Chilled Beam Application Guidebook - Biblioteka | KTU · 2020. 10. 19. · CHILLED BEAM SYSTEM...

Transcript of Chilled Beam Application Guidebook - Biblioteka | KTU · 2020. 10. 19. · CHILLED BEAM SYSTEM...

Chilled Beam Application Guidebook

Maija Virta (ed.)David Butler

Jonas GräslundJaap Hogeling

Erik Lund KristiansenMika Reinikainen

Gunnar Svensson

rehvaFederation of European Heating and Air-conditioning Associations

GUIDEBOOK NO 5

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

.

.

Chilled Beam Application Guidebook

Maija Virta (ed.) David Butler

Jonas Gräslund Jaap Hogeling

Erik Lund Kristiansen Mika Reinikainen

Gunnar Svensson

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

.

.

DISCLAIMER This Guidebook is the result of the efforts of REHVA volunteers. It has been written with care, using the best available information and the soundest judgment possible. REHVA and the REHVA volunteers, who contributed to this Guidebook, make no rep-resentation or warranty, express or implied, concerning the completeness, accuracy, or applicability of the information contained in the Guidebook. No liability of any kind shall be assumed by REHVA or the authors of this Guidebook as a result of reliance on any information contained in this document. The user shall assume the entire risk of the use of any and all information in this Guidebook. ----------------------------------------------------------------------------------------------------------- Copyright © 2004 by REHVA, Federation of European Heating and Air–conditioning Associations Second edition 2007 All rights reserved No part of this publication may be reproduced or transmitted in any form or by any means, electronically or mechanical, including photocopy recording, or any information storage and retrieval system, without permission in writing from the publisher. Requests for permission to make copies of any part of the work should be addressed to REHVA, P.O. Box 82, 1200 Brussels e–mail: [email protected] ISBN 2-9600468-3-8 Printed in Finland, Forssan Kirjapaino Oy, Forssa

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

.

iii

List of contents

Terminology, Symbols and Units ..............................................................................vii 1. CHILLED BEAM COOLING AND HEATING IN A NUTSHELL.................1 2. THEORETICAL BACKGROUND .....................................................................3

2.1 Heat Transfer...................................................................................................3 2.1.1 Radiation ...........................................................................................3 2.1.2 Convection ........................................................................................3 2.1.3 Evaporation .......................................................................................3

2.2 Heat Transfer Efficiency in Chilled Beams .....................................................4 2.3 Room Control ..................................................................................................5

3. ROOM AIR CONDITIONING SYSTEM SELECTION ...................................6 3.1 Overview of Different Room Units ................................................................6 3.2 Conditions for Chilled Beam Applications ......................................................7 3.3 Life Cycle Cost (LCC) ....................................................................................7

4. CREATING GOOD INDOOR CLIMATE WITH CHILLED BEAMS......... 10 4.1 Types of Chilled Beam Systems .................................................................... 10

4.1.1 Passive Chilled Beams....................................................................10 4.1.2 Active Chilled Beams.......................................................................11 4.1.3 Perimeter Passive Chilled Beams....................................................11 4.1.4 Integrated Service Beams ...............................................................12

4.2 Comfortable Indoor Climate with Chilled Beams .......................................... 12 4.3 Room Construction Design Requirements ..................................................... 15 4.4 Positioning of chilled beams.......................................................................... 17

4.4.1 Positioning of passive chilled beams ...............................................17 4.4.2 Positioning of perimeter chilled beams ............................................17 4.4.3 Positioning of active chilled beam....................................................18

4.5 Demonstration of Indoor Climate Conditions ................................................19 5. CHILLED BEAM SYSTEM DESIGN .............................................................. 21

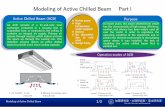

5.1 Cooling with Active Chilled Beams .............................................................. 21 5.2 Heating with Active Chilled Beams............................................................... 24 5.3 Active Chilled Beams in Hot and Humid Climates........................................ 25 5.4 Prevention of Condensation........................................................................... 26 5.5 Air and Water Distribution Systems .............................................................. 27

5.5.1 Distribution Pipe Work .....................................................................28 5.5.2 Chiller Plant and Buffer Vessel ........................................................29 5.5.3 Ductwork and Air Handling Unit .......................................................30

5.6 Use of Free Cooling and Sustainable Heat Sources ....................................... 31 5.7 Room Controls .............................................................................................. 31 5.8 Design Methodology for Chilled Beam System............................................. 32

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

.

iv

6. PRODUCT SELECTION................................................................................... 34 7. INSTALLATION AND COMMISSIONING.................................................... 37

7.1 Installation..................................................................................................... 37 7.2 Flushing......................................................................................................... 38 7.3 Filling-up and venting the system.................................................................. 38 7.4 Commissioning.............................................................................................. 38

8. RUNNING OF CHILLED BEAM SYSTEM .................................................... 41 8.1 Maintenance and Replacement ...................................................................... 41 8.2 Essential Issues in Beam Operation ............................................................... 41

9. CASE STUDIES ................................................................................................. 43 9.1 A Case of Office Building in United Kingdom.............................................. 43 9.2 A case of Office Building in France .............................................................. 44 9.3 A case of Office Building in Sweden............................................................. 45 9.4 A Case of Office Building in Belgium with High Performance Values ......... 46 9.5 A Case of Office Building in Finland with Passive Chilled Beams ............... 47

10. REFERENCES ................................................................................................... 48

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

.

v

Foreword REHVA is a 40-year-old organisation of European professionals in the field of building services (heating, ventilating and air-conditioning). REHVA represents more than 100,000 experts from 30 Euro-pean countries. REHVA´s main activity is to develop and disseminate economical, energy efficient and healthy technology for the mechanical services of buildings. The work is super-vised by the board of directors. Each member of the board is responsible for work in a specific area of REHVA activi-ties. REHVA Guidebook projects are coordi-nated by the Technical Committee of REHVA. The objectives of this work are: Initiate work for technical guidebooks

in the area of building services Establish task forces for such

guidebooks Develop distribution of REHVA

Guidebooks to members and other professionals

Supervise the quality of REHVA Guidebooks

Several task forces are currently working towards REHVA Guidebooks such as: commissioning of HVAC systems for good energy efficiency and indoor cli-

mate, control of exposure to environ-mental tobacco smoke with ventilation, criteria of clean ventilation systems, low temperature heating systems, indoor envi-ronment and productivity. The topic of the guidebook on chilled beam cooling is extremely important with respect to indoor environment. This rela-tively new technology has rapidly spread all over the Europe. Its advantages are in low noise generation, low room velocities and flexibility. High temperature level of cooling media also improves the energy efficiency of the mechanical cooling and allows longer periods of free cooling. The Guidebook presents the principles of chilled beam cooling and illustrates its practical applications. The guidebook on chilled beam cooling is written by a working group of highly qualified international experts under the leadership of Mrs Maija Virta from Finland. The work is done on a voluntary basis with no commercial interest. The document is approved by the REHVA board. The board would like to express its sincere gratitude to the working group for their invaluable work. Olli Seppänen President Elect of REHVA and Chairman of the technical committee

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

.

vi

Member countries of REHVA Belgium Greece Romania Bosnia and Herzegovina Hungary Russia Bulgaria Ireland Serbia and Montenegro Croatia Italy Slovakia Czech Republic Latvia Slovenia Denmark Lithuania Spain Estonia The Netherlands Sweden Finland Norway Switzerland France Poland Turkey Germany Portugal United Kingdom

Work Group This guidebook has been developed in a work-group consisting of the following experts: David Butler, Principal Consultant, BRE, Watford, United Kingdom Jonas Gräslund, Technical Director, Skanska Fastigheter Stockholm AB, Sweden Jaap Hogeling, Director, ISSO, Rotterdam, the Netherlands Erik Lund Kristiansen, Marketing Engineer, Danfoss A/S, Denmark Mika Reinikainen, Director, Olof Granlund Oy, Helsinki, Finland Gunnar Svensson, Export Director, Swegon AB, Stockholm, Sweden Maija Virta, M.Sc., Development Director, Halton Oy, Kausala, Finland

Reviewers The following persons have reviewed the book and made valuable suggestions for improvements: Francis Allard, France Derrick Braham, CIBSE

– Chartered Institution of Building Services Engineers, United Kingdom Peter Novak, Energotech d.o.o. Slovenia Michael Schmidt, Germany Olli Seppänen, Professor, Helsinki University of Technology, Finland Bjarne W. Olesen, DTU, Denmark

Acknowledgements The workgroup wishes to thank the contribution of Mrs. Verity Braham for checking the grammar and spelling and Mr. Harri Itkonen for his help with finalising this book.

