Chemistry Folio Manufacture Substance in Industry

-

Upload

seela-gunalan -

Category

Documents

-

view

234 -

download

5

Transcript of Chemistry Folio Manufacture Substance in Industry

10/2/2013

Name : seela GunalanClass : 4 excellentSchool : SMK Gunsanad II

CHAPTER 9 MANUFACTURE SUBSTANCE IN INDUSTRY

SULPHURIC ACID

1.The manufacture of sulphuric acid is one of the most important chemical industries at the presend time

2.Sulphuric acid , H2SO4 non-volatile disprotic acid.

3.Concentrated sulphuric acid is a viscous colourless liquid.

4. Sulfuric acid is the most widely used acid in industry.

5. It is used to make detergents, dyes, drugs, explosives, pigments, fertilizers, and many other products. It is also the acid in lead-acid electric batteries.

THE USES OF SULPHURIC ACID IN DAILY LIFE

1.There are many uses for the acid including the manufacture of fertilisers, rubber,other acids, detergents, dyes, some medicines and in oil refining.2.Because it is so widely used in industry, exposure may occur in many work places. 3.Burning fossil fuels also releases sulphur dioxide which can react with water in the air to form sulphuric acid. 4.Sulphuric acid is also used to harvest potatoes; the acid damages the leaves killing the plant and making it easier to lift the potatoes from the ground.

5.At home the main sources of sulphuric acid areand somesolutions for unblocking drains.

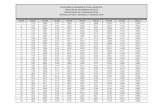

THE INDUSTRIAL PROCESS IN THE MANUFACTURE OF SULPHURIC ACID.

1.Sulphuric acid is manufactured by the Contact process in industry.

2.The raw materials used in the Contact process are sulphure (or sulphide minerals) , air and water.

3.The flowchart of the contact process is shown in the figure.It describes how sulpure or metal sulphuride is convertrd to

concentrated sulphuric acid , throught regulated step in process.

The Manufacture Of Sulphuric Acid (H2SO4)...

Sulphuric acid is manufactured in industry through Contact Process.The raw materials used are sulphur, air and water.The Contact Process consists of three stages.

Stage 1 - Preparation and purification of sulphur dioxide (Furnace)

Molten sulphur is burnt in dry air (oxygen) to produce sulphur dioxide.The gas produced is purified and cooled.

sulpur or metal sulphide

sulphur dioxide

sulphur trioxide

oleumconcentrated sulphuric acid

450˚C to produce sulphur trioxide.

2SO2(g) + O2(g) ↔ 2SO3 (g)

Stage 2 - Catalytic oxidation (using vanadium oxide catalyst) of sulphur dioxide to sulphur trioxide (Converter)

Sulphur dioxide and excess oxygen gas are passed over a few plates of vanadium(V) oxide,V2O5 catalyst at 450˚C to produce sulphur trioxide.

2SO2(g) + O2(g) ↔ 2SO3 (g)

Stage 3 - Conversion of sulphur trioxide to sulphuric acid (Absorber)

The sulphur trioxide is first reacted with concentrated sulphuric acid to form a product called oleum, H2S2O7.

SO3(g) + H2SO4(l) → H2S2O7 (l)

The oleum, H2S2O7 is then diluted with water to produce concentrated sulphuric acid in large quantities.

H2S2O7(l) + H2O(g) → 2H2SO4(l) LT

AMMONIA AND ITS SALT

Ammonia, NH3, is a very important raw material with many industrial usages. It is gaseous at room temperature and colorless with a pungent smell. The density of ammonia gas is lower than air. It is very soluble in water and has low boiling and melting points, -34°C and -78°C respectively.

Ammonia has base properties when it dissolves in water and reacts with acid effectively. The neutralisation reaction of ammonia and acid produces ammonium salt. In the presence of water, the ammonia reacts with the metal ion to form the hydroxide metal.To produce ammonium chloride used as an electrolyted in dry cell.Used in the manufacture of nitrogenous fertilizers.

Uses of Ammonia

Ammonia is used in several ways in industries. These include their usage in the production of fertilisers such as ammonium salts and urea, production of nitric acid and as electrolytes in dry cells. We shall at each of them in detail.

Fertilisers

The most important use of ammonia is in the fertiliser industry. Ammonia undergoes the neutralisation reaction with different acids to form ammonium salts which are fertilisers. The equations below shows an example of the production of ammonium salts used as fertilizers.

