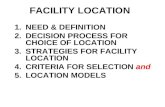

Chapter 2C- Facility Location Techniques

-

Upload

tabishbilgrami -

Category

Documents

-

view

1.834 -

download

1

Transcript of Chapter 2C- Facility Location Techniques

1

Supply Chain Management

Chapter 2

Lecture 4 Part 2:

Facility Location Techniques

Location Analysis Methods

� Analysis should follow 3 step process:� Step 1: Identify dominant location factors� Step 2: Develop location alternatives� Step 3: Evaluate locations alternatives

� Factor rating method

� Center of gravity approach� Load-distance model

� Break-even analysis

� Transportation method

� Simulation Methods

Factor-Rating Method

� Most widely used location technique

� Useful for service & industrial locations

� Rates locations using factors� Intangible (qualitative) factors

� Example: Education quality, labor skills

�Tangible (quantitative) factors

� Example: raw materials, utilities

Steps in Factor Rating Method

� List relevant factors

� Assign importance weight to each factor (0 - 1)

� Develop scale for each factor (1 - 100)

� Score each location using factor scale

� Multiply scores by weights for each factor & total

� Select location with maximum total score

2

Location Factor Rating: Example

Labor pool and climateLabor pool and climate

Proximity to suppliersProximity to suppliers

Wage ratesWage rates

Community environmentCommunity environment

Proximity to customersProximity to customers

Shipping modesShipping modes

Air serviceAir service

LOCATION FACTORLOCATION FACTOR

.30.30

.20.20

.15.15

.15.15

.10.10

.05.05

.05.05

WEIGHTWEIGHT

8080

100100

6060

7575

6565

8585

5050

Site 1Site 1

6565

9191

9595

8080

9090

9292

6565

Site 2Site 2

9090

7575

7272

8080

9595

6565

9090

Site 3Site 3

SCORES (0 TO 100)SCORES (0 TO 100)

Weighted Score for Weighted Score for ““Labor pool and climateLabor pool and climate”” for for

Site 1 = (0.30)(80) = 24Site 1 = (0.30)(80) = 24

Location Factor Rating

24.0020.00

9.00

11.25

6.50

4.252.50

77.50

Site 1

19.5018.20

14.25

12.00

9.00

4.603.25

80.80

Site 2

27.0015.00

10.80

12.00

9.50

3.254.50

82.05

Site 3

WEIGHTED SCORES

Site 3 has the highest factor rating

Light Industry: PP Bags Plant Karachi/

RYK or Sharjah : Example

Ready to occupy siteReady to occupy site

Availability of powerAvailability of power

Low TaxesLow Taxes

Political situationPolitical situation

Proximity to customerProximity to customer

Wage ratesWage rates

Shipping modesShipping modes

LOCATION FACTORLOCATION FACTOR

.30.30

.20.20

.15.15

.15.15

.10.10

.05.05

.05.05

WEIGHTWEIGHT

7070

7070

6060

6565

8080

8080

8080

KHIKHI

9090

9595

9595

9090

5050

8080

8080

SHJSHJ

7070

7070

6060

7575

9595

9090

9090

RYKRYK

SCORES (0 TO 100)SCORES (0 TO 100)

Weighted Score for Weighted Score for ““Ready to Move SiteReady to Move Site”” for for

KHI = (0.30)(70) = 21KHI = (0.30)(70) = 21

Light Industry: PP Bags Plant Karachi/ RYK or Sharjah : Example

21.0014.00

9.00

9.75

8.00

4.004.00

69.75

KHI

27.0019.00

14.25

13.50

5.00

4.004.00

86.75

SHJ

21.0014.00

9.00

11.25

9.50

4.504.50

73.75

RYK

WEIGHTED SCORES

… And the industry goes to

Sharjah!!

Location Factor

Rating

3

Problem

Labor cost is twice as important as utility cost, which is in turn is twice as important as climate. Sukkur has scores of 8, 5 and 2 in these areas; Karachi has scores of 7, 6 and 5 in these areas; Multan has scores of 6, 6 and 6 in these areas and Lahore has score of 3, 7 and 9 in these areas. Which location is the best?

