Chapter10 Flight Control System

Transcript of Chapter10 Flight Control System

-

7/31/2019 Chapter10 Flight Control System

1/11

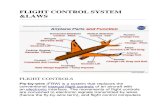

Chapter 10 Flight Control System

Flight Control System: Introduction

An aircraft flight control system (FCS) can range from the simple, unaugmented direct-linksystems of general aviation aircraft to the very complex, multi-mode fly-by-wire systems ofcurrent and next-generation fighters. Because the FCS varies so greatly between differentaircraft, it is necessary for the user to provide some additional C++ code to integrate it into the

full D-Six aircraft flight simulation. Fortunately, because of the modular nature of D-Six, much ofthe difficulty of coding the FCS in C++ (variable declaration, header files, etc.) is performedautomatically. Only a rudimentary knowledge of computer programming (i.e. BASIC, FORTRAN,etc.) is necessary. A simple example will be presented from beginning to end in this section toillustrate the process of building the flight control system in the model dependent code in theMDEPDLL.CPP file and to provide most of the basic C++ syntax that is needed to implement anautomatic FCS.

FCS Block DiagramBecause many modern flight control systems can be quite complex, it is usually convenient torepresent them graphically with a block diagram. Typically, there are several block diagrams;

one for each of the three aircraft axes and for different FCS systems used during various flightmodes. For this F-30 example, located in the sample models directory in D-Six, two blockdiagrams will be presented. The first is a relatively simple longitudinal control system. Thesecond is the lateral-directional control system, which is essentially two distinct block diagramslinked together by a simple aileron-differential tail interconnect or ARI. The configuration usedfor this has conventional wing controls, but uses a V-tail for both longitudinal and directionalcontrol. This aircraft achieves pitch control using symmetric tail deflection, lateral control usingdifferential aileron, and directional control using differential tail deflection.

Before the specifics of coding the FCS are presented, it may be useful to briefly describe theexample FCS. Although this system tries to incorporate realistic FCS parameters and

characteristics, it is by no means intended to be complete or fully robust. It is used solely fordemonstration purposes.

Longitudinal Block Diagram

The longitudinal flight control system, shown above , receives longitudinal stick, dsx, as itsprimary input. This input is multiplied by a stick scale factor, Ksx, to convert the stick input to thedesired angle of attack in degrees, referred to as commanded a or ac. The actual a is subtractedfrom this signal to make the error in angle of attack, or ae. This signal is processed through afirst-order lag (FOL) filter. That filtered alpha error signal is then multiplied by a gain, Ka, andadded to the alpha-rate signal processed through a similar gain, KaD. This total signal represents

-

7/31/2019 Chapter10 Flight Control System

2/11

Chapter 10 Flight Control Systemthe symmetric tail command and is processed through a simple FOL actuator model to get thesymmetric tail position which is used in the D-Six aero model. The functionality describing theeffect of symmetric tail deflection is determined by the InfoFile. Note that the actuator rate limitand control surface hard limits are not represented in the block diagram. They are, however,represented in the model and will be described later in this section.

Obviously, in modeling of a real flight control system, additional filters and lag functions may beinvolved to model the characteristics of other components like the angle of attack sensors, etc.

Lateral-Directional Block Diagram

The lateral-directional block diagram is made up of two simple, essentially independent blockdiagrams. The lateral portion, shown in the top half of the above diagram, receives lateral stick,dsy, as its primary input. This input is multiplied by a stick scale factor, Ksy, to convert the stickinput to the desired aileron deflection in degrees. That signal is added to roll rate, p, processedthrough a FOL filter and multiplied by a gain, Kp. This combined signal is referred to ascomma ded aileron or dac. That signal is passed through a simple FOL actuator transferfunction whose output represents the aileron surface eflection. The dac signal is also passed to

the directional control system for roll coordination.

