Class e Resonant Inverter

-

Upload

hitesh-mehta -

Category

Documents

-

view

35 -

download

2

description

Transcript of Class e Resonant Inverter

A CLASS E RESONANT INVERTER FOR USE AS ELECTRONIC FLUORESCENT LAMP BALLAST

B.D. Singer and G.R. WalkerSchool of Information Technology and Electrical Engineering

University of Queensland

Abstract

Class E Resonant Inverters are theoretically capable of delivering any power to a load andachieve 100% efficiency at any frequency of operation. In practice efficiency in the “high90's” can be achieved into megahertz frequencies regardless of inverter output powers. Thetopology also allows the manipulation of output power through sub-optimal operation, witha negligible efficiency penalty. The 24W inverter discussed in this paper was specificallydesigned to harness the benefits, and discuss the shortcomings, of the Class E topology foruse in the growing market for portable, battery powered lighting. It exhibits a peakrecorded power efficiently of over 98%, and a conservatively measured efficiency of 95%across a range of dimming settings.

1 INTRODUCTION

Well designed electronic ballasts can improvedramatically on the efficiency, flicker, size, andweight of the magnetic ballast used in fluorescentlighting. Electronic ballasts provide power at afrequency where fluorescent lamps exhibit higherefficacy; that is they produce more lumens of lightpower per joule of energy consumed. Understandablytradeoffs exist in EMI, cost and reliability.

Using a Class E Resonant Inverter topology for a lowvoltage electronic fluorescent lamp ballast is anattempt to improve on existing electronic ballastdesigns in the areas of EMI, cost and efficiency.Their sinusoidal current flow keeps radiated andconducted electromagnetic emissions minimal. Theirlow component count, with only one specialisedcomponent keeps unit cost down while low weightand compact geometry maximise portability.

This paper documents a circuit designed with theaforementioned properties. The goal was to designand produce a practical ballast for use as a cheap,portable 12V battery powered lighting solution.Applications of this technology might include outdoorequipment, automotive, marine, or any systems wherebattery life needs to be maximised and advantages aregained by portability.

A brief discussion of class E inverters and fluorescentlight properties is given in section 2, before acomplete specification and design of the invertercircuit and components is presented in section 3.Experimental results are then included and analysedfrom which conclusions are drawn.

2 BACKGROUND

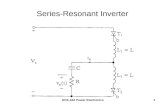

2.1 Class E Resonant Inverter

Figure 1 Class E Inverter

First described by N.O. Sokal and A. D. Sokal [2] theClass E Zero Voltage Switching (ZVS) Inverterexploits LCR resonance to deliver AC power to aload. A series resonant circuit is excited from a DCsource via a large inductance Lf through a switchingMOSFET. Provided Lf is large enough, the input tothe MOSFET and resonant circuit appears as a currentsource. The series resonant circuit generates voltagegain of magnitude equal to its quality factor [4]. Aload may make up any part of the LCR circuit, as dothe parasitic characteristics inherent in the switchingdevice. The body diode of the MOSFET is exploitedto allow for so-called sub-optimum mode operationfor a load with a a variable resistance. [1] describesand derives many circuit networks to match aninverter to any load. An appropriate choice for usewith a fluorescent lamp is the arrangement in Figure4.

Australasian Universities Power Engineering Conference (AUPEC 2004)

26-29 September 2004, Brisbane, Australia

The MOSFET is driven at around 50% duty but witha variable frequency to control power flow. Withcorrect component choice, the MOSFET in thisinverter switches when voltage between its terminalscrosses zero. Switching at zero volts effectivelyeliminates switching losses in the device, anddramatically reduces noise generation. Provided thequality factor of the resonant circuit is high enough,current through the series resonant circuit isapproximately sinusoidal. At lower than ideal Q (<5),an exponential voltage 'roll-off' will occur over theswitch that prevents perfect zero voltage switching.Higher than 50% duty cycle and larger than optimalload resistance can also prevent zero voltageswitching [1].

