Chapter 38: Landing Gear - · PDF fileChapter 38: Landing Gear 38 Landing Gear Summary 566...

Transcript of Chapter 38: Landing Gear - · PDF fileChapter 38: Landing Gear 38 Landing Gear Summary 566...

Chapter 38: Landing Gear

38 Landing Gear

Summary 566

Introduction 567

Solution Requirements 567

FEM Solution 567

Results 574

Modeling Tips 577

Input File(s) 577

Video 578

MD Demonstration Problems

CHAPTER 38566

SummaryTitle Chapter 38: Landing Gear

Contact features • Frictionless Deformable-Deformable Contact• Glued Contact for non-matching meshes

Geometry

Material properties Young’s Modulus = 3.0x107 Psi, Poisson’s ratio = 0.3

Boundary conditions Pinned Connections with/without Glued Contact SOL 400

)

Element types HEXA, TETRA, BAR

FE results Verify the contact conditions (GLUE and nonGLUE)

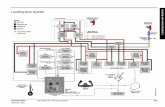

DRAG STRUT

AXLE

SIDE STRUT

GAS SPRING

UPPER CYLINDER

UPPER TORQUE LINK

LOWER TORQUE LINK

TORSION LINK APEX PIVOT

UPPER LINK PIVOT

LOWER LINK SPACER

UPPER LINK SPACER

APEX SPACER

INNER CYLINDER

DRAG STRUT PIVOT

SIDE STRUT PIVOT

P INNED CONNECTIONS

567CHAPTER 38

Landing Gear

IntroductionThis test case demonstrates contact analysis using MD Nastran. Two types of contact conditions between components are considered:

• glue contact

• nonglue contact

In the first one, the contact is maintained for all the analysis after it occurs. In other words, nodes in contact are not allowed to separate whereas, in the second one, separation can change depending on the loading conditions.

Large displacement/rotation and nonlinear materials are not taken into account in this example.

Solution RequirementsThe numerical analysis is performed to demonstrate the behaviors of the 3-D surface contact solution into MD Nastran. In particular, the simultaneous presence of glue, nonglue surface contact is considered. The deformed structure, the satisfaction of the relative motion between components, and the stresses in the contact regions are considered as result of the analysis.

FEM SolutionFEM solutions have been obtained with MD Nastran’s solution sequence 400. The details of finite element models, contact simulations, material, load, boundary conditions, and solution procedure are discussed.

Finite Element ModelsThe structure consists of different components that have been modeled independently taking into account that matching meshes are not needed in the contact regions.

Due to geometrical behaviors:

• The pins and the spacers have been modeled by 8-node HEXA elements

• 4-node TETRA elements have been used to model the remaining components. Note that fine meshes have been used for these components in order to avoid the rigidity of such kind of element associated with this type of element.

For the axle, two BAR elements have been used. In this way the proper load has been applied in the middle grid point. No LGDISP parameter has been defined and therefore no geometrical nonlinearity is considered.

MD Demonstration Problems

CHAPTER 38568

Contact ModelsIn defining the contact regions for the structure, the components are modeled as deformable bodies. In particular, 15 contact bodies have been defined by specific BCBODY and BCSURF entries (each couple of options has been defined using the same identifier). Note that each of them has been defined considering all the elements belonging to the specific components.

Each contact body has been defined in the same way so, as an example, one set of options is used to define one of them that has been listed:

$ Deform Body Contact LBC set: lower_link_spacerBCBODY 13 3D DEFORM 13 0 -1BSURF 13 161551 161552 161553 161554 161555 161556 161557 161558 161559 161560 161561 161562 161563 161564 161565 161566 161567 161568 161569 161570 161571 161572 161573 161574 161575 161576 161577 161578 161579 161580 161581 161582

In the above BCBODY option, the 3-D (third field) elements mentioned in the BSURF which identifier is 13 (look at the fifth field) define the contact body number 13. Furthermore:

• The fourth field defines the general behavior of the contact body. In this case, it is a deformable contact body

• The null value in the sixth field means that symmetric penetration or double side contact check is considered. The contact is verified symmetrically and both the contact surfaces are checked for penetration and, also, if we need to define a MASTER and a SLAVE in any case.