Unlike the lateral portion, the directional portion of the lateral-directional block diagram, shown inthe bottom half of the above diagram, has no direct control input. Instead, it is used to min mizesideslip, b, which includes auto-coordination of wind-axis maneuvers. This is done by summingthe dac signal (multiplied by the gai KARI) and the b (passed through an OL filter) and b-ratesignals, multiplie by th gains Kb and KbD, re pecti ely. The b and b-rate signals (filtered andaugmented) represent what is called the directio al command, or drc. The total differentia tailcommand (drc + dac * KARI) is processed through a simple FOL actuator model, the output ofwhich is differential tail surface deflection.

-

7/31/2019 Chapter10 Flight Control System

3/11

Chapter 10 Flight Control SystemLike the longitudinal portion of the FCS, the functionality describing the effect of aileron anddifferential tail surface deflections is determined in the InfoFile.

Note: The actuator rate limits and control surface hard limits are not represented in the blockdiagram, but are represented in the model and will be described in a later section.

FCS Variables

The block diagrams representing the FCS presented in the Longitudinal Block Diagram and theLateral-Directional Block Diagram can be described by a relatively short segment of C++ code.The more challenging task is to determine the total number of variables and their relativesources. There are four basic types of variables used by the FCS. They are:

1. A stick input from D-Six

Longitudinal Stick

Lateral Stick

Rudder (not used in the example)

Throttle

2. D-Six simulation output

Aircraft States (, , p, q, r, Mach, etc.- internally defined in D-Six)

Output from data tables (i.e. control system gains & other constants which are functionsof , Mach, etc. - defined in the InfoFile.)

3. A new variable that was created solely for the FCS

Output from summation nodes

Error Signals

Actuator rate and position limitsTransfer function constants

4. An intermediate variable created for transfer function integration

Identification of Required FCS Variables

The simplest way to identify each variable required for the FCS is to assign a variable name toeach signal path in the block diagram (represented by a line ending with an arrowhead). Bothfigures below show the block diagrams with the C++ variable names assigned to each path.There are some considerations that should be taken when naming variables:

- variable names cannot start with a number- variable names cannot include any special characters (except underscore _ )

- variable names cannot have spaces in them

- variables cannot have the same name as C++ keywords or functions

- variables are CASE SENSITIVE

Descriptive character names are allowed and encouraged to aid in describing the particularfunction of each variable. There is no limit on variable name length. All of the variable namesused in Longitudinal FCS Diagram are summarized in Table A and variable names used inLateral-Directional FCS Diagram are summarized in Table B.

-

7/31/2019 Chapter10 Flight Control System

4/11

Chapter 10 Flight Control SystemLongitudinal FCS Variable Diagram

Lateral-Directional FCS Variable Diagram

-

7/31/2019 Chapter10 Flight Control System

5/11

Chapter 10 Flight Control SystemTable A C++ variables used in example longitudinal FCS.

C++ VariableName

VariableType

Location Defined Description

Stk_x 1 Variable List Longitudinal stick input

(keyboard, joystick, or file)

ksx 2 InfoFile Gain in longitudinal stick

alpha_com 3 Variable List Commanded angle of attack (deg)

Alphad 2 D-Six True angle of attack (deg)

alpha_error 3 Variable List Error between commanded and true angleof attack (deg)

aa 3 InfoFile Constant for alpha error filter (sec)

alpha_error_flt 3 Afcs(); Local Filtered angle of attack error (deg)

ka 2 InfoFile Gain on filtered alpha

Alpha_dot 2 D-Six Rate of change of angle of attack (deg/sec)

kad 2 InfoFile Gain on alpha dotDh_com 3 Variable List Symmetric tail deflection command sent to

actuator (deg)

Dh 2 Variable List Actual symmetric tail deflection

Note: "Variable Type" is defined in FCS Variables.

Table B C++ variables used in example lateral-directional FCS.