2.2 Sub-Optimum Mode Operation

When switching into a lower than optimal resistance,sub-optimal operation of the inverter occurs. Chargein capacitor C1 expires prematurely into the resonantcircuit, this charge is exhausted earlier in the period.The voltage seen by the switch crosses zeroprematurely and the body diode of the MOSFETconducts. This effectively changes the duty cycle ofthe switch. Losses in this mode are a consequence ofthe MOSFET body diode Vfd and depending onfrequency, relatively small. As discussed below, theuse of various impedance matching networks changesthe nature of sub-optimal switching in the inverter.

2.3 Compact Fluorescent Lamps

Compact fluorescent lamps (CFLs) differ fromconventional fluorescent lamps only in volume andgeometry. They are available in a range of geometry,power consumption, and colour temperatures. Thesedevices are inherently non-linear, their impedance isdetermined by phenomena at the atomic level. CFLsrequire a ballast, as do conventional fluorescentlamps, to limit the power delivered to them. Withoutthis current limiting ballast the path of conducting,ionised gas in the lamp would continue to grow,'snow-ball' fashion, and the lamp would destroy itself.As the conducting path grows and wanes, so too doesits resistance, as illustrated in the experimental resultsdisplayed in Figure 6.

3 CIRCUIT DESCRIPTION

The design discussed herein uses a 12V DC powersupply. The inverter is designed to experienceoptimal mode operation while delivering 24W to acompact fluorescent lamp. The frequency of operationwas limited to below 360kHz to prevent skin effect,and with real components specified, full poweroutput was calculatively estimated at 339kHz.

Output power control would be possible through sub-optimum mode operation. Sub-optimum operationwould be engaged by reducing the equivalentresistance in the inverter's resonant circuit, this wouldbe achieved through frequency control. Changingfrequency will vary the resistance of the lamp bychanging the impedance of it's 'ballast'. Varying the'ballast' impedance governs the current flowingthrough the lamp and, as mentioned, the resistance ofthe lamp will vary with the current it experiences. Theexact extent of the dimming operation was notdesigned or estimated but would be determinedthrough experimentation.

The full power loaded quality factor of the inverterwas estimated to be approximately 14.1 afteraccounting for the ESR of the L1 inductor. Nopreheating techniques were employed in striking thefluorescent lamp. The inverter was expected togenerate it's greatest starting voltage at approximately331kHz, with the given component values. The loadis a Osram brand, Dulux L 24W compact fluorescentlamp, model number FT24DL.

The lamp was assumed to be a resistive load whenstruck and an open circuit when not struck. It wasassumed to have negligible inductance or capacitancein either state.

Figure 2 12V Input 24W Inverter Design

3.1 Component Specification

Component values, tolerance and voltage rating werecalculated from 'Resonant Power Converters' byKazimierczuk & Czarkowski[1]. Much of thecalculation was aided by calculative spreadsheets andMatlab scripts generating solution arrays.

Capacitor C2 is a 10nF 2kV WIMA FKP-1 surgeprotection capacitor with 68pF 600V polystyrenecapacitor in parallel. It is vital that C2 is high voltagetolerant as several hundred volts will be imposedupon it by starting. Capacitors C3 are polystyrene andC1 is polycarbonate. Polycarbonate and polystyrenecapacitors are suitable for the low capacitance values,excellent accuracy, low ESR and high tolerance. Allcapacitors are of 5% value tolerance

Design limitations were imposed by the inductor L1.Given it's position, this inductor required specialtreatment to ensure its ESR did not prevent the circuitfrom starting a lamp and its operating power losseswere not crippling to system efficiency. It is the onlynon 'off the shelf' component in the circuit. This isthe topic of section 3.3

The MOSFET is a BUZ100, but any device able towithstand greater than 43V would have sufficed. Solong as it's drain to source capacitance was consideredin the design, this design did not specifically require ahigh frequency device. Difficulty might arise whenthis capacitance, which is non-linear and changeswith operating mode of the MOSFET, approachessimilar magnitude to capacitance C1.

The BUZ100 MOSFET was switched directly by aHP33120A function generator via it's 50 Ohm sourceimpedance. A 20Vp-p drive centred around zeroVolts ensured relatively rapid switching transitionsfor both turn on and turn off.

3.2 Special Component Specification

Being a low input voltage inverter, all componentsexperience elevated current. The MOSFET,capacitors and inductors can all be chosen to have alow equivalent series resistance. The ferrite inductorssuited for switch mode power supplies are designedfor a DC current with a significantly smallersuperimposed ripple current. This style of bobbininductor is suited and used for the input inductor forthis design.