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

.

vii

Terminology, Symbols and Units Terms and definitions

The terms and definitions are based on the CEN standard of Chilled Beams, testing and rating of active chilled beams. [12, 13] Additional definitions are mainly from an ISSO publication of Climatic Ceilings and Chilled Beams; Applications of Low Temperature Heating and High Temperature Cooling [1].

Active (Ventilated) Chilled Beam A convector with integrated air supply where primary air, induced air or primary air plus induced air passing through the cooling coil(s). The cooling medium in the coil is water. The beam is normally mounted under the ceiling. Chilled Beam A cooled element or cooling coil situated in, above or under a ceiling which cools con-vectively using natural or induced air flows. The cooling medium is usually water. Chilled Ceiling (Radiant Ceiling) Ceiling panels that are made up of elements that connect together and cool primarily through radiation. The cooling medium is usually water. Closed Chilled Beam An active chilled beam where there is an integrated secondary air path directly from the room space. Closed chilled beams are mainly situated within a suspended ceil-ing. The cooling medium is usually water. Dew Point The temperature at which the water vapour present in the air condenses. Draught Unwanted local cooling of the body caused by air movement.

Draught Rating (DR-value) The percentage of people predicted to be dissatisfied due to draught. Effective Length The length of the cooling section of a chilled beam. Induced Airflow The secondary airflow from the room induced into the chilled beam by the primary air. Induction Rate The total volume of air displaced by in-duction, divided by the volume of primary air supplied. Infiltration The transport of air through leakage paths in the envelope of a building, resulting from pressure (e.g. wind) and temperature differences. Mixed Airflow Rate The total airflow rate supplied from the beam to the space (mixture of primary air and induced air) Mean Radiant Temperature The theoretical uniform temperature of a room in which the radiant exchange be-tween the human body and its environ-ment is the same as the radiant exchange in the actual location.

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

.

viii

Nominal Cooling Capacity The cooling capacity calculated from the curve of best fit for the nominal cooling water flow rate at the nominal temperature difference. Nominal Cooling Water Flow Rate The flow rate that gives a cooling water temperature rise of 2 ± 0.2K at the nomi-nal temperature difference of 8K. Nominal Temperature Difference 8 K temperature difference between the reference air temperature and the mean cooling water temperature. Open Chilled Beam An active chilled beam where secondary air is taken in into the top of the beam. Open chilled beams are mainly used with-out a suspended ceiling. Operative Temperature Uniform temperature of an imaginary black enclosure in which an occupant would exchange the same amount of heat by radiation plus convection as in the ac-tual non-uniform environment.

Passive Chilled Beam (Static Beam) The cooled element or cooling coil fixed in, above or under a ceiling fitted with a cooling coil that cools mainly convectively using natural airflows. The cooling me-dium is usually water. Primary Airflow Rate Conditioned and dehumidified outdoor air supplied to the chilled beam through a duct from the air handling unit. Reference Air Temperature Average of the induced air temperature on the inlet side of a chilled beam. Room Air Temperature The average of air temperatures measured at 1.1m high, positioned out of the main air current from the chilled beam. Total Length The total installed length of the cooling section of a chilled beam, including casing. Turbulence Intensity The ratio of the standard deviation of the air velocity to the mean air velocity. Used to measure variations in air velocity.

Symbols and Units

SYMBOL QUANTITY UNIT cp Specific heat capacity, cp = 4.187 kJ/(kg,K) (water), cp = 1.005 kJ/(kg,K) (air) kJ/(kg,K) L Active length of chilled beam m Lt Total length of a chilled beam, including casing m P Total cooling capacity, P = cp·qm·(θw2 − θw1) W PL Specific cooling capacity of a chilled beam, relative to active length L W/m PN Nominal cooling capacity at ΔθN = 8K W PLN Nominal specific cooling capacity at ΔθN = 8K W/m qw Water flow rate l/s qm Water mass flow rate (qm = ρw · qw) kg/s ρw Density of water (1000 kg/m3) kg/m3 θa Room air temperature °C θr Reference air temperature = induced air temperature °C θp Primary air temperature °C Δθ Temperature difference, Δθ = θr − θw K ΔθN Nominal temperature difference (= 8K) K θw1 Water inlet temperature °C θw2 Water outlet temperature °C θw Mean water temperature, θw = 0.5·(θw1 + θw2) °C qp Primary air flow rate m³/s p Primary air temperature °C ρp Density of primary air (1.20 kg/m3, θ = 21°C) kg/m3

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

1

1. CHILLED BEAM COOLING AND HEATING IN A NUTSHELL

Principles Chilled beam systems are primarily used for cooling and ventilating spaces, where good indoor environmental quality and individual space control are appreciated. Chilled beam systems are dedicated out-door air systems to be applied primarily in spaces where internal humidity loads are moderate. They can also be used for heating. Active chilled beams are connected to both the ventilation supply air ductwork, and the chilled water system. When de-sired, hot water can be used in this system for heating. The main air-handling unit supplies primary air into the various rooms through the chilled beam. Primary air supply induces room air to be recircu-lated through the heat exchanger of the chilled beam. In order to cool or heat the room either cold (14−18°C) or warm (30−45°C) water is cycled through the heat exchanger. Recirculated room air and the primary air are mixed prior to diffusion in the space. Room temperature is controlled by the water flow rate through the heat exchanger.

Passive chilled beams comprise a heat exchanger for cooling, and when desired for heating. The operation is based on natural convection. The primary air is supplied to the space using separate dif-fusers either in the ceiling or wall, or al-ternatively through the raised floor. Best suited for: The chilled beam system provides excel-lent thermal comfort, energy conservation and efficient use of space due to high heat capacity of water used as heat transfer medium. The system operation is simple and trouble-free with minimum mainte-nance requirements. The beam system design complements the flexible use of available space, whilst the high tempera-ture cooling and low temperature heating maximise the opportunity for free cooling and heating. Typical applications for beam systems are: Cellular and open plans offices Hotel rooms Hospital wards Retail shops Bank halls

Figure 1.1 Operation principle of closed active, open active and passive chilled beams. In active chilled beams the primary air supply induces room air through heat exchanger where as in passive chilled beam the operation is based on natural convection.

