China PH SOP

-

Upload

khaledali-gap -

Category

Documents

-

view

25 -

download

3

Transcript of China PH SOP

P.1

China PH Control SOP

China Retail Region

CONFIDENTIAL P.2

Question and Answer

China PH Control SOP Product Memo

High Risk Testing in Local China Labs

PH test report

CHINA PH TESTING SOP FOR QA/ DA

Agenda

-Ensure that all China inbound production for washed products fall within the published pH standard, irrespective of Brand, product classification or geographies.

-Current Focus : China PO’s. [ Gap and Gap Outlet brand]

-Going ahead, would be applicable to other Gap Inc. Brands, like Old Navy.

3

OBJECTIVE

1. pH Control Process Flow for China Retail Order

2. Responsibility of garment factory (pre-production)

3. Responsibility of laundry

4. Responsibility of garment factory (final)

5. Responsibility of Vendor DA, Gap QA, PI and Wet Processing (WP) Team

6. GB/T 7573 – 2009 pH test method

4

TOPICS

PH Control Process Flow for China Retail Order (Page 1)

Lau

nd

ryG

arm

en

t Facto

ry

GA

P Q

A

Use significant indicator to classify garment for China Retail Order

Prepare panels for Laundry to test pH for each batch

Separate batches

during WP

Mark down reference batch

number by permanent pen on each panel and put one

panel into each batch

Garment wet processing –

target pH 6.5

Collect all the wash panels from each batch and

conduct 100% pH Test

Pass?

Store received

garment from Laundry batch by

batch separately

P2

Check Laundry pH Test reports

Yes

VM

an

d

WP

Team

Ch

ina P

I

Check the re-wash process

No

PH Control Process Flow for China Retail Order (Page 2)

Lau

nd

ryG

arm

en

t Facto

ry

GA

P Q

AV

M a

nd

W

P Te

am

Local la

b

Send finished garments to

finishing dept.

Random audit 1 garment from bulk

and forward to China PI for pH test validation

Send 1 garment to for local lab

(Intertek / BV) testing

P2

Pass?

Record the result in pH

log

No

Yes

Record the result in pH

log and inform

Garment Factory

Preparation works for garment factory in pre-production stage :

1. Use different colors of string as an indicator to separate China Order vs. other orders.

2. Confirm to use correct China labeling at garments.

3. Follow to prepare fabric panels for pH test specimens. Test pH by each wash batch.

- Size of fabric panel : 50cm X 50cm (edges over-locked)

4. Inform laundry this is a China Order officially.

5. Instruct to check / Test pH , separately, all Wash batches.

7

2. Responsibility of garment factory (pre-production)

Laundry should :

1. Never mix up with China Order together with other orders as there’s different stringent and tightened pH requirements and set the target at pH 6.5 for all wash loads.

2. Should have a batch separation system during production.

3. Write down batch number on each panel (prepared by garment factory as pH test specimen) by permanent pen before load in washing bath.

4. Put one panel (batch no. written) into every single batch during wet processing.

5. Collect all the washed panels and conduct 100% pH test.

6. Passed quantity can send to garment factory for further process.

7. Failed batch should be re-washed to adjust to right pH range and clearly mentioned in failed report accompanying with passed re-test report before sending to garment factory.

8. Pack each batch separately during transportation. 8

3. Responsibility of laundry

Garment factory should :

1. Study laundry pH test reports and select marginal passed batch to conduct random checking (at least one counter check by daily delivery).

2. Passed garment can send to do finishing works.

3. Urgently send ONE bulk garment to local lab testing, factory should hold the shipment for test result.

9

4. Responsibility of garment factory (finishing)

Gap QA / Vendor DA :1. Review test reports from laundry and garment factory.2. Randomly select garment in finishing area and send to local lab for pH

test to verify the accuracy of test result. (Note : To be reviewed the process regularly)

3. Inform PI / WP Team to follow up if test result in (2) failed.PI : 4. Conduct training of pH test method to garment factories and

laundries.5. Periodically calibrate pH test method of laundry and garment factory.6. Inform pH test failure in China test report and request QA/WP to

follow up the corrective action before any retesting.WP Team : 7. Review test reports from laundry during every factory visit and

validate protocol used is as instructed.8. Follow up failed report and re-wash condition and re-validate the

washing recipe used in pH correction.