C++ VariableName

VariableType

Location

Defined

Description

Stk_y 1 Variable List Lateral stick input (keyboard, joystick or file)

ksy 2 InfoFile Gain on lateral stickail_com 3 Variable List Commanded aileron deflection (deg)

Pbodyd 2 D-Six Body-axis roll rate (deg/sec)

ap 3 Variable List Constant for roll rate filter (sec)

p_flt 3 Afcs(); Local Filtered body-axis roll rate (deg/sec)

kp 2 InfoFile Gain on body-axis roll rate

Dar_com 3 Variable List Aileron deflection command sent to actuator(deg)

Da 3 Variable List Actual aileron position (deg)

Dr_com 3 Variable List Differential tail commandBetad 2 D-Six Sideslip angle (deg)

ab 3 Variable List Constant for sideslip filter (sec)

beta_flt 3 Afcs(); local Filtered sideslip angle (deg)

kb 2 InfoFile Gain on filtered sideslip

Beta_dot 2 D-Six Rate of sideslip (deg/sec)

kbd 2 InfoFile Gain on rate of sideslip

kari 2 InfoFile Gain for aileron-rudder interconnect

Ddh 2 Variable List Actual differential tail position (deg)

-

7/31/2019 Chapter10 Flight Control System

6/11

Chapter 10 Flight Control SystemNote: "Variable Type" is defined in FCS Variables.

All type 1 variables in Tables A and B are pilot input variables. Some type 2 variables are alsointernally defined by D-Six (e.g. Betad, Alphad, Pbodyd, etc.) and do not have to be defined bythe user. The other type 2 variables that are defined by the user in the InfoFile are the result of atable lookup. For the example FCS, all of these are FCS gain tables, scheduled with angle of

attack (angle of attack and Mach for body axis roll rate).

Finally, the type 3 variables are either constants, such as filter constants, or variables that werecreated as a result of an operation, such as summation or multiplication (Dh_com, beta_flt, etc.).Notice that there are no type 4 variables. This is because no transfer function, other than asimple FOL, is used in the example. One simple first order differential equation can be used todescribe the relationship between the input and the output, and therefore, no intermediate statevariables are required for the integration. The next section will describe the conversion of simpletransfer functions from the s-domain (Laplace transform) to the time domain (differentialequation) which can be implemented into D-Six.

Conversion of Transfer Functions to Time Domain andImplementation

The transfer functions used in the example are used to describe two things: a FOL filter and asimple actuator model. Using the actuator model as an example, the transfer function can beequated to the ratio of its output to input as follows:

Taking the inverse Laplace transform yields the differential equation:

or

All of the transfer functions in this example can be converted to a single first-order differentialequation in this manner. However, if more complex transfer functions are used, they must be

implemented as a set of first order differential equations. The easiest way to do this is to use amatrix manipulation program (e.g. MATLAB or Matrix X) which converts transfer functions tostate space equations of the form:

Where u is the vector of inputs (usually of length 1), y is the vector of outputs (usually of length1), x is the vector of intermediate state variables (length equal to the order of the transferfunction) and A, B, C and D which are vectors output from the matrix manipulation software.

-

7/31/2019 Chapter10 Flight Control System

7/11

Chapter 10 Flight Control System Conversion Of Transfer FunctionThe code can then be implemented into C++ as several first order differential equations, andone (typically) assignment statement (typically, the matrix D is zero). The following is anexample of the conversion of a second order transfer function to two differential equations andan assignment statement:

Using matrix manipulation software (e.g. the tf2ss function in MATLAB which stands for transferfunction to state space), the differential equations which relate the input of this transfer functionto its output are described by the following equations:

or, in C++ code:

x1dot = -400.0f * x1 - 30000.0f * x2 + Dr_com;

x2dot = x1;

Dr = 30000.0f * x2;

This set of equations can be rearranged into two differential equations, but for simplicity, can beimplemented into D-Six in the three equations shown above. In addition, the new variables, x1

and x2, created by the matrix manipulation software are of type four as described in FCSVariables. Of course, a transfer function of any order may be used in the same fashion, withcomplexity increasing with order.

This completes the description of how to identify FCS variables, define them, and determine thedifferential equations which relate the output from a transfer function to the input. The followingsection will present the example FCS and describe several steps which must be taken toimplement the C++ code into the model dependent code located in MDEPDLL.CPP.

-

7/31/2019 Chapter10 Flight Control System

8/11

Chapter 10 Flight Control System Incorporating FCS Into D-Six

Incorporating FCS into D-Six

The most direct way to describe the coding of the FCS in C++ is to present the F-30s Afcsfunction as it appears in the MDEPDLL.CPP file and explain it one section at a time. No line ofC++ for this function will be omitted or considered out of order as it has been implemented intoD-Six for the example FCS.

