CHAPTER 4 SECTIONAL VIEW DRAWINGportal.unimap.edu.my/portal/page/portal30/Lecture... · Section...

Transcript of CHAPTER 4 SECTIONAL VIEW DRAWINGportal.unimap.edu.my/portal/page/portal30/Lecture... · Section...

1) Introduction

2) Cutting Plane Line

3) Section Lines

4) Sectional View Location

5) Holes in Section

6) Types of Sectional View

7) Breaks

8) Sectional View of Castings

9) Drawing Conventions in Section

10) Sectional View in AutoCAD

CONTENT

Sectional views are used to expose internal features and surfaces.

Sectional views do not contain hidden lines.

Hatch lines are drawn on the surfaces that represent where the cutting plane passed through

solid material.

Sectional views do include all lines that are directly visible.

Sectional views are always viewed in the direction defined by the cutting plane arrows.

Any surface that is behind the cutting plane is not included in. Thus, in other words, hidden

lines are omitted from section views.

6.1 Introduction

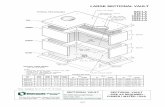

Example 1

Example 2

Hidden lines (not shown in section view)

Center lines (to indicate

circular features)

Cutting plane lineHatching

6.1 Introduction

Cutting plane lines are used to define the location for the sectional view’s cutting plane.

Figure below shows two linetype patterns for the cutting plane lines, i.e. Dashed and

Phantom. Either pattern is acceptable.

The direction of the arrow indicates the line of sight and it is always perpendicular to the

cutting plane.

6.2 Cutting Plane Line

Placement of Cutting Plane Line

The cutting plane line is placed in

the view where the cutting plane

appears on edge.

If the cutting plane appears as an

edge in the top view and is

normal in the front view; thus, it

is a frontal cutting plane.

6.2 Cutting Plane Line

Class Activity 1

Determine the direction of the following cutting plane lines.

1 2

6.2 Cutting Plane Line

To Draw a Cutting Plane Line using AutoCad

Change a given continuous line, A-A to a cutting plane line;

1. Select line A-A.

2. Click Home, Properties panel.

3. Select Linetype pull down menu.

4. Select Dashed or Phantom and return to the drawing screen.

Given continuous line

Linetype

6.2 Cutting Plane Line

To Draw an Arrowhead

1. Type qleader at the command prompt.

Command: qleader

Specify first leader point, or [Settings] <Settings>:

2. Select the location for the tip of the arrow.

Specify next point:

3. Select the end of the line, then right-click the mouse.

Specify text width <0>:

4. Press Enter or key-in text width then Enter.

Enter first line of annotation text <Mtext>:

5. Press Enter. The Text Editor tab will appear.

6. Click Close Text Editor.

To Change the Size of an Arrowhead

1. Select the Dimension Style tool from the Dimensions panel.

2. Select Modify. The Modify Dimension Style: Standard dialog box will appear.

3. Select the Symbols and Arrows tab and use the Arrow size box to change the

arrowhead’s scale factor.

4. Return to the drawing screen and use qleader to create the needed arrowheads.

Note: The arrowhead size can also be changed by typing dimasz in command line and

type in the new scale factor.

6.2 Cutting Plane Line

Section lines are used to define areas that represent where solid material has been cut in a

sectional view.

Section lines are evenly spaced at any inclined angle that is not parallel to any existing

edge line and should be visually distinct from the continuous lines that define the boundary of

the sectional view.

Figure below shows an area that includes uniform section lines evenly spaced at 45°.

Some areas include a 45° edge line; hence, the section line cannot be drawn at 45°. Lines at

135° were drawn instead.

6.3 Section Lines

Figure below shows an object that contains edge lines at both 45° and 135°. The section lines

within this area were drawn at 60°.

If two or more parts are included within the same sectional view, each part must have visually

different section lines.

Different

section lines

6.3 Section Lines

The recommended spacing for sectional lines is spaced 0.125 inches or 3 millimeters.

They should never be spaced so close together as to look blurry or be so far apart that they

are not clearly recognizable as section lines.

Recommended

spacing

Closer for

smaller areas

Wider for

larger areas

Too denseToo wide

6.3 Section Lines

Section lines are drawn in AutoCAD using Hatch tool, which located on the Draw panel. The

general pattern of evenly spaced lines at 45° is defined as pattern ANSI31, and is default

setting for the Hatch tool.