10

5.Responsibility of Vendor DA, Gap QA, PI and Wet Processing (WP) Team

11

6. GB/T 7573 – 2009

pH Test Method

Glass flasks, with a capacity of 100 ml

Mechanical shaker, providing rotational or reciprocating movement. A to-and fro movement at a rate of 60/min

Beakers, chemically resistant, with a capacity of 150 ml.

Glass rods, chemically resistant.

Volumetric cylinder with a capacity of 100 ml.

pH-meter (e.g. Mettle Toledo), with a glass electrode, capable of measuring to at least 0.01 pH-units.

Electronic Balance, accurate to 0.01 g.

1L volumetric flasks, of grade A quality.

Equipment Required for pH Test

1. Calibrate the pH-meter at the temperature of the extract to be measured.

2. Check the calibration of the pH-meter using two or three buffer solutions. Immerse the electrode several times in the same solution (KCl) used to prepare the extract until the indicated pH-value stabilizes

3. Decant the first extract into a beaker, immediately immerse the electrode to a depth of at least 10 mm and stir gently with a rod until the pH-value stabilizes (do not record the pH-value of this solution).

4. Decant the second extract into another beaker, immediately immerse the electrode, without washing, in the beaker to a depth of at least 10 mm and allow to stand without stirring until the pH-value stabilizes. Record this value.

13

Measurement of the pH of the Aqueous Extract

5. Decant the third extract into another beaker, immediately immerse the electrode, without washing, in the beaker to a depth of at least 10 mm and allow to stand without stirring until the pH-value stabilizes. Record this value.

6. Record the pH-values of the second and third extracts as measurements.

7. If the difference between the two pH-values, expressed to the nearest 0.1 pH-units, is greater than 0.2, repeat the procedure with other test samples. When two valid measurements have been obtained, calculate the mean value.

NOTE : If there have dispute when use water and KCL solution, then KCL solution as the extracting solution be recommended.

14

Measurement of the pH of the Aqueous Extract (cont’d)

GB/T7573 ISO3071Water Distilled or de-ionized water (at least grade 3 water), having a

pH 5.0-7.5

Extracting solution

DI Water or 0.1 mol/L KCl solution

If pH value is not within 5.0-7.5, the water shall be redistilled (acid or organic matter can be removed by distilling water from a solution of 1g/L KMnO4 and 4g/L NaOH. Alkalinity can be removed by distilling the water from a solution of dilute H2SO4.

If the distilled water is not grade 3 water, may make 100mL water boiling 10 mins and cool to room temperature

Testing procedure

Placed each test specimen and 100 ml of extracting solution into a stoppered flask. Agitate the flask for a short period by hand to ensure that the textile material is properly wetted out.

then shake it mechanically for 2 hr +/- 5 mins (MIN)

then shake it mechanically for 2 hr +/- 5 mins

Result Mean of two pH values, to the nearest 0.1 unit15

Differences between GB and ISO Method

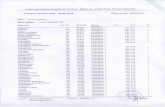

Differences among pH Detection StandardsTest Method GB/T 7573-2009 ISO 3071-2005 AATCC 81-2006

(modified)Applicable to Any textile form Any textile form After wet finished1) Accuracy of Apparatus installed- pH meter < 0.1 < 0.1 0.1- electronic balance 0.01 g 0.01 g no spec. required- Aqueous extract shaker (traverse speed :

60/min, rotary 30 cycles/min) with stopped glass flake

shaker (traverse speed : 60/min, rotary 30 cycles/min)

with stopped glass flake

No shaker, glass beaker and glass cover

2) Extraction samples - moistening before testing no control no control no control- tested specimen sizes (2.00 +/- 0.05)g in 3 sets (2.00 +/- 0.05)g in 3 sets (10.0 +/- 0.1)g in 2 sets

- cut specimens dimen. 5mm x 5mm 5mm x 5mm no control but small pieces

3) Extracting solution - extraction solvent / pH distilled water pH 5.0 - 7.5 or

KC solution with 0.1 mol/L distilled water pH 5.0 - 7.5 or

KC solution with 0.1 mol/LBoiled distilled water

(10 mins and no cooling down) at pH 7.0

- volume 100 ml. 100 ml. 250 ml.

