CISC Advantage Steel Magazine No44 2012

Transcript of CISC Advantage Steel Magazine No44 2012

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

1/60

CanadianMuseumfor HumanRightsExperts turn tostructural steel

CANADIAN INSTITUTE OF STEEL CONSTRUCTION

PM#40787580

STEELN O 4 4 F A L L 2 0 1

ADVANTAGE

Life-cycleassessmentmethodologiesfor buildings

Girder-Slabconstruction

Staggered trussframing system

CISC National SteelDesign Awards

CANADIAN INSTITUTE OF STEEL CONSTRU

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

2/60

Plate Processing SystemsV320C / V330C / V330S

Drilling, Thermal Cutting, Layout Marking, Part Identification, Tapping

and Countersinking in one precise, high-speed and compact unit.

Voortman USA Corporation / Unit F / 450 South Spruce st. / Manteno IL-60950 USA(t) 1 815 468 6300 / (f) 1 815 468 6333 / (e) [email protected] / (w) www.voortmancorp.com

> High-speed 30HP Drill spindle> Automatic 10 tool Changer> Layout-marking and

part identification

> Dump table withpart removal.

Automated loading of stockmaterial from the side or endMaterial gripped from the rear

and side for absolute accuracy.

> Oxy/Fuel HyperthermHPR 260XD

> Auto Height sensing> Layout-marking and

part identification

Voortmans unique approach to plate processing solves the issues fabricators experience daily withthe new range of plate processing centers. Voortmans technology addresses the issues of plate edgeand unevenness conditions that roller feed pass through systems cannot grasp. The result is unsur-passed productivity with absolute accuracy for all steel fabricators and service centers.

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

3/60

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

4/60

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

5/60

Jumbo HSS Meets ASTM A500, CSA G40 StandardsWhen a structure has greater demands, Jumbo HSS is the solution.

New Jumbo HSS from Atlas Tube can be an economical alternative fo

concentric bracing, heavy column loads or long spans. For the largest

offering of HSS in North America, look to Atlas Tube.

Design questions?Call 800.733.5683 to schedule a Lunch & Learn, or

to speak with an Atlas structural engineer today!

atlastube.com/jumbo-HSS

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

6/60

6 F A L L 2 0 1 2 A D V A N T A G E S T E E L

INTHIS

I SSUE

40

32

36

N O 4 4 F A L L 2 0 1 2

From the President 10 Ed Whalen, P.Eng.

F E A T U R E S

Canadian Museum for Human Rights: Experts turn to structural steel 20Neb Erakovic, M.Sc., P.Eng., Crispin Howes, P.Eng., Terry Dawson, M.Eng., P.Eng.

Supreme Group awarded Canadas first Girder-Slabmethod of construction project 32

Peter Timler, M.Sc., P.Eng.

Staggered Truss Framing system at the Toronto Christian Resource Centre 36Fernando Cruz, M.Eng., P.Eng., & Michael Jelicic, P.Eng.

2012 CISC National Steel Design Awards 40

C O L U M N S

Technical Column 12 Alfred F. Wong, P.Eng.

Seismic Corner 14 New provisions for eccentrically braced frames in CSA S16-09 Charles Albert, P.Eng.

For Greens Sake 17 Life cycle assessment methodologies for buildings

Ivan Pinto, Dr. Mark Gorgolewski, Prof. Vera Straka

News and Events 47

CISC Members 51

20

ADVANTAGE STEEL

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

7/60

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

8/60

A CENTURY OF SERVICE

VANCOUVER | VICTORIA | PRINCE GEORGE | KAMLOOPS | CRANBROOK | EDMONTON | CALGARY | FORT MCMURRAY | SASKATOON | REGINA

www.wilkinsonsteel.com

PRODUCTS SERVICES SUPPLY CHAIN SOLUTIONS

Wilkinson Steel and Metals is proud to celebrate 100 years.

Thanks to our extensive depth and breadth of structural steel products, combined with local

inventories at 10 locations across Western Canada, you can count on us to have what you need,

when you need it.

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

9/60

Specializing in structural shapes.Cut to size and stock length.Wide Flange Beams, Structural Channel and H.S.S.

The Distributor of Choicefor Structural Steel

in Canada

DYMIN STEEL INC.133 Van Kirk Drive, Brampton, Ontario L7A 1A4 T: (905) 840-0808 1-800-461-4675 F: (905) 840-5333

657 Sumas Way, Abbotsford, B.C. V2S 7P4 T: (604) 852-9964 1-800-852-9664 F: (604) 852-0557

16th Avenue, Nisku, Alberta T: (866) 979-0454

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

10/60

ADVANTAGE STEEL

Advantage Steel and the French-language edition Avantage Acier(available on request) are published by the Canadian Institute of

Steel Construction (CISC) on behalf of itsmembers. CISC is not responsible for theopinions expressed in this publication by those

contributing articles. CISC gratefully acknowledges the

support contributed to this publication by the CWB Group.Visit us atwww.cisc-icca.caor Tel 905-946-0864, Fax905-946-8574

CHAIRMANStephen Benson, Benson Steel Limited

EDITORRob White, BFA

EDITING/TECH ADVISORSuja John, P.Eng.

PUBLISHER MediaEdge Publishing Inc.5255 Yonge St., Suite 1000Toronto, ON M2N 6P4Toll-Free: 1-866-216-0860 ext. [email protected]

www.mediaedgepublishing.com

Professional engineers, architects, structural steel fabricatorsand others interested in steel construction are invited to inquireabout CISC membership. Readers are encouraged to submittheir interesting steel construction projects for consideration forinclusion in this publication by contacting CISC.

I SSN 1192- 5248 PUBLICAT IONS NUMBER 40787580

PLEASE RETURN UNDELIVERED COPIES TO:

Canadian Institute of Steel Construction3760 14thAvenue, Suite 200Markham, Ontario, Canada L3R 3T7

By Ed Whalen, P.Eng.

On its annual SteelDay, on September 28, theCanadian steel industry will showcase its strengthand present steel as the premier building materialacross Canada.

As we prepare for this important event, I cant help butremember a presentation made by Don McDonald of theAustralian Steel Institute at CISCs annual conference inOttawa in June. In approximately two years, the prac-tices of the mining EPCs (Engineering Procurement and

Constructors) changed their world forever.

The steel fabricators had done everything right. Theyinvested heavily in technology, they minimized their over-head, and they upgraded the skills of their employees.They were ready and well positioned to reap the rewardsof Australias natural resource boom.

Or, so they thought. Today, their industry is running at30 per cent capacity or less, at a time when Australiasmining industry is booming.

What did they miss?

Fact one: The act of buying technology alone does notnecessarily make you competitive. As they say, you areonly as fast as the slowest process. How many of us havetruly assessed all of our processes? Do we know howmuch process improvement we need in order to be locally,provincially, nationally and globally competitive? Australiadid not benchmark their production against the rest of theworld. Up until that point they were competing locally.

Fact two: There are new methods of constructing. The daysof stick-built structures are being replaced with modular-

ization and containerization, allowing for locations of lowlabour wages in other building tradessuch as mechan-ical and electricalto affect whether we can get the job.In Australia, most mining projects are located along thecoast, making it easy for super-large 10,000-ton modulesto be delivered in one piece by ship.

No longer a pipe dreamFact three: EPCs are not holding their suppliers in other partsof the world to the same safety, quality and environmentalstandards as they do in Canada. Governments in other coun-tries, such as China, have dramatically different safety andenvironmental standards from what we have in Canada.

So what to do? The rst thing is to determine if you truly arecompetitive locally and nationally. Once that is established

you determine your companys competitiveness against therest of the world.

A doctorate project coming out of Alberta led by Jim Kanervaof Waiward Steel will try to determine just that. In a recentstudy, Kanerva was able to establish that most companieswere looking to set up key performance indicators (KPIs)measuring productivity and competitiveness, but few wereable to nd the right metrics.

Jim Kanervas project will establish an Alberta StructuralSteel Fabrication and Erection Industry Key PerformanceIndicator Benchmarking Network. This leading edge researchproject will:

Determine, establish and standardize a set of benchmark-able key performance indicators (KPIs);

Use this set of KPIs to determine, establish and standardizean overall competitiveness factor; and

Establish a network of industry-sector specic organizationscommitted to implementing a standardized, third-partyaudited benchmarking program for determining ongoingcompetitiveness.

With this information, participating companies will be able

to identify and benchmark their position of competitiveness,thus improving their ability to compete.