A. LahoreB. MultanC. KarachiD. Sukkur

Example:

Solution:

84

74

68

“Grid” Method for Facility Location

� Procedure– Raw material and/or finished goods points on a grid– Equation to find Center of Gravity

� Advantages– Simplicity– Heuristic, but excellent “first cut” solution

� Limitations– Assumes demand, etc. at “points”– Assumes linear rate structure– Assumes straight-line routes– Based on variables costs only– Static approach - not dynamic– Not an “optimizing” approach

4

�� Locate facility at center of Locate facility at center of geographic area geographic area

�� Based on weight and distance Based on weight and distance traveled establish gridtraveled establish grid--map of areamap of area

�� Identify coordinates and weights Identify coordinates and weights shipped for each locationshipped for each location

Center-of-Gravity Technique

0 100 200 300 400 500 600 700

Grid Location

Center of Gravity Method� Finds location of single distribution

center serving several destinations

� Used primarily for services

� Considers

�Location of existing destinations

� Example: Markets, retailers etc.

�Volume to be shipped

�Shipping distance (or cost)

� Shipping cost/unit/mile is constant

Center of Gravity Method Steps

� Place existing locations on a coordinate grid�Grid has arbitrary origin & scale

�Maintains relative distances

� Calculate X & Y coordinates for ‘center of gravity’�Gives location of distribution center

�Minimizes transportation cost

5

Center of Gravity Method Equations

ddixix = x coordinate of = x coordinate of

location ilocation i

WWii == Volume of Volume of

goods moved to or from goods moved to or from

location i location i

ddiyiy = y coordinate of = y coordinate of

location ilocation i

X CoordinateX Coordinate

Y CoordinateY Coordinate

∑

∑

=

ii

iiix

xW

Wd

C

∑

∑

=

ii

iiiy

yW

Wd

C

Grid-Map Coordinates

where,where,

xx, , y y == coordinates of new facility coordinates of new facility

at center of gravityat center of gravity

xxii, y, yii == coordinates of existing coordinates of existing

facility facility ii

WWii == annual weight shipped from annual weight shipped from

facility facility ii

∑∑∑∑∑∑∑∑nn

WWii

i = i = 11

∑∑∑∑∑∑∑∑ xxiiWWii

i = i = 11

nn

x =x =

∑∑∑∑∑∑∑∑nn

WWii

i = i = 11

∑∑∑∑∑∑∑∑ yyiiWWii

i = i = 11

nn

y =y =

xx11 xx22 xx33 xx

yy22

yy

yy11

yy33

1 (1 (xx11, , yy11), ), WW11

2 (2 (xx22, , yy22), ), WW22

3 (3 (xx33, , yy33), ), WW33

Center-of-Gravity Technique: Example

AA BB CC DD

xx 200200 100100 250250 500500

yy 200200 500500 600600 300300

WtWt 7575 105105 135135 6060

yy

700700

500500

600600

400400

300300

200200

100100

00 xx700700500500 600600400400300300200200100100

AA

BB

CC

DD

(135)(135)

(105)(105)

(75)(75)

(60)(60)

MilesMiles

Mil

es

Mil

es

Center-of-Gravity Technique: Example (cont.)

x = = = 238n

∑∑∑∑ Wii = 1

∑∑∑∑ xiWii = 1

n

∑∑∑∑n

Wii = 1

∑∑∑∑ yiWii = 1

n

y = = = 444(200)(75) + (500)(105) + (600)(135) + (300)(60)

75 + 105 + 135 + 60

(200)(75) + (100)(105) + (250)(135) + (500)(60)

75 + 105 + 135 + 60

6

Center-of-Gravity Technique: Example (cont.)

AA BB CC DD

xx 200200 100100 250250 500500

yy 200200 500500 600600 300300

WtWt 7575 105105 135135 6060

yy

700700

500500

600600

400400

300300

200200

100100

00 xx700700500500 600600400400300300200200100100

AA

BB

CC

DD

(135)(135)

(105)(105)

(75)(75)

(60)(60)

MilesMiles

Mil

es

Mil

es Center of gravity Center of gravity (238, 444)(238, 444)

Center of

Gravity with

Excel

Center-of-Gravity Technique

� This method only considers the distances traveled. It does not consider the other factors such as the availability of roads on the selected location. Therefore, applying solely this method may not be applicable in every case.