4) Extraction condition - extraction method Shaking/Stirring at room temp Shaking/Stirring at room temp Boiling

- extraction duration (120 +/- 5) min (120 +/- 5) min 10 min- pH value assessed temp. Room temp (~25°C) Room temp (~25°C) Room temp (~25°C)

5) Buffer solution

- pH required 4.0, 7.0 or 9.0 4.0, 7.0 or 9.0 4.0, 7.0 or 10.0 and other buffer sol.

- pH calculation result and accuracy

average pH and variant <0.2. If not retest another set of

samples

average pH and variant <0.2. If not retest another set of

samples

average pH value and report by 0.1 decimal

place 16

17

APPENDIX IDifference in China product requirements in comparison to Gap Inc. protocols

Property Type ABaby <36 months

Type B & CDirect skin

contact

Gap Inc. Test Protocol

Colorfastness to Water* 3 -4 3 2.5 – 3.0

Colorfastness to Acid Perspiration* 3 -4 3 2.5 - 3.0

Colorfastness to Alkaline Perspiration*

3 -4 3 2.5 - 3.0

Colorfastness to Dry Rubbing* 4 3 4.0 (baby)3.5 (Adult/Kid)

Colorfastness to Light 3 – 4 3.0 (all colors)2.0 (neon)

pH Value 4.0 -7.5 4.0 -7.5 4.0-7.0 ( Wool, Nylon) 5.5-7.0 (Whites ) 7.0 – 8.5 (Sulphur-dyed) 5.5 - 8.5 ( Others)

Same Test Requirements

Colorfastness to Saliva* 4 - 4.0

Formaldehyde (ppm) ≤ 20 75 20 (<36 months)75 (Kids & Adult)

Denim Example

LAUNDRY WORK FLOW

1.Separation of batches during WP.

2.Never mix together with NA orders in production.

3.Mark down reference batch no. by permanent pen on each panel.

4.Put one panel into each batch during WP.

5.Collect all the washed panels from each batch and conduct 100% pH test.

6.Record down test result for each batch and present to garment factory during delivery.

7.Passed garment send to garment factory.

8.Failed batch should be re-washed till pass

PH TEST MACHINE

Equipment Required for PH Test

•Glass flasks, with a capacity of 100 ml

•Mechanical shaker, providing rotational or reciprocating movement. A to-and fro movement at a rate of 60/min

•Beakers, chemically resistant, with a capacity of 150 ml.

•Glass rods, chemically resistant.

•Volumetric cylinder with a capacity of 100 ml.

•pH-meter (e.g. Mettle Toledo), with a glass electrode, capable of measuring to at least 0.01 pH-units.

•Electronic Balance, accurate to 0.01 g.

•1L volumetric flasks, of grade A quality.

(Gap Merchant) & (Gap QA Lead) were the one point of contact regarding this SOP.

Gap QA/ DA need to follow up on any China shipment based on ship cxl—need to get a weekly shipment schedule exclusive for China PO’s.

No Shipment will be released without the Passed test report from Lab—Gap QA/ DA need to check with Gap Merch before releasing shipment.

If the test report is Failed, shipment will be on hold and will be escalated to the respective category leads/ China team—may be need to rework on shipment and delivery dates.

Tested Specimen from Lab should be returned and stored at Gap local office—maintained by Gap merchant.

Points to be followed with immediate effect

CHINA PH TESTING SOP FOR QA/ DA

Gap QA/ DA need to pull out randomly one garment/ per color/ on every China PO.

Sample drawn should be from the finished garment i.e., after wash garment if it’s a Wash program.

This sample can be from the Laundry or Finishing or Packing—but should be the bulk representative of shipment.

Sample drawn should have the below details;1. Factory name

2. Style no.

3. PO no.

4. Color

5. QA name & Signature

6. Date

Contd…

SOP for drawing test samples from China PO

The details on the sample should be written as; (enclosed digitals)

1. Shirts—across inside collar/ yoke

2. Pants—across inside Waistband

3. Baby/ Crew neck T—across inside yoke

Gap QA/DA/ factory merchant should write a dispatch mail along with the Lab request form to Gap local merchant Attn: kahled afifi

kahled_ afifi @gap.com cc; Gap immediate merchant managers.

Subject of the e-mail should in the below format;

China pH/Fcty name/ style #/color/Gap QA

Eg., China pH/ ING/153229/ blue/Mohsen

The body of the email in addition should have the ship cxl & planned inspection date.

SOP for drawing test samples from China PO- Contd..

CONFIDENTIALP.18

Thank You

By

Khaled Ali