RchanSource Drain

S/D Ext S/D Ext

GateDielectric

???

Gate

Source Drain• Spin-based devices • Molecular devices• Rapid single flux quantum• Quantum cellular automata• Resonant tunneling devices• Single electron devices

Plummer et al.

Broader Impact of Silicon Technology

Tip on Stage Individual ActuatorPart of 12 x 12 arrayCornell University

-3.0x10-6

-2.5

-2.0

-1.5

-1.0

-0.5

0.0

Ids(A)

-1.4 -1.2 -1.0 -0.8 -0.6 -0.4 -0.2 0.0

VD(V)

-0.75V

-2.5V

-2.25V

-2V

-1.75V

-1.5V

-1.25V

-1V

-0.5V

Stanford, Cornell

• Many other applications e.g. MEMs and many new device structures e.g. carbon nanotube devices, all use basic silicon technology for fabrication.

Source

Gate

Drain

SiO2

Plummer et al.

Summary of Key Ideas• ICs are widely regarded as one of the key components of the information age.

• Basic inventions between 1945 and 1970 laid the foundation for today's silicon industry.

• For more than 40 years, "Moore's Law" (a doubling of chip complexity every 2-3 years) has held true.

• CMOS has become the dominant circuit technology because of its low DC power consumption, high performance and flexible design options. Future projections suggest these trends will continue at least 15 more years.

• Silicon technology has become a basic “toolset” for many areas of science and engineering.

• Computer simulation tools have been widely used for device, circuit and system design for many years. CAD tools are now being used for technology design.

• Chapter 1 also contains some review information on semiconductor materials semiconductor devices. These topics will be useful in later chapters of the text.

Plummer et al.