CIMExcel Software Inc. Slide 1 Optimal Mineral Processing Control (OMPC) for Pit-to-Plant...

-

Upload

chrystal-malone -

Category

Documents

-

view

222 -

download

0

Transcript of CIMExcel Software Inc. Slide 1 Optimal Mineral Processing Control (OMPC) for Pit-to-Plant...

CIMExcel Software Inc. Slide 1

Optimal Mineral Processing Control (OMPC) for Pit-to-Plant Optimization

CIMExcel Software Inc. Slide 2

Optimal Mineral Processing Control (OMPC) for Pit-to-Plant Optimization

• Increases Stability and Reduces Variability. • Increases Ore Throughput and Metal Recovery.

Increased Throughput 3 - 5 % Increased Recovery 1 - 2 %

CIMExcel Software Inc. Slide 3

OMPC Input - Output Variables

OMPC

CIMExcel Software Inc. Slide 4

Optimal Mineral Processing Control (OMPC) - Features

• Conventional PID with Feedforward Control

• Discrete-time Control

• Non-linear Model Reference Control

• Modal Control

• Advanced Hill-Climbing Optimization

• Continuous Response Identification and Learning

• Model-based Virtual Measurements

• Advanced Signal Analysis and Process Variable Filtering

• Accurate Dynamic Models for Design and Testing

• Implemented in a DCS and a PC (via OPC)

CIMExcel Software Inc. Slide 5

OMPC Pit-to-Plant Optimization Variables

• Drill Hardness, Blast Pattern, and Powder Factor Tracking

• Primary Crusher Discharge Ore Size Distribution

• Primary Mill Feeder Ratios

• Primary Mill Feedrate

• Primary Mill Feedrate - Rate of Change

• Primary Mill Solids and Speed

• Primary Mill Steel Charge and Size (long term)

• Ball Mill Steel Charge and Size (long term)

• Ball Mill Solids and Speed

• Flotation Solids and Grinds

• Flotation Air and Reagents Ratios and Cell Levels

CIMExcel Software Inc. Slide 6

OMPC Pit-to-Plant Optimization - Manipulated Variables

• Blast Pattern and Powder Factor (long term)

• Primary Crusher Gap

• Feeder Speeds

• Feedrate and Rate of Change

• Primary Mill Solids

• Primary Mill Speed

• Cyclone Scheduling (Active Cyclones)

• Cyclone UF and OF Water Addition

• CFPB Water Addition

• Flotation Air Flow and Reagents Valves

• Flotation Cell Level Valves

OMPC CIMExcel Software Inc. Slide 7

OMPC – Other Features

• Primary Crusher Performance Analysis

• Primary Mill Performance Analysis

• Ball Mill - Cyclones Performance Analysis

• Flotation Performance Analysis

• Primary Mill Dynamic Response Model

• Conventional DCS PID Control Loops with Feedforward

• Discrete-time Control Loops

• Primary Mill Dual Power-Pressure Control with Ore Quality Feedforward

• Stockpile - Feeders Ore Size Classification Identification

• Primary Mill Design/Equipment Performance Improvement Analysis

(feed, steel, lifters, liners, grate, motors)

OMPC CIMExcel Software Inc. Slide 8

OMPC - Increased Ore Throughput ~ 5%

A and B Primary Mills are identical and are fed equally from the same stockpile.

A-line has OMPC turned on, B-line does not. A-line averages 951 Tph. B-line averages 901 Tph.

OMPC CIMExcel Software Inc. Slide 9

OMPC - Increased Metal Recovery ~ 2 %

A1 and A2 Ball Mill - Cyclones - Flotation sides are identical and are fed equally from the same primary mill with the same particle size distributions.

A1-side has OMPC - Cyclone Scheduling turned on, A2-side does not.Both sides have OF Density Optimization, Feedforward Air Ratio, and Reagents Flow Ratio turned on.

A1-side averages 89.8 % recovery efficiency.A2-side averages 87.6 % recovery efficiency.

OMPC CIMExcel Software Inc. Slide 10

OMPC - Integrated Conventional and Advanced Control

Conventional Control (implemented in DCS/PLC via ST):

• Ore Quality Analysis• Feeder Speed• SAG / AG Mill Dual Power - Load Control with Feedforward Ore Quality - discrete time • SAG / AG Mill Speed• SAG / AG Mill Water Ratio• SAG / AG Mill Water Addition• SFPB and CFPB Level• Cyclone - Underflow and Overflow Water Addition• Flotation - Air Flow and Reagents Flow• Lube Systems Temperature (with Feedforward)

Advanced Control (external PC via OPC):

• Feeder Modal Control• SAG / AG Feedrate, Water Ratio, and Mill Speed • Cyclone Scheduling • Cyclone - Overflow Solids• Flotation - Air Flow and Reagents Feedforward• Flotation Cell Levels - Multivariable Nonlinear Model Reference Modal Control with Feedforward and Dynamic Observer

OMPC CIMExcel Software Inc. Slide 11

OMPC - Primary Mill Control• Ore Quality Analysis and Feedforward Control for Feedrate, Solids, and Speed • Short-term Ore Quality Stabilization• Feeder Modal Control• Advanced Hill-Climbing Optimization for Feedrate, Solids, and Speed• Overload Prediction and Prevention• Grindout Optimization• Ore Load Control Mode • Feedrate Rate of Change Optimization• Feedrate and Power Constraints Mode• Dynamic Grinding Rate Model • Continuous Response Identification and Learning