CISC is hoping to eventually bring this project to a nationallevel. The benets to our industry are great, especially if wewish to be long-term players in the global world of steel.

F r o m t h e P r e s i d e n t

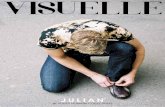

On the Cover: Canadian Museum forHuman Rights

CANADIAN INSTITUTE OF STEEL CONSTRUCTION

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

11/60

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

12/60

12 F A L L 2 0 1 2 A D V A N T A G E S T E E L

By Alfred F. Wong, P.Eng.

T e c h n i c a l C o l u m n

CISC provides this column as a part of its commitment to the education of those interested in the useof steel in construction. Neither CISC nor the author assumes responsibility for errors or oversightsresulting from the use of the information contained herein. Suggested solutions may not necessarilyapply to a particular structure or application, and are not intended to replace the expertise of aprofessional engineer, architect or other licensed professional.

QUESTION 1: When designing fillet welds in shear, is it necessary to check the basemetal resistance at the fusion face?

ANSWER:In accordance with S16-01, the shear resistance of lletwelds is taken as the lesser of: (a) the weld metal resistancegiven as a function of the ultimate strength of the electrode,Xu, and the effective throat area, Awand (b) the base metalresistance given as a function of its tensile strength, Fu,and

the fusion face area, Am. Unless over-matched electrodesare used, the base metal resistance does not govern thedesign of longitudinally loaded joints. However, when theweld orientation approaches the transversely loaded casethe base metal resistance governs due to the signicantlylarger weld metal resistance.

In S16-09, it is no longer necessary to check the base metalstrength at the fusion face when matching electrodes areused (Clause 13.13.2.2). Research studies conducted atthe University of Alberta have demonstrated that the basemetal resistance determined using the virgin strength of thebase metal does not represent the shear resistance. The

researchers pointed to the fact that the properties of thebase metal at the fusion face are inuenced by intermixingof the weld and base metals. Unless over-matched elec-trodes are used, base metal resistance at the fusion faceneed not be checked, regardless of weld orientation.

For a list of matching electrodes for CSA G40.21 steels,see Table 4 in S16-09.

QUESTION 2: When designing bolted connections, are seismic loads considered tobe static or cyclic?

ANSWER: The Seismic Corner article entitled BoltedConnections for Seismic Applications in the CISC publi-cation Advantage Steel No. 31 (Summer 2008) outlinedthe requirements for bolted connections for seismic applica-tions in accordance with S16-01. The article is available at:www.cisc.ca/publications/advantagesteel/31/Default.aspx.

In NBC 2010 and S16-09, the building heightrestriction for Conventional Construction where thespecied short-period spectral acceleration, IEFaSa(0.2),exceeds 0.35 has been increased. The above-mentionedrequirements for bolted connections also apply to these tallerstructures of Conventional Construction.

QUESTION 3: How do I determine the elastic bending resistance of a cantilever

plate subject to lateral-torsional buckling?

ANSWER: For a x-ended plate subject to bending about its strongaxis but laterally unbraced, the Guide to Stability DesignCriteria for Metal Structures, 6th Edition (R.D. Ziemian, JohnWiley & Sons, 2010) gives expressions for the elastic buck-ling moment (Mu), depending on the height of load applica-tion. For example, when subjected to a point load at its tip:

a) For top surface loading:

where E and G are the elastic and shear modulii respectively,Iyis the minor-axis moment of inertia, J the St. Venant torsionalconstant , d the plate depth, and Lcthe cantilever length.

d

a) Top surface loading

b) Shear centre loading

t

P

P

Lc

Questions on various aspects of design and construction of steel buildings and bridges are welcome. They may be submitted via email [email protected]. CISC receives and attends to a large volume of inquiries; only a selected few are published in this column.

CANTILEVER PLATE

b) For shear centre loading:

u yc

4M EI GJ

L=

u

GJM 1.5

d=

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

13/60

STEELD

AY.CA

INTERACT.

LEARN.

BUILD

.ONSEP

TEMBER

28,20

12STEEL

DAYisCOMIN

G!

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

14/60

14 F A L L 2 0 1 2 A D V A N T A G E S T E E L

Figure 1: Eccentrically Braced Frame - Tubular Link

Eccentrically braced frames (EBFs) are usedin seismic force-resisting systems to dissipateenergy through the yielding of links which

form part of the beams in braced bays. Their mainadvantage consists in combining the structuralstiffness of braced frames with the ductility ofmoment frames.

In an EBF, one or both ends of each brace is connectedto a beam so as to form an isolated segment calledthe link. Other members of the braced frame aredesigned for elastic behaviour while the link yieldsand strain-hardens during seismic motion. Links areclassied as short if they yield in shear, or aslong if they yield in exure.

Design requirements for EBFs rst appeared in anappendix to the 1989 edition of CSA Standard S16,taken mostly from the Structural Engineers Associationof California (SEAOC 1988). Currently, in S16-09Clause 27.7, they are referred to as ductile

eccentrically braced frames and are characterizedby a ductility-related force modication factor, Rd=4.0, and an overstrength-related force modicationfactor, Ro= 1.5.

This article highlights the principal changes for EBFsin S16-09 with regard to tubular links, columns,column splices and protected zones.

New provisions for eccentricallybraced frames in CSA S16-09

A

A Section A-A

Stiffeners

Tubular linksA new feature in S16-09 is the option of using a tubular linkconsisting of a built-up rectangular box beam (see Figure1). Unlike the more conventional wide-ange links, tubularlinks do not require lateral bracing at the link ends. Thisalternative can offer an attractive solution in areas wherelateral bracing is undesirable, for example along an exteriorcolumn line, or near elevators and stairwells.

Design and detailing criteria for tubular links include:

Plastic shear resistance, Vp(Clauses 27.7.2.3 and 27.7.3)

Complete joint penetration groove welds for connectingthe webs to the anges (27.7.2.4)

Plate slenderness ratios for the anges, b/t, and webs,h/w (27.7.2.5)

Ratio of moment of inertia for out-of-plane bending tothat for in-plane bending, eliminating the need for lateralbracing (27.7.2.5)

Web stiffeners (27.7.6.2.1). Weld attachment of angestiffeners is not required. Intermediate stiffeners maybe welded to the inside faces, enhancing architecturalappeal and improving corrosion resistance.

Increased forces in braces, end connections and columnsassociated with tubular links (27.7.10.2) are due to theirhigher strain-hardening response than wide-ange links.

By Charles Albert, P.Eng.

s E I S M I C C O R N E R

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

15/60

15F A L L 2 0 1 2 A D V A N T A G E S T E E L

d/2 d/2e

d

Link

ColumnsIn S16-01, columns in EBFs were designed for combinedaxial compression and bending with the interaction valuelimited to 0.65 for the top tier, and 0.85 for all othercolumns in the braced bay. In S16 09, instead of limitingthe interaction value, an additional bending moment of0.2 Z F

y is applied in the direction of the braced bay

together with the computed moments and axial loads. Inthe top two storeys, the additional moment is 0.4 Z Fy.

Column splicesAccording to a new design requirement in S16-09,splices in columns must provide the required axial, shearand bending moment resistances including the effectsof additional moments of 0.2 Z Fyin the direction of thebraced bays, acting either in the same or the oppositedirections at the column ends. These criteria ensurecolumn continuity as a means of preventing soft-storeydeformations due to yielding of the links.

Protected zonesThe concept of protected zones was introduced inS16-09, Clause 27.1.9. Protected zones are identiedas regions where large plastic strains will occur in the

force-resisting system during seismic motion. With someexceptions, attachments giving rise to metallurgicalnotches or stress concentrations (such as shear studs anddecking attachments) are not permitted in protected zones.

For EBFs, the link beam is designated as the protected

zone, which extends to one-half the beam depth beyondthe ends of the link (see Figure 2). The attachment ofwelded link stiffeners is permitted in the protected zone.

Figure 2: Protected Zone in an Eccentrically Braced Frame

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

16/60

2012

S-CALC

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

17/60

17F A L L 2 0 1 2 A D V A N T A G E S T E E L

F o r G r e e n s Sa k e

Life cycle assessmentmethodologies for buildingsBy Ivan Pinto, Dr. Mark Gorgolewski, Prof. Vera Straka

Effectiveness of the Athena Environmental Impact Estimatora leadingbuilding LCA tool in North America

Life cycle assessment (LCA) methodology establishedby the International Organization of Standardization(ISO 14040) evaluates all environmental impacts

cumulatively stage by stage over the entire lifespan of abuilding, product or process. It can provide a more accu-

rate picture of environmental trade-offs and help to avoidshifting environmental burdens between each life-cyclestage. In other words, it is a scientic framework thatevaluates the inherent environmental impacts of products,including resource extraction, manufacturing, use anddisposal over the full life cycle.