Load-Distance Technique

� Compute (Load x Distance) for each site

� Choose site with lowest (Load x Distance)

� Distance can be actual or straight-line

7

Load-Distance Calculations

∑ li di

i = 1

n

LD =

LD = load-distance value

li = load expressed as a weight, number of trips or unitsbeing shipped from proposed site and location i

di = distance between proposed site and location i

di = (xi - x)2 + (yi - y)2

(x,y) = coordinates of proposed site

(xi , yi) = coordinates of existing facility

where,

where,

Load-Distance: Example

Potential SitesPotential Sites

SiteSite XX YY

11 360360 180180

22 420420 450450

33 250250 400400

SuppliersSuppliers

AA BB CC DD

XX 200200 100100 250250 500500

YY 200200 500500 600600 300300

WtWt 7575 105105 135135 6060

Compute distance from each site to each supplierCompute distance from each site to each supplier

= (200= (200--360)360)22 + (200+ (200--180)180)22ddAA = (x= (xAA -- xx11))22 + (y+ (yAA -- yy11))22Site 1Site 1 = 161.2= 161.2

= (100= (100--360)360)22 + (500+ (500--180)180)22ddBB = (x= (xBB -- xx11))22 + (y+ (yBB -- yy11))22 = 412.3= 412.3

ddCC = 434.2= 434.2 ddDD = 184.4= 184.4

Load-Distance: Example (cont.)

Site 2Site 2 ddAA = 333= 333 ddCC = 226.7= 226.7ddBB = 323.9= 323.9 ddDD = 170= 170

Site 3Site 3 ddAA = 206.2= 206.2 ddCC = 200= 200ddBB = 180.4= 180.4 ddDD = 269.3= 269.3

Compute loadCompute load--distancedistance

i = 1i = 1

nn

∑∑∑∑∑∑∑∑ lli i ddiiLD =LD =

Site 1 = (75)(161.2) + (105)(412.3) + (135)(434.2) + (60)(434.4)Site 1 = (75)(161.2) + (105)(412.3) + (135)(434.2) + (60)(434.4) = 125,063= 125,063

Site 2 = (75)(333) + (105)(323.9) + (135)(226.7) + (60)(170) = 9Site 2 = (75)(333) + (105)(323.9) + (135)(226.7) + (60)(170) = 99,7919,791

Site 3 = (75)(206.2) + (105)(180.3) + (135)(200) + (60)(269.3) =Site 3 = (75)(206.2) + (105)(180.3) + (135)(200) + (60)(269.3) = 77,55577,555**

* * Choose site 3Choose site 3

Load-Distance

with Excel

8

Break-Even Analysis� Break-even analysis can be used for location analysis especially

when the costs of each location are known� Step 1: For each location, determine the fixed and

variable costs� Step 2: Plot the total costs for each location on one graph� Step 3: Identify ranges of output for which each location

has the lowest total cost

� Step 4: Solve algebraically for the break-even pointsover the identified ranges

� Remember the break even equations used for calculation total cost of each location and for calculating the breakeven quantity Q.

� Total cost = F + cQ� Total revenue = pQ

� Break-even is where Total Revenue = Total Cost

Problem

The US Navy is considering four ports for their submarine service: San Diego, Bremerton, Virginia Beach and Tulsa. The fixed and variable cost at each location are given below. Which location can most economically service the four submarines per year?

Location Fixed Cost Variable Cost/ submarine

A. San Diego $500,000 $300,000B. Bremerton $700,000 $200,000C. Virginia Beach $1,000,000 $100,000D. Tulsa $250,000 $1,000,000

� Method of cost-volume analysis used for industrial locations

� Steps

�Determine fixed & variable costs for each location

�Plot total cost for each location

�Select location with lowest total cost for expected production volume

�Must be above break-even

Locational Break-Even Analysis Locational Break-Even Analysis Example-1

You’re an analyst for AC Delco. You’re considering a new manufacturing plant in Akron, Bowling Green, or Chicago. Fixed costs per year are $30k, $60k, & $110krespectively. Variable costs per case are$75, $45, & $25 respectively. The price per case is $120. What is the best location for an expected volume of 2,000 cases per year?

© 1995 Corel Corp.