Closed active chilled beam Open active chilled beam Passive chilled beam

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

REHVA Chilled Beam Application Guidebook

2

Due to dry cooling operation the beam system is used where the internal humidity loads are moderate, the primary air is de-humidified and any infiltration through the building envelope is limited and controll-ed. Active chilled beams provide an option to integrate lighting and other building services with the air conditioning units. Less suited for: Spaces in which high ventilation rates are required, (i.e. where heat loads and con-taminant loads from occupants are con-current) such as conference areas, meet-ing rooms and classrooms, and where all-air systems are more practical. Demand based variable airflow systems (VAV) are recommended if heat and contaminant loads vary strongly all the time. In spaces, where internal humidity loads are high, or increased risk of infiltration exists e.g. through open doors, all-air sys-

tems or wet operating cooling systems (e.g. fan coils) are recommended. Operating range: The active chilled beam system can be used when the total sensible cooling (air + water) requirement is under 120 W/floor-m² in comfort conditions. The optimum operating range, when good thermal comfort in sedentary type occu-pations is required, is 60−80 W/floor-m². The active chilled beam system is typi-cally a dedicated outdoor air system, where primary airflow rates are between 1.5 – 3 l/s,floor-m². Passive chilled beams can be used when total sensible cooling requirement is 40 − 80 W/floor-m². Higher cooling requirements can be met, where optimal thermal comfort is not re-quired or where the occupancy type is not sedentary (for example in copying rooms, computer rooms etc.).

Figure 1.2 Examples of active and passive chilled beam installations.

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

3

2. THEORETICAL BACKGROUND 2.1 Heat Transfer

An individual’s heat exchange with the surroundings primarily occurs in three ways, these are: heat emission through radiation to

surrounding areas or to free space heat emission through convection

to the surrounding air heat emission through

the evaporation of fluid. A fourth form of heat exchange can also occur through conduction to fixed or floating objects in direct contact with the body. However, in normal cases this is so small it is negligible. 2.1.1 Radiation Radiant heat is constantly emitted from warmer to colder surfaces and increases with the temperature difference between them. The radiant heat exchange is primar-ily dependent on the following factors: the size and location of the surfaces and

the view factor in relation to each other the temperatures of

the individual surfaces the character of the surfaces, which

determines the emission and absorption factors, i.e. the ability to emit and absorb radiant heat.

As the room surfaces and conventional heaters have relatively low temperatures, an individual’s heat transfer with sur-rounding surfaces takes place in the form of long wave, low temperature radiation.

The structure and colour of the surfaces have virtually no significance for low temperature radiation as regards its ca-pacity to emit and absorb thermal radia-tion, with the exception of untreated metal surfaces. Examples of sources of low temperature radiation are panel radia-tors as well as ceiling and floor heating/ cooling systems. 2.1.2 Convection If a surface is warmer than the room air it emits heat to the room air. In the same way, the room air emits heat to a surface that is colder than the room air. This form of heat transfer is called convection, and is divided into: Natural convection Forced convection

Natural convection is obtained through the density differences of the air in the different layers, which are created by the temperature differences between the air and the objects against or around which the air flows. Forced convection is heat transfer in a fluid due to motion induced by mechani-cal means such as a fan. 2.1.3 Evaporation Evaporation heat is expended when a liq-uid changes to a gas state. When a person perspires this latent heat is transferred by the body surface, which then cools. Heat transfer through evaporation and convec-tion also takes place during breathing.

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

REHVA Chilled Beam Application Guidebook

4

Figure 2.1 Radiant heat transfer occurs between all surfaces of differing temperatures.

Convection occurs when air moves along a surface. Natural convection is obtained through the density differences of air, and forced convection e.g. fans.

Heat emissions due to evaporation are de-pendent on the room air temperature but also on the absolute humidity of the room air. At average temperatures between ap-proximately 18°C to 25°C with normal relative humidity 20−50% this effect is small for sedentary persons. If the humid-ity level rises to 60% RH and above, the skin surface becomes clammy and evapo-ration is difficult. 2.2 Heat Transfer Efficiency in

Chilled Beams

Heat transfer within chilled beam occurs primarily by convection via the heat ex-changer. The heat exchanger is typically a coil with copper pipes and aluminium fins con-nected to the cooling / heating water sys-tems. In active chilled beams heat transfer is enhanced by forced convection gener-ated by high induction effect of primary air supply. The heat transfer in the ex-changer depends on several variables. Water mass flow rate is selected to achieve a desired outlet water tempera-ture for a given inlet water temperature and to ensure efficient heat transfer by maintaining turbulent flow conditions with sufficient water flow velocity.

Specific conductance of the heat ex-changer depends on coil and pipe dimen-sions and coil width. Convective heat transfer properties de-pend on primary airflow and induction airflow rates. Induction rate depends on the type and number of supply air nozzles. Inlet water and room temperatures af-fect the mean temperature difference be-tween the air and the water in the heat exchanger. Water is a much more efficient heat car-rier than air. Therefore high airflow rate and consequently large duct work are needed to provide the same cooling effect as water. The specific heat capacity per kg of water is 4.2 times higher than the specific heat capacity of air.

100%80%60%40%20%

0%

0.02

0.010

0.03

0.04

0.05

0.06

0.07

0.08

0.09

0.10

0.11

0.12

0.13

0.14

0.15

P L (W

)

qm (kg/s) Figure 2.2 The specific heat transfer of a chilled beam. Water flow rate (qm) should be turbulent to ensure effective heat transfer (PL) but after a certain point any increase of water flow rate does not improve the heat transfer.

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

2. THEORETICAL BACKGROUND

5

The water flow rate inside the pipe should be high enough to ensure a turbulent flow in design conditions. The heat transfer is significantly more effective in turbulent flow than in laminar flow. However the chilled beam heat exchanger has an opti-mum specific capacity above which higher water velocity does not increase the cooling output. Table 2.1 Minimum water flow rate with dif-ferent pipe diameters to ensure fully turbulent flow.

Outside diameter

(mm)

Water velocity

(m/s)

Minimum water flow rate

(kg/s)

10 0.28 0.016

12 0.23 0.018

15 0.18 0.024

18 0.15 0.030

22 0.12 0.038

2.3 Room Control The objective of room control is to mini-mize the difference between the ac-tual/controlled room temperature and the end-user defined set point temperature. There are two basic types of controllers used with chilled beam cooling system: self-acting controllers and electronic con-trollers. There are different solutions for control-ling room temperature in chilled beam installations: On/off time proportional on/off proportional (P) proportional-integrating (PI)

The on/off controller has two stages: “on” (valve fully open – full flow of water) or “off” (valve fully closed – no water flow). An on/off actuator takes 3−5 min-utes to open and close the valve, and therefore provides reasonable stability in the room temperature. The proportional (P) controller is modu-lating the position of the valve and the water flow continuously. The P-controller is associated with a proportional band (P-band), typically 1−3°C – which represents the deviation from the temperature set point that produces 100 % control signal (valve fully open). The P-controller en-sures a stable control and continuous wa-ter flow. P-controller does not eliminate the offset from the set point. The PI-controller is a proportional con-troller with an integrating-function that increases the gain and eliminates the off-set from the set point temperature over time. However, in the cooling season when cooling is only required for part of the day, there is actually little or no dif-ference between P- and PI-control.

Figure 2.3 Room temperature controls can be integrated inside the chilled beam or more typi-cally installed on the wall.