However, the resonant inductor sees a largesinusoidal current swing equal to the RMS current itis carrying. This requires an inductor with both lowESR and low hysteresis losses, since every currentcycle is a complete cycle of the major hysteresis loop.Hysteresis loss in the ferrite core material is furtheraggravated by high frequency operation.

Clearly care must be taken when designing L1. Aftermuch mathematical analysis and spreadsheeting, noavailable core material was found which would notrequire an unreasonably large air gap in its core toreduce flux density levels. Predicted losses wouldalso affect unacceptably both the unloaded Q beforestriking and the efficiency once struck. To keep theresonant circuit quality factor high, and ensuresuccessful striking of the lamp, an air cored inductorwas designed and constructed that would not sufferany core loss. An air core frees the inductor offrequency constraints, other than the skin effect in itswindings [10].

Early air cored inductor attempts showed that skineffect if not properly accounted for would lower the

Q and the ability of the inverter to start the lamp. Toavoid skin effect, 0.25mm diameter copper was usedand design frequency was limited to 360kHz. Afterthis frequency, skin depth becomes less than theradius of this wire and skin effect cannot beneglected[4]. To use copper this thin, several parallelstrands are wound on the air core to keep DC lossesunder control, especially as a lot of copper length isrequired to achieve a significant inductance with onlythe permability of air. The inductor L1 was woundaround a plastic core and had 67 turns, of 11 parallelstrands. The mean diamter of the toroid was 119mm,and its height was 45mm. Its DC resistance was34.7mR, it's inductance was 23.0uH, both quantitieswere measured on a HP4275A LCR meter. Atoroidal shape was chosen to contain the flux and soreduce the posibility of unacceptable emissions, andalso because of the predictability of the inductancebased purely on geometry. The completed 24Wconverter, and CFL tube are shown in Figure 3.

3.3 Impedance Matching Network

The arrangement of capacitors C2 and C3 matches thehigh impedance (345Ω at rated power) of the lamp tothe inverter. This is necessary for the low inputvoltage of the inverter. This network has a secondpurpose in generating the voltage necessary to strikethe fluorescent lamp. Before ignition, the lamp isopen circuit with negligible effect in the cirucit.

Figure 3 24W Inverter and CFL that achieve >95%power efficiency.

Capacitor C3 has no effect, and C2 forms the seriesresonant circuit with L1. There is no resistance todamp resonance in this circuit, other than the ESR ofthe the said components, and the MOSFET thatexcites them. This circuit has very high Q, limitedonly by the ESR of its components, the bulk of whichis contributed by L1. As such, with well selectedcomponents, very high voltage, in excess of thatrequired to strike the lamp, is easily generated.Keeping ESR low in the starting circuit is essential togenerate the voltage required for starting.

Figure 4 Capacitive Impedance Matching

4 RESULTS

The inverter delivered between 28W and 17W, in thefrequency range of 329kHz to 348kHz respectively,and with high efficiency.

The inverter starts most quickly at 338kHz, at thisfrequency it generates in excess of 1kV with the lampremoved. The inverter delivers 24W, full rated power,with 96.5% efficiency at a frequency of 337kHz. Themost perfect zero voltage switching occurred at334kHz while delivering 24.24W at an efficiency of95.3%. At frequency below 334kHz, the inverterleaves optimum operation, generating switching lossand exhibiting low Q exponential roll-off over theswitch. The inverter dims through sub-optimum modeoperation up to the frequency of 348kHz where itoutputs 17W. After this frequency the lamp faltersand is extinguished.

4.1 Important Observations

4.1.1 Input Voltage

During the inverter design process it was noted thatthis style of inverter is well suited to low inputvoltage. With input voltage decreased, the capacitivematching network makes the load appear a smallerresistance to the inverter. A lower resistance dampsthe resonant circuit less, which can then be designed

with smaller reactive components and still maintainadequate Q.