Table 38-1 Contact Body General Information

BCBODY/BSU Component Name Elements

1 Drag Strut 217804 - 237802

2 Drag Strut Pivot 159301 - 160572

3 Gas Spring 160575 - 161534

4 Inner Cylinder 200218 - 217803

5 Lower Link Pivot 157797 - 158596

6 Lower Torque Link 277629 - 297917

7 Side Strut 237803 - 257846

8 Side Strut Pivot 159717 - 160332

9 Torsion Link Ape Pivot 158597 - 159300

10 Upper Cylinder 161663 - 200217

11 Upper Link Pivot 156997 - 157796

12 Upper Torque Link 257847 - 277628

13 Lower Link Spacer 161551 - 161582

14 Upper Link Spacer 161599 - 161630

15 Apex Spacer 161647 - 161662

569CHAPTER 38

Landing Gear

• The empty seventh field forces a null friction coefficient. It means that no tangential forces are generated when the contact condition occurs, unless these bodies are glued together.

• The negative value in the eighth field allows activating the analytic option for a deformable body. It is used in this case because the part of each component involved in the contact process is cylindrical and therefore is simple to represent it analytically. In this way, the contact is represented in the best way.

After the definition of the contact bodies, each couple of bodies that could be in contact must be defined in the BCTABLE option. In this entry, one of the contact bodies is defined as the MASTER while the other one is the SLAVE. The contact behaviors are completely defined. An example of the option format used in this case is listed below:

BCTABLE 1 19 SLAVE 1 4.-2 0. 0. 0. 1 0 0 0 FBSH 1.+20 0. 0. MASTERS 2 SLAVE 2 4.-2 0. 0. 0. 1 0 0 0 FBSH 1.+20 0. 0. MASTERS 10 SLAVE 3 4.-2 0. 0. 0. 0 0 0 0 FBSH 1.+20 0. 0. MASTERS 4 SLAVE 3 4.-2 0. 0. 0. 1 0 0 0 FBSH 1.+20 0. 0. MASTERS 10 ... ... SLAVE 12 4.-2 0. 0. 0. 1 0 0 0 FBSH 1.+20 0. 0. MASTERS 14 SLAVE 12 4.-2 0. 0. 0. 0 0 0 0 FBSH 1.+20 0. 0. MASTERS 15

It can be checked how the nineteen contact regions (look at the fifth field of the above BCTABLE option) are defined in the same. The only difference is in the eighth field of the option where the SLAVE option is defined. In fact, we can see a unit or null value. If a unit value is defined, the two contact surfaces must be glued. It means that the glue option is activated and all the degrees of freedom of the nodes are tied in case of deformable-deformable contact once the node comes in contact. In general, if the unit value is defined, all degrees of freedom are MPCd in the deformable-deformable contact once the grids have come in contact. To turn on the general SOL 400 contact algorithm the entry:

BCPARA, 0, NLGLUE,1

is used. It should be taken into account that if, in SOL 400 on the BCTABLE, there are multiple GLUE and nonGLUE entries associated with different SLAVE entries, then, the above option must be used. It is the case in this example.

A null value activates the standard contact conditions. It means that a SLAVE node can move only over the MASTER contact surface when it comes in contact (except if glued). In this case, if the general load condition leads to the separation of the contact bodies, the slave node start again to move without constraints. Note that in this entry different

MD Demonstration Problems

CHAPTER 38570

contact parameters (the distance below which the node is considered in contact, friction coefficient, separation force, stress friction limit, contact tolerance bias, etc…) can be defined for each contact region.

The BCTABLE entry is activated by BCONTACT option in the Case Control section. Note that in this case, a BCONTACT = 0, defined above the subcase level activates the corresponding BCPARA,0 and BCTABLE,0 entries defined in the Bulk Data Section. It allows to initially identify contacting bodies. Note that in SOL 400, a BCONTACT = 0 is allowed above all subcases but is not required. Any of the contact Bulk Data entries that allow a 0 and have a 0 value ID field are automatically sensed by SOL 400 with or without a BCONTACT = 0 command. The contact regions are summarized in the table below.

Table 38-2 Contact Body General Information (ID in Parenthesis)

