Chapter Two Transparencies

-

Upload

frightmar3 -

Category

Documents

-

view

236 -

download

0

Transcript of Chapter Two Transparencies

-

8/12/2019 Chapter Two Transparencies

1/61

-

8/12/2019 Chapter Two Transparencies

2/61Page | 2

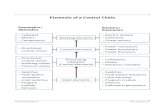

THE PLANNING AND CONTROL CYCLE

He who fails to plan, plans to fail Planning is the most basic of all managerial functions. Planning involvesselecting from a number of alternative courses of action the means ofachieving specified goals or objectives. All other managerial functionssuch as organizing, staffing, controlling, etc. are based upon theattainment of goals according to plans.

Planning involves selecting not only the companys objectives, but alsothe means of reaching them. This type of approach cannot take place in avacuum. Good planning must consider the nature of the future in which

planning decisions and actions are intended to operate.

Planning is answering, in advance, the questions: what to do, how to doit, when to do it, and who is going to do it? Planning bridges the gapfrom where we are to where we want to go. Without planning, events areleft to chance.

There are four major reasons to plan: To offset uncertainty and change . Change is accelerating based on new

technologies that impact one another. Business is becoming more complex due

to more external regulations. Change and complexity create this uncertainty. To focus attention on objectives . Your company is more efficient because youhave determined where you want to go and then focus on getting there.

To gain economical operations . Resources are allocated effectively to achieveyour goals.

To facilitate control . There is an implied risk and lack of control in not planning. You and your company are left to the mercy of chance.

-

8/12/2019 Chapter Two Transparencies

3/61Page | 3

Department Budget Actual VarianceFood

Bakery 1,100$ 1,050$ (50)$Meat 2,500 2,700 200 Fish 1,500 1,750 250 Dairy 1,500 1,500 -

Total food 6,600 7,000 400

Labor Manager and chef 2,000 2,000 - Counter 800 1,000 200

Total labor 2,800 3,000 200

Total Sandwich Costs 9,400$ 10,000$ 600$

Number of Sandwiches sold 4,100 4,100 -

Danny's Sandwich ShopStore Budget versus Actual

October 31, 2010

Possible Questions:Why were costs higher if we sold the budgeted amount ofsandwiches?

Why are costs of meat, fish and counter labor so high? And willthis continue?

Was there excess waste of meat and fish?

Did the cost per pound rise suddenly?

Were customers given larger portions than expected?

Was there overtime required for counter staff?

-

8/12/2019 Chapter Two Transparencies

4/61Page | 4

Why Plan?

Some business executives have made some of the followingcomments regarding planning:

too much of a hassle a waste of time plans are never any good because they always change

The net result is that theyre saying: we dont want to thinkabout our business and what it is, where its going and what wecan do about it! Planning is a part of business and should never

be considered a waste of time or a hassle. Plans can and possiblyshould change as our model, or paradigm, of future eventschanges. An example of what will happen with that thought

process is seen is a paradigm-shifting experience as told byFrank Koch in Proceedings, the magazine of the Naval Institute i.

Two battleships assigned to the training squadron had beenat sea on maneuvers in heavy weather for several days. Iwas serving on the lead battleship and was on watch on the

bridge as night fell. The visibility was poor with patchyfog, so the captain remained on the bridge keeping an eye

on all activities.Shortly after dark, the lookout on the wing of the bridgereported, Light, bearing on the starboard bow. Is it steady or moving astern? the captain called out. The lookout replied, Steady, captain, which meant wewere on a dangerous collision course with that ship.

The captain then called to the signalman, Signal that ship:We are on a collision course, advise you change course 20degrees. Back came a signal, Advisable for you to change course20 degrees.

i The 7 Habits of Highly Effective People , Stephen R. Covey, A Fireside Book Published by Simon &Schuster, 1990.

-

8/12/2019 Chapter Two Transparencies

5/61Page | 5

The captain said, Send, Im a captain, change course 20degrees. Im a seaman second class, came the reply. You had

better change course 20 degrees. By that time, the captain was furious.He spat out, Send, Im a battleship.Change course 20 degrees. Back came the flashing light, Im alighthouse. We changed course.

The planning process is simply a rational

approach to the future. The only thingscertain about the future are change anduncertainty as to its outcome. Planning provides the rudder toguide the course of the business through the problems andopportunities of the future. Without planning, a business may beleft to flounder on the sears of uncertainty. A well thought-out

business plan will assist in steering the business.

Plans have a need for flexibility. Since plans are based uponassumptions, as these assumptions deviate from expectations,the plan must be updated.

-

8/12/2019 Chapter Two Transparencies

6/61Page | 6

AN OVERVIEW OF COST CLASSIFICATIONS

Purpose of classification Cost classifications

Preparing an incomestatement and balance

sheet

Product costs Direct materials

Direct labor Manufacturing overhead

Period costs (nonmanufacturingcosts)

Selling costs Administrative costs

Predicting changes incost due to changes inactivity

Variable costs

Fixed costs Mixed costs

Assigning costs Direct costs Indirect costs

Making decisions Differential costs

Sunk costs

Opportunity costs

-

8/12/2019 Chapter Two Transparencies

7/61Page | 7

COST CLASSIFICATIONS INMANUFACTURING COMPANIES

-

8/12/2019 Chapter Two Transparencies

8/61Page | 8

COST CLASSIFICATIONS TO PREDICT COSTBEHAVIOR

To predict how costs react to changes in activity, costs are oftenclassified as variable or fixed.

Categories of costs:

Fixed Semi-fixed (step) Variable

Semi-variable (mixed)Dependent variable total cost

Independent variable activity cost driver

Cost structures TC = VC + FC

Less risk cost structures dominated by VC

More risk cost structures dominated by FC

-

8/12/2019 Chapter Two Transparencies

9/61Page | 9

VARIABLE COSTS Variable cost behavior can be summarized as follows:

Variable Cost BehaviorIn Total Per Unit

Total variable cost increasesand decreases in proportion

to changes in activity.

Variable cost perunit is constant.

EXAMPLE: A company manufactures microwave ovens. Each ovenrequires a timing device that costs $30. The cost per unit and thetotal cost of the timing device at various levels of activity (i.e.,number of ovens produced) would be:

Cost per Number of Total VariableTiming Ovens Cost TimingDevice Produced Devices$30 1 $30$30 10 $300$30 100 $3,000$30 200 $6,000

Costs that change with a change in volume of activity or changein cost drivers

-

50

100

150

200

250

300

350 400

450

- 5 10 15

-

8/12/2019 Chapter Two Transparencies

10/61

-

8/12/2019 Chapter Two Transparencies

11/61Page | 11

TYPES OF FIXED COSTS Committed fixed costs relate to investment in plant, equipment,

and basic administrative structure. It is difficult to reduce thesefixed costs in the short-term. Examples include:

Equipment depreciation.

Real estate taxes.

Salaries of key operating personnel.

Discretionary fixed costs arise from annual decisions bymanagement to spend in certain areas. These costs can oftenbe reduced in the short-term. Examples include:

Advertising; public relations.

