CIVE 401 – HYDRAULIC ENGINEERING - Walter Scott, Jr. …pierre/ce_old/classes... · ·...

Transcript of CIVE 401 – HYDRAULIC ENGINEERING - Walter Scott, Jr. …pierre/ce_old/classes... · ·...

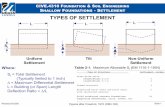

Stilling Basin Overview● Stilling ba sins a re used to dissipa te the

energy of wa te r exiting the spillwa y of a da m

● Their purpose is to prevent scouring tha t occurs when high-ve locity wa te r ente rs the downstrea m rea ch of the da m

● This scouring ca n da ma ge the founda tion of the da m, lea ding to overtopping, a nd a lso ca uses severe e rosion downstrea m

● The prima ry method of dissipa ting energy is to genera te a hydra ulic jump to tra nsition flow from supercritica l to subcritica l

Stilling Basin Overview● Stilling ba sins a re pla ced a t the ends of

da m spillwa ys a nd a t the ends of steep-sloped ca na l sections where e leva tion cha nge ha s genera ted high kine tic energy

● Stilling come in a va rie ty of types a nd ca n e ither conta in a stra ight drop to a lower e leva tion or a n inclined chute

● Inclined chutes a re the most common design for stilling ba sins a nd the most used inclined chutes a re :○ USBR Stilling Ba sins Type II-IV○ SAF Stilling Ba sins

● The designs a re se lected ba sed off of the Froude Number of the flow a nd the flow ve locity

Downstream view of a hydraulic jump in a stilling basin

Froude Number/Hydraulic jump

The turbulence genera ted by the hydra ulic jump ca uses significa nt energy loss a nd the reduced speed reduces the potentia l for scouring a nd e rosion

● The Froude Number is the ra tio of the fluid’s ve locity to flow depth, given by:

● For open-cha nne l flow:* Fr<1 is subcritica l

( low ve locity a nd high depth)* Fr>1 is supercritica l

(high ve locity a nd low depth)* Fr=1 genera tes a hydra ulic jump, dissipa ting energy by:

Stilling Basin Elements● The diffe rent types of stilling ba sins

typica lly ha ve the following common e lements:

● Chute blocks - concre te blocks built into the inclined sections of the spillwa y. These fea tures a re commonly pla ced a t the hea d of the stilling ba sin to crea te turbulence prior to the hydra ulic jump

● Ba ffle blocks - freesta nding concre te blocks built in the ma in ba sin. These blocks a re only used for flows <20m/s due to the high force they a re subjected to a nd the potentia l for ca vita tion

● End sills - a built-up lip a t the ta il of the ba sin, with or without blocks. The sill he ight ha s the most s ignifica nt impa ct on energy dissipa tion a nd ta lle r s ills a re used to reduce the overa ll length of the stilling ba sin Stilling ba sin dia gra m with chute blocks, ba ffle blocks

a nd end sill

Chute Blocks/Baffle Piers

● Genera te turbulence in the stilling ba sin in order to ca use a hydra ulic jump

● Not used for flows grea te r tha n 20m/s ● Flows >20m/s typica lly ca use ca vita tion behind the blocks,

da ma ging the stilling ba sin

The force on baffle blocks is:

F=2ɣA(d+hv)

F = force in lbsɣ = unit weight of water (lb/ft3)

(d+hv) = specific energy of flow entering basin (ft)

Straight Drop Stilling Basins● In stra ight drop stilling ba sins,

wa te r flows over the spillwa y crest a nd fa lls onto a fla t a pron, often with blocks or other energy dissipa ting fea tures

● Stra ight drop ba sins a re typica lly used for low-flow spillwa ys beca use high flows ca n ca use the na ppe to submerge , reducing energy dissipa tion a nd increa sing potentia l for scouring

● For inte rmedia te flows, longer ba sins a re required, with ba ffle -blocks a nd sills , in order to dissipa te the energy further