Initialize Ncs Model Dependent Global Variable

Before a discussion of theAfcs function is started, the global variable Ncs at the beginning ofthe MDEPDLL.CPP file must be initialized. This variable represents the number of FCSvariables that need to be integrated by D-Six after Afcs is called. This is typically equal to thesum of the individual orders of all of the transfer functions. Therefore, for the F-30 example FCSNcs is set equal to 6 because it has a total of six had 4 first order actuators, 2 second order and5 first order filters, then Ncs would be initialized to 13.

Afcs Function in MDEPDLL.CPP file

This first section of Afcs does not need to be modified unless local variables need to be defined

as in this example. If any local variables need to be declared or defined, that should be doneimmediately following the left brace, {, after void Afcs() as shown below.

// Flight control system routine.

void Afcs()

{

// Define F-30 flight control local variables

static float alpha_error_flt;

static float beta_flt;

static float p_flt;

Typically, global and intermediate variables used in a flight control system should be initializedprior to the start of a simulation run to avoid numerical problems, such as division-by-zero. Codeto mechanize the initialization process should be placed in Init_gains() function in theMDEPDLL.CPP. At time-zero, the code in Init_gains()is called and executed from the afcs() asshown below. However, for the F-30 FCS example, no initialization is required and no code isimplemented in Init_gains().

// Provide initialization support at the start of a run.

if ((pGetFlightModes)()->Time==0) Init_gains();

The section below begins the code for the FCS. All characters on a line following a // arecomments. The comments, along with previous discussions should provide adequate

information to follow the C++ code, with one exception. That is the handling of the six differentialequations created by the individual transfer functions.

This is simply done by using the D-Six array pCsdot. Instead of assigning the FCS timederivatives to new variables (such as Dh_dot for the time derivative of symmetric tail deflection)D-Six keeps all FCS derivatives in one array named pCsdot. This is done so D-Six can integrateall of the FCS derivatives, store their integrated states in pCs and return them to the Afcsfunction for the next time step. The global variable Ncs, initialized above, is used to initialize thedimension of the pCsdot and pCs arrays.

-

7/31/2019 Chapter10 Flight Control System

9/11

Chapter 10 Flight Control System Incorporating FCS Into D-SixEach differential equation uses the pCsdot array to store an individual time derivative value. Forthe example the pCs array is assigned to FCS variables as follows :

pCs[0][0] assigned to alpha_error_flt

pCs[0][1] assigned to Dh

pCs[0][2] assigned to Ddh

pCs[0][3] assigned to beta_flt

pCs[0][4] assigned to DapCs[0][5] assigned to p_flt

Note that the C++ array index starts with zero.

// Longitudinal Channel

// calculate the derivatives for the longitudinal (AOA) control system:

alpha_com = ksx * Stk_x;

// limit alpha based on D-six user's input

if (alpha_com > alpha_lim) alpha_com=alpha_lim;

if (g_limit_switch != 0.0f){if (alpha_com > g_limit_lookup) alpha_com=g_limit_lookup;

}

// raw alpha_error signal

alpha_error = alpha_com - Alphad;

// FOL filter for alpha_error_flt (or pCs[0][0])

if (aa)

pCsdot[0][0] = 1.0f / aa * (alpha_error - alpha_error_flt);

else {

pCsdot[0][0] = 0.0f;

pCs[0][0] = alpha_error;

}

// raw Dh_com signal

Dh_com = Dh_com + ka * alpha_error_flt + kad * Alpha_dot;

// limit Dh_com

if (Dh_com > 30.0f) Dh_com = 30.0f;

if (Dh_com < -30.0f) Dh_com = -30.0f;

// define Dh-dot; also limited by actuator rate

pCsdot[0][1] = 20.0f * (Dh_com - pCs[0][1]);

In the longitudinal channel, there is algorithm to model the rate limit on the symmetric tailactuator. Since the pCs[0][1] variable is assigned to Dh or the actuator output, limiting thepCsdot[0][1] variable is equivalent to imposing the actuator-rate limit. This actuator, like theother two, is limited to 60 degrees per second.

if (pCsdot[0][1] > 60.0f) pCsdot[0][1] = 60.0f;

if (pCsdot[0][1] < -60.0f) pCsdot[0][1] = -60.0f;

-

7/31/2019 Chapter10 Flight Control System

10/11

Chapter 10 Flight Control System Incorporating FCS Into D-SixBelow is the lateral portion of the flight control system. The lateral channel is calculated beforethe directional portion because the aileron command, Dar_com, is required for the command tothe differential tail actuator.