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

6

3. ROOM AIR CONDITIONING SYSTEM SELECTION

PROPERTIES OF CHILLED BEAM SYSTEM Low life cycle costs:

Low maintenance cost Good energy efficiency Free cooling possible in cold and temperate climate

Hygienic system

No filters to be changed or cleaning of drain pans for condensate Easy cleaning of coils and surfaces, only once in every 5 years

Chilled beams operate with a dry cooling coil

No condensate collection system Primary air should be dehumidified in the air handling unit and/or Control of water temperatures is needed to avoid condensation

Building conditions when chilled beams are used:

Cooling demand in the space is less than 80 W/floor-m² (max 120) Heating demand less than 40 W/floor-m² Limited infiltration through building envelope Special attention to the building management system if windows are

openable

3.1 Overview of Different

Room Units

There are a variety of air conditioning systems (air-water systems), where water is used as the heat transfer medium for cooling. The most common room air con-ditioning units and arrangements in these systems are: Fan coil unit High pressure induction unit (floor or

ceiling mounted) Climatic ceilings • Chilled ceilings

- Ceiling panels - Plastic pipes covered with plaster

• Chilled beams - Active chilled beams (open and

closed) - Passive chilled beams - Integrated service beams (active

or passive beam)

Different systems have different proper-ties with respect to thermal and acoustic performance, operation, maintenance and investments. The chilled beam system promotes excel-lent thermal comfort, energy conservation and efficient use of space due to the high heat capacity of water used as the heat transfer medium. The operation principle of the system is simple and trouble-free, because the chilled beam system does not use fans which consume energy and may break down. In active chilled beam sys-tems ventilation is integrated in the room units and no separate equipment for room air distribution is needed. Maintenance requirements are minimal because there are no filters to be changed or any condensate collection system to be cleaned annually. It is recommended that

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

3. ROOM AIR CONDITIONING SYSTEM SELECTION

7

the beam system is vacuum-cleaned every 3 − 5 years, and the control system opera-tion checked at the same time. Beam system design complements the flexible use of the available space, whilst the high temperature cooling and low temperature heating maximise the oppor-tunity for free cooling and heating. The final selection between systems depends on the design of the building, its spaces and their use, as well as the desired qual-ity level of indoor climate conditions and life cycle cost.

3.2 Conditions for Chilled Beam Applications

The operation of all climatic ceiling ap-plications (chilled beams and ceilings) is based on dry-cooling operation and typi-cally the units or arrangements do not include any condensate collection system. This means that temperature of heat trans-fer surfaces has to be higher than the dew point temperature of the room air. For this reason the humidity in these build-ings has to be controlled. In most cases this means, that the outdoor air has to be dehumidified by being cooled in the cen-tral air-handling unit. The building envelope should meet the best National Standard of Air tightness to limit the infiltration through the building envelope. If openable windows are used, then special attention should be paid to the control system of the water temperature to avoid condensation on the chilled beam. Chilled beams have a limited cooling ca-pacity when high thermal comfort re-quirements of spaces are set. Conse-quently all fenestration should be provid-

ed with efficient solar shading to limit the total room cooling demand to less than 80 (max 120) W/floor-m², particularly on the south façade spaces.

3.3 Life Cycle Cost (LCC) When making a decision between the dif-ferent systems, the life cycle cost analysis should be performed. Even though the investment cost presents about 80% of the overall life cycle cost with a life cycle of 15 years and respectively 50% with a life cycle of 50 years; the saving potential in energy, replacement and maintenance costs is still significant. It is difficult to give any general values of life cycle cost for different systems, as the result of LCC is very much dependent on the design of the building, climatic conditions etc. For this reason it is recommended to make a life cycle cost analysis of each building individually. The investment cost of the chilled beam system is influenced by the flexibility of the space. When beams are installed lengthwise in the room, the typical chilled beam installation is one beam in every second or third module. This means the minimum flexibility of about 0.9 m. When beams are installed crosswise the individual beam can be as short as 0.6m, and in consequence only has minimum flexibility. However such short lengths raise the investment cost due to the in-creased number of duct and pipe connec-tions, as well as valves and control damp-ers. This is why it is more cost-effective to install either longer beams, or use a mix-ture of shorter and longer beams e.g. alter-nating beam length equal to width of one space module and two space modules.

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

REHVA Chilled Beam Application Guidebook

8

Figure 3.1 In lengthwise (left) installation there are often less pipe and duct connections with same module division, because there is only one beam in every second or third module, while in cross-wise installation (right) there is typically one beam per module. The smaller the module division is, the more expensive the beam installation is.

The installation time of a chilled beam is about 1 hour. Transportation costs are often included in the purchase price, but if not, 5 to 20% can be added depending on the distance between the building site and the manufacturing works. Estimating energy, maintenance and re-placement costs is laborious. Energy costs include typically heating and electric en-ergy costs. Annual energy consumption and energy price increases should be taken into account as well as the interest rate and calculation period. The energy consumption should be calculated with a dynamic energy simulation program. Chilled beams and chilled ceilings require only minimum maintenance. The finned coil of the beam should be vacuum-cleaned every 3−5 years and the operation of room controls should also be checked at the same time. When replacement costs are calculated, a maintenance period of 20 years can be used for beams, and 10 years for controls

(wax bulb actuators may need replace-ment earlier). Life cycle costs depend on local condi-tions and are project specific, and highly dependant on which cost items have been included in the analysis. Accordingly the cost difference between the different sys-tems is more significant and more reliable than the absolute cost level. Use of chilled ceilings and beams has a positive effect on the energy consumption of buildings. Since water is primarily used as an energy carrier instead of air, the sys-tem is using energy efficiently. Since wa-ter is the primary energy carrier, the sys-tem is more energy efficient than an all air system. Additionally it is possible to fur-ther improve the overall efficiency by us-ing higher cooling water temperatures and lower heating water temperatures than are used in air based systems. Even sustain-able energy sources (waste heat, ground heat etc.) and free cooling can be utilized in order to improve the energy perform-ance of the building.

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

3. ROOM AIR CONDITIONING SYSTEM SELECTION

9

Figure 3.2 Example of different costs in a Scandinavian office building, where chilled beams are used for cooling in the office spaces, and all-air system in other spaces. [5]

The following investment costs (includ-ing purchase price, installation and trans-portation costs) should be taken into ac-count in life cycle cost calculations. Building Automation • Building automation and room con-

trol equipment Ventilation and Air Conditioning • Air handling units, fans, and ductwork • Room equipment, chilled beams, fan

coils, VAV units, re-heat coils Cooling and heating • Water cooling equipment • Central heating units

Piping and plumbing • Cooling pipe work • Heating pipe work and radiators • Condensate collection systems

(drain pans and drains) Electricity consumption and

power demand • HVAC electricity components

(fans, chiller, pumps etc.) Extra building costs • Suspended ceiling and raised floor

Reservations for modifications during the building process (%).

Fan coil in 300 rooms, 20-year life cycle: Filter change: €25/filter twice a year € 300.000 15 min to replace @ €20/hr € 60.000 Cleaning of condensation system: 3 times/year @ 15 min € 90.000 Motor replacement: €200/motor € 60.000 2 h work @ €20/hr € 12.000 Fan coil replacement: € 1000/ unit € 150.000 Total € 672.000 Chilled beam in 300 rooms, 20-year life cycle: Cleaning of chilled beam: once in every 5 years á 15 min @ €20/hr € 6.000 Difference in maintenance and replacement costs € 666.000

Figure 3.3 Example of maintenance and replacement costs of a fan coil system and chilled beam system.

Share of different life cycle costs over 15 years

Maintenance Investment Energy

Share of different investment costs

Building automation Electricity Plumbing Cooling Equipments Beams Ventilation and air conditioning

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

10

4. CREATING GOOD INDOOR CLIMATE WITH CHILLED BEAMS

PRACTICAL GUIDELINES

− Comfortable indoor environment can be achieved when: Cooling capacity of active chilled beams is typically 250 W/m

(max 350 W/m) and passive chilled beams 150 W/m (max 250 W/m) to avoid draughts in the occupied zone

Highly insulated airtight windows with effective solar shading are used Window draught (radiation and downward air movement) in cold seasons

is eliminated Heating capacity of active beams is typically150 W/m to create sufficient

mixing between the supply air from the beam and the room air Operation is designed taking into account the conditions during seasons

(winter, summer, intermediate season) An efficient control system is used Chilled beams are installed and placed correctly in the space.