9

Locational Break-Even Crossover Chart

0

50000

100000

150000

200000

0 500 1000 1500 2000 2500 3000

Volume

An

nu

al

Co

st

Akron

Chicago

Bowling Green

Akron

lowest cost

Bowling Green

lowest costChicago

lowest

cost

Example-2 using Break-even Analysis: Clean-Clothes Cleaners is considering four possible sites for its new operation. They expect to clean 10,000 garments. The table and graph below are used for the analysis.

� From the graph you can see that the two lowest cost intersections occur between C & B (4667 units) and B & A (9000 units)

� The best alternative up to 4667 units is C, between 4667 and 9000 units the best is B, and above 9000 units the best site is A

Transportation Model� Finds amount to be shipped from

several sources to several destinations

� Used primarily for industrial locations

� Type of linear programming model

�Objective: Minimize total production & shipping costs

�Constraints

�Production capacity at source (factory)

�Demand requirement at destination

Transportation Model

� The transportation model technique can be used to determine how many units should be shipped from each plant to each warehouse To Minimize Total Transportation Cost.

10

Simulation Models

� Firms often Consider many variables and Factors when they choose a facility location.

� These variables are often difficult to estimate and they also change in time.

� In these kinds of Dynamic Situations, Simulation may be the best modeling technique.

Simulation Models

� Simulation models allow managers to examine a range of Scenarios AND are well suited to open-ended problems.

� However, the determination of the parameters in a simulation is also a challenging task.

� Also, developing a simulation model may take considerable time and effort.

Study Questions

1. What are the steps in the process of logistics network design? Of these steps, which are most relevant to the task of selecting a specific site for a logistic facility?

2. Discuss the factors that cause a company to analyze the design of a logistics network or to reconsider the location of a particular facility.

3. Describe the grid technique. What is the purpose, and how does it lead to the making of a decision? What are its strengths and limitations?

The end

11

Example

� Straub Ltd. has three plants running at full capacity in Des Moines, Racine, and Gary.

� These plants supply four Distribution warehouses in St. Paul, Milwaukee, Chicago, and Detroit.

Racine, WisconsinMilwaukee, Wisconsin Gary, IndianaDes Moines, IowaSt. Paul, Minnesota,Detroit, MichiganChicago, Illinois

Example

� Straub plans to build a new plant. It has narrowed down the choice of sites to two possibilities: Kalamazoo and Duluth.

� We will now determine which site results in the lowest transportation Cost by using the unit transportation costs, warehouse demands, and plant capacities shown in the following:

Kalamazoo, MichiganDuluth, Minnesota,

Example

12

Example

22

Example

� We will approach this problem in the following manner:

� We will first assume that the selected plant is the Kalamazoo plant, and calculate the total transportation cost.

Example

� Later, we will assume the selected plant is Duluth. Then we will compare the transportation costs for both plants.

� Now, the first step is to find the Optimal number of units to ship between each plant-warehouse combination. This also gives the optimal transportation cost for the problem.

Example

� We can use any of the computerized LP tools for finding the optimum values for this problem.

� Some of these include WINQSB, Lindo, OM Expert, and Excel.

13

Transportation Problem- KalamazooExample

Example

� The total transportation cost will be $10,225 if the new plant is built in Kalamazoo.

� (This can be calculated simply by multiplying the shipment in each cell by its unit cost)

� On the other hand, The optimal number of units to ship between each plant and Duluth Warehouse is found as follows:

Transportation Problem- Duluth

14

Example Example

� The total transportation cost will be $13,825 if the new plant is built in Duluth.

� Therefore, the Kalamazoo plant will incur the lowest transportation cost.

0 100 200 300 400 500 600 700

Selection of Location for Manufacturing Plant

15

Grid Locations

Potential Manufacturing Sites

X Y

Karachi 300 92Lahore 665 502

Multan 545 405

Raw Material Supply and Warehouses Location

RM W1 W2 W3 W4 W5 W6 W7KHI B'Pur Sh'wal F'abad Sgodha G'wala P'war Sukkur

X 280 539 625 605 578 658 545 400Y 85 370 460 495 522 550 622 265

WT. 2600 150 700 350 550 450 300 100

CHOOSE KARACHI