// Lateral/Directional Channels:

// calculate the derivatives for the lateral control system:

ail_com = -Stk_y;

// FOL filter for roll rate

if (ap)

pCsdot[0][3] = 1.0f / ap * (Pbodyd - p_flt);

else {

pCsdot[0][3] = 0.0f;

pCs[0][3] = Pbodyd;

}

// raw Dar_com signal

Dar_com = ail_com + kp * Pbodyd;

// define Dar_com-dot; also limited by actuator rate

pCsdot[0][4] = 20.0f * (Dar_com - pCs[0][4]);

The following is the aileron actuator rate limit:

if (pCsdot[0][4] > 60.0f) pCsdot[0][4] = 60.0f;

if (pCsdot[0][4] < -60.0f) pCsdot[0][4] = -60.0f;

For the directional channel:

// Directional Channel

// FOL filter for Betad feedbackif (ab)

pCsdot[0][5] = 1.0f / ab * (Betad - beta_flt);

else {

pCsdot[0][5] = 0.0f;

pCs[0][5] = Betad;

}

// raw Dr_com signal

Dr_com = kb * beta_flt + kbd * Beta_dot;

// define Dr-dot; also limited by actuator rate

pCsdot[0][2] = 20.0f * (Dr_com + kari * ail_com - pCs[0][2]);

The differential tail actuator rate limit follows.

if (pCsdot[0][2] > 60.0f) pCsdot[0][2] = 60.0f;

if (pCsdot[0][2] < -60.0f) pCsdot[0][2] = -60.0f;

-

7/31/2019 Chapter10 Flight Control System

11/11

Chapter 10 Flight Control System Incorporating FCS Into D-SixThe following C++ statements are used to assign the values from the integrated pCs array to theappropriate global project or local variables. This function is necessary so that these FCSvariables can be returned to D-Six correctly to be used for table look-up, plotting, etc.

// assign integrated values to control surface variables

Dh = pCs[0][1];

Da = pCs[0][4];

Ddh = pCs[0][2];Dlef = Dlef_schedule;

// assign integrated values to local FCS variables

alpha_error_flt = pCs[0][0];

beta_flt = pCs[0][3];

p_flt = pCs[0][5];

The final section of C++ code sets the surface hard limits. For the aileron this is quitestraightforward. However, for the symmetric and differential tail this is slightly more complicatedbecause they use the same surfaces. Although the specific logic used will not be discussedhere, this section of code does introduce two new variables, _Dhr and _Dhl, which representright and left tails, respectively. These variables could have been declared locally at the top ofthe Afcs function, but that would not allow them to be plotted in D-Six. Instead, for this example,they were defined as global D-Six project variables using the Variable List from D-Six.

// set limit Dh

if(Dh > 30.0f) Dh = 30.0f;

if(Dh < -30.0f) Dh = -30.0f;

// set aileron limitsif (Da > 30.0f) Da = 30.0f;

if (Da < -30.0f) Da = -30.0f;

// set tail limits:

_Dhr = Dh + Ddh / 2.0f;

_Dhl = Dh - Ddh / 2.0f;

if (_Dhr > 45.0f) _Dhr = 45.0f;

if (_Dhr < -45.0f) _Dhr = -45.0f;

if (_Dhl > 45.0f) _Dhl = 45.0f;

if (_Dhl < -45.0f) _Dhl = -45.0f;

Dh = (_Dhr + _Dhl) / 2.0f;

Ddh = (_Dhr - _Dhl);

} // end of afcs{}