4.1.2 The Importance of Starting Quickly

Before the lamp is struck, the circuit can consumevery high current. The lamp at this stage is an opencircuit and is receiving none of the power. Excitationof a resonant circuit at it's peak admittance, itsresonance, is essentially exciting a short circuit butfor parasitic ESR. With the lamp removed and theinverter turned on at starting frequency, the MOSFETwill burn out quickly; in under 5 seconds for thisinverter. As such it is important to have a stableoscillator and to start the lamp as quickly as possiblethrough correct starting frequency choice. Duringcircuit testing, the best frequency for starting wasdetermined non-destructively by removing the lamp,decreasing input voltage to around 1V, and sweepingthe oscillator to find the frequency with the highestvoltage gain.

Better starting times could be achieved throughpreheating of the lamp.

4.1.3 Low Q Exponential Switching Waveform

With the lamp struck at the appropriate startingfrequency, 338kHz, the inverter is operating in sub-optimum mode with no exponential roll-off.Frequencies lower than 334kHz exhibit a roll off andincreased current consumption. Decreasing frequencybeyond this point sees efficiency steadily fall.

4.1.4 Flicker Free Operation

Illumination from the lamp was completely flickerfree. When attempting to strike the lamp close to, butnot at the correct starting frequency it will flicker andfalter. Beyond 348kHz it would flicker and then falterfor diminished light output.

4.1.5 Circuit Heat Generation

The inductor L1 slowly heats up, and is noticeablywarmer than room temperature after a few minutes,but does not get hot. In earlier inverter attempts thatultimately failed, the inductor L1 would becomewarm quickly and slowly become hot.

4.2 Measurements

These measurements were made using current senseresistors in series with the fluorescent lamp, andvoltage measured with a Tektronix TDS-224 digitaloscilloscope. The potential for ±5% measurementerror was estimated to exist in the system.

5 Analysis

5.1 Inverter Resonance After Starting

Refer to Figure 4. It isn't until the lamp starts that thecapacitor C3 becomes part of the circuit. Adding this

capacitance lowers the resonant frequency of the newequivalent circuit immediately. The circuit is nolonger at perfect resonance, but above it, and theinverter's input current drops. At perfect resonance,and peak admittance, the lamp would only havecomponent ESR to act as ballast and would self-destruct. Away from resonance the impedance of thecircuit provides stabilising ballast for the lamp.Needless to say the luminous output of the lamp isgreatest near its new resonance and decreases asfrequency is increased. Figure 8 shows lampresistance changing over a range of frequencies.

5.2 Sub Optimum Mode Operation

Sub-optimum operation is engaged by decreasingresistance in the resonant circuit by frequency control.The inverter will operate in sub-optimum mode for arange of load resistances from zero to a resistancewhere optimal switching occurs. Increasing frequencyaway from resonance increases impedance of theentire circuit and limits current to the lamp. Lessexcited, the lamps resistance rises. The capacitiveimpedance matching circuit acts as an impedanceinverter. As the lamp resistance rises, it causes theequivalent resistance of the resonant circuit decreases,and this is the mechanism through which sub-optimum operation occurs. The lower powerdelivered to the lamp coincides with a diminishedvoltage-time integral seen across the switch terminals,and larger voltages are produced in the resonantcircuit through improved quality factor.

5.3 Capacitive Impedance Matching as an Impedance Inverter

If it seems unusual for the impedance of a circuit todecrease as it draws less current from a higher voltageconsider the burden this circuit would place on an LCresonant system. The series resonant circuit willresonate and generate voltage gain according to itsquality factor. With no damping, energy will oscillateresonantly freely between magnetic and electricfields. Voltage superposition and gain will only belimited by reactive component ESR dissipating someof this energy. When current can flow through C3,energy is lost from the resonant circuit. Tapping thisenergy away from the L and C components damps theresonant circuit; in effect the same as increasing itsresistance and lowering quality factor.

The current seen by the lamp is controlled byfrequency. There are two possible resonant circuitsthat interplay in this inverter. Struck resonance is thefrequency dictated by all the components, includingthe lamp. The other is the circuit formed by C1, C2and L1, the starting resonance. Moving operatingfrequency between the two determines how muchcurrent flows to the lamp; peak current will flow to

Figure 8 Lamp Resistance

Figure 5 MOSFET Gate and Drain capturedwaveforms showing ZVS operation.

