Circular Column Formwork Circo TechnicalInstructionManual · 2021. 3. 3. · Circular Column...

Transcript of Circular Column Formwork Circo TechnicalInstructionManual · 2021. 3. 3. · Circular Column...

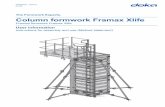

Circular Column Formwork Circo

Technical Instruction Manual

circ

o-a

vag

b.p

df

St. 24/0

7/0

9 P

rin

ted

in

Germ

an

y

CIRCO-2

Updated 24 July 2009

The circular column formwork is totally made of steel and used to

form fairfaced concrete columns.

The standard panel sizes are available in increments of 5 cm for

diameters of 25 cm to 80 cm. The standard height of 300 cm and

two extension heights of 50 cm and 100 cm allow users to pour

columns of different heights in increments of 50 cm. The maximum

admissible fresh concrete pressure is 120 kN/m².

The circular column formwork consists of 2 identical semicircular

column panels that are KTL/ACCcoated.

Only persons with suffi cient skills and knowledge are permitted

to assemble and disassemble the circular column formwork. This

manual describes the standard assembly and disassembly. Devia

tions from the described standard assembly are permitted provided

that users are able to judge and perform them.

The product components must be checked visually for damage

before assemling and using them.

The circular column formwork must be assembled in the order

described in this manual.

Product features and important safety notes

Abbreviations, measurements, decimal numbers, fi gures and

tables

DIN means Deutsche IndustrieNorm (German Industrial Standard).

E DIN (E = Entwurf / draft) means that the DIN is in draft status and

not yet approved of. TÜV means Technischer Überwachungsverein.

This is the independent German organisation that tests the safety

of technical installations, machinery and motor vehicles. If a prod

uct passes the test, it is permitted to carry the GS seal. GS stands for

Geprüfte Sicherheit (approved safety). Any further abbreviations

are explained where they are used the fi rst time.

Measurements: This manual uses the metric system and thus m

(for metre), cm (for centimetre) and mm (for millimetre). Dimen

sions without a measure are in cm. Decimal numbers: Note that the

comma is used in a decimal numbers, e.g. 1,5 means 1 and a half.

The page numbers in this manual start with CIRCO. The fi gures and

tables are numbered per page. Depending on its product abbrevia

tion, a cross reference in the text refers to a page, table or fi gure in

this or in another manual.

Circular Column Formwork Circo

circ

o-a

vag

b.p

df

St. 24/0

7/0

9 P

rin

ted

in

Germ

an

y

CIRCO-3

Please note

These Technical Instruction Manual contains information, instruc

tions and hints describing how to use the MEVA equipment on

the construction site in a proper, quick and economic way. Most

examples shown are standard applications that will occur in prac

tice most often. For more complicated or special applications not

covered in these instructions, please contact the MEVA experts for

advice.

When using our products the federal, state and local codes and

regulations must be observed. Many of the details shown do not

illustrate the formwork system in the readytopour condition as

to the aforementioned safety regulations. Please adhere to this

manual when applying the equipment described here. Deviations

require engineering calculations and analysis to guarantee safety.

Please observe the assembly instructions that your local contractor

or employer has created for the site on which the MEVA equipment

is used. Such instructions are intended to minimise sitespecifi c risks

and must contain the following details:

¢ The order in which all working steps including assembly and

disassembly must be carried out

¢ The weight of the panels and other system parts

¢ The type and number of ties and braces as well as the distance

between them

¢ The location, number and dimensions of working scaffolds

including working area and protection against falling down

¢ Pick points for panel transport by crane. With regard to panel

tranport, please observe this manual. Any deviation will require a

static proof.

Important: Generally, only well maintained material may be used.

Damaged parts must be replaced. Apply only original MEVA spare

parts for replacement.

Attention: Never wax or oil assembly locks.