− Be aware of increased risk of draught if cold air from chilled beams is supplied

towards the cold window surface or directly down to the occupied zone.

− Chilled beams installed above the door can create draught problems if the internal loads near the window are strong enough to bend the air jet from the beam to the occupied zone.

− Passive and open active chilled beams installed in the suspended ceiling

always require sufficiently large openings in the ceiling for the induced room air path.

− When demonstrating the operation of chilled beams with full-scale mock-ups

or computational fluid dynamics (CFD) simulations, the input parameters should be adequately defined, especially the boundary conditions of beam when using CFD.

4.1 Types of Chilled Beam

Systems

4.1.1 Passive Chilled Beams Heat transfer from passive beams occurs mainly by natural convection with a minor part by radiation. Warm room air in con-tact with the cooled surface of the heat exchanger flows downwards through the beam into the room. Passive chilled beams are not connected to the ventilation system and can be positioned fully exposed, re-cessed within a suspended ceiling or above

a perforated ceiling. Supply air can be in-troduced either from high or low level.

Figure 4.1 Operation principle of a passive chilled beam is mainly based on natural con-vection.

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

4. CREATING GOOD INDOOR CLIMATE WITH CHILLED BEAMS

11

Ventilation air supply (outdoor air) ar-rangements need to be designed carefully in order not to interfere with the operation of passive chilled beam. When the air is supplied using ceiling diffusers, the air jet should not obstruct the convective flow of passive chilled beam. In some cases where this could be exploited to prevent downdraught from a beam, the reduction in capacity of the chilled beam should be taken into account (e.g. in full scale mock-up). Passive chilled beams can also be used with under floor supply or with sidewall displacement terminals. This arrangement typically creates a good mixed flow sys-tem, where the convective down flow from passive chilled beams mixes with the low velocity air supply. Room air quality can be improved using high supply airflow rates. However, the size and number of diffusers should be selected so that the air velocities in the occupied zone are low.

4.1.2 Active Chilled Beams Active chilled beams combine the supply of ventilation air (outdoor air) and cool-ing in order to enable effective heat trans-fer due to forced convection, and ensure good air distribution also at high cooling capacity levels. Primary air is supplied into the space via a supply air plenum through nozzles along its length. The supply air jet induces room air through the heat exchanger. The mixture of outdoor air and induced room air is supplied into the room through the longitudinal slots along both sides of the beam. Depending on re-quirements, available space and beam

positioning, it is possible to supply air in one or two opposite directions. An active chilled beam can be either open or closed with an integral induced air path. In closed chilled beams induced room air flows directly through the heat exchanger so that is not circulated via the suspended ceiling.

65 l/s18.5°C

50 l/s24°C

15 l/s18°C

65 l/s18.5°C

15 l/s18°C

50 l/s24°C

Figure 4.2 Active chilled beam operation is based on induction of room air through the cooling coil. The induction rate varies between 1:3 and 1:5 depending on the design.

4.1.3 Perimeter Passive Chilled Beams Perimeter passive chilled beams are in-stalled close to glazed façades or win-dows, and are designed to offset solar gains in the perimeter zone and minimise the depth of the zone of high cooling de-mand. They minimise the disruptive ef-fect that solar gains can have on air tem-perature and air circulation away from the perimeter, which is especially important where displacement ventilation and/or chilled ceilings are used. A further advan-tage of locating chilled beams in the

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

REHVA Chilled Beam Application Guidebook

12

perimeter is that any warm plume rising from the window or blind enhances the air-water temperature difference in the chilled beam and this raises its cooling performance. [7]

Lighting heat extracted in exhaust

Chilled ceiling panels

Displacement ventilation

Chilled beam

Figure 4.3 An example of a perimeter chilled beam installation. It can be used with different kind of climatic ceilings as in this illustration, with chilled ceiling panels and under floor sup-ply but also with active or passive chilled beams.

4.1.4 Integrated Service Beams Traditional chilled beam installations have chilled beams as the ventilation, cooling and heating solution, but an inte-grated service beam concept proposes an all-in-one solution for all ceiling mounted room technical services like down and/or up lights, exhaust, sprinklers, PA/VA speakers, PIR sensors, smoke detectors, power and IT cabling and connections. The integrated service beam concept is suitable for both active and passive beams for both flush and exposed mounted in-stallations. The service beam is an integration of aes-thetics and economics. Pre-assembly of all desired services at the factory in-creases installation speed and quality

while reducing costs. Single source re-sponsibility lowers risk and reduces the need for co-ordination. In addition, the space achieves architectural finish when fewer separate pieces of equipment are fixed to ceiling and walls. Often available room height is increased, as no suspended ceiling is needed.

Figure 4.4 Different room services can be inte-grated into the chilled beam at the factory.

4.2 Comfortable Indoor Climate with Chilled Beams

Indoor climate target values should be taken into account, when defining design values for chilled beam systems. Specific cooling capacity and primary airflow rate should be limited to the range where proper operation conditions and comfort-able thermal conditions can be ensured

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

4. CREATING GOOD INDOOR CLIMATE WITH CHILLED BEAMS

13

e.g. by avoiding too high air velocities in the occupied zone. The higher the spe-cific cooling output, the higher the induc-tion rate (typically 1:3−1:5) and therefore the risk of draught is increased with high linear cooling capacities. To ensure comfortable conditions in spaces, it is recommended that the building is de-signed so that heat loads can be maintained below 80 (max 120) W/floor-m².

The required cooling capacity should always be calculated using dynamic simulation software taking into account the simultane-ous heat loads as well as the transient heat transfer effects of the thermal mass of the construction. Unnecessary over-sizing of the system increases the investment costs. The intentional over-sizing for future flexibility is realised by paying attention to the sizing of water flow rates and ensuring the stable room temperature control.

Table 4.1 The following values can be used as a guideline the interdependency between the maxi-mum cooling output of the chilled beam system and the supply airflow rate. Actual values need to be checked case by case using the data of selected beam type and model.

Airflow Rate ( l/s,m²)

Cooling Capacity (W/m²)

1.5 … 70 2 … 90 3 … 120

Table 4.2 Recommended indoor climate target values. These values are based on good indoor climate level of international standards and recommendations like EN ISO 7730 and CEN report 1752, noticing some limitations of chilled beam system.

Summer Winter Comfort

PMV -0.5…+0.5 -0.5…+0.5 Temperature

Operative room air temperature 24.5 ± 1.5°C 22 ± 2°C Vertical air temperature difference (0,1…1,1 m) < 3°C < 3°C Radiant temperature asymmetry of windows < 23°C < 10°C Radiant temperature asymmetry of ceiling < 14°C < 5°C Floor surface temperature 19…26°C 19…26°C

Air Quality Outdoor air requirement per floor area 1.5…3 l/s,m² 1.5…3 l/s,m² Outdoor air requirement per person 8…20 l/s,person 8…20 l/s,person

Air Velocity Draught rating (DR) < 15% < 15% Average air velocity in the occupied zone (PMV=0) 0.18 m/s 0.15 m/s Maximum air velocity in the occupied zone 0.23 m/s 0.18 m/s

Air Humidity Relative humidity 30…55% 25…40%

Acoustics Sound level requirement NR15-NR30 NR15-NR30

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

REHVA Chilled Beam Application Guidebook

14

Figure 4.5 The design cooling capacity of chilled beam should be defined based on hourly solar, occupancy, light and equipment loads. The cooling demand can be calculated by taking into ac-count the thermal mass of constructions and, when desired, the night ventilation.