Research; management development programs.At the dawn of television history there were two distinct paths oftechnology experimented with byresearchers. Early inventors attempted toeither build a mechanical televisionsystem based on the technology of Paul

Nipkow's rotating disks; or they

attempted to build an electronictelevision system using a cathode raytube developed independently in 1907

by English inventor A.A. Campbell-Swinton and Russian scientist BorisRosing. Electronic television systemsworked better and eventual replacedmechanical systems.The very first prototype for a plasma display monitor wasinvented in July 1964 at the University of Illinois by professorsDonald Bitzer and Gene Slottow, and then graduate studentRobert Willson. However, it was not until after the advent ofdigital and other technologies that successful plasma televisions

became possible. According to Wikepedia "a plasma display is

-

8/12/2019 Chapter Two Transparencies

12/61Page | 12

an emissive flat panel display where light is created by phosphors excited by a plasma discharge between two flat panels of glass."Various forms of plasma screens have been in use since 1983.The first plasma TV screen for general public use was retailed in1997 by Fujitsu, followed by Phillips and then Pioneer. All were42 inches in size, and the prices were around $15,000 .

LG Electronics PN450042PN4500 42-Inch Plasma720p 600Hz TV (Black)

by LG See the Amazon Page for this brand 4.8 out of 5 stars See all reviews (18 customer reviews )

List Price: $449.99Price: $439.97

http://wiki.answers.com/Q/What_year_did_the_first_plasma_tv_come_outhttp://wiki.answers.com/Q/What_year_did_the_first_plasma_tv_come_outhttp://wiki.answers.com/Q/What_year_did_the_first_plasma_tv_come_outhttp://www.amazon.com/s/ref=bl_sr_electronics?_encoding=UTF8&field-brandtextbin=LG&node=172282http://www.amazon.com/s/ref=bl_sr_electronics?_encoding=UTF8&field-brandtextbin=LG&node=172282http://www.amazon.com/s/ref=bl_sr_electronics?_encoding=UTF8&field-brandtextbin=LG&node=172282http://www.amazon.com/s/ref=bl_sr_electronics?_encoding=UTF8&field-brandtextbin=LG&node=172282http://www.amazon.com/s/ref=bl_sr_electronics?_encoding=UTF8&field-brandtextbin=LG&node=172282http://www.amazon.com/LG-Electronics-PN4500-42PN4500-42-Inch/product-reviews/B00BB1C140/ref=dp_top_cm_cr_acr_img?ie=UTF8&showViewpoints=1http://www.amazon.com/LG-Electronics-PN4500-42PN4500-42-Inch/product-reviews/B00BB1C140/ref=dp_top_cm_cr_acr_txt?ie=UTF8&showViewpoints=1http://www.amazon.com/LG-Electronics-PN4500-42PN4500-42-Inch/product-reviews/B00BB1C140/ref=dp_top_cm_cr_acr_txt?ie=UTF8&showViewpoints=1http://www.amazon.com/LG-Electronics-PN4500-42PN4500-42-Inch/product-reviews/B00BB1C140/ref=dp_top_cm_cr_acr_txt?ie=UTF8&showViewpoints=1http://www.amazon.com/LG-Electronics-PN4500-42PN4500-42-Inch/product-reviews/B00BB1C140/ref=dp_top_cm_cr_acr_txt?ie=UTF8&showViewpoints=1http://www.amazon.com/LG-Electronics-PN4500-42PN4500-42-Inch/product-reviews/B00BB1C140/ref=dp_top_cm_cr_acr_img?ie=UTF8&showViewpoints=1http://www.amazon.com/LG-Electronics-PN4500-42PN4500-42-Inch/product-reviews/B00BB1C140/ref=dp_top_cm_cr_acr_img?ie=UTF8&showViewpoints=1http://www.amazon.com/s/ref=bl_sr_electronics?_encoding=UTF8&field-brandtextbin=LG&node=172282http://www.amazon.com/s/ref=bl_sr_electronics?_encoding=UTF8&field-brandtextbin=LG&node=172282http://wiki.answers.com/Q/What_year_did_the_first_plasma_tv_come_out -

8/12/2019 Chapter Two Transparencies

13/61Page | 13

May-June 1932

-

8/12/2019 Chapter Two Transparencies

14/61

-

8/12/2019 Chapter Two Transparencies

15/61Page | 15

A GRAPHIC VIEW OF COST BEHAVIOR

100 2000

$3,000

$6,000

Microwaves produced

Total Variable Cost

100 2000

$9,000

Microwaves produced

Total Fixed Cost

RELEVANT RANGEIf activity changes enough, fixed costs may change. For example,if microwave production were doubled, another factory buildingmight have to be rented.

The relevant range is the range of activity within which theassumptions that have been made about variable and fixed costsare valid. For example, the relevant range within which total fixedfactory rent is $9,000 per month might be 1 to 200 microwavesproduced per month.

Range of activity over which the theoretical cost behavior patternis assumed to describe actual costs costs may not behaveoutside relevant range. Different costs can have different relevantranges.

-

8/12/2019 Chapter Two Transparencies

16/61Page | 16

STEP COSTS

Fixed costs over one range of activity and shifts abruptly to adifferent level and are fixed in those adjacent ranges of activities.

A cost that increases with volume in steps (semi-fixed cost), i.e.

supervisor (can only handle so many people),warehouse/manufacturing space.

Fixed costs are referred to as capacity costs as they represent theresources that provide the capability of making goods and

services.

- 2,000 4,000 6,000 8,000

10,000

12,000 14,000 16,000 18,000 20,000

Q 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52

Step Costs

-

8/12/2019 Chapter Two Transparencies

17/61Page | 17

MIXED COSTS

A mixed (or semi-variable) cost contains elements of bothvariable and fixed costs.

Example: Lori Yang leases an automated photo developer for

$2,500 per year plus 2 per photo developed.

Equation of a straight line: Y = a + bX

Y = $2,500 + $0.02X

-

8/12/2019 Chapter Two Transparencies

18/61Page | 18

SCATTERGRAPH METHOD

As the first step in the analysis of a mixed cost, cost and activityshould be plotted on a scattergraph. This helps to quicklydiagnose the nature of the relation between cost and activity.

Example: Piedmont Wholesale Florists has maintained records ofthe number of orders and billing costs in each quarter over thepast several years.

Quarter Number of Orders Billing Costs Year 1 1st 1,500 $42,000

2nd 1,900 $46,0003rd 1,000 $37,0004th 1,300 $43,000

Year 2 1st 2,800 $54,0002nd 1,700 $47,0003rd 2,100 $51,0004th 1,100 $42,000

Year 3 1st 2,000 $48,0002nd 2,400 $53,0003rd 2,300 $49,000

These data are plotted on the next page, with the activity(number of orders) on the horizontal X axis and the cost (billingcosts) on the vertical Y axis.

-

8/12/2019 Chapter Two Transparencies

19/61Page | 19

A COMPLETED SCATTERGRAPH

The relation between the number of orders and the billing cost isapproximately linear. (A straight line that seems to reflect thisbasic relation was drawn with a ruler on the scattergraph.)

Because a straight line seems to be a reasonable fit to the data,we can proceed to estimate the variable and fixed elements ofthe cost using one of the following methods.

1. High-low method.

2. Least-squares regression method.

$0

$10,000

$20,000

$30,000

$40,000

$50,000

$60,000

0 500 1,000 1,500 2,000 2,500 3,000

$48,000

Number of Orders

B i l l i n g

C o s

t s

X

Y

Regression Line

-

8/12/2019 Chapter Two Transparencies

20/61Page | 20

ANALYSIS OF MIXED COSTS: HIGH-LOWMETHOD

EXAMPLE: Kohlson Company has incurred the following shippingcosts over the past eight months:

Units Sold Shipping CostJanuary .. 6,000 $66,000February . 5,000 $65,000March ..... 7,000 $70,000

April ....... 9,000 $80,000May ........ 8,000 $76,000June ....... 10,000 $85,000July ........ 12,000 $100,000

August .... 11,000 $87,000With the high-low method, only the periods in which the lowestactivity and the highest activity occurred are used to estimate thevariable and fixed components of the mixed cost.