Production of urea

The urea fertiliser is also synthesised using ammonia. At a sufficiently high temperature and pressure, ammonia gas reacts with carbon dioxide gas to produce urea. Urea contains a high amount of nitrogen suitable for the healthy growth of plants.

Production of nitric acid

Nitric acid is also an important industrial chemical and is used in the production of nylons, explosives, paints, varnishes, etc. Ammonia is used as raw materials in the production of nitric acid and the process is called the Ostwald process. In this process, ammonia is oxidised in excess of oxygen to form nitrogen monoxide. Platinum is used as the catalyst. Subsequently, nitrogen momoxide is oxidised again to form nitrogen dioxide. The nitrogen dioxide and air are dissolved in water to form nitric acid.

Electrolytes in dry cells

Ammonium chloride has good electrical conductivity. It can be used in dry cells as an electrolyte. Ammonium chloride is produced by the reaction of ammonia with hydrochloric acid.

THE PROPERTIES OF AMMONIA

Other Uses of Ammonia

The properties of ammonia – it is a very volatile liquid and has a high heat capacity – makes it suitable to be used as a cooling agent in refrigerators. Ammonia is also used in the rubber industry to prevent the coagulation of latex. This ensures that the rubber remains in its liquid form. Ammonia is also used to make explosive materials. Ammonia reacts with toluene to form trinitrotoluene (TNT) which is an explosive material.

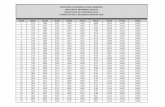

THE INDUSTRIAL PROCESS IN THE MANUFACTURE OF AMMONIAThe process of synthesising ammonia in the industries on a large scale is called the Haber process. The raw materials for the Haber process are hydrogen and nitrogen gas. They are combined directly to form ammonia. Nitrogen gas is obtained by the fractional distillation process of liquid air whereas hydrogen gas is obtained by the catalysed reaction of methane CH4 gas with steam. See the equation below for the production of hydrogen gas. ere are several optimal conditions required in the Haber process. The nitrogen and hydrogen are mixed at the ratio of 1:3 respectively. The mixture is compressed at a pressure of about 200 atm – 500 atm and the temperature of the reaction is maintained at around 450°C – 500°C. Iron filings are also added in the reaction chamber to speed up the reaction .The ammonia is liquefied in the cooling

chamber and it flows out from the chamber in liquid form. The diagram below shows the sequence of the Haber process

The manufacture of ammonia gas by the Haber process.

AMMONIUM FERTILISERS

The essential ingredients for plants to grow are carbon dioxide, light, water as well nutrients such as nitrogen, phosphorous, potassium and calcium. Nitrogen is the important ingredient for the synthesis of protein of plants at the leaves. Nitrogen is absorbed by the roots of the plants in the form of soluble nitrate ions. These nitrate ions are produced by bacteria from ammonium fertilisers such as ammonium nitrate, ammonium sulphate, urea and ammomium phosphate. We have seen above how these ammonium fertilisers can be produced.

The amount of nitrogen in the fertilisers determines their effectiveness. The percentage of nitrogen, N, in the fertiliser can be calculated using the formula:

Percentage of nitrogen by mass

= mass of nitrogen x 100 %

Molar mass of fertilizer

ALLOYS

Meaning and Purpose of Making Alloys

1.An alloy is a mixture of two or more elements with a certain composition in which the major component metal.

2.Pure metals are weak and soft because the arrangement of atoms in pure metal makes them ductile and malleable.

3.Arrangement of the pure metal atoms.A pure metal contain atoms of the same size arranged in a regular and organized closedpacked structure (figure 1.1)

Pure gold is too make jewellery.916 gold consiststs of 91.6% gold The some of alloys

Figure 1.1 Arrangement of atoms in a pure metal

4.Weakness of pure metal

(a) Ductility

: Pure metal are soft because the ordely arrangement of atoms enables the layers of atom to slide over each other easily when an external force is applied on them.This makes the metal ductile and metal can be drawn to form long wires ( figure 1.2)

Figure 1.2 Ductility of pure metal

(b) Malleability

: There are imperfection in the natural arrangement of metal atoms.Empty space exists in the structures of pure metals.When hammered or passed , group of metal atom may slide into new position in these empty space.This makes metals malleable, able to be made into different shapes or pressed into thin sheets ( figure 1.3)

5.The making of alloys

(a) In an alloy , these atoms of foreign elements disrupt the orderly arrangement of the metal atom and also fill u any empty spaces in the metal crystal structure.