This allows the identication of environmental hot-spotsamongst life-cycle stages, which may lead to improvementof products. LCA is useful for improving the sustainabilityof products and processes by identifying greeneropportunities, and therefore is a tool useful for decisionmakers. Green building rating tools such as LEED and

GreenGlobes are beginning to integrate LCA methodolo-gies into their points systems as a way of demonstratingthe greenness of the building materials used, andEnvironmental Product Declarations (EPDs) using LCA toassess construction product characteristics are increas-ingly required in some parts of the world.

The Athena Environmental Impact Estimator (EIE) is theleading building LCA tool in North America, designed

to facilitate the assessment of environmental impacts ofindustrial, institutional, ofce and residential buildings. Thesoftware simulates over 1,000 different assembly combi-nations for building envelope and structural systems andit claims applicability to about 95 per cent of the building

stock in North America. It predicts cradle-to-grave environ-mental impact data for building designs using categoriesdened by the U.S. Environmental Protection Agency(EPA), which include: primary energy consumption, globalwarming potential, weighted resource use, acidicationpotential, human health respiratory effects, eutrophicationpotential, smog potential and ozone depletion.

A project at the Department of Architectural Science atRyerson University investigated the accuracy of alternativemodelling options available in the Athena EIE model tocalculate the impact of steel- and concrete-framed buildings.

There are two approaches to modelling of a building usingAthena EIE. First, the conventional Athena EIE input methoduses standard assembly dialogue boxes to select construc-tion assemblies from a predetermined menu (Model 2 EIEby assemblies). This user-friendly method has a series ofpredened assembly groups: foundations, walls (exteriorand interior), roofs, columns and beams, and oors. Theuser can select envelope characteristics for each assemblygroup in order to better represent the whole building

STEEL BUILDING - EMBODIEDWhole building models

1. ECO-CALCULATOR

2. Athena EIEusing defaultassemblies

3. Athena EIEusing material

quantities

PEC - Primary Energy Consumption (GJ) 20,444* 24,243 22,050

GWP - Global Warming Potential (tonnes CO2eq) 1,556 1,306 1,283

CONCRETE - EMBODIEDWhole building models

Primary Energy Consumption PEC (GJ) 26,064* 22,187 21,818

Global Warming Potential GWP (tonnes CO2eq) 2,438 1,720 1,697

Note: Eco-Calculator software does not provide Primary Energy Consumption result; instead it shows Fossil Fuel Consumption.

Table 1 Comparison of the embodied impacts for the steel and concrete buildings using different LCA tools

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

18/60

18 F A L L 2 0 1 2 A D V A N T A G E S T E E L

0%

20%

40%

60%

80%

100%

120%

140%

160%

180%

1. ECO-CALCULATOR

2. EIE BY ASSEMBLIES

3. EIE BY QUANTITIES

4. EIE + GABI

design. Once the user has developedthe model of a building or its parts,the software can provide a bill ofmaterials which is used to calculateenvironmental impacts.

To test the accuracy of the Athena-

calculated bill of material quantitiesused in typical steel-framed andconcrete-framed ofce buildings,a second analysis was carried out.This second method required themanual quantity take-off of materialsand inputting them by units of weightor volume (Model 3 EIE by quanti-ties). The software then calculates theenvironmental impacts. This methodallows more exibility and is consid-ered to be more accurate because

the material quantities can be moreaccurately tailored to a specicproject.

For further comparison, the buildingswere also analyzed using AthenaEco-Calculator (EC), which is a free,online, spreadsheet tool that allowssimplied LCA comparisons (Model1 - EC).

Building type assessedLCA analysis requires that a

consistent functional unit is usedfor comparison, and for this study

F o r G r e e n s Sa k e

Figure 1 - Steel building models embodied impact (structure only) results (relative to EIE by quantities)

ITW Welding North America888.489.9353

www.itwwelding.com

POWER

andPERFORMANCE

to satisfy

all of yourwelding needs.

this was dened as a six-storey,94,000-sq-ft (8,740m2) ofcebuilding located in Toronto.The Canadian Institute of SteelConstruction (CISC) provided detailsof a typical ofce building with asteel structure. The Department of

Architectural Science at RyersonUniversity designed an equivalentbuilding using concrete. In order toensure a consistent functional unit,both the steel- and concrete-framedbuildings have the same character-istics and the structural system is theonly design variation.

Modelling methodologycomparisonsTable 1 shows results of different

modelling options for the steel- andconcrete-framed buildings. Thiscomparison shows a signicantdifference in the results between thefour modelling methods. Particularlysurprising is that the Athena EIEmodels using dialogue boxes (Model2) and Athena EIE using materialquantities (Model 3) show signicantvariation, particularly for the steel-framed design. This is likely due tothe assumptions Athena EIE softwareadopts for steel systems. Figure 1

shows a comparative graphic anal-ysis of the various impact categories.

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

19/60

19F A L L 2 0 1 2 A D V A N T A G E S T E E L

F o r G r e e n s Sa k e

Steel Detailers since 1979

Heavy Industrial

Platework

Commercial Structures

Miscellaneous Metals

www.tdsindustrial.com

Join our growing Team

Now Hiring

People with Experince in

Steel Detailing

Checking

Project Coordinaon

Producon Management

Quality Control

Contact in confdenceTim Dawson

Proudly Canadian

Further investigation suggests thatAthena EIE assembly dialogs over-estimate materials for columns andbeams. A comparison of the bill ofmaterials generated by the AthenaEIE (Model 2 by assemblies) withhand-calculated material quanti-

ties and volumes (Model 3 byquantities) found that the Athena EIEpredetermined assemblies under-estimate the mass of steel deckingand rebar, but signicantly overes-timate the amount of steel requiredfor wide ange (WF) sections.Compared to the manual calcula-tions the predened assembliesincluded nearly double the amountof steel for WF sections. Since WFsections are approximately 57 per

cent of the total weight of steel inthe building, this difference meansthat the EIE software overestimatedthe steel weight by approximately28 per cent, which has a signicantimpact on the overall LCA results.Furthermore, the software seemsto automatically assume OWSJsupporting steel deck oor system atspacing of 48 (1200 mm) o/c, anddoes not allow for modication.

For the concrete building a similar

comparison for above-gradestructural materials suggested thatthe Athena EIE predened dialogmethod signicantly overestimatedthe volume of concrete and rebarweight for columns. However,columns are a small proportion ofthe total concrete used in a concretestructure and therefore when consid-ering the total material quantitiesin the building, the results indicatereasonable agreement (an average

variation of six per cent) for the twoalternatives of data input methods.Furthermore, the results using thesimplied, web-based EcoCalculatortool vary signicantly for the concreteframe design.

ConclusionsThe research highlights the difcultyof carrying out accurate LCA forcomplex building projects, andin particular of using simplied,standardized systems to predict thestructure of complex buildings. The

Athena EIE tool is respected as auseful design tool to help with under-standing the life-cycle environmentalburdens of design decisions. Thesoftware has a signicant applica-bility for the construction industryas a design tool and this articlepresented one of many. However,this project highlights that usingthe standardized dialogue boxesto input structural information leadsto some error, and so for accurate

assessment alternative methods arerecommended (especially importantfor structural systems with unevenbays).

It also suggests that without carefulconsideration it is dangerous tocompare results of LCA analysesusing different tools or methodolo-gies. These tools are perhaps morepowerful as aids to design improve-ment of a particular building, ratherthan as a way of comparing a

variety of buildings.

This study was carried out byIvan Pinto, MASc candidate,and supervised by Dr. MarkGorgolewski and Prof. Vera Strakaat the Department of ArchitecturalScience, Ryerson University, incollaboration with the CanadianInstitute of Steel Construction(CISC), and funded by the SteelStructures Education Foundation

(SSEF) and MITACS Accelerate.The authors are grateful for theassistance provided by Mr. DavidMacKinnon from CISC and Ms.Clare Broadbent from the WorldSteel Association (WSA).

To access the full report, pleasevisit www.arch.ryerson.ca/?page_id=366.