Figure 7 Power Output

Figure 6 Inverter Power Efficiency

327.5 330 332.5 335 337.5 340 342.5 345 347.5 350

0.92

0.94

0.96

0.98

1

Frequency(kHz)

Eff.

327.5 330 332.5 335 337.5 340 342.5 345 347.5 350

15

17

19

21

23

25

27

Frequency(kHz)

Power(W)

327.5 330 332.5 335 337.5 340 342.5 345 347.5 350

200

300

400

500

600

700

Frequency(kHz)

Rlamp(Ohm)

the lamp as struck resonant frequency is approached.Moving the frequency higher, away from struckresonance, towards and beyond the starting frequencyprovides a greater impedance to limit current reachingthe lamp. The effect is higher Q and higher voltage,even though output power is diminished.

5.4 Open Circuit Load Operation

When the lamp was disconnected from the circuit,accidentally or by failure, the inverter consumed analarming amount of current and the MOSFET switchheated up rapidly as mentioned in Chapter 4.1.2. Ifthe input current were sufficient to destroy a lead acidbattery, people or material in the immediate areacould be harmed. A slow blow fuse is a necessity.

This performance is contrary to text in literature[1]that suggest sub-optimum, and efficient operation ofthe inverter, is possible through a range of loadresistances from an optimal value through to a shortcircuit. With the lamp removed the equivalent circuitis a short circuit resistively.

Oscilloscope measurements of the voltage waveformgenerated on the switch during this operation exhibita dramatic exponential 'kick' before the MOFSETswitches on. The heat generated is from switchingloss, but the mechanism through which this 'kick' isgenerated is unclear, low circuit Q and the 'roll-off'artifacts that accompany it should not occur with anequivalent short circuit load.

6 CONCLUSIONS

The Class E inverter described in this text has theadvantages of high efficiency, low input voltage, lowcomponent count and potentially small geometry.These properties make it ideal for battery powered,portable lighting. This inverter has exhibited effectivedimming of its luminous output without anyappreciable efficiency penalty.

The disadvantage of potential damage when the loadis open circuit, might be solved with further work andexperimentation. If an explanation or solution to thisproblem is not forthcoming, it could be thwarted bysimple work-arounds to make the circuit practical andreliable. A current sense resistor and a timer forinstance, could stop the inverter if it's lamp wasdisconnected. More sophisticated implementationscould use thermometry of the MOSFET to detect thisscenario.

7 REFERENCES

1. M. K. Kazimierczuk and D. Czarkowski,“Resonant Power Converters”. New York:John Wiley & Sons Inc, 1995.

2. N. O. Sokal and A. D. Sokal. “Class E – Anew Class of High-Efficiency Tuned SingleEnded Switching Power Amplifiers”. IEEEJournal of Solid State Circuits, Volume.SC-10, no.3. June ’75, pp168-176.

3. M. K. Kazimierczuk and J Jozwik.“Resonant dc/dc Converter with Class-EInverter and Class-E Rectifier”. IEEETransactions on Industrial Electronics. Vol.36, no. 4. Nov '89, pp568-578.

4. A. R. Hambley, “Electronics: SecondEdition”, New Jersey: Prentice Hall, 2000.

5. N. Mohan, T. Undeland and W. Robbins,“Power Electronics”. New York: John Wileyand Sons Inc, 1995.

6. P. Horowitz and W. Hill, “The Art ofElectronics: Second Edition”. Cambridge:Cambridge Press, 1989.

7. Ferroxcube, “Soft Ferrites: Introduction”.PDF Application Note,www.ferroxcube.com

8. J, Funke and P. J. Oranje, “Gas DischargeLamps: Principles, Characteristics andApplications”. Amsterdam: N. V. PhillipsTechnical and Scientific LiteratureDepartments, 1951.

9. R. L. Ropp, “The Chemistry of ArtificialLighting Devices”. Amsterdam: Elsevier,1993.

10. J. Everard, “Fundamentals of RF CircuitDesign: with Low Noise Oscillators”. NewYork: John Wiley and Sons Inc, 2001.

Figure 9 A second working 24W inverter showingmore compact geometry, a 12V lead acid battery and

compact fluorescent lamp.