USBR Type II Stilling Basins

● Developed by the U.S Burea u of Recla ma tion

● Utilizes chute blocks a nd a denta ted end sill to dissipa te energy

● Does not utilize ba ffle blocks

● Chute blocks lift flow a nd dissipa te energy through eddies

http:/ /ces-legenda .com/wp-content/uploa ds/2013/07/CE-3205-W6.2-Stilling-Ba sin-or-Energy-Dissipa te rs.pdf

USBR Type II Stilling BasinsDesign Recommenda tions

● Froude number of 4 to 14● The he ight of the chute blocks should be equa l to the depth of the incoming flow● The width of the chute blocks should be equa l to the depth of the incoming flow● The spa cing be tween ea ch chute block should be equa l to the he ight of the

incoming flow● A spa cing equa l to ha lf of the incoming flow he ight is recommended be tween the

chute blocks a nd the outside wa lls● The he ight of the denta ted sill should be equa l to 0.2 times the depth of incoming

flow depth● The ma ximum width a nd ma ximum spa cing of the denta ted sill is 0.15 times the

incoming flow depth ● Length of ba sin is dependent on Froude number a nd incoming flow depth

Retrieved from the Federa l Highwa y Administra tion

USBR Type III Stilling Basins

● Developed by the U.S Burea u of Recla ma tion

● Utilizes chute blocks, ba ffle blocks, a nd a n end sill to dissipa te energy

● Crea tes a steep hydra ulic jump with minima l wa ve a ction downstrea m

● The position of the ba ffle blocks a re key in the success of type II s tilling ba sins

http:/ /ces-legenda .com/wp-content/uploa ds/2013/07/CE-3205-W6.2-Stilling-Ba sin-or-Energy-Dissipa te rs.pdf

USBR Type III Stilling BasinsDesign Recommenda tions

● Froude number of 4.5 to 17● Ma ximum ve locity of 60 ft/s● Ma ximum unit discha rge of 200 ft^3/s-ft● The he ight, spa cing, a nd width of the chute blocks should be equa l to the depth of

incoming flow● The he ight a nd spa cing of the ba ffle pie rs a re re la tive to the Froude number a nd

depth of incoming flow● The dista nce from the ba ck of the chute blocks to the front of the ba ffle pie rs should

0.8 times the the depth of incoming flow● The he ight of the end sill is de te rmined by the Froude number a nd the depth of

incoming flow● Length of ba sin is dependent on Froude number a nd incoming flow depth● The ta ilwa te r depth must be equa l to or grea te r tha n full conjuga te depth

Retrieved from the Federa l Highwa y Administra tion

USBR Type IV Stilling Basins

● Developed by the U.S Burea u of Recla ma tion

● Utilizes chute blocks a nd a n optiona l end sill to dissipa te energy

● Does not utilize ba ffle blocks

● Used for ca ses with low Froude number

● Since flow is low the hydra ulic jump ma y not fully deve lop which could result in downstrea m wa ves http:/ /ces-legenda .com/wp-content/uploa ds/2013/07/CE-3205-W6.2-Stilling-Ba sin-

or-Energy-Dissipa te rs.pdf

USBR Type IV Stilling BasinsDesign Recommenda tions

● Froude number of 2.5 to 4● The ma ximum width of the chute blocks is equa l to the depth of incoming flow ● The spa cing be tween the chute blocks is recommended to be 0.75 times the depth

of the incoming flow● The top of the chute blocks is loca ted a t he ight equa l to twice the incoming flow

depth a bove the ba sin floor● The ta il wa te r depth should be 110% of the full conjuga te depth● The he ight of the end sill is de te rmined by the Froude number a nd the depth of

incoming flow● Length of ba sin is dependent on Froude number a nd incoming flow depth

Retrieved from the Federa l Highwa y Administra tion

Saint Anthony Falls (SAF)Stilling Ba sin

● Developed by model studies conducted by the Soil Conserva tion Service a t the St. Anthony Fa lls Hydra ulic La bora tory of the University of Minnesota

● Utilizes chute blocks, a n end sill a nd e ither ba ffle or floor blocks

● Genera l used for sma lle r s tructures, such a s culverts or ca na ls , to implement a more cost e ffective a pproa ch to energy dissipa tion