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

20/60

C o v e r S t o r y

By Neb Erakovic, M.Sc., P.Eng.Crispin Howes, P.Eng.Terry Dawson, M.Eng., P.Eng.

Canadian Museum

for Human Rights

20 F A L L 2 0 1 2 A D V A N T A G E S T E E L

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

21/60

21F A L L 2 0 1 2 A D V A N T A G E S T E E L

Experts turn to structural steel toovercome challenges in constructingCanadas newestand possibly mostambitiousnational museum

C o v e r S t o r y

Located in the geographical centre of the continent atThe Forks of the historic Red and Assiniboine rivers

in Winnipeg, Manitoba, the architectural design forthe Canadian Museum for Human Rights (CMHR) wasselected from an international competition that included62 submissions from 21 countries.

Antoine Predocks winning design draws inspirationfrom the natural scenery and open spaces of Canada.Initiated in 2003 by CanWest founder Israel (Izzy) Asperto be the largest human rights institution and educationcentre in the world, the CMHR is currently underconstruction and is made possible by a partnership thatincludes the Government of Canada.

Yolles, A CH2M HILL Company, (Yolles) was selectedto provide structural engineering consulting services forthe building. Yolles completed this challenging task bycollaborating with the architects to translate their vision.It is one that turns organic forms into rational structuralcomponent solutions, tied together to create a uniquebuilding structure that is both stable and constructible.

As illustrated in Figure 1, the CMHR is generallycomposed of four base Roots radiating out from acentral Great Hall and Garden of Reection beneatha suspended Mountain, Cloud and Tower of Hope.

The 50m-tall Hall of Hope atrium at the back of thebuilding cuts into the Mountain and Roots like a canyonand houses circulation ramps. The Roots contain thefunctional spaces of the museum and are constructedof sloping, segmented, reinforced concrete walls. TheMountain contains the bulk of the exhibition spacesand the Cloud encapsulates ofce spaces and a largeatrium. Projecting above the Cloud roof, the Tower ofHope houses an observation gallery to provide visitorswith a stunning view of The Forks, downtown Winnipegand the surrounding prairie.

Generally, the building superstructure is constructed ofstructural steel to frame the complex geometry, includingthe sloping walls of the Mountain exhibition galleries,the curved Cloud faade, the Tower of Hope spire, theGarden of Reection and the Hall of Hope ramps. Inthis article, we look at how structural steel is applied toovercome design and construction challenges for manystructural components of the building.

Figure 1: Exploded view of museum components

(Courtesy: Antoine Predock Architect)

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

22/60

22 F A L L 2 0 1 2 A D V A N T A G E S T E E L

Marmon/KeystoneSPECIALTY STEELS

Your Source for Hollow Structural Tubing

Across Canada

www.mkcanada.come-mail: [email protected]

QUEBEC, BouchervilleToll Free: 1-800-361-8142

ONTARIO, BurlingtonToll Free: 1-800-263-6262

MANITOBA, WinnipegToll Free: 1-800-665-0126

BRITISH COLUMBIA, LangleyToll Free: 1-800-663-9572

ATLANTIC CANADA (Sales Office)Toll Free: 1-800-565-1637

SASKATCHEWAN, SaskatoonToll Free: 1-800-665-0126

ALBERTA, LeducToll Free: 1-800-222-6504

C o v e r S t o r y

Project Team

OWNER: Canadian Museum for Human Rights

DESIGN ARCHITECT:Antoine Predock Architect PC (Albuquerque, NM)

EXECUTIVE ARCHITECT: Smith Carter (Winnipeg, MB)

CONSTRUCTION MANAGER:

PCL Constructors Canada Inc. (Winnipeg, MB)STRUCTURAL ENGINEER OF RECORD:Yolles, A CH2M HILL Company (Toronto, ON)

LOCAL STRUCTURAL ENGINEER:Crosier Kilgour & Partners Ltd. (Winnipeg, MB)

CISC STRUCTURAL STEEL FABRICATOR:Walters Inc. (Hamilton, ON)

GLAZING SUPPLIER:Josef Gartner GmbH (Germany)

MECHANICAL & PLUMBING ENGINEER:The Mitchell Partnership Inc. (Toronto, ON)

ELECTRICAL ENGINEER:Mulvey+Banani International Inc. (Toronto, ON)

MountainThe Mountain consists of a seemingly randomly stackedarray of ve stone-clad closed forms of irregular shapeshown in Figure 2 suspended 18 metres above ground-oor level. Initially conceived in reinforced concrete, designchallenges including highly stressed contact points betweenforms, long column-free spans, signicant form cantilevers,large circulation openings in form walls, sloping form

walls, eccentricity of stone cladding, and unconventionalvertical and horizontal load paths necessitated a change tostructural steel framing.

Structural steel W-sections combine with corner circularhollow sections to form primary diagrid wall trusses withineach two-storey form wall. Signicant oor openings added

complexity to the buckling restraint of diagrid wall trusscompression members, requiring heavy W360 column sectionsin some locations. Composite steel beams and slabs framethe Mountain oors by clear spanning between the diagridwall trusses. Steel bracing beams and cover plates are addedwhere diaphragm oor forces overstress concrete slabs.

Diagrid wall trusses span signicant unsupported distancesbetween concrete wall and steel column supports. The locationsand angles of the diagonal and vertical elements within thediagrid wall trusses are positioned around wall openings toprovide direct load paths down to supports. The diagonals also

transfer lateral loads down the building with oor diaphragmsdistributing those loads across to supporting walls.

Parametric sensitivity analyses were conducted to assessthe effects of changes in temperature, concrete slab andwall cracking, construction sequencing and staging, andconnection xities. Optimizing the diagrid wall truss memberlocations, designs and connections with consideration tothese parameters is complicated by the redistributive natureof the stacked diagrids. However, alternate load pathbenets are ultimately realized with the implementationof a lower bound philosophy to the member andconnection designs.

Steel connections are designed by Walters Inc. withutilization of their four-dimensional design and modellingcapabilities to rationalize the Mountain connection nodes.

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

23/60

23F A L L 2 0 1 2 A D V A N T A G E S T E E L

All Fabrication Machinery Ltd.Edmonton PH: 780-980-9661 Calgary PH: 403-710-5063 FX: 780-980-9668

Email: [email protected] [email protected]

V808 BEAM COPER 8 AXIS

At one of the super-nodes, colloquially dubbed the turkeytail, 10 members join where two sloping wall trusses meetover a supporting wall. The complexity of the super nodes isillustrated in the modelling and fabrication examples shownin Figure 3.

The lower Mountain form cantilevers 16 metres over part of

the Garden of Reection. A disproportionately small 20-metreback span requires the oor diaphragms at the top and bottomlevels of this form to act as a horizontal force couple to providesupplemental resistance to overturning of the cantilever. Themassive supported weight of stone cladding, heavily loadedexhibition and plant oors, upper Mountain, Cloud roof andthe Tower of Hope require this form to be super elevated at

C o v e r S t o r y

Figure 2: Diagrid wall trusses of stacked mountain forms

erection to ensure at oors in the nal condition. Extremeloads also require six 500mm x 100mm solid steel plates to bebuilt up to form a solid 500x600 steel diagrid member. Fourfreestanding, 18-metre-tall mega shore towers temporarilyshored the form during erection of the frame until the concreteslabs of the oor diaphragms were poured and cured. Thedesign and construction of this cantilever form proved to be

the most challenging aspect of the project, and the successfulrelease of the mega shores was a celebrated project milestone.

Cloud and Tower of HopeThe glazed Cloud encapsulates the large central atriumshown in Figure 4, allowing natural light to ood themuseum ofces and the Garden of Reection. A primary

Antoine Predockswinning designdraws inspirationfrom the naturalscenery and openspaces of Canada

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

24/60

24 F A L L 2 0 1 2 A D V A N T A G E S T E E L

C o v e r S t o r y

Figure 3a: Mountain super node

Figure 3b: Mountain super node fabrication (Photos courtesy Walters Inc.)

structural framing geometry incorporates thecurvature of the Cloud including the folding CloudDove Wings shown in Figure 5. Raking built-uphollow steel columns span over 30 metres fromthe Roots up to the Cloud roof and support aseries of 610mm-diameter hollow circular steelpipes curving around the Cloud perimeter at

varying radii. Balcony-like partial perimeter ofceoors encircle the atrium at three levels and actas diaphragms to provide lateral stability to theraking columns.

