Chemical Vapor Infiltration Systems - CVD Equipment for R ... · • Hydride Vapor Phase Epitaxy...

Transcript of Chemical Vapor Infiltration Systems - CVD Equipment for R ... · • Hydride Vapor Phase Epitaxy...

enabling tomorrow’s technologies™

www.cvdequipment.com

The systems have application configured safety protocols embedded into relay logic, PLC, and CVDWinPrC™ software.

Operated through our CVDWinPrC™ process control software, the systems automatically log data and graphically show time-dependent values of user-selected parameters. CVDWinPrC™ also allows users to load preprogrammed recipes, modify, check and create new recipes, and view realtime or saved process data.

powered by

Safety Protocols

Chemical Vapor Infiltration SystemsAdvanced process tools for coating the internal surfaces of porous/fibrous materials

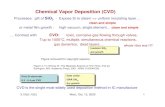

Chemical vapor infiltration (CVI) is a chemical vapor deposition (CVD) process that is performed at low pressures to allow for coating the internal surfaces of a porous material. Using heat and low pressure, precursor vapors penetrate the pores / fibers of the material and deposit to form a conformal coating on the internal surfaces.

Our CVI platform is used to coat the internal surfaces of porous materials having complex shapes and geometries. Multiple systems are in production for coating biocompatible porous material used in medical implants and aerospace components.

Metal coated foamFibers

enabling tomorrow’s technologies™

CVD Equipment Corporation355 South Technology Drive, Central Islip, NY 11722Tel: +1 631-981-7081 | Fax: +1 631-981-7095E-mail: [email protected]

www.cvdequipment.com© 2016 CVD Equipment Corporation | All rights reserved.

V I S I T O U RWEBSITE TO LEARN MORE

Call us at +1 631-981-7081 to discuss a product solution for your project.We can also be reached at [email protected] or visit our website.

Images of CVI Coated Materials

3D graphene on nickel foam (SEM)

CVI metal foam (SEM)

100 µm

100 µm

3D graphene on nickel foam (SEM)

CVD Equipment Corporation offers CVD processing systems with support equipment such as gas cabinets and exhaust gas conditioning systems. All

major components from one vendor makes component interfacing seamless.

3D graphene on nickel foam (Macro Photograph)

Our Other System Capabilities• Atomic Layer Deposition (ALD)• Atmospheric Pressure CVD (APCVD)• Crystal Growth• Chemical Vapor Infiltration (CVI)• High Temperature Annealing (HTA)• Hydride Vapor Phase Epitaxy (HVPE)• Low Pressure CVD (LPCVD)• Liquid Phase Epitaxy (LPE)

• Metal Organic CVD (MOCVD)• Plasma Enhanced CVD (PECVD)• Rapid Thermal Processing / Annealing

(RTP/A)• Selenization and Sulfurization (SAS)• Ultra-High Vacuum CVD (UHVCVD)• Ceramic Matrix Composites (CMCs)

Selected Core Expertise• Automation• Cluster Tools• Dry Etching• Exhaust Abatement/Scrubbing• Multi-Chamber Tools• Reel-to-Reel Processing• High Vacuum / UHV Systems

100 µm

CVI metal foam (SEM) CVI metal foam (SEM)

100 µm 200 µm