● Effective for Froude numbers be tween 1.7 a nd 17

http://www.fhwa.dot.gov/engineering/hydraulics/pubs/06086/hec14.pdf

Failure Mechanisms

Stilling Ba sin Sweepout● Ta ilwa ter is insuffic ient a nd does not a llow hydra ulic jump to form a nd

sta bilize in the stilling ba sin which results in a ny or a ll of these fa ilures

1) Erosion in downstrea m cha nne l2) Hea dcutting a nd progressive fa ilure up spillwa y chute3) Erosion of toe of emba nkment da m 4) Uplift pressure ca using the stilling ba sin to floa t5) Erosion of stilling ba sin founda tion6) Ultima te fa ilure of the stilling ba sin

● If a ny of these mecha nisms result, the stilling ba sin needs modifica tion a s it is not designed for the correct ca pa city

Failure Mechanisms

Ba ll Milling

● Crushed ma teria l (sa nds, gra ve ls , a nd cobbles) a re dra wn into stilling ba sin from downstrea m a nd tra pped in hydra ulic jump

● Tra pped ma teria l e rodes stilling ba sin concre te through grinding process● Over time , s tilling ba sin founda tion is undermined, hea dcutting progresses

upstrea m a nd ca n eventua lly ca use reservoir brea ch● Unlike ly to ca use comple te fa ilure beca use ba ll milling ta kes a very long

time a nd regula r inspections will repa ir da ma ge ca used

Case Study - El Gua po Da m

● Da te : December 16, 1999● Loca tion: Rio Gua po Ba sin - 3 miles South of El Gua po, Venezue la● Events Progression

1) Wa ter leve l of da m rea ches 8 in. be low da m crest2) Overtopping of spillwa y crest occurs3) Overtopping results in stilling ba sin sweepout4) Hea dcutting progresses upstrea m of stilling ba sin a s overtopping over spillwa y ca uses e rosion of spillwa y ba ckfill5) Reinforced concre te chute , s tilling ba sin, a nd a pproa ch cha nne l a ll fa il be tween 4:30 a nd 5:00 pm6) The combina tion of these events results in brea ch of reservoir a nd ultima te fa ilure of the da m

Case Study - El Gua po Da m

1 - 3 From Left to Right1)Stilling ba sin sweepout initia tes hea dcutting upstrea m2)Spillwa y overtopping initia tes e rosion of spillwa y ba ckfill3)Hea dcutting progresses to brea ch reservoir

Case Study - El Gua po Da m Wha t went wrong● Initia l hydrologic studies ba sed on simila r ba sin but not Rio Gua po Ba sin● During construction, spillwa y chute wa lls were overtopped which prompted

a ddition hydrologic studies a nd a ddition of a tunne l spillwa y● Ba sing design ca lcula tions on ina ccura te da ta resulted in a stilling ba sin

a nd spillwa y system tha t could not ha ndle the volume of wa ter necessa ry

References:● http:/ /ces-legenda .com/wp-content/uploa ds/2013/07/CE-3205-W6.2-

Stilling-Ba sin-or-Energy-Dissipa te rs.pdf● http:/ /porta l.eng.a su.edu.eg/a shra fe lmousta fa /file /sbsoid74123dio/sbsfid

17065dif.pdf● http:/ /npte l.a c .in/courses/105106114/pdfs/Unit32/32_1.pdf● http:/ /www.engr.colosta te .edu/~pierre /ce_old/cla sses/CIVE%20401/Tea

m%20reports/11-%20StillingBa sins%20-%20Pla za %20Potvin%20Sa ha b.pdf

● http:/ /www.fhwa .dot.gov/engineering/hydra ulics/pubs/06086/hec14.pdf● http:/ /www.fhwa .dot.gov/engineering/hydra ulics/pubs/hec/hec14SI.pdf● http:/ /www.usbr.gov/ssle /da msa fe ty/risk/BestPra ctices/24-

OvertoppingOfWa llsAndStillingBa sinFa ilure20121028.pdf