Steel framing also allows light into the Tower of Hopeand practically unobscured panoramic views out.The underlying geometry consists of two overlappingcones discretized into faceted shards of layeredglazed panels.

Other structural building features

Envisioned as Winnipegs Winter Garden, theGarden of Reection is located at the base ofthe Cloud atrium. After descending the elevatorfrom the Tower of Hope, still water reective poolsand Basalt stone seating offer an opportunity forcontemplation. A two-directional, long spanning,steel truss support system provides column-freespace for the dark void of the Great Hall belowand supports the Tower of Hope elevator hoist-wayand spiral stair above. In its central location,the Garden of Reection is adjacent to all fourRoots, three building cores and the Hall of Hope,and oats between these structural components

on sliding bearings to prevent the attraction ofsignicant compatibility forces.

Up to 25-metre long-span steel pony trusses arelocated within the glowing backlit alabaster stone-clad balustrades of the circulation ramps that linkthe museum exhibition spaces and y throughthe Hall of Hope atrium. Each ramp is unique inspan and supports; however, a repetitive structuralframing system rationalizes the fabrication andconstruction as shown in Figure 6.

The complex interfaces between the structuralsteel superstructure and supporting concretewalls required careful design and constructioncoordination. Hundreds of cast-in-plates, numerousbearings and corbels, and thousands of reinforcingsteel form savers, couplers and terminators areutilized to tie the structural components of thebuilding together. Concrete elements were surveyedfor location and orientation for incorporation intosteel fabrication where permitted by schedule tomitigate potential erection problems.

Four freestanding, 18-metre-tall megashore towers temporarily shored theform during erection of the frame untilthe concrete slabs of the floor diaphragmswere poured and cured

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

25/60

25F A L L 2 0 1 2 A D V A N T A G E S T E E L

M&GSTEELLTD.2285 Speers Road Oakville ON L6L 2X9

Tel: 905-469-6442 Fax: 905-469-9662

www.mgsteel.ca

Project Management Engineering Drafting Fabrication Erection

STRUCTURAL STEEL FABRICATOR

CELEBRATING OUR 25th YEAR

C o v e r S t o r y

Structures exposed to extreme temperatures requirethe designer to consider the method and schedule ofconstruction. Owing to the prairie climate, it was anticipatedthat the structure could experience temperature differentialsof at least 30 C prior to enclosing the building. Locking thevarious steel components of the structure into the supportingconcrete walls would result in unacceptably high thermal

restraint forces and potential damage. No expansionjoints are possible for the building because of the needfor continuous diaphragms to resist wind loads and holdsloping, cantilevered, unbalanced parts of the buildingtogether. For mitigation, temporary steel slip connectionsand slab separation strips are used to disconnect selectedstructural components during construction with temporarybracing introduced to maintain stability until the buildingwas enclosed.

Classical by hand methods of structural load pathvisualization and analysis for temporary and permanent

conditions are impractical for a building with this degreeof complexity. Finite Element Method (FEM) analysis ismore suitable; however, its use is contingent on being ableto accurately represent the three-dimensional geometry ofthe building.

Figure 4: Cloud Atrium between offices andMountain and over Garden of Reflection

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

26/60

26 F A L L 2 0 1 2 A D V A N T A G E S T E E L

C o v e r S t o r y

By now, the advantages and disadvantages ofBuilding Information Modelling (BIM) are welldocumented in the building construction industry.However, at the time of CMHR design initiationit was a relatively new technology that forced acultural change to the design consultant teams.For the complex three-dimensionally curved and

sloping geometric forms of this building, Yollesdeveloped a sophisticated workow to capitalizeon the best aspects of several software programsmore common to the industrial, automotiveand aircraft industries. Various components ofthe building, such as the Mountain, Cloud andTower of Hope, were broken out and individuallytranslated from design concept into structuralcomponents that were manipulated back intothe master BIM geometric model. Ultimately,the benets of BIM were realized in excellent3D visualization, sharing of information for

coordination, and clear contract documentation.BIM was clearly the best tool to manage thestructural complexity of this building.

In summary, structural steel is used to overcomenumerous design and construction challenges forthe architecturally complex CMHR superstructure.

Figure 5: Cloud Dove Wings and Tower of Hope

Construction start 2009,

completion 2013 $350 million approximate

construction cost

50-metre height to top ofCloud Roof

100-metre height to top ofTower of Hope

12 storeys with average5.2-metre oor-to-oor height

24,154 square metres total

oor space 4,350 square metres of

exhibition space

4800+ metric tonnes ofstructural steel

770 metres total length of ramps

LEED Certied Silver(expected upon completion)

Building statistics

Hot-Dip Galvanized SteelProviding Maintenance-Free Corrosion Protection of our Infrastructure

No Maintenance costs

Aesthetically pleasing, consistent appearance.

100% recyclability at the end-of-life

Safe structural steel, handrail, and deck

Sustainable project lasting 100 years or more

Immediate availability for construction in anyweather condition

(780) 468-6868www.daamgalvanizing.com

(306) 242-2202www.galv.ca

Daam Galvanizing Ltd

Provincial Galvanizing Ltd

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

27/60

27F A L L 2 0 1 2 A D V A N T A G E S T E E L

Contact information

Jason Collins - President3740 - 73 Ave

Edmonton, AB T6B 2Z2

TEL 780-440-1414FAX 780-466-6583

INDUSTRIAL COMMERCIAL INSTITUTIONAL HIGH-RISE RESIDENTIAL

FABRICATIONSTRUCTURAL MISCELLANEOUS STEELAND

Since 1984, Collins Industries has been providing Western Canada with

structural steel fabrication and installation services. We believe ourlongevity can be attributed to a foundation of ethical and responsible

business practices and a continual investment back into people and

operations. Collins Industries Ltd. serves the commercial, institutional,

industrial and high-rise residential market sectors. Our objective is to be

the preferred supplier of our customers in each market.

Collins Industries is a leader in the steel fabrication industry in the delivery

of Building Information Modeling (BIM). The organization views eachproject as an opportunity to partner with customers and looks to add

value and efficiencies where possible. Collins Industries Ltd. has its ISO

9001-2008 designation, is Canadian Welding Bureau W47.1 certified and is

a member of Canadian Institute of Steel Construction (CISC) .

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

28/60

28 F A L L 2 0 1 2 A D V A N T A G E S T E E L

Figure 7: CMHR

construction progress

(Courtesy: AntoinePredock Architect)

These challenges include the stacked forms of theMountain, the rationalized geometry of the Cloud andTower of Hope, the Garden of Reection and the long-span Hall of Hope ramps. BIM was successfully used tomodel and document the building structure, with varioussoftware used to analyze and design advanced, rational,geometric solutions for each structural component.

Museum visitors sitting and gazing into the still waters ofthe Garden of Reection to contemplate the issue of humanrights will see the reection of a stunning building abovethem, which in turn reects the innovative design andconstruction employed to realize the architectural visionof Antoine Predock. Steel was the only feasible material ofchoice to satisfy the challenges posed by this architecturalvision, and the resulting magnicent building will be a truetestament to the importance that Canada, as a nation,places on human rights.

C o v e r S t o r y

Figure 6: Hall of Hope ramps prior to installation of stone cladding

Neb Erakovic, M.Sc., P.Eng., is a Principal in YollesToronto ofce. He specializes in structures witharchitectural complexity and can be reached at

Crispin Howes, P.Eng., is a Senior Associate inYolles Toronto ofce. He specializes in advanced

geometric structural engineering and heads YollesStudio for Progressive Modelling. He can bereached at [email protected].

Terry Dawson, M.Eng., P.Eng., is an Associatein Yolles Toronto ofce. He has over 10 years

experience in structural engineering in Canada, theU.K., U.S. and New Zealand and can be reached at

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

29/60

29F A L L 2 0 1 2 A D V A N T A G E S T E E L

ISO 9001 : 2008 Registered

www.aclsteel.ca

519.568.8822

2255 Shirley DriveKitchener, ON, N2B 3X4

QUASARCAN3-

Z299.3

.85

QUALI TY CERTI FI ED

STEEL STRUCTURES

72 Commercial Road, Bolton, Ontario, Canada L7E 1K4 Tel: 905-857-0684 Fax: 905-857-4005 www.bensonsteel.com

Benson Steel.... because performance matters

QUALITY

CONSUMABLESAT LOWER PRICES.

GIVE US A TRY.