Units Sold Shipping CostHigh activity level, July .. 12,000 $100,000Low activity level, February 5,000 65,000Change ......................... 7,000 $ 35,000

Change in cost $35,000 Variable cost= = =$5 per unitChange in activity 7,000 units

Fixed cost = Total cost - Variable cost element

= $100,000 - (12,000 units $5 per unit)

= $40,000

The cost formula for shipping cost is: Y = $40,000 + $5X

-

8/12/2019 Chapter Two Transparencies

21/61Page | 21

EVALUATION OF THE HIGH-LOW METHOD

The high-low method suffers from two major defects:

1. It throws away all but two data points.

2. The periods with the highest and lowest volumes are oftenunusual (outliers).

$0

$20,000

$40,000

$60,000

$80,000

$100,000

0 2,000 4,000 6,000 8,000 10,000 12,000

Units Sold

S h i p p

i n g

C o s

t s

Y

X

VariableCost

$5/unit

Fixed

Cost$40,000

low level of

ac t iv i ty

high level of ac t iv i ty

-

8/12/2019 Chapter Two Transparencies

22/61Page | 22

LEAST-SQUARES REGRESSION METHOD

The least-squares regression method for analyzing mixed costsuses mathematical formulas to determine the regression line thatminimizes the su m of the squared errors.

-

8/12/2019 Chapter Two Transparencies

23/61Page | 23

LEAST-SQUARES REGRESSION (continued)

Example: Montrose Hospital operates a cafeteria for employees.Management would like to know how cafeteria costs are affectedby the number of meals served.

Meals Served X Total Cost Y April ......... 4,000 $9,500May ......... 1,000 $4,000June ......... 3,000 $8,000July .......... 5,000 $10,000

August ..... 10,000 $19,500September 7,000 $14,000

Statistical software or a spreadsheet program can do the

computations required by the least-squares method. The resultsin this case are:

Intercept (fixed cost) .... $2,433Slope (variable cost) ..... $1.68r2 ................................. 0.99

Statistical software or a spreadsheet program can do thecomputations required by the least-squares method. The results

in this case are:Month x y xy x2 y2 Apr 4,000.00 9,500.00 38,000,000.00 16,000,000.000 90,250,000.00 May 1,000.00 4,000.00 4,000,000.00 1,000,000.000 16,000,000.00 Jun 3,000.00 8,000.00 24,000,000.00 9,000,000.000 64,000,000.00 Jul 5,000.00 10,000.00 50,000,000.00 25,000,000.000 100,000,000.00

Aug 10,000.00 19,500.00 195,000,000.00 100,000,000.000 380,250,000.00 Sep 7,000.00 14,000.00 98,000,000.00 49,000,000.000 196,000,000.00

30,000.00 65,000.00 409,000,000.00 200,000,000.000 846,500,000.00

a= 2,433.33 b= 1.68

r 2= 0.99618898

-

8/12/2019 Chapter Two Transparencies

24/61Page | 24

The fixed cost is therefore $2,433 per month and the variablecost is $1.68 per meal served, or:

Y = $2,433 + $1.68X, where X is meals served.

r2 is a measure of the goodness of fit of the regression line. In

this case, it indicates that 99% of the variation in cafeteria costsis due to the number of meals served. This suggests an excellentfit.

-

8/12/2019 Chapter Two Transparencies

25/61Page | 25

LEAST-SQUARES REGRESSION (continued)

EXAMPLE: Kohlson Company has incurred the following shippingcosts over the past eight months:

Units Sold Shipping Cost

January .. 6,000 $66,000February . 5,000 $65,000March ..... 7,000 $70,000

April ....... 9,000 $80,000May ........ 8,000 $76,000June ....... 10,000 $85,000July ........ 12,000 $100,000

August .... 11,000 $87,000

With the high-low method, we previously calculated the followingequation:

Y = $40,000 + $5X

Using linear regression method, we get:Month x y xy x2 y2

Jan 6,000 66,000 396,000,000 36,000,000 4,356,000,000 Feb 5,000 65,000 325,000,000 25,000,000 4,225,000,000 Mar 7,000 70,000 490,000,000 49,000,000 4,900,000,000

Apr 9,000 80,000 720,000,000 81,000,000 6,400,000,000 May 8,000 76,000 608,000,000 64,000,000 5,776,000,000 Jun 10,000 85,000 850,000,000 100,000,000 7,225,000,000 Jul 12,000 100,000 1,200,000,000 144,000,000 10,000,000,000

Aug 11,000 87,000 957,000,000 121,000,000 7,569,000,000 68,000 629,000 5,546,000,000 620,000,000 50,451,000,000

Number of observations= 8

a= 38,250.00 b= 4.75

r 2= 0.992566503

Y = $38,250 + $4.75X

-

8/12/2019 Chapter Two Transparencies

26/61Page | 26

TRADITIONAL VERSUS CONTRIBUTIONINCOME STATEMENT

If sales doubled, what would be the net operating income?

Traditional Format = $2,000?

Contribution Format = $6,000!

-

8/12/2019 Chapter Two Transparencies

27/61Page | 27

COST FLOWS IN A MANUFACTURINGCOMPANY

-

8/12/2019 Chapter Two Transparencies

28/61Page | 28

COST FLOWS EXAMPLE

EXAMPLE: Ryarder Company incurred the following costs lastmonth:

Purchases of raw materials .... $200,000

Direct labor ........................... $270,000Manufacturing overhead ........ $420,000

Total Costs last month $890,000

But:

Some of the goods sold this month may have been producedin a previous month.

Some of the costs listed above were incurred to make goodsthat were not sold this month and may not be sold for anumber of months.

Therefore:

Cost of goods sold does not necessarily equal the sum of theabove costs.

We need to determine the values of the various inventories;raw materials, work in process and finished goods.

-

8/12/2019 Chapter Two Transparencies

29/61Page | 29

COST FLOWS EXAMPLE (continued)

Additional data for Ryarder Company:

Raw materials inventory:Beginning raw materials inventory ...... $10,000

Purchases of raw materials ................ $200,000Ending raw materials inventory .......... $30,000Raw materials used in production ....... ?

Work in process inventory:Beginning work in process inventory... $40,000Total manufacturing costs .................. ?Ending work in process inventory ....... $60,000

Cost of goods manufactured (i.e., finished) ?

Finished goods inventory:Beginning finished goods inventory .... $130,000Cost of goods manufactured (i.e., finished) ?Ending finished goods inventory ......... $80,000Cost of goods sold ............................. ?