OMPC CIMExcel Software Inc. Slide 12

OMPC – Primary Mill Control and Optimization

Advanced Hill-Climbing

Feedraterate of change

constraints

FeederModal

Control

Short-term Ore Quality

Stabilization

Overload Prediction GrindingRate Model

FeederSpeed

Controllers

Power-Feedrate Constraints

Ore Quality Analysis

Ore Quality Feedforward

Ore LoadControl

GrindoutOptimization

Identificationand Learning

Primary Mill Water Flow

Setpoint

Primary Mill Speed

Controller

SolidsOptimization

SpeedOptimization

Pit Blasting and Primary Crusher Operations

OMPC CIMExcel Software Inc. Slide 13

OMPC CIMExcel Software Inc. Slide 14

OMPC - Ore Quality Feedforward Control

The particle size distributions for the relative toughness (RT = 0.8, 1.0, 1.2) are determined from belt cut testing and correlation with the Ore Size Analyzer data.

The realtime Ore Size Analyzer data is used to determine the current value of the Relative Toughness.

The Relative Toughness, the current steel load, and the time from the last lifter/liner rebuild are used to determine the Maximum Feedrate.

OMPC uses the Maximum Feedrate value as the remote setpoint to the Feedrate Control Loop.

OMPC CIMExcel Software Inc. Slide 15

OMPC - Primary Mill Performance Analysis

OMPC CIMExcel Software Inc. Slide 16

Optimal Mineral Processing Control (OMPC) - Primary Mill Analysis and Optimization

OMPC CIMExcel Software Inc. Slide 17

Optimal Mineral Processing Control (OMPC) Advanced Hill-Climbing Optimization

Optimal Mineral Processing Control (OMPC) Feeders Modal Identification

OMPC CIMExcel Software Inc. Slide 18

Optimal Mineral Processing Control (OMPC) Feeders Modal Control

OMPC CIMExcel Software Inc. Slide 19

OMPC CIMExcel Software Inc. Slide 20

OMPC - Ball Mill - Cyclones - Flotation Control

• Ball Mill Solids - Cyclone Scheduling Hill-Climbing Optimization

for Flotation Solids and Grinds

• Flotation Flow - Flotation Air and Regents Ratio - Recovery Efficiency Analysis

(at constant Flotation Solids and Grinds)

• Overall Recovery Efficiency Analysis and Optimization

• Flotation Air and Regents Ratio Feedforward Control

• Multi-line Ball Mill - Cyclone Hill-Climbing Optimization

• Ball Mill Overload Prediction and Prevention

• Comprehensive Constraints

• Cell Levels - Multivariable Non-linear Model Reference Modal Control with

Comprehensive Feedforward and Dynamic Observer

OMPC CIMExcel Software Inc. Slide 21

OMPC – Recovery Optimization

• Cyclone Scheduling and Optimization

• Flotation Solids Control and Optimization

• Flotation (Air and Reagents) Feedforward Control

• Flotation Levels – Multivariable Nonlinear Model Reference Modal

Control with Comprehensive Feedforward and Dynamic Observer

OMPC CIMExcel Software Inc. Slide 22

OMPC - Model-based Virtual Measurements

• Ore Quality

• Primary Mill Ore Discharge Rate

• Cyclone Size Partition

• Flotation Solids

OMPC CIMExcel Software Inc. Slide 23

OMPC - Ore Stockpile - Multiple Feeders Material Transport Model

OMPC CIMExcel Software Inc. Slide 24

OMPC – SAG / AG Mill Control and Optimization

OMPC CIMExcel Software Inc. Slide 25

OMPC - SAG / AG Mill Advisory Control Mode

OMPC CIMExcel Software Inc. Slide 26

OMPC – Ore Quality Analysis

OMPC CIMExcel Software Inc. Slide 27

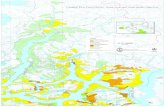

OMPC – Pit-to-Plant Ore Size Reduction

OMPC CIMExcel Software Inc. Slide 28

OMPC – Primary Mill Ore Size Reduction Model

OMPC CIMExcel Software Inc. Slide 29

OMPC – Ball Mill – Cyclone Models

OMPC CIMExcel Software Inc. Slide 30

OMPC – Primary Mill Performance Analysis

OMPC CIMExcel Software Inc. Slide 31

OMPC - Pebble Crusher Models

Flotation Cell Levels - Non-linear Model Reference Modal Control

Qslurry in

÷ fi-1()

HysteresisCompensator

valve position

Vj

Feedforward

Dynamic Observer

PI

actuator positioner

Uj

Level Setpoints

• Operator Fixed• Feed Dependent• Startup/Shutdown

Leveli

Qair i

Solidsin

Leveli

Qair i

Li

+

-

++

OMPC CIMExcel Software Inc. Slide 32

Cyclones 5 -> 6 -> 4 -> 5, Solids in MANUAL Control, Air Flow in Flow Ratio Control

Flotation Cell Levels - Non-linear Model Reference Modal Control

OMPC CIMExcel Software Inc. Slide 33