BEST IN CLASSF a b r i c a t i n g S o l u t i o n s

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

30/60

30 F A L L 2 0 1 2 A D V A N T A G E S T E E L

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

31/60

31F A L L 2 0 1 2 A D V A N T A G E S T E E L

At least it was to the construction team on the Missouri River Bridge

project when their initial concrete design priced over budget at almost

$45 million. They then had to scramble for other options.

Turned out the solution was steel. After coming up with a new design,

they turned to Nucor. And we were able to help them build a

beautiful, easy to maintain and environmentally fr iendly bridge at less

than half the cost of concrete. Who wouldve thought.

www.nucoryamato.com

Its Our Nature.

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

32/60

32 F A L L 2 0 1 2 A D V A N T A G E S T E E L

C o N S T R U C T I O N

A rst for CanadaSupreme Group awarded Canadas rst Girder-Slab

method of construction for its work on EdmontonsCourtyard Marriott Hotel

By Peter Timler,M.Sc., P.Eng.

For Supreme Group, an opportunity to be involved in athird consecutive project for the ongoing expansions atthe Edmonton International Airport was reason enough

to propose innovative ideas with the owner and design teamassembled for the planned 178,000 sq. ft. Courtyard MarriottHotel. Those early meetings were focused on understandingthe needs of the project and sharing knowledge of a newermethod of steel-framed construction to satisfy the imposedrequirements of minimizing cost and construction durationwithin a cold-climate environment.

Figure 1: East wing of hotel under construction by ironworkers

Figure 2: Construction progress in early June 2012

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

33/60

33F A L L 2 0 1 2 A D V A N T A G E S T E E L

Figure 3: SupremeGroup preliminary

structural RAM

model of hotel

Its no secret that relatively limited construction projects utilizesteel framing for the structure of residential developments inCanada, and in a grander sense, North America. However, thattrend is denitely changing, and for good reason. To meet anaggressive opening season soon after the planned completionof expansion works at the airport, Supreme Group introducedthe concept of a successful composite-steel-framed and hollow-

core plank ooring system known as the Girder-Slabmethodof construction.

Originally conceived, tested and further developedin the United States over a decade ago for broadapplication to the residential market (hotels, dormitories,apartments, condominiums and senior care facilities),it has been applied to approximately 90 constructionprojects spanning several countries and encompassessome 6,200,000 sq. ft. of nished oor area. Hence,ample evidence of numerous benets over conventionalmethods of multi-storey residential construction has been

well demonstrated.

The core of the innovative structural system that couldbe competitive to cast-in-place concrete construction isrecognized as the D-Beam, a simply modied structuralwide-ange shape that supports long-span 8 hollow-corepanels on its bottom ange. The shape is produced by cuttinga saw-toothed pattern on the web area of a select range ofwide ange shapes to produce two equal, yet opposite hand,T-Sections and generates no waste. By centring and weldinga narrow at bar of greater thickness than the bottom ange,

Courtyard Marriott Hotel

PROJECT OWNER: Diamond AirportHotels Ltd. (Platinum Investments)

CONSTRUCTION MANAGER: GoldsmithConsulting Design Associates

HOSPITALITY DESIGN CONSULTANT:Goldsmith Consulting DesignAssociates

ARCHITECT:E.F. GoochSTRUCTURAL ENGINEER:Williams Engineering Canada

STEEL FABRICATOR/ERECTOR:Supreme Steel LP

STEEL DETAILER:CadMax

HOLLOW-CORE SUPPLIER/ERECTOR:Armtec

C o N S T R U C T I O N

a dissymmetric section is produced with a regular pattern ofpenetrations through the web.

This family of specialized oor framing elements, togetherwith the assembly of supported hollow-core panels groutedmonolithically with the special purpose beams, are the patentedmethods for oor construction by Girder-Slab Technologies

LLC of New Jersey. By pulling nearly all the structural depth ofthe steel framing system into the thickness of the oor plate, aminimal oor-to-oor height condition is achieved, essentiallymatching the cast-in-place method that had previously been anear monopoly in such a construction market.

By introducing a low oor-to-oor height solution to theowner and design team for the six-level tower section abovethe main two-storey podium, with promise for a shortererection period (coupled with strong potential that heatingand hoarding costs could be either eliminated or reduceddramatically due to the near dry construction method),

well-founded arguments had been made to change from theoriginal plans for a full concrete structure. In fact, the ownershared that an additional level of hospitality space could beincorporated due to budget allowance and minimal structuralheight requirement. Further to that, for additional benetof single-site trade dependence and reduced temporaryworks, Supreme Group developed a preliminary structuraldesign for consideration that proposed elevator and stairshaft cores as braced-frame lateral load resisting elementsfor the structure, including steel stair inclusion for immediateconstruction access in the primary steel contract.

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

34/60

34 F A L L 2 0 1 2 A D V A N T A G E S T E E L

Figure 4: Hollow-core panel installation

Design refinementWith enough information gleaned from Supreme Groupsearly involvement work reecting better value propositions,the next step was to work through design renement withthe established team. To meet a fall 2011 steel framingconstruction start, Supreme Group proposed an IntegratedProject Delivery method and set out the program that wouldmeld the efforts of its engineering and project managementexpertise with the architectural, hospitality specialists andstructural consultants already engaged.

Apart from model le sharing and conditions of continuous

open dialogue, an atmosphere of trust and collaborationfor the benet of the project was quickly realized. Withina few short weeks, conrmation of the proposed all-steeldesign, and late architectural changes made to satisfy newrequirements for the Marriott Hotel chain, were managedand steel was ordered. This process alone shortened theconventional design period for development of constructiondrawings by several months.

The Girder-Slabsystem has recognition through UL and ULClistings in the U.S. and Canada, respectively, and Girder-Slab Technologies LLC has referenced this information in

their design guide, which is available on their website. Forthe pre-cast industry in Canada, the long-established processto satisfy jurisdictional building ofcials for two-hour rerating of hollow-core oor systems has been by submission ofcalculations under a Professional Engineers Seal followingthe Precast/Prestressed Concrete Institutes method ofderivation that is acceptable by the National Building Codeof Canada.

Hence, for those that recognize ULCs reference to a selectnumber of U.S. precast suppliers in their listing due to

limited historical test data, the alternate submission route isa viable method. The exposed steel ange of the D-Beamis re protected by conventional means, i.e., sprayed-oncementitious reproong or through standard gypsum wallboard application.

For the Edmonton International Airport Courtyard Marriott Hotel,a decision was set on application of a nominal levelingcompound as the topping for the hollow-core planking. TheGirder-Slabsystem has the capability of accepting 2 toppingas well. Alternatively, in many lower cost applications in the U.S.,dormitories in particular, oor nishes are applied to carpet

ready hollow-core planking without any topping. The StructuralEngineer of Record is typically involved in this decision-makingprocess, as some consideration may be required respectingperformance of diaphragm horizontal load transfer in seismicregions. For this projects application, however, seismic designis not a governing factor in the Edmonton region.

The Girder-Slab method of construction is predicated ondelivery of a completed structural system by a qualiedsteel fabricator that has previously achieved recognitionwithin Girder-Slab Technologies LLCs licensed distributornetwork. Although various elements and the system

have been patented in many countries, the application isnon-proprietary and hence invites open-market suppliers inthe steel and pre-cast industries to vie for projects designedfor tendering. Therefore, it is to be understood that for theright to build with this method, the steel fabricator is engagedin the full structural frame and hollow-core supply and erect,reinforcing steel supply and install (composite D-Beamjoints) and grouting supply and placement.

Topping and re protection application could also beconsidered as part of the scope, however they are optional

C o N S T R U C T I O N

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

35/60

35F A L L 2 0 1 2 A D V A N T A G E S T E E L

in delivery of a completed structural system. By encompassing the full structuralsystem scope, effective control is maintained in planning the erection of thestructure from an efciency perspective. At the conclusion of the project, the steelfabricator is obligated to issue a compliance certicate to the owner identifyingthat the structure was built in accordance with Girder-Slab Technologies LLCsspecic requirements.

Supreme Group and the design team were also faced with the challenge ofincorporating an exterior precast wall panel system that had been non-typicalfor earlier Girder-Slab structures in the U.S. A dressed-up D-Beam forspandrel applications became the most cost-effective means to support theheavy cladding system.

Solid executionWith top-out of the structural system scheduled for early summer of 2012,Supreme Group and its supply team are very pleased with the projectsexecution given this rst application experience. In fact, all others associatedwith the decision process on the structural schemeowner, architect,hospitality design consultant, structural engineer of record and construction

managerhave expressed very complimentary statements regarding thecleanliness, efciency and prociency on the installation of the system.