-

8/12/2019 Chapter Two Transparencies

30/61Page | 30

INVENTORY FLOWS

Basic Equation for Inventory Accounts:Beginning Additions Ending Withdrawals + = +balance to inventory balance from inventory

or

Withdrawals Beginning Additions Ending = + -from inventory balance to inventory balance

-

8/12/2019 Chapter Two Transparencies

31/61Page | 31

COST FLOWS EXAMPLE (continued)

Computation of raw materials used in production

Beginning raw materials inventory ....... $ 10,000+ Purchases of raw materials .................. 200,000 Ending raw materials inventory ............ 30,000= Raw materials used in production ........ $180,000

Computation of total manufacturing cost

Raw materials used in production ........ $180,000+ Direct labor ........................................ 270,000+ Manufacturing overhead ...................... 420,000= Total manufacturing cost ..................... $870,000

Computation of cost of goods manufacturedBeginning work in process inventory .... $ 40,000

+ Total manufacturing cost ..................... 870,000 Ending work in process inventory ......... 60,000= Cost of goods manufactured (i.e., finished)

.......................................................$850,000

Computation of cost of goods sold

Beginning finished goods inventory ...... $130,000+ Cost of goods manufactured (i.e., finished)

.......................................................850,000

Ending finished goods inventory .......... 80,000= Cost of goods sold .............................. $900,000

-

8/12/2019 Chapter Two Transparencies

32/61Page | 32

SCHEDULE OF COST OF GOODSMANUFACTURED

Ryarder CompanySchedule of Cost of Goods Manufactured

Direct materials:Beginning raw materials inventory .. $ 10,000

Add: Purchases of raw materials..... 200,000Raw materials available for use ...... 210,000Deduct: Ending raw materials

inventory ....................................30,000

Raw materials used in production ... $180,000Direct labor ..................................... 270,000Manufacturing overhead ................... $420,000Total manufacturing cost .................. 870,000

Add: Beginning work in processinventory ......................................

40,000

910,000Deduct: Ending work in process

inventory ......................................60,000

Cost of goods manufactured ............. $850,000

Cost of Goods SoldBeginning finished goods inventory ... $130,000

Add: Cost of goods manufactured ..... 850,000Goods available for sale ................... 980,000Deduct: Ending finished goods inventory 80,000Cost of goods sold ........................... $900,000

-

8/12/2019 Chapter Two Transparencies

33/61Page | 33

COST CLASSIFICATIONS FOR ASSIGNING COSTSTO COST OBJECTS

COST OBJECT

A cost object is anything for which cost data are desired.

Examples of cost objects:

Products Customers Departments Jobs

DIRECT COSTS

A direct cost is a cost that can be easily and conveniently tracedto a particular cost object.

Examples of direct costs:

The direct costs of a Ford SUV would include the cost ofthe steering wheel purchased by Ford from a supplier, thecosts of direct labor workers, the costs of the tires, and soon.

The direct costs of a hospitals radiology departmentwould include X-ray film used in the department, thesalaries of radiologists, and the costs of radiology labequipment.

INDIRECT COSTS

An indirect cost is a cost that cannot be easily and convenientlytraced to a particular cost object.

Examples of indirect costs: Manufacturing overhead, such as the factory managers

salary at a multi-product plant, is an indirect cost of anyone product.

General hospital administration costs are indirect costs ofthe radiology lab.

-

8/12/2019 Chapter Two Transparencies

34/61Page | 34

COST CLASSIFICATIONS FOR DECISION-MAKINGDIFFERENTIAL/INCREMENTAL COST

Every decision involves choosing from among at least twoalternatives. Any cost that differs between alternatives is adifferential cost or incremental cost. Only the differential costs are

relevant in making a decision.EXAMPLE: Bill is currently employed as a lifeguard, but he hasbeen offered a job in an auto service center in the same town.When comparing the two jobs, the differential revenues and costsare:

Auto DifferentialLife- Service costs and

guard Center revenuesMonthly salary ............... $1,200 $1,500 $300Monthly expenses:

Commuting ................. 30 90 60Meals ..........................

................................150 150 0

Apartment rent ............ 450 450 0Uniform rental ............. 0 50 50

Sunscreen ................... 10 0 (10)Total monthly expenses .. 640 740 100Net monthly income ....... $ 560 $ 760 $200

-

8/12/2019 Chapter Two Transparencies

35/61Page | 35

OPPORTUNITY COST An opportunity cost is the potential benefit given up whenselecting one course of action over another. It is its value when itis used in its next-best alternative.

EXAMPLE: Linda has a job in the campus bookstore and is paid$65 per day. One of her friends is getting married and Lindawould like to attend the wedding, but she would have to miss aday of work. If she attends the wedding, the $65 in lost wageswill be an opportunity cost of attending the wedding.

EXAMPLE: The reception for the wedding mentioned above will beheld in the ballroom at the Lexington Club. The manager of the

Lexington Club had to decide between accepting the booking forthe wedding reception and accepting a booking for a corporateseminar. The hall could have been rented to the corporation for$600. The lost rental revenue of $600 is an opportunity cost ofaccepting the reservation for the wedding.

-

8/12/2019 Chapter Two Transparencies

36/61Page | 36

SUNK COST

A sunk cost is a cost that has alreadybeen incurred and that cannot bechanged by any decision made nowor in the future. Sunk costs areirrelevant and should be ignored indecisions.

Some managers mistakenly attempt to recover the costs of pastdecisions in their pricing or marketing decisions for new productsand processes.

For example, an extensive research and development effortproduces a new product. The decision to market the productdepends only on the cost of new facilities to produce the product,its sales potential and its costs of production. The amount alreadyspent on R&D is irrelevant to the marketing decision; it hasalready been spent and the expenditure will be unaffected bywhether the product is marketed or not. It has become a sunkcost.

EXAMPLE: Linda has already purchased a ticket to a rock concertfor $35. If she goes to the wedding, she will be unable to attendthe concert. The $35 is a sunk cost that she should ignore whendeciding whether or not to attend the wedding. [However, anyamount she can get by reselling the ticket is NOT a sunk cost.

And while she should ignore the $35 sunk cost, she should notignore the enjoyment she would get if she were to attend the

concert.]

-

8/12/2019 Chapter Two Transparencies

37/61Page | 37

ACCOUNTING FOR LABOR COSTS

Labor costs can be categorized as follows:

Direct labor

Indirect labor(part of manufacturing

overhead) Other labor costsDiscusse ear ier Janitors I e timeSupervisors Overtime premiumMaterials handlers Labor fringe

benefitsEngineersNight security guardsMaintenance workers

IDLE TIME

Idle time represents the wages of direct labor workers who areidle due to machine breakdowns, material shortages, powerfailures, and the like. The cost of idle time is often added tomanufacturing overhead.

EXAMPLE: An assembly line worker is idle for 2 hours during theweek due to a power failure. If the worker is paid $15 per hourand works a normal 40 hour week, labor cost would be allocated

as follows between direct labor and manufacturing overhead:

Direct labor cost ($15 per hour 38 hours) ...... $570Manufacturing overhead cost ($15 per hour 2 hours)

....................................................................30

Total cost for the week ..................................... $600

-

8/12/2019 Chapter Two Transparencies

38/61Page | 38

OVERTIME PREMIUM Any overtime premium paid to factory workers (direct as well asindirect labor) is usually considered to be part of manufacturingoverhead .

EXAMPLE: Assume again that an assembly line worker is paid $15per hour. The worker is paid time and a half for overtime (time inexcess of 40 hours per week). During a given week this employeeworks 46 hours and has no idle time. Labor cost would beallocated as follows:

Direct labor cost ($15 per hour 46 hours) ........... $690Manufacturing overhead cost ($7.50 per hour 6 hours) 45Total cost for the week .......................................... $735

LABOR FRINGE BENEFITSLabor fringe benefits are made up of employment related costspaid by the employer. These costs are handled in two differentways by companies:

Many companies treat all such costs as indirect labor andadd them to manufacturing overhead .