Contents

Pro duct overview .................................................................................4

Storage and transport ..........................................................................5

Assembly – Basic column formwork unit ............................................6

Assembly – Extension panels ...............................................................8

Assembly – Close the formwork ..........................................................9

Assembly – Round stopends .............................................................10

Assembly locks – Required quantity and spacing .............................11

Assembly locks – Formwork examples ..............................................12

Access to the Circo platform ..............................................................13

Disassembly ........................................................................................14

Services ................................................................................................15

Product List .........................................................................................17

Cir

co

circ

o-a

vag

b.p

df

St. 24/0

7/0

9 P

rin

ted

in

Germ

an

y

CIRCO-4

�

�

�

�

�

�

�

�

�

� Circular column form

work Circo Ø 25–80 cm

� Circo platform for the

circular column formwork

Ø 25–80 cm

� Circo scaffolding

bracket

� Circo railing

� Brace frame

� Foldable protection

(back)

� Foldable lateral pro

tection

� Toeboard

� Access hatch

� Aluminium fl oor

Delivery of the Circo

platform includes:

¢ 2 head bolts 16/90

¢ 2 cotter pins 4

Fig. 4.1

Description Artikel-Nr.

Circo platform ............ 29-415-10

Circo scaffolding

bracket ....................... 29-415-20

Circo railing ................ 29-415-25

Flange screw 18 .......... 29-401-10

Brace frame 250

without connector ...... 29-109-25

M assembly lock ......... 29-400-71

Hexagonal screw

M16x40 ...................... 63-120-49

Hexagonal locking nut

M16 ........................... 63-130-00

�

Product overview

Circular Column Formwork Circo

circ

o-a

vag

b.p

df

St. 24/0

7/0

9 P

rin

ted

in

Germ

an

y

CIRCO-5

The circular column

panels can be stacked as

shown in Fig. 5.1. This

kind of storage protects

the panel facing as much

as possible from the

weather.

The panels are stacked

and transported in pairs

of 2 semicircular halves

per stacking racks. The

semicircular halves can

be transported individu

ally, by crane, while in

the stacking rack or by

forklift.

When transporting the

stacked panels in the

stacking rack by crane,

the crane slings are

attached to the lateral

suspension points of

the stacking rack. For

transport by forklift, the

forklift moves its fork

crosswise below the

stacking rack.

Truck transport: 2 stack

ing racks can be placed

side by side and 3 stack

ing racks on top of each

other (Fig. 5.2).

Fig. 5.1

Fig. 5.2

Storage and transport

Cir

co

circ

o-a

vag

b.p

df

St. 24/0

7/0

9 P

rin

ted

in

Germ

an

y

CIRCO-6

Fig. 6.1

This double page

describes the assembly

of a complete column

formwork unit with

platform and brace

frames without connec

tors. Page 6 shows the

parts that are required

to assemble such a unit

with a standard height

of 300 cm. Refer to

page 7 for a steptostep

assembly description.

Assembling extension

panels, closing the form

work and other assembly

topics are described in

separate chapters start

ing on page CIRCO8.

Bracing

Depending on its height,

the column formwork

is braced with 2 brace

frames or with 2 push

pull props or – when the

formwork is higher than

6,00 m – with Triplex

braces. Table 7.2 helps

you decide what type of

bracing to use and what

material to select.

The bracing is attached

at the pushpull prop

connectors to a semi

circular panel with the

delivered head bolts

16/90 and cotter pins 4.

The circular column formwork with standard height requires the following parts:

Ref. No. Description Quantity Weight

� 2941510 Circo platform 1 95,0 kg

� 2941520 Circo scaffolding bracket 2 17,0 kg

� 2941525 Circo railing 2 4,5 kg

� 2910925 Brace frame 250 without connector 2 28,0 kg

2940110 Flange screw 18 4 1,1 kg

2940071 M assembly locks 8 3,0 kg

The following parts are included in the circular column formwork delivery:

2 head bolts 16/90 and 2 cotter pins 4

�

�

�

�

Assembly – Basic column formwork unit

Table 6.2

Circular Column Formwork Circo

circ

o-a

vag

b.p

df

St. 24/0

7/0

9 P

rin

ted

in

Germ

an

y

CIRCO-7

We recommend assem

bling the parts while

they are lying on timber

on fl at ground (Fig. 7.1).

1. Place a semicircular

column panel � on the

timber with the panel's

inside facing showing to

the timber.