Satisfactory heating operation of active chilled beams is by selecting units with low specific capacity so that the warm mixed airflow mixes well with the room air. High supply air temperature and high specific heating capacity decrease the ven-tilation efficiency and increase the tem-perature difference between the floor and ceiling. Cold and extensive window sur-face increases the risk of stratification. Attention should be paid to the fabric, and size of the fenestration to keep the heat losses moderate and surface temperatures close to the room air temperature. If possible the chilled beam arrangement should be designed to allow for future layout changes within the space. This will apply to speculative office buildings, owner-occupier developments and refur-bishments. Chilled beams may be se-

lected to allow for higher primary airflow and water flow rates to compensate po-tential increases in heat loads within the space. The beam design and arrangement can allow for both future partitioning re-quirements and the modular design of the space. Since both active and passive chilled beam operation is sensitive to internal conditions, design parameters should be considered not only for summer and win-ter conditions but also for intermediate seasons, when the system is often operat-ing in cooling mode due to high internal and external heat loads, although the ex-ternal weather conditions are closer to winter conditions. This is especially im-portant when the airflow from the active chilled beam is directed towards the cold window surface.

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

4. CREATING GOOD INDOOR CLIMATE WITH CHILLED BEAMS

15

Table 4.3 Recommended design values for chilled beam system. Cooling Heating

Cooling and Heating Optimum heat loads / losses 60…80 W/floor-m² 25…35 W/floor-m² Maximum heat loads / losses < 120 W/floor-m² < 50 W/floor-m² Specific capacity of passive beam above occupied zone < 150 W/m − Specific capacity of passive beam outside occupied zone < 250 W/m − Specific capacity of active beams (highest class of indoor climate) < 250 W/m < 150 W/m Specific capacity of active beams (medium class of indoor climate) < 350 W/m < 150 W/m

Supply air Specific primary air flow rate of active beam 5…15 l/s,m 5…15 l/s,m Supply air temperature 18…20°C 19…21°C Pressure drop of active beam 30…120 Pa 30…120 Pa

Room air Reference air temperature (air into the beam): active beam Room air temp. Room air temp. + 0…2°C Reference air temperature (air into the beam): passive beam Room air temp. + 0…2°C −

Inlet water Water flow rate with pipe size of 15 mm (turbulent flow) > 0.03…0.10 kg/s > 0.03…0.10 kg/s Water flow rate with pipe size of 10 mm (turbulent flow) > 0.015…0.04 kg/s > 0.015…0.04 kg/s Inlet water temperature 14…18°C 30…45°C Pressure drop 0.5…15 kPa 0.5…15 kPa

The successful operation of passive beams is dependent on the correct positioning of the beam with respect to the internal heat loads. If the loads are located right under the beam, the convective flow of the heat loads may obstruct the natural convection through the coil. On the other hand the correct positioning may slightly improve the performance of passive chilled beams. A chilled beam system (mainly passive beams) can also be partly designed as a self-regulating system without a room con-troller. The water inlet and outlet tempera-tures (typically 19/22°C) are selected close to the minimum room air temperature. This ensures that with minimum heat load level the room is not becoming too cold. Once the heat loads start to increase, the room air temperature rises. As the tem-perature difference between the ambient

room air and inlet water increases the cooling outlet of the passive beam is also increased. The system operation is reliable and the room temperature is kept within the desired range. To avoid heating and cooling at the same time this solution should be combined with free cooling by air handling unit heat recovery. 4.3 Room Construction Design

Requirements

When installing open active chilled beams or passive chilled beams into a suspended ceiling, a minimum clearance between the top of the beam and soffit should be pro-vided for a sufficient return air path. Shadow gaps, dummy beam sections and transfer grilles are recommended for return air path arrangements. The return air path

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

REHVA Chilled Beam Application Guidebook

16

should be placed at the unit’s short side if possible. The net free area of return air path should be at least 0.1m² per linear active chilled beam meter and a minimum 50% of the surface area of passive beams. Secondary air recirculation into the ceiling void only through the air handling light fittings is not recommended due to the higher air pressure drop incurred.

Figure 4.6 A minimum clearance between the top of the passive chilled beam and soffit should be provided for a sufficient return air path.

The selection of windows critically af-fects the indoor climate conditions. The heat transmission coefficient of win-dow should be sufficiently low to ensure that during the winter the internal window surface is warm enough to avoid direct radiation between the window and the

occupants, as well as to prevent any down draught from the internal window surface. Whenever chilled beams are used for heating with extensive glass facades, spe-cial attention should be paid to window construction. There are several options to increase the surface temperature of win-dow and minimise the draught created by the window. As long as the window internal surface temperature is high enough (at least 14°C) the risk of draught is small. In practice this means that the average U-value of window (frame and glass areas) should be around 1.2 W/m²K. A radiant panel or passive chilled beam above the window cannot measurably increase the surface temperature of win-dow. However it lowers the radiant tem-perature asymmetry near window, and because air is warmer above the window, the air temperature underneath the win-dow is also higher and thereby reduces the draught.

Table 4.4 Air velocity underneath the window created by cold window surfaces. However in a typical office application the air velocity underneath the window is not important, but it should be studied in the occupied zone 1 meter from the window.

Troom (°C) Toutdoor (°C) U-value (W/m²K) Window height (m) Tsurface (°C) V (m/s) 21 −20 1 1.5 14.9 0.22 21 −20 1 2 14.9 0.24 21 −20 1.5 1.5 11.8 0.26 21 −20 1.5 2 11.8 0.31 21 −5 1 1.5 17.1 0.18 21 −5 1 2 17.1 0.2 21 −5 1.5 1.5 15.2 0.21 21 −5 1.5 2 15.2 0.23 21 −5 2 1.5 13.2 0.24 21 −5 2 2 13.2 0.27

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

4. CREATING GOOD INDOOR CLIMATE WITH CHILLED BEAMS

17

A warm radiator underneath the window prevents down draught. It is also impor-tant to remember that there should be no obstacles close to the window (table at least 100 mm from window). Heating strips (electrical) underneath the window or heated window glass can also be used. There are also other constructional tech-niques to reduce down draught from a window. It can be divided to several sec-tions when turbulence between each win-dow sector decreases the velocity under-neath. Obstacles like cable chases have the same effect. 4.4 Positioning of chilled beams

4.4.1 Positioning of passive chilled beams Passive beams should not be installed directly above fixed working positions, because the velocity created by natural convection is highest underneath the beam. If the beam is situated above the window or above other high convective heat loads, the possible reduction of cool-ing output should be taken into account.

Figure 4.7 Passive beams should always be positioned outside of occupied zone.

The risk of draught can be minimised by positioning the passive beam above the perforated ceiling, in which case the per-forations in the ceiling should be large enough (approximately 50% free area) to

ensure proper cooling output, but on the other hand small enough to avoid down draught directly from beam. 4.4.2 Positioning of perimeter chilled

beams The performance of perimeter chilled beams has been shown to be very sensi-tive to the design and configuration of the perimeter area including suspended ceil-ings and window blinds. In practice this has often led to poor performance and conflict with architectural and aesthetic requirements. The following guidelines should mini-mise the negative impact of interaction of thermal plumes and building construction and ceiling elements. Internal roller blinds are more effective at guiding the thermal plumes from solar gains to perimeter chilled beams than slatted horizontal blinds. If the blind is not installed in a box then the gap be-tween the top of the blind and the under-side of the building frame should be as small as possible. The installation of ceiling tiles below chilled beams restricts the free flow of air into and out of the ceiling void and there-fore through the chilled beams. Ceiling tiles should therefore have at least 50% free area and hole size maximised (for example 10 mm diameter). Ideally no ceiling tiles should be fitted or louvered tiles should be used below perimeter chilled beams. Lowering the chilled beams and ceiling relative to the underside of the building perimeter frame results in more of the thermal plume being captured and