Other companies treat that portion of fringe benefits thatrelates to direct labor as additional direct labor cost .

-

8/12/2019 Chapter Two Transparencies

39/61Page | 39

Example (Kaplan, 1982):

The Connors Company manufactures a basic chemical, Noxium,which can be sold directly or processed further into a morevaluable chemical, Valmite. The Connors Company can sell allthe Noxium that it produces at a price of $100 per ton. The

Valmite market is more volatile, with prices ranging between$125 and $200 per ton. The Connors Company accountingsystem reports the following costs for Noxium and Valmite:

Noxium ValmiteDirect materials (VC) $50Direct labor (VC) 10Manufacturing Overhead 30

Cost per ton $90 $90Processing costs: Additional direct materials (VC) 20 Additional direct labor (VC) 10Manufacturing Overhead 15

Cost per ton $135Selling price (SP) $100 $125-200

Further investigation reveals that the manufacturing overheadcost per ton is obtained by dividing the total estimatedmanufacturing overhead cost for the year by the total hours ofavailable capacity. The manufacturing overhead cost isallocated to products in proportion to processing time.Manufacturing overhead costs, however, do not vary with theamount of production. Two hours are required to produce a tonof Noxium, and one additional hour is needed to process thefinished Noxium into Valmite ($15 per DLH). Both productsshare the same production facilities, which can be usedinterchangeably to produce Noxium or Valmite.

-

8/12/2019 Chapter Two Transparencies

40/61Page | 40

Productionand sale ofValmite shouldbediscontinued

whenever its

The cost ofproducing

Valmite isactually $130 (not $100),but it wouldstill be a

rofitable

The sales manager of the Connors Companyargues that production and sale of Valmiteshould be discontinued whenever its sellingprice drops below $135 per ton , sinceotherwise the firm would be losing money oneach ton sold. This reasoning is clearlyfallacious, since, among other failings, it doesnot distinguish between the fixed and variable costs ofproduction. The manufacturing overhead costs charged to bothNoxium and Valmite are fixed costs that will not change ifproduction of Valmite is discontinued. On a variable cost basis,Noxium costs $60 per ton to produce, so that its contributionmargin per ton sold is $40 (SP less VC). The $60 is also the

variable cost of using Noxium as an input material for Valmite.Therefore the total variable cost of Valmite is $90 (the $60Noxium cost plus the $30 direct materials and direct labor costfor additional processing). Even with a selling price as low as$135 per ton, Valmite shows a contribution margin per ton of$45. Thus, the initial analysis shows that by distinguishingbetween fixed and variable costs, we are not misled intothinking that the Connors Company is losing money on sales of

Valmite.But this is only the start of the complete analysis. For if Noxiumcan be sold outside the firm at a price of $100 per ton, everyton of Noxium that is used to produce Valmite costs thecompany not only the $60 variable cost but the lost $40contribution margin that could otherwise beearned if it were sold. Therefore the cost ofNoxium to produce Valmite is actually $100 (itsopportunity cost ), not $60. With thisrefinement, the cost of producing Valmite isactually $130 (not $100), but it would still be aprofitable product at a selling price of $135. Infact, at this stage, Valmite at a price of $135 perton would appear to be more profitable thanNoxium, since it can show a profit even after paying for the

-

8/12/2019 Chapter Two Transparencies

41/61Page | 41

Only when the selling pricereaches $150 , are the two

productsequally

profitable.

foregone contribution margin of Noxium. At the $125 price atthe low end of the price range, Valmite does not cover itsvariable plus opportunity costs.

We now reach the final stage of the analysis, where we use theinformation that Noxium and Valmite share the same

production facilities . Every hour used to produce a ton of Valmite consumes an hour that otherwise could be used toproduce a half-ton of Noxium. Therefore the opportunity cost ofproducing a ton of Valmite is not only the $40 contributionmargin from not selling a ton of Noxium but also the loss inproduction time that could otherwise be used to produceadditional amounts of Noxium. If the price of Valmite is only$135, then each ton manufactured produces a contribution

margin (after paying the opportunity cost ofNoxium) of $5. But the one hour of time requiredto produce the ton of Valmite could have beenused to produce a half-ton of Noxium, whichwould generate a contribution margin of $20 (0.50x 40). Thus, after the opportunity cost of thescarce production facilities is recognized, a $135selling price for Valmite makes it a less profitable product than

Noxium. Only when the selling price reaches $150, where Valmite is generating a net contribution margin of $20per hour of production time (the same as Noxium), arethe two products equally profitable.

In summary, the opportunity cost of producing a ton of Valmite is the $100 foregone by not selling the ton of Noxiumrequired for Valmite plus the $20 in contribution margin lost bynot producing a half-ton of Noxium during the hour that theproduction facilities are used to produce the ton of Valmite.

Adding the direct materials and labor cost of $30 for Valmite to the $120 opportunity cost yields the $150incremental cost (or foregone revenue) for producing Valmiterather than Noxium. Note that traditional accounting would notshow the $120 opportunity cost of using Noxium to produce

Valmite.

-

8/12/2019 Chapter Two Transparencies

42/61Page | 42

Summary:

Failure to consider alternative uses for the firms resources could lead one to underestimate theopportunity cost of these resources and, consequently,to a less than optimal utilization.

-

8/12/2019 Chapter Two Transparencies

43/61Page | 43

APPENDIX 2A: LEAST-SQUARES REGRESSIONCOMPUTATIONS

Example: Montrose Hospital operates a cafeteria for employees.Management would like to know how cafeteria costs are affectedby the number of meals served.

Meals Served X Total Cost Y April ......... 4,000 $9,500May ......... 1,000 $4,000June ......... 3,000 $8,000July .......... 5,000 $10,000

August ..... 10,000 $19,500September 7,000 $14,000

Statistical software or a spreadsheet program can do thecomputations required by the least-squares method. The resultsin this case are:

Intercept (fixed cost) .... $2,433 Slope (variable cost) ..... $1.68 R 2 ................................ 0.99

The fixed cost is therefore $2,433 per month and the variable

cost is $1.68 per meal served, or: Y = $2,433 + $1.68X,where X is meals served.

$-

$5,000

$10,000

$15,000

$20,000

$25,000

- 2,000 4,000 6,000 8,000 10,000 12,000

Total Cost

Total Cost

-

8/12/2019 Chapter Two Transparencies

44/61Page | 44

0

5000

10000

15000

20000

25000

0 2000 4000 6000 8000 10000 12000

y

X

R 2 is a measure of the goodness of fit of the regression line. Inthis case, it indicates that 99% of the variation in cafeteria costsis due to the number of meals served. This suggests an excellentfit.

-

8/12/2019 Chapter Two Transparencies

45/61Page | 45

QUALITY COSTS (Appendix 2B)

The costs of correcting defective units before they reachcustomers are called internal failure costs. Examples:

Scrapped units.

Rework of defective units. Costs that are incurred by releasing defective units to

customers are called external failure costs. Examples:

Costs of fixing products under warranty. Loss of sales due to a tarnished reputation.

The costs of internal and external failures can be avoidedby:

Preventing defects.

Finding defective units before they are released.The costs associated with these activities are called preventioncosts and appraisal costs, respectively.

Generally, prevention is the best policy . It is usually fareasier and less expensive to prevent defects than to fixthem.