To Hatch a Given Area

Select the Hatch tool from the Draw panel. The Hatch Creation tab will appear.

Select the Pick Points option.

Select a point within the area to be hatched, then right-click the mouse, then select Enter.

The area will be hatched.

6.3 Section Lines

To Change Hatch Patterns

1. Select the Hatch tool from the

Draw panel. The Hatch

Creation tab will appear.

2. Click the arrow to the lower right

corner of the Pattern panel.

3. A list of available ANSI pattern

will appear.

4. Select the desired pattern and

apply it as described above.

To Change the Spacing and Angle

of a Hatch Pattern

1. Select the Hatch tool from the

Draw panel. The Hatch

Creation tab will appear.

2. Change the Angle and Scale to

desired values.Before

After

6.3 Section Lines

Figure below shows an object with a cutting plane line. Draw the following drawings

of the object in Third Angle Projection. All dimensions are shown in millimetres.

a) Top view.

b) Sectional view A-A.

Example 6.1

Sectional views should be located on a drawing behind the arrows. The arrows represent the

viewing direction for the sectional view.

If it is impossible to locate sectional views behind the arrows, they may be located above or

below, but still behind the arrowed portion of the cutting plane line.

Sectional views should NEVER be located in front of the arrows.

Full sectional

right-side view

6.4 Sectional View Location

Figure below shows a sectional view of an object that contains three holes.

As with orthographic views, a conical point must be included on holes that do not completely

penetrate the object.

A common mistake is to omit the back edge of a hole when drawing a sectional view.

The sectional view of a hole drilled through an object should include a straight line across the

top and bottom edges of the view that represents the back edges of the hole.

6.5 Holes in Section

Figure below shows a countersunk hole, a counterbored hole, a spotface, and a hole

through a boss.

6.5 Holes in Section

Types of Sectional Views

a) Full b) Half c) Offset d) Aligned e) Removed f) Multiple

g) Broken-out

6.6 Types of Sectional View

This view is made by passing the imaginary cutting plane completely through the object.

All the hidden features intersected by the cutting plane are represented by visible lines in the

section view.

Surfaces touched by the cutting plane have section lines drawn at a 45-degree angle to the

horizontal.

Full

cut

(C) Full sectional

front view

a) Full Section

Class Activity 2

The following figure shows an object. Sketch the following drawings of the part in Third Angle

Projection.

a) Front view.

b) Full sectional right-side view.

a) Full Section

Half and partial sectional views allow a designer to show an object using an orthographic view

and a sectional view within one view.

A half-sectional view shows half the view is sectional view; the other half is a normal

orthographic view excluding the hidden lines.

The cutting plane line is drawn to include an arrowhead at only one end of the line.

Half cut

(C) Half sectional

front view

b) Half Section

Cutting plane lines need NOT be drawn as straight lines across the surface of an object.

They may be stepped so more features can be included in the sectional view.

In the figure below, the cutting plane line crosses two holes and a directly visible open surface

that contains a hole.

There is no indication in the sectional view that the cutting plane line has been offset.

A) Offset section B) Offset sectional view D-D

c) Offset Section

Class Activity 3

A rectangular support is shown in the following figure. Sketch the following drawings of the part

in Third Angle Projection.

a) Top view.

b) Sectional A-A view.

c) Offset Section

Cutting plane lines taken at angles on circular shapes may be aligned as shown in figure

below.

Aligning the sectional views prevents the foreshortening that would result if the view were

projected from the original cutting plane line location.

A foreshortened view would not present an accurate picture of the object’s surfaces.

A) Aligned sectional view A-A

X

X

SECTION A-A

d) Aligned Section

B) Aligned sectional view

Aligned section conventions are used to rotate the holes into position along the vertical center

line.

X

X

d) Aligned Section

Class Activity 4

A round plate is shown in the following figure. Sketch the following drawings of the part in Third

Angle Projection.

a) Front view.

b) Full sectional right-side view.

d) Aligned Section

Removed sectional views are used to show how an object’s shape changes over its length.