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

REHVA Chilled Beam Application Guidebook

18

directed into the ceiling void. This pro-vides both increased cooling performance and improved thermal comfort. [7] 4.4.3 Positioning of active chilled beam The recommended location of active beams is above work places, because ve-locity is lowest precisely underneath the beam (if the throw pattern of the beam is horizontal). If the beam is positioned near the wall, the asymmetrical / unidirec-tional throw pattern is recommended. The lowest velocity conditions for all sea-sons can be created, when chilled beams are installed lengthwise in the space. This normally ensures the use of longer beams, which means lower cooling capacity re-quirement per linear meter. Lengthwise installation is also beneficial in intermediate seasons, when window surface is still cold but due to internal loads cooling is required in the space. In the crosswise installation the cool supply air is discharged towards the cold window surface increasing the velocity underneath the window. The beam installation above the door is sensitive to internal convection flows if the supply air is discharged towards the window. Due to the long distance from the beam to the opposite wall, the supply air jet may be interfered by uprising con-vective flows from heat loads and de-flected directly into the occupied zone. When active beams discharge downwards e.g. from above the door, the distance from the beam to the occupied zone must be long enough to avoid high velocity close to the floor in the occupied zone.

This positioning is acceptable only when it is agreed to limit the occupied zone.

Figure 4.8 Active beams should be positioned above the work place in the space to ensure the lowest air velocities in all seasonal condi-tions.

Figure 4.9 Room air velocities in the interme-diate season with the same beam installed ei-ther crosswise or lengthwise in the room. [11]

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

4. CREATING GOOD INDOOR CLIMATE WITH CHILLED BEAMS

19

Figure 4.10 Possible risk of room loads influ-encing the throw pattern of the beam. In the top picture there is no internal load in the space and in the bottom picture the room is occupied and the window surface is warm. [11]

4.5 Demonstration of Indoor Climate Conditions

When chilled beams are used within the normal operation range and in normal installation positions, any special demon-strations of operation is not necessarily needed. But if the operational parameters of a chilled beam are close to or beyond the recommended limits, and if the posi-tioning of the beam is critical, it is rec-ommended to demonstrate the operation of the product in the specified design conditions. There are two options to demonstrate the operation: full-scale mock-up tests and Computational Fluid Dynamics (CFD) simulations. CFD-simulation equations

describing physical phenomena are solved numerically. Both options are ca-pable of demonstrating the velocities and temperatures in the space in steady-state conditions, as long as the input parame-ters are correct. If there is no real boundary data of chilled beam available (given by a manufac-turer), the mock-up then gives more reli-able information. It is critical to model the internal condi-tions and external solar loads as naturally as possible. A chilled beam system is sen-sitive to convective flows and for this reason the ratio of convective and radiant heat transfer should be correct when demonstrating the process in the space. The surface temperature and area of each mock-up of heat sources should be at the correct level. For the same reason the po-sitioning of all the loads should be identi-cal to an actual case. Using the even dis-tribution of loads inside the space, or transferring all the loads through the wall construction (as in a standard capacity measurement), the velocity and tempera-ture values measured in the occupied zone are unrealistic. In CFD simulations the critical issue is the boundary conditions of selected beam. This is why whenever CFD simulations are used; the product boundary conditions specified by the manufacturer should be used. The difference between simulated and actual velocity and temperature val-ues can be remarkable if using generic product model.

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

REHVA Chilled Beam Application Guidebook

20

Figure 4.11 Example of full-scale mock-up, where internal loads are simulated with dummies giving the correct ratio of convective and radiant load. Window wall and floor close to window is heated to give external loads to the space. Air movements are visualized with smoke.

When ordering a full-scale mock-up or CFD demonstrations the following items should be specified: Target of the test

(what problems need to be solved) Sizes of the space

(length, width, height) Window construction

(type, width, height and heat transmission coefficient, solar shading)

External temperatures (summer / winter)

Furniture and ceiling lay-out Specification of internal loads

(also positioning)

Specification of solar gain through the window (surface temperatures of walls and floor)

Tested products, locations and manufacturer

Details of different test cases: • Room air temperature • Supply air temperature and airflow rate • Water inlet temperature and water

flow rate Velocity and temperature measurement

grid and heights e.g. 0.1 m, 0.6 m, 1.1 m, 1.4 m and 1.8 m (measurement points to find maximum velocity need to be defined e.g. by smoke during the test).

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

21

5. CHILLED BEAM SYSTEM DESIGN

PRACTICAL GUIDELINES − Design the chilled beam system based on real cooling requirements.

Overdesign of the system makes it more expensive and decreases comfort.

− Primary air should be dehumidified in most cases and the airflow rate must be high enough to absorb the humidity generated in the space and fulfil the hygienic needs (1.5 – 3 l/s,floor-m²) (5−15 l/s,beam-m). Very high primary airflow rates increase the risk of draughts in the occupied zone.

− Try to use only a few different type of beams (type, length, nozzle size etc.) in

order to make the tendering process, logistics on the construction site and maintenance of building easier.

− Oversizing of heating system may prevent the proper operation of chilled

beams used as a heating unit. Use as low an inlet water temperature as possible (max 45°C)

− Chilled beam systems can be used also in a hot and humid climate, as long as

infiltration is controlled, primary air volume is high enough and morning start-up is in control.

− Condensation must be prevented in chilled beam systems by:

Sufficiently high inlet water temperature (14°C or higher) Dehumidification of primary air (especially when the outdoor air

temperature is above 22°C) Insulating valves and pipes Using condensation sensors on the pipe surface Raising the chilled water temperature or switching off valves locally if there

is an increased risk of condensation

− Distribution pipework dimensions are larger due to dry cooling system operation (low temperature drop across the coil 2 – 4°C)

− Typical room air temperature control is time proportional on-off control with

2-way valves.

− Chilled beam system increases the opportunities to use free cooling and sustainable heat sources.

5.1 Cooling with Active Chilled

Beams

Having defined the design room tempera-ture (normally between 23−26°C in the summer) and established the external de-sign ambient conditions, external sensible

heat loads together with internal gains can be calculated. The thermal capacity of the construction should be taken into account in cooling load calculations by using dynamic simulation software. The difference of external heat loads through windows based on dynamic simulation in

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

REHVA Chilled Beam Application Guidebook

22

different geographical locations in Europe, is smaller than those generally used in design practice. Overdesign of the system increases the installation cost, and even if the thermal comfort criteria is fulfilled, the percent-age of satisfied occupants is reduced due to increased air velocities in the occupied

zone. The use of protection against exces-sive solar gain is therefore highly recom-mended (special glass, different types of shading etc). The chilled beam system primary airflow rate is defined to satisfy comfort condi-tions, minimum ventilation requirement and internal humidity level.

Figure 5.1 The chilled beam system creates comfortable air velocity and temperature conditions in the space when the overall building and chilled beam system is designed correctly.

Figure 5.2 A study shows the cooling load using different window types and directions in three dif-ferent geographical areas in Europe. According to this study the difference in the cooling load in different areas is 10−18% depending on the case and the maximum cooling load is 110 W/m²,floor.

50

60

70

80

90

100

110

120

2xCl

ear,

No

blin

ds

,

West South East Window type and direction

Cool

ing

requ

ired

[W/m

² floor

]

HelsinkiParis Rome

2xCl

ear,

Blind

s 50%

2xCl

ear,

No

blin

ds

2xCl

ear,

Blind

s 50%

2xCl

ear,

No

blin

ds

2xCl

ear,

Blind

s 50%

Low-

emis.

, An

tis.g

reen

Low-

emis.

, An

tis.g

reen

Low-

emis.