2. Attach the bracing

with the head bolts

16/90 and cotter pins

4 to the semicircular

column panel. In the

example brace frames

250 without connector

� are used.

3. Attach the Circo scaf

folding brackets � with

fl ange screws 18 to the

panel.

4. Attach the Circo

platform � with the

hammerhead screws

of the Circo scaffolding

brackets at the plat

form's Tsection to the

scaffolding bracket.

5. Fold the platform's

back protection � and

lateral protection �

up and plug both Circo

railings to the Circo

platform.

6. Attach 2rope crane

slings to the lateral

brackets of the panel on

the ground and erect it

with the bracing and the

Circo platform.

7. Immediately attach

the footplates of the

bracing to the concrete

slab or mobile prefab

concrete parts. Use

adequate dowels for

attachment.

�

�

�

�

�

Fig. 7.1

Description Ref. No.Adjustment range (m)

Adm. pressure

(kN)

Adm. ten-sile force

(kN)

Weight (kg)

Recommend use

Braces SRL

SRL 120 2910880 0,90–1,50 20,0 30,0 6,0Horizontal alignment of wall foot, brace frame 250, climbing formwork

SRL 170 2910890 1,20–2,20 25,0 40,0 10,5 Fold shaft formwork

Push-pull props R

R 160 2910940 1,35–2,00 25,0 25,0 11,0 Horizontal alignment

R 250 2910960 1,90–3,20 25,0 30,0 18,5Top support of the brace frame 250 for formwork height up to 350 cm

R 460 2910980 3,40–5,20 20,0 30,0 35,8Column formwork up to a height of 600 cm

R 630 2910985 5,10–7,60 9,5 25,0 67,8Column formwork up to a height of 600 cm

Wall or column heights higher than 6,00 m

Triplex R 680 — 6,40–7,20 45,0 45,0 123,0 Wall formwork, columns

Triplex R 780 — 7,40–8,20 45,0 45,0 139,0 Wall formwork, columns

Triplex R 880 — 8,40–9,20 45,0 45,0 149,0 Wall formwork, columns

Triplex R 980 — 9,40–10,20 35,0 45,0 160,0 Wall formwork, columns

Table 7.2

�

�

Assembly – Basic column formwork unit

Cir

co

circ

o-a

vag

b.p

df

St. 24/0

7/0

9 P

rin

ted

in

Germ

an

y

CIRCO-8

The column formwork's

height can be adjusted

with extension panels.

We recommend assem

bling the extension pan

els while the formwork

lies on the ground. We

also recommend adding

the extension panels at

the bottom of the exist

ing circular formwork

unit. This way, the Circo

platform does not need

to be detached from and

reattached to the form

work unit (Fig. 8.2).

1. Remove the screws.

2. Move the extension

panels and basic form

work unit together and

insert the screws again

(Fig. 8.1).

Note that you can

extend the circular col

umn formwork several

times without reducing

their stability.

The panel joints get

centered automatically

so that they are fl ush.

Disassembly

Proceed in the opposite

order.

Fig. 8.1

Fig. 8.2

Fig. 8.1

Fig. 8.2

Assembly – Extension panels

Circular Column Formwork Circo

circ

o-a

vag

b.p

df

St. 24/0

7/0

9 P

rin

ted

in

Germ

an

y

CIRCO-9

The formwork cannot

be closed unless the

assembled and erected

semicircular column half

(see p. CIRCO7) stands

solid and stable on the

ground

1. Lift the second semi

circular column half

with a crane next to the

erected semicircular

column half (Fig. 9.1).

2. Tightly connect both

semicircular column

halves with M assembly

locks (Fig. 9.2).

Keep in mind that the

number of required

assembly locks depends

on the formwork's hight

and the column diam

eter. See p. CIRCO11

and 12.

Fig. 9.1

Fig. 9.2

Assembly – Close the formwork

Description Artikel-Nr.