(b)Hence the layer of metal are prevented from sliding over each other easily.This make the alloy harder and stronger, less ductile and less malleable than its pure metals.

SYNTHETIC POLYMERS

(a) The meaning of polymers

1.The word polymers originared from the Greek polumeros which means “have many parts”.

2.Polymerisation is the chemical process by which the monomers are joined together to form the big molecule known as the polymer.

(b)Naturally Occurring Polymers

1.Naturally occurring polymers exist in plants or animals.

*protein : in muscles , skin , hair , wool and fur

*carbohydrates : in starch and cellulose

*natural rubber : in latex

(c)Synthetic Polymers

1.Synthetic polymers are polymers made in the industry from chemical substances.

2.Many of raw materials for synthetic polymers are obtained from petroleum , after the refining and cracking processes.

3.Thermoplastics

a) Thermoplastic is a polymer which when subjected to heat becomes soft so they can be moulded into various shape.

4.Synthetic fibres

a) Synthetic fibres are long chained polmers withstand stretching.

5.Elastomer

a)An elastomer is a polymer that can reagain its original shape after being stretched or pressed.

Issues Of Use Of Synthetic Polymers In Every Day Life.

1.Synthetic polymers have been used widely to replace natural material

a)Strong and light

b)Cheap

c)Able to resist corrosion

d)Inert to chemical reaction

e)Easily moulded

Pollution problem caused by Synthetic Polymers.

1.Most polymers are non-biodegradable that is they cannot be decomposed by bacteria or other micro-organisms.This will cause

disposal problems as the polymers will not decay like other organic garbage.Discarded plastic items may cause blockage of the drainage.

2.Plastic bottles and containers that are not buried in the ground will become breeding grounds for mosquitoes which will cause diseases such as dengue.

3.The main source of raw materials for the making of synthetic polymers is petroleum.Petroleum is a non-renewable resource

GLASS AND CERAMICS

1.The raw materials for making glass and ceramics are obtained from the Earth’s crust.

2.The main component of both glass and ceramics is silica or silicoa dioxide, SIO2

GLASS CERAMIC

Transparent Opaque

softens when heated High melting point , hence retain shape on heating

Impermable Usually porous except when glazed

The differences in the properties between glass and ceramic

The Uses Of Glass

Property of galss Uses Example

Inert household materials lamp,bottles,glasses,plates,bowls and

kichen wares

Transparent building materials mirrors and window glass

Intert and easily cleaned scientific apparatus lens,burrettes,beaker,test tube,conical

flask,glass tube and prisms

The uses of ceramics

1.Ceramics is manufactured substance made from clay that is dried and then baked in a kiln at high temperature.

2.The main constituent of clay is aluminate , silica and feldspar.

Property of ceramics Example

Hard and strong Bricks , tiles , and cement

Intert and hard Artificial hands , legs and teeth

Semiconductor type of ceramics To make microchips in computers , radio and television.

COMPOSITE MATERIALS

The meaning of composite materials

1.A composite material is a structural material formed by combining two or more materials with different physical properties , producing and a complex mixture.

Composite materials Components

Reinforced concrete Concrete (cement, sand and small pebbles ) and steel

Superconductor Yttrium oxide (Y2O3),barium carbon (BaCO3) and copper(II) oxide (CuO)

Fibre Optic Glass,sodium carbonate and calcium oxide

Fibreglass Class fibre and polyester (a type of plastic)

Photochromic glass Glass and silver chloride or silver bromide

Reinforced concrete

Superconductor

Fibre Optic

Fibreglass

Photochromic glass

R eference

http://www.slideshare.net/faridahhamat/chapter-9-manufacture-substances

http://0812intesaber.blogspot.com/2011/09/folio-chemistry-chapter-9.html

https://www.google.com/search?q=chemistry+chapter+9+form+4&source=lnms&tbm=isch&sa=X&ei=3ppnUpjCMIeJrQe-4YD4CA&ved=0CAkQ_AUoAQ&biw=1366&bih=567

The Success SPM series of oxford fajar is a reavisin guides.

__________________________________

( Chemistry Teacher )