By KEN THOMAS, Associated PressWriter Tue Sep 29, 7:42 pm ETWASHINGTON Toyota Motor Corp.said Tuesday it will recall 3.8 millionvehicles in the United States, thecompany's largest-ever U.S. recall, toaddress problems with a removable floor mat that could causeaccelerators to get stuck and lead to a crash. The recall willinvolve popular models such as the Toyota Camry, the top-selling passenger car in America, and the Toyota Prius, the best-selling gas-electric hybrid.

http://news.yahoo.com/nphotos/Toyota-dealership/photo/090929/480/e3f82e9c90784d30b8b736f80065329e/s:/ap/20090929/ap_on_bi_ge/us_toyota_floor_mats -

8/12/2019 Chapter Two Transparencies

46/61Page | 46

Ford Recalls Millions of Firestone Tires Number two automaker cites safety as reason behind one of the largest voluntaryrecalls in automotive history By Peter D. duPre

Ford Motor Company launched one of the largest automotive recalls in history May 22with the announcement it will replace all Firestone Wilderness AT tires on its vehicles.

Jacques Nasser, Ford president and CEO, said the move was designed to ensure the

safety of Ford customers and bolster the company's position as a leader in customersatisfaction.

"We feel it is ourresponsibility to actimmediately," said Nasser."Our customers look to usto ensure the safety of ourvehicle. That is why Fordwill replace the AT tires onall our vehicles. The costto Ford will be more than

$2 billion after taxes , butthe greater concern is theinconvenience to, and thesafety of, our customers."

Ford issued a recall lastyear on the FirestoneWilderness tires, replacingalmost 6 million tires onFord vehicles, mainlyExplorer. This newestrecall includes all the non-recall replacement tiresfrom last summer and allWilderness tires currently installed on current and new model Ford vehicles.

Ford has volun tar ily reca l led so me 13 mi l l ion Fi res tone Wilderness AT t i res dueto safe ty con cerns . They say t read fa i lure on th ese t i res i s h igher than no rmal .

"Some of the tires we are replacing do not have a substantial risk of failure," Nassercontinued, "but rather than segregate the tires, we are offering to replace all theWilderness AT tires to eliminate any doubt by our customers about the safety of theirtires."

According to John Rintamaki, Ford group vice president and chief of staff, the decisionto voluntarily recall the tires was made after an intensive study of the tires.

"The process that brought us to this decision was intensive," said Rintamaki. "It isimportant to understand that the decision (to recall the tires) was made by studying thefield data, information supplied by NHTSA, and by completing our own technicalanalysis."

"We have been analyzing the field data over the past several days and it shows that thefailure rate is increasing. The data showed that even the non-recalled Wilderness ATtires will continue to have a failure rate that is higher than acceptable," Rintamakicontinued.

-

8/12/2019 Chapter Two Transparencies

47/61Page | 47

What is the acceptable failure rate? According to Rintamaki, the only standard ofcomparison for tire failures is the 2.9 million Goodyear installed on Ford Explorers sincelast year (as a replacement for the recalled Firestone tires). He said that the companyinstalled an equal number of Goodyear replacement tires and Firestone replacementtires and pointed out that of the 2.9 million Goodyear tires, there were just two treadseparations. Out of the 2.9 million Firestone replacement tires, the company noted1,183 tread separations.

Rintamaki said that Ford's replacement plan will concentrate first on the oldest Firestonetires installed on its vehicles as the company feels that they have highest chance offailure.

"Tires less than three years old have a lower failure rate," said Rintamaki, "so we willreplace older tires first, then the newer ones. But all Wilderness tires installed on Fordvehicles will be replaced."

Rintamaki also said that the tires will be replaced at Ford dealerships and that the

company will reimburse Ford customers for any replacement Firestone tires purchasedfrom other sources up to $130 for each tire. He also said that the company was idlingthree truck plants in the U.S. while the changeover to replacement tires was beingmade.

-

8/12/2019 Chapter Two Transparencies

48/61Page | 48

Toyota to hold world's biggest car recall in 16years

David McNew / Getty Images, fileToyota is to recall over 7 million vehicles over faulty window switches.By Paul A. Eisenstein, NBC News contributor

UPDA TED 9:43 a.m. EDT : Toyota Motor Co., still in recovery mode after a seriesof problems that plagued its global operations over the last three years, announcedWednesday it is recalling 2.5 million vehicles sold in the United States due to a

potential risk of fire.The recall involves 7.43 million vehicles worldwide sold under the Toyota andScion brands. This is the largest safety-related service action the maker hasannounced since it began a series of recalls related to the risk of unintendedacceleration in late 2009. That and other safety issues led Toyota to recall 14million vehicles in 2009 and 2010.

It's the biggest single recall since Ford Motor Co pulled back 7.9 million vehiclesin 1996.

Many of the vehicles involved in the new Toyota recall also were called back oneor more times due to unintended acceleration issues.

The latest recall is the result of a problem with a potentially defective powerwindow switch on the drivers side of the affected vehicles which, the maker says,may experience a 'notchy' or sticky feel during operation. If commerciallyavailable lubricants are applied to the switch in an attempt to address the 'notchy'or sticky feel, melting of the switch assembly or smoke could occur and lead to afire under some circumstances.

http://bottomline.nbcnews.com/_news/2012/10/10/14333663-toyota-to-hold-worlds-biggest-car-recall-in-16-years?litehttp://bottomline.nbcnews.com/_news/2012/10/10/14333663-toyota-to-hold-worlds-biggest-car-recall-in-16-years?litehttp://bottomline.nbcnews.com/_news/2012/10/10/14333663-toyota-to-hold-worlds-biggest-car-recall-in-16-years?lite -

8/12/2019 Chapter Two Transparencies

49/61Page | 49

Toyota already announced recalls for several models involving similar windowswitches and in February, the National Highway Traffic Safety Administrationannounced it would open an investigation into the issue. But at the time it focusedon just 830,000 Camry and RAV-4 models sold during the 2007 model year.

The massive size of the new recall underscores the risks manufacturers like Toyotaface when they share basic components on a wide range of vehicles hoping to

improve manufacturing economies of scale.In the U.S., the vehicles involved in the latest recall include:

2007 2009 Camry sedans, approx. 938,100 vehicles; 2007 2009 Camry Hybrids, approx. 116,800 vehicles; 2007 2009 RAV4 crossovers, approx. 336,400 vehicles; 2007 2009 Tundra pickups, approx. 337,100 vehicles; 2007 2008 Yaris subcompacts, approx. 110,300 vehicles; 2008 Highlander SUVs, approx. 135,400 vehicles; 2008 Highlander Hybrids, approx. 23,200 vehicles; 2008 2009 Scion xD models, approx. 34,400 vehicles; 2008 2009 Scion xA models, approx. 77,500 vehicles; 2008- 2009 Sequoia SUVs, approx. 38,500 vehicles; 2009 Corolla compacts, approx. 270,900 vehicles; and 2009 Matrix crossovers; approx. 53,800 vehicles.

To check whether your call is involved, you can go to Toyota's recall web page . The maker estimates the inspection and repair process will take little more than anhour and involves the disassembly of the master switch and, if necessary, theapplication of a special fluorine grease.

NHTSA has received more than 200 reports of problems involving the defectiveswitch including fires, though there are no known crashes or injuries. At least 39similar problems were reported in Japan, where 460,000 Toyota vehicles wererecalled.