NumberSLAVE Component

(BCBODY ID)MASTER Component

(BCBODY ID) GLUE

1 Drag Strut (1) Drag Strut Pivot (2) YES

2 Drag Strut Pivot (2) Upper Cylinder (10) YES

3 Gas Spring (3) Inner Cylinder (4) -

4 Gas Spring (3) Upper Cylinder (10) YES

5 Inner Cylinder (4) Lower Link Pivot (5) -

6 Inner Cylinder (4) Upper Cylinder (10) -

7 Inner Cylinder (4) Lower Link Spacer (13) -

8 Lower Link Pivot (5) Lower Torque Link (6) YES

9 Lower Torque Link (6) Torsion Link Apex Pivot YES

10 Lower Torque Link (6) Lower Link Spacer (13) YES

11 Lower Torque Link (6) Apex Spacer (15) YES

12 Side Strut (7) Side Strut Pivot (8) YES

13 Side Strut Pivot (8) Upper Cylinder (10) YES

14 Torsion Link Apex Pivot Upper Torque Link (12) -

15 Upper Cylinder (10) Upper Link Pivot (11) -

16 Upper Cylinder (10) Upper Link Spacer (14) -

17 Upper Link Pivot (11) Upper Torque Link (12) YES

18 Upper Torque Link (12) Upper Link Spacer (14) YES

19 Upper Torque Link (12) Apex Spacer (15) -

571CHAPTER 38

Landing Gear

Figure 38-1 Glued Contact Regions Panels a-e, Nonglued Contact Panel f

Looking at the behaviors of the defined contact regions, it can be checked that:

• The gas spring is attached in its upper end to an internal surface of the UPPER cylinder. This system can move along their common axis according to the non-glued contact regions defined between them and the INNER cylinder.

• The torsion link apex pivot is rigidly connected to the LOWER torque link while a nonglued contact region is defined between the first body contact and the UPPER torque link. Also, the APEX SPACER is in the same contact condition. Considering the null friction coefficient, this modeling solution allows to avoid any singularity maintaining the relative rotational motion between the two links.

• The rigid link pivot is rigidly connected to the LOWER torque link but it is connected by nonglued contact region with the INNER CYLINDER. It is the same modeling solution than the above one.

• The two struts are rigidly connected to the UPPER cylinder.

• The two torque links (UPPER and LOWER) can rotate around the axes of the two pivots that connect each of them respectively with the UPPER and the INNER cylinders.

DRAG STRUT

DRAG STRUT PIVOT DRAG STRUT PIVOT

UPPER CYLINDER

GAS SPRING

UPPER CYLINDER

LOWER LINK PIVOT

LOWER TORQUE LINK

LOWER TORQUE LINK

TORSION LINK APEX PIVOT

LOWER TORQUE LINK

LINK LOWER SPACER

a b c

d e f

MD Demonstration Problems

CHAPTER 38572

Figure 38-2 Possible Relative Motion Between the Different Components

MaterialThe isotropic elastic material properties of the steel used for all the components have been defined by the following MAT1.

MAT1 1 3.+7 .3 7.3-4

Nonlinear behaviors of the material are not considered.

Loading and Boundary Conditions

The set of boundary conditions (SPC = 2) defined in the model simulates hinges between some components and the ground. In particular, they are positioned in the upper ends of the:

Drag StrutSide StrutUpper Cylinder

The following options are used to define this boundary condition:

SPCADD 2 1...SPC1 1 123 108520 108521 313468 313469 313470 313471

The braking load condition is considered. It consists of:

• Concentrated forces and moments applied to the middle point of the axle. They define three different loads acting on this component:

573CHAPTER 38

Landing Gear

Brake drag

FORCE 1 314410 0 60000. -1. 0. 0.MOMENT 3 314410 0 0. .57735 .57735 .57735

Brake side moment

FORCE 4 314410 0 0. .57735 .57735 .57735MOMENT 5 314410 0 1.335+6 0. 1. 0.

Brake vertical

FORCE 6 314410 0 140000. 0. 0. 1.MOMENT 7 314410 0 0. .57735 .57735 .57735

Figure 38-3 Pressure Load Applied to the Axle

• Breaking Pressure in the inner part of the Upper Cylinder (Load sets from 8 to 11)

PLOAD4 11 164669 1190.4 33161 7479PLOAD4 11 164864 1190.4 33236 7156PLOAD4 11 166091 1190.4 55196 49965...PLOAD4 10 199542 1190.4 54157 106392PLOAD4 10 199546 1190.4 105944 106130

Figure 38-4 Pressure Load Applied to the Axle

FX MY FZ X

Z

Y

XZ

Y

XZ

Y

MD Demonstration Problems

CHAPTER 38574

All these loads are combined by LOAD Bulk data entry to define the applied static load condition

LOAD 2 1. 1. 1 1. 3 1. 4 1. 5 1. 6 1. 7 1. 8 1. 9 1. 10 1. 11

Solution ProcedureIn the present analysis, contact is the only nonlinearity. It means that the provided load condition generates small displacements and only the stresses are in the linear elastic part of the stress-strain curve of the material. As consequence, no geometrical and material nonlinearity are taken in account. Furthermore, looking at the geometries, the contact conditions seems to be not so complicated, It simplifies the approach to be used in the analysis.