This doesnt happen through an osmosis process. Very careful planninga forte for Supreme Groupto cover many aspects of the design forsafe and reliable erection was continuous behind the scenes. Examplesof the areas where consideration was required included camber controlon D-Beams, camber differential control with hollow-core, stabilization ofstructure during erection with weld plates, pre-cast plank end preparations,weep requirements, sequence planning for steel and hollow-core placementwith single trade (ironworker) crews, grouting operations, temporaryframing works, exterior panel connections, mechanical penetrations layoutplanning, grout damming details and transport logistics, to name a few. It is

estimated that this construction method shaved approximately six months offthe build-out schedule for a project of similar size had conventional meansbeen deployed.

In summary, what was promised is being delivered: a sound structural systemmeeting the requirements of a high-end hospitality industry provider aheadof schedule and below cost compared to previous conventional means. Weuse the word previous as a literary gauntlet to the perception that thecast-in-place method of construction will continue as the preferred structuralsystem for such projects. Since securing the Edmonton International AirportCourtyard Marriott Hotel, many developers have expressed interest andattended site visits to view rsthand the general simplicity of the construction

method. They are either developing their own projects with the Girder-Slab

system or are serious about its consideration.

Having examined many projects for potential incorporation of the Girder-Slabmethod of construction, Supreme Group has developed a considerableknowledge base on efcient application objectives and welcomesinquiries to assist in best value determination of projects. Please [email protected] for further information.

Peter Timler, M.Sc., P.Eng., is Corporate Business Development Ofcerand Vice President Engineering at Supreme Group LP.

C o N S T R U C T I O N

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

36/60

36 F A L L 2 0 1 2 A D V A N T A G E S T E E L

F R A M I N G S Y S T E M

Design revitalizedStaggered Truss framing system used inthe Toronto Christian Resource Centresnew headquarters

By Fernando Cruz, M.Eng., P.Eng.& Michael Jelicic, P.Eng.

The Toronto Christian Resource Centres (CRC) newbuilding at 40 Oak Street in downtown Toronto is amultipurpose facility designed to help the agency fullits objective to provide people with lifes basic necessities,including affordable housing. It is located in the heart of

Regent Park, Canadas largest and oldest social housingcommunity. Funded by the CRC, Toronto Community Housingand government partners at the city, provincial, and nationallevels, the building is part of the City of Torontos plan toredevelop and revitalize the Regent Park area.

Providing an efcient, cost-effective structural system thatwould accommodate the CRCs functional requirementswas essential to successful project delivery. The solution thatHalsall Associates proposed to CRC and Hilditch Architectof Toronto was outside the box: a Staggered Truss system.

40 Oak Street under construction

The team recognized, however, that the system wouldpresent a number of construction challenges. Topping thelist was the fact that this framing system was last used inCanada around 20 years ago and was not generallyfamiliar to contractors.

The concept of Staggered Trusses was developed in the1960s at the Massachusetts Institute of Technology (MIT).The system has proved to be a practical and efcientframing system for mid-rise apartments, motels, dormitoriesand similar buildings. Low oor-to-oor height helps reducethe cost of the building envelope and is achieved in part bythe use of precast slabs that provide a large depth-to-spanratio. Construction times are reduced due to the simplicity oftruss fabrication and construction. The result is an effective,low-cost structural system.

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

37/60

37F A L L 2 0 1 2 A D V A N T A G E S T E E L

Figure 1: Typical Staggered Truss system vertical stacking arrangement

F R A M I N G S Y S T E M

40 Oak StreetCertain features of the building at 40Oak Street made it suitable for theuse of the Staggered Truss system: itsrectangular shape, its oor plan andits height.

The building has ve storeys anda basement, with a total area ofapproximately 70,000 square feet.The main oor houses the headquartersof the CRC, a community kitchenand 10,000 square feet of exible,

multipurpose space. This exibility isachieved by a column-free main level;the layout can be easily modied tomeet future program needs.

The upper levels accommodate 87units of affordable housing dividedinto bachelor, one-bedroom andtwo-bedroom units. Amenity space islocated on the second level. A circulartwo-storey room provides worshipspace for the community. Mechanical

rooms and bicycle storage are locatedin the basement.

The building was designed to meetTorontos Green Development Standardat a level equivalent to LEED Silver.

In a typical Staggered Truss system,trusses spanning the width of thebuilding are located every othergridline, and their location is shifted

one bay the next level up. In this way,each truss supports two levels at a time,one on each chord; the depth of thetruss is equal to the oor-to-oor height(Figure1).

With such an arrangement, columnsare only required along the long sidesof the rectangular oor plan, creatingan opportunity for a column-free groundoor if trusses are not used between theground and second oor, as in the caseof 40 Oak Street.

The ideal building layout to take fulladvantage of Staggered Trusses hasgridlines equally spaced; however, inreality such buildings are rare. At the

east and west ends of 40 Oak Street,grid spacing differs from the equallyspaced middle portion of the buildingto accommodate stairs, the elevatorcore and the double-height worshipspace. For this reason, the StaggeredTruss arrangement at both ends of

the building departs from the idealconguration (Figure 2).

The structureBasement and ground oor slab at40 Oak Street is conventional cast-in-place concrete. Precast slabs form theoor from the second oor to roof level.Precast slabs are the best option for aStaggered Truss system to maintain thespeed and simplicity of constructionand keep the building height to a

minimum. At 40 Oak Street, the typicalbay is 9.6m, and 200mm-thick precastslabs with 50mm topping are used. Thedistance between trusses in a typicaloor is 19.2m (9.6m x 2), providinglarge structure-free spaces.

The trusses at 40 Oak Street have aspan of 16.8m and a height of 2.7m.Both chords are W250 sections;verticals and diagonals are W200,and columns are W310 sections.These sizes were coordinated with the

architectural design so the trusses couldbe hidden in walls.

When Staggered Trusses are used fromthe ground oor up, they can serve as

Staggered Truss System at 40 Oak Street under construction

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

38/60

38 F A L L 2 0 1 2 A D V A N T A G E S T E E L

F R A M I N G S Y S T E M

The All-In-One Structural

Fabrication Machine

www.PythonX.com

One and Done.

Figure 2: 40 Oak Street typical floor plan

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

39/60

39F A L L 2 0 1 2 A D V A N T A G E S T E E L

the structures lateral system. However, to maintain a column-free ground level at 40 Oak Street, cast-in-place concrete coresprovide the structure resistance framing system (elevator andeast stair). Although the trusses do not extend to the groundlevel, they add lateral stiffness to the upper levels. During thestructural analysis, close attention was paid to ensure properbehaviour of the lateral system and to identify the additional

forces induced to the trusses from wind and earthquake.

To achieve a column-free ground oor, we used hangers fromtrusses located between Levels 3 and 4 to support the secondoor. Similarly, to maintain the staggered truss layout andoptimize steel tonnage, we supported the roof structure onalternate gridlines with posts seated on top of trusses providedbetween levels 4 and 5. These special combination trusseswere therefore designed to support three levels (Figure 3).

Another important feature of the Staggered Truss system isthe use of Vierendeel panels to create openings in the trusses

to facilitate circulation inside the building. At 40 Oak Street,these panels are used almost at the mid-span of the trusses tocreate a corridor along the long dimension of the building.Similar panels are used at the east and west end frames toaccommodate windows. This required close coordination withthe architectural design to provide the building with naturallight and ventilation to meet sustainability requirements whilemaintaining structural integrity.

At 40 Oak Street, the soil conditions and the load carriedby the columns required the use of bored concrete piles.Since Staggered Trusses require only two columns for everyframe, the number of bored piles was minimized, reducing

construction costs.

ConstructionWith input from Buttcon Limited, the general contractor, andSteelcon Fabrication Inc., it was decided that the fastestway to build 40 Oak Street was by casting the elevator andstair cores from foundation to roof using sliding forms, thenerecting the structural steel. The columns were erected in twosections, three and two storeys. Then trusses were connected

to the columns and nally the precast slabs were droppedin place. This process was simple, efcient and fast.

In the original design, the intention was to support the precastslabs on the bottom ange of the W250 truss chordsinthis way the chords would be hidden within the slab leavinga at soft and minimizing the size of drop ceilings formechanical pipes and ducts in corridors. The precast slabsupplier suggested, however, that supporting the slabs onthe top ange would simplify the erection process and wouldbe more cost-effective. The design details were modied toaccommodate this change.