Another 1.39 million vehicles are subject to the new recall in Europe, while themassive safety campaign also covers Australia, China and other parts of Asia andthe Mideast.

In the U.S. market, the Toyota announcement is the largest recall of the year andcould revive concerns about quality control at a manufacturer normally at the topof the charts. Such concerns plagued the maker during much of 2009 and 2010 andofficials including President Akio Toyoda were hauled before Congress to explainthe massive recalls related to the unintended acceleration issue.

Toyoda has repeatedly promised, since that sca ndal began, to ramp up the makersquality control process, and it is important to note that all the vehicles impacted bythe latest recall were produced during or before the 2009 model year. Nonetheless,the new service action will again put an unwanted spotlight on the maker.

http://bottomline.nbcnews.com/_news/2012/10/10/14333663-toyota-to-hold-worlds-biggest-car-recall-in-16-years?litehttp://bottomline.nbcnews.com/_news/2012/10/10/14333663-toyota-to-hold-worlds-biggest-car-recall-in-16-years?litehttp://bottomline.nbcnews.com/_news/2012/10/10/14333663-toyota-to-hold-worlds-biggest-car-recall-in-16-years?litehttp://www.toyota.com/recall/http://www.toyota.com/recall/http://www.toyota.com/recall/http://bottomline.nbcnews.com/_news/2012/10/10/14333663-toyota-to-hold-worlds-biggest-car-recall-in-16-years?litehttp://bottomline.nbcnews.com/_news/2012/10/10/14333663-toyota-to-hold-worlds-biggest-car-recall-in-16-years?litehttp://bottomline.nbcnews.com/_news/2012/10/10/14333663-toyota-to-hold-worlds-biggest-car-recall-in-16-years?litehttp://www.toyota.com/recall/http://bottomline.nbcnews.com/_news/2012/10/10/14333663-toyota-to-hold-worlds-biggest-car-recall-in-16-years?lite -

8/12/2019 Chapter Two Transparencies

50/61Page | 50

Toyota had more vehicles involved in recalls than any other maker in the U.S. in2010 and came just short of achieving that dubious distinction again in 2011. Alarge recall late in the year, however, put Honda at the top of the list. Indeed,Honda recalled 1.7 million vehicles as part of three separate service actions lastweek while NHTSA launched an investigation into potential problems involvinganother 600,000 vehicles.

While there have been scores of recalls announced this year involving every brandfrom Chevrolet to Ferrari, with todays announcement, it appears that both Toyotaand Honda are again in an unwanted race to lead the recall list again for 2012.

http://bottomline.nbcnews.com/_news/2012/10/10/14333663-toyota-to-hold-worlds-biggest-car-recall-in-16-years?litehttp://bottomline.nbcnews.com/_news/2012/10/10/14333663-toyota-to-hold-worlds-biggest-car-recall-in-16-years?litehttp://bottomline.nbcnews.com/_news/2012/10/10/14333663-toyota-to-hold-worlds-biggest-car-recall-in-16-years?litehttp://www.thedetroitbureau.com/2012/10/as-honda-keeps-racking-up-recalls-will-it-tarnish-makers-quality-reputation/http://www.thedetroitbureau.com/2012/10/as-honda-keeps-racking-up-recalls-will-it-tarnish-makers-quality-reputation/http://bottomline.nbcnews.com/_news/2012/10/10/14333663-toyota-to-hold-worlds-biggest-car-recall-in-16-years?lite -

8/12/2019 Chapter Two Transparencies

51/61Page | 51

Faulty brakes cause recall of 76,200BMWsMatt Schmitz and Chris Woodyard, Cars.com and USA TODAY 7:10 p.m. EDT October 1, 2013

About 76,200 BMWs equipped with 2-liter four-cylindergasoline engines are being recalled out of fear of a glitch thatcould cause the brakes to malfunction.

The recall includes the 1 Series, 3 Series and 5 Series sedans, aswell as the X1 and X3 crossovers and Z4 sports car from the2012 to 2014 model years.

The recalled vehicles could have an interruption in the oil supplythat could result in loss of the power brakes. Without power brakes, the car could still bestopped. It would just bemore difficult, requiring a lotmore pedal pressure.

BMW is telling drivers thatmay have had the problem to

pull their car off the road andcall for a tow truck.

-

8/12/2019 Chapter Two Transparencies

52/61Page | 52

Costco recalls 40,000 pounds of rotisseriechicken for salmonella riskJoNel Aleccia NBC News

October 12, 2013

A Costco wholesale store in South San Francisco, Calif., is recalling nearly 40,000 pounds of rotisserie chicken products because the food may be linked to anoutbreak of salmonella poisoning that now has sickened more than 300 people in20 states, federal health officials said early Saturday.

The Costco store at 1600 El Camino Real is recalling 8,730 Kirkland SignatureFoster Farms rotisserie chickens and 313 units of Kirkland Farm rotisserie chickensoup, rotisserie chicken leg quarters and rotisserie chicken salad, according to anotice issued by the U.S. Department of Agriculture's Food Safety and InspectionService. The products were sold directly to consumers between Sept. 11 and Sept.23.

The rotisserie chickens may have been contaminated with a type of salmonellaHeidelberg rarely found in the United States, FSIS officials said. The strain islinked to an ongoing food poisoning outbreak associated with three Foster Farms

poultry plants in Fresno and Livingston, Calif. The USDA issued a public healthalert for products from the plant on Monday, but on Thursday agreed that thefacilities could remain open if the company made promised food safety fixes.

At least 317 people in 20 states have been sickened by the outbreak since March,according to an updated notice from the Centers for Disease Control andPrevention. Most of the cases have been in California, where 232 people have beenreported ill. It is the second outbreak of salmonella Heidelberg tied to Foster Farmsin less than a year. A previous outbreak sickened 134 people in 13 states.

Some of the seven strains of salmonella detected in the outbreak are drug-resistant,which has created hard-to-treat infections in some patients. About 42 percent ofvictims in the outbreak have been hospitalized, twice the typical rate for salmonella

infections.It was not immediately clear if other Costco stores would recall Foster Farms

products, too. Earlier on Friday, Craig Wilson, Costco's vice president for foodsafety, told NBC News that Costco was not recalling products tied to the FosterFarms outbreak.

The Kroger Co., a large chain of grocery stores, removed the affected Foster Farmsraw chicken products from store shelves earlier this week and notified customersthat they may have bought contaminated meat. The company removed products

http://www.nbcnews.com/health/foster-farms-makes-changes-can-stay-open-after-salmonella-outbreak-8C11375651http://www.nbcnews.com/health/foster-farms-makes-changes-can-stay-open-after-salmonella-outbreak-8C11375651http://www.nbcnews.com/health/foster-farms-makes-changes-can-stay-open-after-salmonella-outbreak-8C11375651http://www.cdc.gov/salmonella/heidelberg-10-13/index.htmlhttp://www.cdc.gov/salmonella/heidelberg-10-13/index.htmlhttp://www.cdc.gov/salmonella/heidelberg-10-13/index.htmlhttp://www.cdc.gov/salmonella/heidelberg-10-13/index.htmlhttp://www.nbcnews.com/health/foster-farms-makes-changes-can-stay-open-after-salmonella-outbreak-8C11375651http://www.nbcnews.com/health/foster-farms-makes-changes-can-stay-open-after-salmonella-outbreak-8C11375651 -

8/12/2019 Chapter Two Transparencies

53/61Page | 53

from its Fred Meyer, Fry's, King Soopers/City Market, Ralphs, Food 4 Less,Smith's in southern Nevada and New Mexico and QFC stores and warehouses,officials said in a statement. Not all Foster Farms products were affected by the

public health alert, so some chicken remains on store shelves, officials said.