M assembly lock ......... 29-400-71

Cir

co

circ

o-a

vag

b.p

df

St. 24/0

7/0

9 P

rin

ted

in

Germ

an

y

CIRCO-10

The semicircular column

halves can be used to

form round stop ends

for walls that are poured

using a MEVA wall form

work system. The diam

eter of the semicircular

column half must match

the wall's thickness. For

walls up to 60 cm thick,

the M assembly lock

is used to connect the

Circo and wall formwork

panels (Fig. 10.1 and

10.2). If the wall is 65 cm

thick or thicker, use the

transition lock Circo

Mammut to connect the

panels (Fig. 10.3).

Keep in mind that the

number of required

assembly locks depends

on the formwork's hight

and column diameter

(see p. CIRCO11 and 12).

An additional bracing of

the semicircular column

half is not required.

Fig. 10.2Fig. 10.2

Assenbly – Round stop ends

Fig. 10.1

Fig. 10.3

Transition lock Circo-Mammut

Mammut panel

Circo semicircular half > 65 cm

Description Artikel-Nr.

M assembly lock ......... 29-400-71

Transition lock

CircoMammut ........... 29-400-80

Circular Column Formwork Circo

circ

o-a

vag

b.p

df

St. 24/0

7/0

9 P

rin

ted

in

Germ

an

y

CIRCO-11

The number of the

required M assembly

locks depends on the

formwork height and

column diameter, see

fi gures 11.1 und 11.2.

The maximum load is

120 kN/m².

Fig. 11.1 Fig. 11.2

Column diameter

Ø 25–50 cm

Column diameter

Ø 55–80 cm

Pouring height

Quantity of assembly locks

Spacing of assembly locks

Pouring height

Quantity of assembly locks

Spacing ofassembly locks

Assembly locks – Required quantity and spacing

Description Ref. No.

M assembly lock ......... 29-400-71

Cir

co

circ

o-a

vag

b.p

df

St. 24/0

7/0

9 P

rin

ted

in

Germ

an

y

CIRCO-12

Please note

The fresh concrete pres

sure is higher at the bot

tom of the column than

at the top. This is why

more assembly locks are

required at the bottom

than higher up, i.e. the

spacing of the assembly

locks must be smaller

at the bottom (Fig. 12.1

und 12.2).

Fig. 12.1

Fig. 12.2

Column diameter

Ø 25–50 cm

Column diameter

Ø 55–80 cm

Example 1

Column diameter: 30 cm

Pouring height: 6,00 m

Fig. 12.1 indicates that 22 assembly locks

are required for a pouring height of 6,00 m

(this height lies between 20 and 22 assembly

locks, in this case the next higher quantity

of assembly locks is chosen). This means that

11 assembly locks are required per semicircu

lar column half.

The spacing of the assembly locks (seen from

the top of the column):

The maximum spacing is 75 cm up to the

5th level of assembly locks, it is maximum

50 cm for the 6th through the 9th level (seen

from the top). The spacing is 33 cm for the

10th and the 11th level. The lowest level of

assembly locks should be located as near to

the ground as possible, however make sure

you leave enough room and distance to the

ground for disassembly.

Assembly locks – Formwork examples

Description Artikel-Nr.

M assembly lock ......... 29-400-71

Example 2

Column diameter: 60 cm

Pouring height: 6,00 m

Fig. 12.2 indicates that 30 assembly locks

are required for a pouring height of 6,00 m

(this height lies between 28 and 30 assembly

locks, in this case the next higher quantity

of assembly locks is chosen). This means that

15 assembly locks are required per semicircu

lar column half.

The spacing of the assembly locks (seen from

the top of the column):

The maximum spacing is 75 cm up to the 4th

level of assembly locks, it is maximum 50 cm

for the 5th through the 7th level (seen from

the top). The spacing is 33 cm for the 8th

through the 10th level. The lowest level of

assembly locks should be located as near to

the ground as possible, however make sure

you leave enough room and distance to the

ground for disassembly.

Circular Column Formwork Circo

circ

o-a

vag

b.p

df

St. 24/0

7/0

9 P

rin

ted

in

Germ

an

y

CIRCO-13

Access to the Circo platform

Ladder or stair tower

For a platform height of

up to 5,00 m, a ladder

can be used to access the

platform (Fig. 13.1).