, An

tis.g

reen

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

5. CHILLED BEAM SYSTEM DESIGN

23

The required ventilation rate in a typical of-fice space is 1.5 − 3 l/s,m² (6 – 12 m3/h,m²). In order to keep humidity levels within the design parameters the primary air handling unit normally requires the facility to de-humidify the supply air. The primary air-flow rate should also be high enough to absorb the humidity generated inside the space. Chilled beam systems normally use a constant air flow and operate with a pri-mary supply air temperature reset by the season (summer: 18 − 20°C and winter: 19 − 21°C). Lower supply air tempera-tures can be used if the room system (beam or other heating element) has the capacity to also heat the cold supply air in order to avoid too cold room air tempera-ture. When the specific length (of the heat ex-changer) of the chilled beam and the pri-mary air flow rate are defined, it is impor-tant to note that each beam has a mini-mum operating airflow rate to keep the minimum pressure inside the beam cham-ber, as well as to ensure effective heat transfer of the cooling coil and to guaran-tee the operation of air diffusion. On the other hand the primary airflow rate should not be too high in order to avoid excessive induced air flow which can cause draughts in the occupied zone. The typical airflow rate of an active chilled beam is 5 l/s,m – 15 l/s,m. Chilled beams are selected with inlet and outlet water temperature differences of typically 2 − 4°C. Water flow rates and connection method (chilled beams con-nected in parallel or series) should also be considered. As the chilled beam system is designed to provide sensible cooling

only, the inlet water temperature must be selected to avoid condensation. The inlet water temperature (normally no lower than 14°C) must be selected so that the surface temperature of the cooling water inlet pipe is above the dew point tempera-ture of the room air. The cooling water inlet temperature and water flow rate are selected so that an adequate temperature difference between the mean water temperature and room temperature (Dq = 6 – 10°C) and the re-quired cooling capacity can be achieved. Cooling water mass flow rate is selected so that the flow is turbulent in the normal operating situation, typically 0.025 – 0.10 kg/s for a ø15 mm pipe. Beams can be connected in parallel or series. Parallel connection is normally used, but for short-length or low-capacity chilled beams, series connection may also be used. To suit architectural requirements the length of the beam casing can be selected longer than the actual capacity requires (e.g. as long as the room). In this case the actual heat exchanger section is sized ac-cording to the required cooling load, after deducting the cooling effect of the pri-mary air supply. However it is always beneficial to select as few different types and lengths of beam as possible in each floor or building. It simplifies both the tendering process and the logistics on the building site. In the case of large cold windows, the simultaneous operation of both the beam cooling and the under window heating system is recommended. This avoids cold draughts from the window, and compen-

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

REHVA Chilled Beam Application Guidebook

24

sates the internal heat loads with cooling. This increases the operative temperature and ensures the comfort of the occupants. The energy wasted from the heating ele-ments is recovered by the heat recovery system of the air-handling unit.

5.2 Heating with Active Chilled Beams

The design of the heating system begins by defining the required heating capacity. In traditional heating systems the design is often based on high safety margins when heat losses are calculated. When a chilled beam system is used for heating, proper system operation cannot be achieved by oversizing the heating sys-tem. In a new office building 30 –45W/m²,floor of heating capacity is typi-cally enough. If the heating inlet water temperature of a chilled beam is higher than 40 – 45°C (linear output of an active beam is higher than 140 − 160 W/m) in a typical installa-tion, secondary air is often too warm to mix properly with the room air. The rela-tively low temperature gradient in the space raises the air temperature near the floor thus maintaining comfortable ther-mal conditions, as well as ensuring the energy efficiency of the system (by de-creasing the short circuit and thus the ex-haust air temperature). The mixing is also dependent on the win-dow size and surface temperature. The higher and colder the window, the colder the air falling down to the floor, and the temperature gradient between secondary air and room air becomes higher. For this reason using beams for heating is recom-mended when the heat transmission of the windows is moderate (e.g. surface tem-

perature is higher than 14°C and height is not more than 1.5 m).

Figure 5.3 Temperature gradient in the space with different inlet water temperatures.

Inlet w ater 36 O C

28°C

24°C

Inlet w ater 55°C

38°C

26°C

Figure 5.4 IR Measurements of a closed beam during heating mode with two different inlet water temperatures made by KTH in Sweden.

0

0.5

1

1.5

2

2.5

0 2 4 6 8 10 Temperature difference dT (C)

Room

hei

ght (

m)

40 deg.C 60 deg.C 74 deg.C

3

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

5. CHILLED BEAM SYSTEM DESIGN

25

The heating capacity of active beams is dependent on the primary airflow rate. This is why ventilation must be operating when heating is required. The heating of static beams is based on the mixing effect of primary air supply and cold window surface, partly because the warmer upper part of the space is ra-diating to other surfaces and warming them up. The temperature gradient between the cold floor and the warm ceiling is slightly mixed by the cold window but is still relatively high in early morning. There-fore the ventilation needs to be started early enough to ensure that the warm room air near the ceiling is mixed well before space is occupied. Sometimes it is necessary to close the warm water circu-lation of the beam system to increase the mixing of room air at start up.

When an office room is occupied the in-ternal heat sources normally reduce the required heating output and the tempera-ture gradient stays at an acceptable level. 5.3 Active Chilled Beams in Hot

and Humid Climates

In a hot and humid climate, it is important to control the relative humidity concur-rently with the temperature. Decreasing the indoor air temperature and humidity could improve the perceived air quality signifi-cantly. The results have shown that the ac-ceptability of indoor climate increases line-arly with decreasing enthalpy of air. The use of a chilled beam system in a hot and humid climate has been studied using the case-study approach [14]. Field meas-urements were conducted in two rooms of an office building, located in Singapore, served by a ventilated chilled beam system.

10,0

12,0

14,0

16,0

18,0

20,0

22,0

24,0

00:00 02:00 04:00 06:00 08:00 10:00 12:00 14:00 16:00 18:00 20:00 22:00 00:00

27 of March

tem

pera

ture

(o C)

Beam Water InletTemperature

Beam Water OutletTemperature

Room AirTemperature

Dew PointTemperautre

Off-Coil Temperature (AHU)

Figure 5.5 Case study measurement results of an office room during 24 hours in Singapore. With these set points, the objective was to prevent condensation in the beam unit and to achieve dry cooling. The humidity level was high because the supply airflow rate was much lower (39%) than the design specification due to undersized fan capacity. It should be noted that the humidity level was not significantly increased during the night. During the nighttime the dew point was only 1OC higher than the daytime value. [14]

Single user license only, copying and networking prohibited. All rights reserved by REHVA.

REHVA Chilled Beam Application Guidebook

26

Based on the measurements, it is possible to prevent the condensation in the beam system and achieve dry cooling. But only if the infiltration is minimized, the supply airflow rate is sufficient to extract humid-ity caused by people, and the control sys-tem has correctly designed and commis-sioned. Consequently night ventilation is not recommended and the exhaust fans must also be stopped during the night time. The most critical time to reach dry cool-ing is to maintain the required humidity level during the morning start-up period. Condensation can be prevented by start-ing dry air ventilation about 30 minutes before the water-based cooling by adjust-ing the operating hours of the fans and the chilled water pump of the beam sys-tem. The target temperature and humidity lev-els are the starting point for the system design. Typically, the target for the room temperature is 23−24°C and 60−65% for the relative humidity. 5.4 Prevention of Condensation

Cooled beam systems must be designed to ensure that there is no risk of conden-sation. This means selecting an inlet wa-ter temperature higher than the dew point temperature. The inlet water temperature must be reset accordingly, if the internal humidity levels are affected by external influences. Dehumidification of the primary supply air by the main air handling unit plant is