Foster Farms officials have declined to issue voluntary recalls for their chicken products, saying that USDA continued to inspect the products daily and that the

raw chicken is safe if handled properly and cooked to 165 degrees Fahrenheit,which will kill the bacteria.

Salmonella Heidelberg can cause illness that may be life-threatening in people withweak immune systems such as children, the elderly and those with cancer or HIVinfection. Most common symptoms include diarrhea, abdominal cramps and feverwithin eight hours to three days after eating the contaminated product. Chills,headache, nausea and vomiting can last up to a week.

Foster Farms is a West Coast poultry producer with plants in Oregon, Washington,

California and Alabama.

JoNel Aleccia is a senior health writer with NBC News. Follow her on Twitter at@JoNel_Aleccia or send her an email.

mailto:%[email protected]:%[email protected] -

8/12/2019 Chapter Two Transparencies

54/61Page | 54

EXAMPLES OF QUALITY COSTS

-

8/12/2019 Chapter Two Transparencies

55/61Page | 55

TRADING-OFF QUALITY COSTS

-

8/12/2019 Chapter Two Transparencies

56/61Page | 56

QUALITY COST REPORTS

Quality cost reports summarize prevention costs, appraisalcosts, internal failure costs, and external failure costs thatwould otherwise be hidden in general overhead.

Managers are often surprised by how much defects cost. The report helps identify where the biggest qualityproblems lie.

The report helps managers assess how resources shouldbe distributed. If internal and external failure costs arehigh relative to prevention and appraisal costs, moreshould probably be spent on prevention and appraisal.

Because quality cost reports are largely an attention-directing device, the costs do not have to be precise. Unfortunately, the cost of lost sales due to external failures

is usually excluded from the reports due to measurementdifficulties.

-

8/12/2019 Chapter Two Transparencies

57/61Page | 57

SAMPLE QUALITY COST REPORT

-

8/12/2019 Chapter Two Transparencies

58/61Page | 58

Quality costs Costs incurred to prevent defects or that result fromdefects in products. Many companies are working hard to reduce theirquality costs. Those companies that are succeeding have a high quality ofconformance in the sense that the overwhelming majority of the productsthat they produce conform to design specifications and are free fromdefects.

There are four broad categories of quality costs:Prevention costs Are incurred to support activities whose purpose is to

reduce the number of defects.

Suppose an ice cream company has been having problems withunpleasant gritty ice crystals in its ice cream. How would we prevent theice crystal defect? One approach would be to investigate themanufacturing process. Perhaps the gritty ice crystals are caused bytemperature variations in the freezer. Controlled experiments could berun varying the temperature and inspecting for ice crystals. If this is thecause, the variation in temperature could be decreased or theingredients changed so they would be less sensitive to temperaturechanges.

Appraisal costs Are incurred to identify defective products before theproducts are shipped to customers.

Continuing the ice cream example, how would you inspect out the ice

crystal problem? This may be more difficult and expensive than it firstappears. For example, the problem could occur only in half-galloncontainers or at random in a small (but important) number ofcontainers. Or, the ice crystals could only be detected by tasting icecream near the bottom of the container. Inspecting out the problemwould make a lot of ice cream unsaleable.

Internal failure costs Are incurred as a result of identifying defectsbefore they are shipped to customers.

External failure costs Are incurred as a result of defective productsbeing delivered to customers.

Continuing with the ice cream example, how would you identifyexamples of internal and external failure costs? Internal failure costscould result from throwing away defective ice cream. External failurecosts could result from customers returning defective ice cream or

failing to purchase the ice cream companys product at a later date.

-

8/12/2019 Chapter Two Transparencies

59/61Page | 59

Examples of each type of quality cost include:Prevention Quality training, quality circles (group of employees who

perform similar duties and meet at periodic intervals, often withmanagement, to discuss work-related problems), statistical processcontrol activities, etc.

Appraisal Testing and inspection of incoming materials, final product testing, depreciation of testing equipment, etc.

Internal failure Scrap, spoilage, rework, etc.External failure Cost of field servicing and handling customer

complaints, warranty repairs, lost sales arising from reputation of poor quality, etc.

Distribution of quality costs Graphs are often used to depict therelationship between the four types of quality costs. The graph illustrates

four key concepts.When the quality of conformance is low, total quality cost is high andmost of this cost consists of internal and external failure costs.

Total quality costs drop rapidly as the quality of conformance increases.Companies reduce their total quality costs by focusing their efforts on

prevention and appraisal because the cost savings from reduceddefects usually overwhelm the costs of additional prevention andappraisal.

Continuing with the ice cream example, the prevention activitiesmentioned earlier may reveal that, if fluctuating temperatures is the

problem, a simple thermostat may solve the problem. The cost to identifythe problem and install a thermostat is much less that the costs of

scrapped ice cream, customer returns and complaints, and lost futurebusiness.

Total quality costs are minimized when the quality of conformance isless than 100%. This is a debatable point in the sense that some experts

believe that total quality costs are not minimized until the quality ofconformance is 100%.

-

8/12/2019 Chapter Two Transparencies

60/61Page | 60

Quality cost report this report details the prevention, appraisal,internal failure, and external failure costs that arise from a c ompanyscurrent quality control efforts.

When interpreting a cost of quality report managers should look for twotrends. First, increases in prevention and appraisal costs should be more

than offset by decreases in internal and external failure costs. Second,the total quality costs as a percent of sales should decrease.

Quality cost reports can also be prepared in graphic form. Managersshould still look for the same two trends whether the data is presented ina graphic or table format.

Uses of quality cost information:

It helps managers see the financial significance of defects.It helps managers identify the relative importance of the quality

problems faced by the company.It helps managers see whether their quality costs are poorly distributed.

In general, costs should be distributed more toward prevention andto a lesser extent appraisal than toward failures.

Limitations of quality cost information Simply measuring and reporting quality cost problems does not solve

quality problems.Results usually lag behind quality improvement programs. Initially,

prevention and appraisal cost increases may not be offset bydecreases in failure costs.

The most important quality cost, lost sales arising from customer ill-will, is often omitted from quality cost reports because it is difficultto estimate.

-

8/12/2019 Chapter Two Transparencies

61/61

International aspects of quality

The International Organization for Standardization, based in GenevaSwitzerland, has established quality control guidelines known as theISO 9000 standards . For a company to become ISO 9000 certified by acertifying agency it must demonstrate that:

i. A quality control system is in use, and the system clearlydefines an expected level of quality.ii. The system is fully operational and is backed up with

detailed documentation of quality control procedures.iii. The intended level of quality is being achieved on a sustained

basis.

Although the ISO 9000 standards were developed in Europe they have become widely accepted elsewhere throughout the world including the

United States.

ISO is the world largest standards developing organization. Between1947 and the present day, ISO has published more than 17,000International Standards, ranging from standards for activities such asagriculture and construction, through mechanical engineering, to

medical devices, to the newest information technology developments. At the end of 2004, the worldwide total of certificates:

ISO 9000 670,000 in 154 countries ISO 14000 90,000 in 127 countries