For a platform higher

than 5,00 m, a stair

tower or lift must be

used. The area between

the stair tower and the

Circo platform must

be closed with planks

and safety equipment

(customtailored onsite

solution).

Please note

The above regulations

are valid for Germany. If

you use the Circo column

formwork and platform

outside Germany, please

make sure you observe

the local regulations as

set out by local law.

Fig. 13.1Fig. 13.1

Cir

co

circ

o-a

vag

b.p

df

St. 24/0

7/0

9 P

rin

ted

in

Germ

an

y

CIRCO-14

Disassembly

1. Attach 2rope crane

slings to the second

semicircular column half

(the one without the

platform and bracing).

Tension the crane slings

and remove all M assem

bly locks (Fig. 14.1).

2. Force the semicircular

columns halves apart

with a wooden wedge.

Place the one that is

attached to the crane on

the ground for cleaning

(Fig. 14.2).

3. Attach the crane

slings to the semicircu

lar column half that is

still erected. Tension the

crane slings.

4. Loosen the doweled

footplates of the brac

ing.

5. Place the semicircular

column half also on the

ground for cleaning, the

platform must be on the

ground side (Fig. 14.3).

6. Remove dirt with a

broom or cloth. Do not

clean the steel facing

with scratching devices

or beat on it.

7. Spray the release

agent MevaTrenn.

8. In order to detach the

bracing and platform,

turn the semicircular

column half so that its

steel facing is on the

ground side.

Fig. 14.1

Fig. 14.2

Fig. 14.3

Description Ref. No.

MevaTrenn FTP

30 litre can ................. 29-203-93

200 litre barrel ............ 29-203-97

1000 litre container .... 29-203-98

Stainless steel jet FT8 .. 29-203-94

Sprayer (5 litre tank) .... 29-903-70

Tap for

1000 litre container ... 29-203-99

Circular Column Formwork Circo

circ

o-a

vag

b.p

df

St. 24/0

7/0

9 P

rin

ted

in

Germ

an

y

CIRCO-15

Services

Cleaning

The formwork is cleaned

professionally upon

return. Cleaning is done

using industrial equip

ment with assembly

lines.

Regeneration

The regeneration is car

ried out as follows: The

frames are checked and,

if necessary, repaired,

painted and provided

with a new facing.

As long as the formwork

equipment is upto

date, a regeneration

will always be a more

economical solution

than purchasing new

formwork.

Please note that the

cleaning and regenera

tion service is not avail

able in all countries

in which MEVA does

business.

Rentals

With much equipment

on stock, we offer our

customers the option of

renting supplementary

material during peak

times. We also give

prospective customers

the chance to test MEVA

formwork so they can

see its benefi ts for

themselves in actual use.

Special solutions

We can help with special

parts, customdesigned

for your project, as

a supplement to our

formwork systems.

Static calculations

Generally, this is only

necessary for applica

tions like single-sided

formwork where the an

chor parts are embedded

in the foundation or the

base slab. If requested,

we can perform static

calculations for such

applications at an ad

ditional charge.

Formwork seminars

To make sure that all

our products are used

properly and effi ciently,

we offer formwork

seminars. They provide

our customers a good

opportunity to keep

themselves uptodate

and to benefi t from

the knowhow of our

engineers.

RentalPlus

Since MEVA started the

fl at rate for cleaning

and repair of rented

formwork systems

in early 2000, more

and more contractors

experience the out

standing advantages.

Ask our representatives

about the details!

Formwork drawings

Of course, all offi ces

in our technical

department have CAD

facilities. You get expert,

clearly represented

plans and work cycle

drawings.

MBS

MEVA Basic Support

MBS is an addition to

AutoCAD, developed

by MEVA Formwork

Systems in 2000. MBS

is based on standard

programs (AutoCAD and

Excel) and can be used

on any PC that has these

two programs installed.

It includes pull down

menues for AutoCAD

and applications to ease

forming. It also includes

the possibility to create

take-offs.C

irco

circ

o-a

vag

b.p

df

St. 24/0

7/0

9 P

rin

ted

in

Germ

an

y

CIRCO-16

Notes