Challenges in Wind Turbine Components

description

Transcript of Challenges in Wind Turbine Components

Challenges in Wind Turbine Components

Charles D. Schultz, PE

Beyta Gear Service

Winfield, Illinois

What is going on in Wind Energy?

Activity on a national scale

Progress has been made but much remains to be done!

It is all about jobs!

Domestic Content Progress

US Wind Resource Map

• US is the “Saudi Arabia” of wind

• Transmission of power from central plains to coasts is a problem

• Even states that aren’t “colorful” have wind potential

Examples of Components

• Blade Hubs are huge castings – up to 15,000 pounds

• Gearbox Assemblies weigh up to 60,000 pounds and are getting larger

• Chassis are big fabrications or castings –up to 40,000 pounds and getting larger

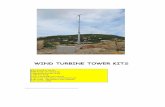

Towers & Blades

• Transport issues, 50 meter lengths & 40 ton weights

• High cost items• Potential for big

improvements• Big incentive to make

locally

Big Market, Long Term Potential

Where are the problems?

Quality is a given

• Due to high cost of warranty work all parts have strict quality specifications

• Tolerances test equipment capabilities• Documentation requirements similar to

aircraft industry• Little acceptance of non-conformances• Metallurgical cleanliness at aircraft levels• Expect to cut up lots of samples for

metallurgical checks

Consistency is Mandatory

• Expect customers to dictate suppliers, methods, and even tooling

• Customers will have quality observers in your facility

• Once a method is approved changes are difficult to make

• Rework –especially in thermal processing- is subject to extreme scrutiny

Big portion of value is in the Nacelle

Large, precision gearboxes required

• Aerospace precision in a mining machine sized package

• Quality levels far in excess of industrial equipment

• Huge warranty and maintenance costs

Other Geared Products

Planetary designs predominate

Typical Gearbox Parts

Typical Pinion

• Not dissimilar to industrial gearing

• Large cross sections challenge heat treat response

• 18CrNiMo7-6 typical material

• Current weights up to 2500 pounds and getting bigger

Typical Sun Pinion

• Large thru hole helps heat treat response

• 18CrNiMo7-6 typical material

• Heat treat distortion common

• Current weights up to 2000 pounds and getting bigger

Typical Gear

• Not dissimilar to industrial gears

• Large cross sections challenge heat treat response

• 18CrNiMo7-6 typical material

• Super finishing issues• Current weights to 10,000

pounds and getting bigger

Typical Splined Hub

• Typically thru hardened but some nitrided or induction hardened

• Length [up to 30”] is a shaping challenge

• 42CrMo4 typical material• Current weights up to

2500 pounds and getting bigger

Typical Ring Gear

• As large as 3 meters• Many thru hardened• Nitriding popular• Induction hardening is

also used• Carburizing possible

but problematic• Shot peening and

super finishing issues

Typical Planet

• Lots of planets needed; 3, 4, or 5 per stage

• Precision size matching within sets

• 18CrNiMo7-6 typical material

• Current weights up to 2200 pounds and getting larger

Serial Production – not job shop!

• 7,000 turbines per year = 27 per day

• 10,000,000 cars per year = 38,462 per day

• Typical large industrial gear shop does less than 5 gearboxes per day

• Aircraft production –similar in quality and complexity – is on the order of 1000 per year

Thermal Processing Issues

• Large parts require large furnaces

• Economic load sizes typically over 5,000#

• Large teeth require deep cases

• Cycle times of 60+ hours not uncommon

• Aerospace quality required at all steps

Volume & price pressure drive equipment purchases

• Customers want lowest possible costs

• Existing job shop equipment can’t keep up

• New technology offers improved quality with faster cycle times

Dramatic Cycle Time Reductions Possible

• Shaping an internal ring takes 30 hours

• Gashing takes 3 hours

• Hobbing a gear can take 8 to 10 hours

• Gashing takes less than 2 hours

Big non-chip making investments needed

• SPC needed on everything

• 100% magnaflux, UT, & nital etch typical

• Shot peening required on everything

• Full met lab checks on every furnace load

• Verification of geometry requires big CMM

• Everything that can be inspected must be inspected

Big investments needed in QC

Super Finishing required on many componentsTo achieve 4 to 8 AA surface finish

An Industrial Challenge worthy of a great nation!

• Potential to transform the economy

• Positive environmental impact

• Huge export market available

• US was once the world leader in wind energy and can be once again

• Plenty of room for innovation at all levels of the business