Removed sectional views are most often used with long objects whose shape changes

continuously over its length.

The sectional views are not positioned behind the arrowheads but are positioned across the

drawing.

e) Removed Section

More than one sectional view may be taken off the same orthographic view.

Figure below shows a drawing that includes three sectional views, all taken off a front view.

Each cutting plane line is labeled with a letter.

Identifying letters are also placed below the sectional view and written using the format

SECTION A-A, or SECT A-A, and so on.

The letter I, O, and X are generally not used to identify sectional views because they can be

easily misread.

f) Multiple Section

Broken-out Sectional Views

Broken-out sectional views are used to show only

small internal portions of an object.

Broken lines are used to separate the broken-out

section from the rest of the orthographic views.

To Draw a Broken Line

1. Type Sketch in response to a command prompt.

Command: sketch

Record increment <0.10>:

2. Press Enter.

Sketch. Pen eXit Quit Record Erase Connect .

3. Press the left mouse button.

<Pen down>

4. Move the cursor across the screen. A green

freehand line will emerge from the crosshairs as

it is moved.

5. Press the left mouse button again.

<Pen up>

6. Press Enter. 68 lines recorded.

g) Broken-Out Section

It is often convenient to break long continuous shapes so that they take up less drawing

space.

Two methods to show breaks: freehand lines used for rectangular shapes, and S-Breaks

used for cylindrical shapes.

Freehand break lines are drawn using the Sketch command.

Freehand lines

S-Break lines

6.7 Breaks

To Draw an S-break

1. Draw a rectangular view of the cylindrical object and draw a construction line

where the break is to be located. The rectangular view should include a

centerline.

2. Draw two 30° lines: one from the intersection of the construction line and the

outside edge line of the view, and the other from the intersection of the

construction line and the centerline.

3. Draw an arc using the intersection created in step 2 as the center point. Mirror

the arc about the centerline and then about the construction line.

4. Use Fillet, set to a small radius, to smooth the corners between the arc and the

edge lines. Any small radius may be used for the fillet, provided it produces a

smooth visual transition between the arc and the edge lines.

5. Erase and trim any excess lines.

6. Hatch the area created by the two arcs and fillet.

6.7 Breaks

Cast objects are usually designed to include a feature called a rib or web.

Ribs and webs add strength and rigidity to an object.

Sectional views of ribs or webs do not include complete section lines because this is

considered misleading to the reader.

Ribs are usually narrow, and a large sectioned area gives the impression of a denser and

stronger area than is actually on the casting.

There are two conventions used to present sectional views of cast ribs: one that does not

draw any section lines on the ribs, and one that puts every other section line on the rib.

Sectional views of castings that include section lines on ribs are created using Hatch

command for those areas that are to be hatched.

Ribs

6.8 Sectional View of Castings

Slots and small holes that penetrate cylindrical surfaces may be drawn as straight lines.

Larger holes, i.e. holes whose diameters are greater than radii of their cylinders should be

drawn showing an elliptical curvature.

6.9 Drawing Conventions in Section

Intersecting holes are represented by crossed lines, as shown in figure below.

The crossed lines are drawn from the intersecting corners of the holes.

6.9 Drawing Conventions in Section

1. What is the units? (Use ‘units’ command)

Inches

Millimetres

2. What types of sectional view?

Full sectional view

Half sectional view

Offset sectional view

Removed sectional

3. How many lines? (Create new lines in Line Properties Manager)

Visible line

Hidden line

Center line

Construction lines

4. Draw the normal orthographic projection view either top, front or side view together

with cutting plane line.

5. Project all information from the normal orthographic view to the sectional view drawing

that will be created using ‘xline’ command.

6. Erase and trim the objects to complete the drawings.

6.10 Sectional View in AutoCAD

A stock guide is shown in the following figure. Draw in full scale the following drawings of the

part in Third Angle Projection. All dimensions are shown in millimeters.

a) Front view.

b) Half sectional right-side view.

Example 6.2

A flanged support is shown in the following figure. Draw in full scale the following drawings of

the part in Third Angle Projection. All dimensions are shown in millimeters.

a) Front view in the direction of F.

b) Full sectional right-side view.

Hint: Aligned sections;

Sectional views of casting

Example 6.3