In conclusion, the use of the Staggered Truss system at 40Oak Street helped reduce project costs and accelerateconstruction. The system was also appropriate for thebuildings functional requirements: CRC was pleased with theexibility the structure-free spaces provided, and modicationscan be made in the future as program requirements change.

There was some initial uncertainty about the integrity of thesystem during the construction stage. In the end, however, thesystem proved to be a good example of thinking outside thebox to provide an efcient and cost-effective structural solution.

Fernando Cruz, M.Eng., P.Eng., is a Project Managerwith Halsall Associates in Toronto. He has 13 years of

experience in structural engineering, and has participatedin many large projects involving use of structural steel in

Canada and overseas.

Michael Jelicic, P.Eng.,is a Project Principal with

Halsall Associates in Toronto.

Figure 3: Structural framing of mid-portion of 40 Oak Street

F R A M I N G S Y S T E M

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

40/60

40 F A L L 2 0 1 2 A D V A N T A G E S T E E L

2012 CISC NationalSteel Design AwardsThree commendable constructionprojects gain special recognition The Canadian Institute of Steel Construction (CISC)announced the winners of its biennial National SteelDesign Awards competition during a gala dinner at its

Annual General Meeting & Convention in Ottawa last June.

The prestigious National Design Awards are open to architects,engineers, developers, owners and other stakeholders involvedwith a building, bridge, industrial or other steel work projectin which engineering demands, architectural considerations orsustainability requirements inuenced the designers choice ofsteel as the most appropriate structural solution.

The awards are a culmination of a two-year competition thatbrings together regional winners from across the countryin three award categories: Architecture, Engineering andSustainability.

The award winners for 2012 are outlined below.

ENGINEERING

The Bow, Calgary, Alberta

Iconic Calgary ofce tower is unique in North America

OWNER: H&R REIT

ARCHITECT:Foster + Partners in collaboration with ZeidlerPartnership Architects

STRUCTURAL ENGINEERS:Halcrow Yolles

GENERAL CONTRACTOR: Ledcor Construction Ltd.(Construction Manager)

CISC FABRICATOR, DETAILER & ERECTOR:

Supreme Steel in joint venture with Walters GroupThe Bow, the iconic crescent-shaped ofce tower rising onthe east side of Calgarys downtown core, has provided aspectacular show for Calgarians during its construction.Spectators might not have realized they are also witnessing aNorth American rst.

The Bow is unique on the continent in its application of atriangular steel diagrid system to a curved building. Thediagrid, composed of six-storey-high diagonal elements,

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

41/60

41F A L L 2 0 1 2 A D V A N T A G E S T E E L

creates a perimeter frame of linked equilateral triangles curvedto match the bow of the building on the north and south faces.

The external structural system frees up more oor spacethan a traditional building, and the diagrid design alsosignicantly reduces the amount of steel required comparedto a conventional structure. The crescent-shaped oor planincreases the number of perimeter ofces that are possible

and improves access to natural light.

The curve had its own rationale, says Stephen Carruthers,Managing Partner, Western Canada, Zeidler PartnershipArchitects. It also decreases the wind resistance that wouldbe associated with a rectangular building of the same size.Its an aerodynamic shape that allows the wind to slip aroundthe curve, much like the wing of an airplane.

The curve is also intended to be a sun catcher. It orients thebuilding to the southwest to capture maximum sun and givesoccupants a more direct view of the mountains.

The combination of the crescent shape and diagrid systemnecessitated a faceted curtain wall solution, Carruthers says.What would be a straightforward rectilinear geometry ina conventional ofce tower suddenly becomes very subtlegeometry. Because of the curvature, each steel member of the

diagrid had to connect into a node at very precise angles andwith very exacting tolerances.

It was a very tense moment when the rst node was set intoplace. We were all very anxious that it should t perfectly.The rst one dropped into place beautifully. Everyone heaveda sigh of relief. From that point on we said: This is going togo well.

Another unique aspect of The Bow is the series of three multi-storey sky gardens located at each of the elevator transitionoors. The sky gardens provide all the common-use facilitiessuch as copy shops, coffee and snack kiosks, and generousseating areas.

The sky gardens will become like village squares whereemployees can sit under trees, have coffee with their colleaguesand exchange ideas, Carruthers says. They will be quite grand.The oor structure allowed us to put tree pits into the oors sowe can plant full-size trees. These forests were enabled by the

steel structure and will be visible as you look up at the building,particularly at night when the trees are illuminated.

All of these features combined will ensure that The Bowwill become Calgarys premier landmark. It is going to bespectacular.

N a t i o n a l S t e e l D E S I G N A W A R D S

Island Industries Ltd.

8669 Coronet Road, Edmonton, AB T6E 4P2

Phone: (780) 465-3384 Cell: (780) 886-9632

Fax: (780) 465-3394 Email: [email protected]

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

42/60

42 F A L L 2 0 1 2 A D V A N T A G E S T E E L

ARCHITECTURE

The Art Gallery of AlbertaBuilding is a work of art in steel

ARCHITECTS:Randall Stout Architects, Inc. andHIP Architects, Associate Architect

STRUCTURAL ENGINEERS: DeSimone Consulting Engineersand BPTEC-DNW Engineering Ltd.

CISC FABRICATOR /DETAILER /ERECTOR AND ENGINEER: Empire Iron Works Ltd.

GENERAL CONTRACTOR:Ledcor Construction Limited

Sinuous stainless steel surfaces and complex curvinggeometry inspired by the aurora borealis render the ArtGallery of Alberta a work of art in itself.

The project, on the edge of Edmontons downtown ChurchillSquare, is a renovation of the existing concrete buildingintended to create expanded, exible, museum-quality space

for the gallerys permanent collection and major travellingexhibitions. The renovation consisted of a two-storey verticaladdition above the existing building to contain gallery spaceand ofces, and the addition of an atrium that exhibits thecreative and dramatic use of steel to invoke the borealis.

Structural steel was the obvious choice for the verticaladdition because it minimized the impact on the existing

N a t i o n a l S t e e l D E S I G N A W A R D S

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

43/60

43F A L L 2 0 1 2 A D V A N T A G E S T E E L

structure, reduced loads on thefoundation, and provided unimpededcolumn-free interior space tomaximize exibility for exhibitions.The entire addition is supported byonly six columns located on the northand south perimeters.

The building envelope of the atriumis formed from angular, transparentglazing planes penetrated by curving,reective metal-clad elements thatcreate the borealis. You couldnt dothat with anything other than structuralsteel because of the complexity ofthe shapes, says Trevor Hobbs,Detailing and Technical Lead, EmpireIron Works.

Construction of the atrium presentednumerous challenges due to thecomplex geometry, Hobbs says.While the structure itself looks quitelight and airy, we were dealing withheavy loads and members that had toline up with each other precisely. Bothexposed and concealed connectionsrequired special attention due to the3D aspect, the aesthetics and the closeproximity of other building elements.This was most difcult where the skint tightly to the structure and restricted

the space we could work with.

Adding to the challenges, the borealisedging panels were pre-fabricated inSt. Louis and then attached to bracketson the steel framing on site. We hadto make sure the structural steel wascorrect and that the brackets were inthe correct locations. Its a shame itscovered up, because its by far thebest part, Hobbs says.

Ensuring museum-quality, climate-controlled interior space demanded ahigh-performance building envelope.This requirement created a challengewhere architectural features weredesigned to penetrate the envelope.

Some elements of structural steelwere cantilevered through the skin,Hobbs says. Because steel is agood thermal conductor, this could

compromise the museum qualityspace. The team resolved this issue byincorporating a thermal break in thesteel at the point where it penetratesthe building envelope and adding anon-conducting material in the jointto isolate the interior steel from the

exterior steel.

A large measure of the success of theproject is due to teamwork and the use

of a variety of emerging techniquesin 3D modelling to coordinate andcommunicate the design detailsnecessary for efcient site construction,Hobbs says.

Everybody used different programs

and there were many les transferredback and forth. It was a really goodproject in terms of the level of teamworkthat we achieved.

Proudly Serving Western Canada

Commercial and Industrial projects for

Structural Steel and Miscellaneous Iron

N a t i o n a l S t e e l D E S I G N A W A R D S

-

7/21/2019 CISC Advantage Steel Magazine No44 2012

44/60

44 F A L L 2 0 1 2 A D V A N T A G E S T E E L

SUSTAINABILITY