First of all no STEP is defined under the SUBCASE level.

BCONTACT = 0SUBCASE 1 TITLE=This is a default subcase. BCONTACT = 1 SPC = 2 LOAD = 2 DISPLACEMENT(plot)=ALL$ SPCFORCES(SORT1,REAL)=ALL STRESS(plot)=ALL BOUTPUT(SORT1,REAL)=ALL NLPARM = 1

The nonlinear procedure is defined through the following NLPARM entry with ID 1.

NLPARM 1 1 FNT PV YES

Here:

• Only one increment is considered.

• FNT represents the Full Newton-Raphson Technique wherein the stiffness is reformed at every iteration.

• PV indicates that convergence will be checked on vector component (V) of the residuals (P). In this V method, convergence checking is performed on the maximum vector component of all components in the model.

• YES indicates that intermediate output is produced after every increment.

ResultsNo results to compare are available for this test case so what has been obtained by the calculation will be checked from a qualitative viewpoint. The maximum total displacement occurs in the bottom part of the inner cylinder, close to the axle (where the concentrated loads are applied).

575CHAPTER 38

Landing Gear

Figure 38-5 Undeformed and Scaled Deformed Structure

To check how the contact is working it is possible to take advantage of a procedure that in MD R2 Nastran allows storing all the contact results into the database. In fact it is not possible to obtain these data into XDB (PARAM,POST,0) or OUTPUT2 (PARAM,POST,-1) postprocessing files while adding the keyword:

scr = post

in the Nastran command line, all the results, including the contact ones, are stored into the database. They are retrieved into MD Patran selecting:

in the Results Window.

The following results can be displayed for contact regions

Contact StatusFriction contact force, MagnitudeNormal contact force, MagnitudeContact force, FrictionContact force, NormalContact stress, Friction 1Contact stress, Friction 2Contact stress, Normal

It is possible to understand which components are in contact displaying the Contact Status output. As first example some of the contact regions belonging to the lower and upper torque links will be considered.

Looking at the Contact Status Contours in Figure 38-7 and taking into account the contact regions behaviors (as summarized in Figure 38-6) we can say that:

• Both the contact bodies regions (MASTER and SLAVES) are highlighted.

Action Access Results

Object Attach Entities

Method Result Entities or Both

MD Demonstration Problems

CHAPTER 38576

• The contact status in the UPPER TORQUE LINK-TORSION LINK APEX PIVOT nonglued contact region put in evidence how the deformation of the structure determines the contact only in a limited part of the bodies.

• A good contact modeling is recognized by a congruent representation of the Contact Status output in the MASTER and SLAVE contact bodies. In particular in case of glued contact a continuous contact status contour should be displayed. A different representation could highlights problems in the geometries of the contact bodies.

Figure 38-6 Upper and Lower Torque Links Connections

Figure 38-7 First Contact Status Contour Plot Example

A nonclear situation is displayed for the nonglued contact between UPPER TORQUE LINK and TORSION APEX PIVOT. In fact, the contact status is differently represented in the corresponding contact regions of the two components. Probably, the combined effects of the deformation and the different element types in the two components determine it.

UPPER LINK PIVOT

- SLAVE in contact region with UPPER TORQUE LINK (GLUED)

- MASTER in contact region with UPPER CYLINDER

577CHAPTER 38

Landing Gear

Differently, in case of nonglued contact regions defined in the UPPER CYLINDER-UPPER LINK PIVOT connection the contact status seems to be represented correctly (see Figure 38-8). In fact, there is a complete congruency between the two regions that are in contact.

Figure 38-8 Second Contact Status Contour Plot Example

Modeling TipsImportant behaviors of this example are the definition of glued and nonglued contact regions and the effects of contact geometries to obtain good results. Contact is only verified in a qualitative viewpoint by the analysis of the Contact Status output.

The following are some guidelines and tips for modeling this benchmark:

• The geometry of a contact surface should be defined property in order to avoid problems when it touches another surface contact.

• The density of the mesh affects the results in the contact region in particular in case of contact surfaces with nonplanar shape and in which different types of elements are used.

• Use the Contact Status output to check if the contact is working properly (use scr=post in the Nastran command line to obtain this kind of output).

Input File(s)File Description

nug_38.dat MD Nastran SOL 400 input for the landing gear model

MD Demonstration Problems

CHAPTER 38578

VideoClick on the image or caption below to view a streaming video of this problem; it lasts approximately 40 minutes and explains how the steps are performed.

Figure 38-9 Video of the Above Steps