CHAINS AND SPROCKETS - Cobalt Chains · In addition to this, the company inspects and quality...

Transcript of CHAINS AND SPROCKETS - Cobalt Chains · In addition to this, the company inspects and quality...

2

a CROMANT chain company

Ex��p�i�n�� P�rf��m�n��, S����i�� Re��lt�

Formerly

Cobalt Chains is YOUR source for quality chains and components for the Sugar Industry.

In 2004, Cobalt Chains, Inc. was opened in East Peoria, IL by President and CEO Christopher J. Robinson. The plant

keeps in stock many of the popular chains used today such as: engineered steel, forged link, welded steel, ANSI

roller and transport chains to name a few. Cobalt Chains also fabricates their own chain, chain attachments and

sprockets in house. In addition to this, the company inspects and quality control tests each chain, sprocket, and

attachment that we manufacture. In 2016, Cobalt Chains saw the addition of a robotic welder to the facility. This

allows the company to produce 100% accurate welds.

When it comes to the Sugar Industry, Cobalt Chains produces the highest quality products such as: Welded

Steel, Drop Forged Rivetless, Main Cane & Auxiliary Carrier Chains and many more. This industry requires

products that can withstand the rigors of constant use with no down time. Our products are designed and man-

ufactured to not only stand up to this challenge, but also increase the efficiency of sugar mills in the process.

Today, Cobalt Chains offers the widest variety of chains to fit almost any application. The company has

excelled through the constant development of new markets and new product lines, to its enviable position

today as a true worldwide supplier of premium quality conveyor and power transmission chains. Cobalt Chains

is dedicated to its position as a world-leader in implementing the newest technology available in the conveying

industry.

Exceptional Performance, Superior Results

www.cobaltchains.com

3a CROMANT chain company

33

01 09

16 04

06 07 08 09 10

14 11

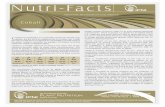

FEEDING

CANE CARRIER

ELEVATOR

MIXED JUICE

PRE-LIMINGTANK

JUICEHEATER

CLARIFICATION

QUADRUPLE EFFECTEVAPORATOR

CRYSTALLIZER

CENTRIFUGING

SUGAR ELEVATOR

RAWSUGAR BIN

VACUUM PAN

BOILER

SHREDDER

MILLINTERMEDIATE CARRIER

JUICE STRAINER/CUSH CUSH ELEVATOR

BAGASSE ELEVATOR BAGASSECARRIER

BAGASSE HOUSE0302

Welded Steel Chains for Feed & Washing Tables

Note: The Diffuser system varies slightly.

Combination Chains for Feed & Washing Tables

Drop Forged Rivetless Chains for Feed & Washing Tables

Main Cane & Auxiliary Carrier Chains

Outboard Roller Cane Carrier Chains

Intermediate Carrier Chains

Intermediate Carrier Chains (FG Attachment)

Intermediate Carrier Cast Link Chains

Forged Inter-carrier Chains

Diffuser Chains

Juice Strainer/Cush Cush Elevator

Bagasse Conveyor and Elevator Chains

Sugar Bucket Elevators

Boiler Grate Chains

Heay Duty Rotary Drive Chains for Pressure Feeder Rollers

Slats and Scraper

Sugar Chain Sprockets

Sugar Chain Sprockets

Carbon / Stainless Steel Tubes

Carbon / Stainless Steel Tubes

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

TYPICAL PROCESS LAYOUT

12

04 05

13

TABLE OF CONTENTS

Telephone: 309-698-9250

4 www.cobaltchains.com

T(mm) H(mm) D (mm) A(mm) R (mm)

E(mm)Sidebar Pin Barrel

F( mm)

Min.Ult.

Strength(KN)

Chain No.Average

Pitch

Avg. Weight

chain kg/FT

WH78

WH78XHD

WH82

WH82XHD

WH9103HD

WH124

WH124XHD

WH111

WH106

WH720C

WH110

WH106XHD

WH132

WH132XHD

WH150

WH155

WH157

WH150XHD

WH159

WELDED STEEL CHAINS FOR FEED & WASHING TABLES

66.27

66.95

78.10

78.10

78.11

101.60

103.20

120.90

152.40

152.40

152.40

153.67

153.67

153.67

153.67

153.67

153.67

153.67

155.57

25.40

25.40

28.58

28.60

31.80

38.10

38.10

57.10

38.10

28.58

47.70

38.10

76.20

76.20

76.20

73.20

76.20

76.20

69.85

6.40

9.50

6.40

9.70

9.70

9.70

12.70

9.60

9.70

9.70

9.60

12.70

12.70

15.88

12.70

12.70

15.90

15.70

15.90

31.75

31.75

31.75

38.10

38.10

38.10

50.80

38.10

38.10

38.10

38.10

50.80

50.80

50.80

63.50

63.50

63.50

63.50

76.20

12.70

14.29

14.29

19.05

19.10

19.05

25.40

19.00

19.05

19.05

19.00

25.40

25.40

25.40

25.40

28.40

29.10

28.40

31.75

75.00

82.00

82.30

96.50

92.30

107.00

119.50

123.90

107.00

96.75

117.30

120.20

156.00

168.86

156.00

158.70

171.00

171.40

170.50

21.34

25.40

25.40

31.75

31.80

31.75

44.45

31.70

31.75

31.75

31.70

44.45

44.45

44.45

44.50

41.10

44.50

41.10

50.80

51.00

50.80

57.15

60.90

57.90

71.40

76.20

85.80

69.85

60.32

76.20

76.20

112.30

118.60

112.30

111.20

117.50

117.30

117.50

146.80

163.50

160.00

254.00

287.00

250.00

542.00

254.00

250.00

254.00

357.00

542.00

542.00

543.00

620.00

771.00

820.00

920.00

950.00

2.00

2.80

2.20

3.90

4.00

3.60

6.40

3.64

3.00

2.95

2.14

5.60

6.50

6.90

7.40

8.61

9.20

7.98

11.30

● WR chains have only thru-hardened rivets.● WH chains have all parts thru-hardened.● WHX chains have thru-hardened parts and induction hardened rivets as standard.● Riveted construction is standard. Pin and cottered construction can be furnished on a made-to-order basis.

HFE

A DT

R

PITCH

HFE

A DT

R

PITCH

IBR or fully heat treated parts plus induction hardened barrels and rivets.

a CROMANT chain company

5Telephone: 309-698-9250

C55

C77

C188

BRH188

C131

C102B

C111

C110

C132

41.43

58.62

66.27

66.27

78.10

101.60

120.90

152.40

153.67

17.48

17.48

23.80

23.80

28.50

50.80

60.33

49.20

79.38

4.75

4.75

6.35

5.80

9.53

9.53

9.53

9.53

12.70

19.05

22.23

28.58

28.58

38.10

38.10

44.45

38.10

50.80

9.53

11.10

12.70

12.70

15.88

15.88

19.05

15.88

25.40

50.03

53.59

68.32

--

92.20

113.54

130.30

113.53

165.35

18.25

18.25

22.25

--

31.75

25.40

36.50

32.51

45.21

57.00

67.50

84.00

62.30

146.30

146.30

220.30

146.30

305.90

0.91

1.04

1.63

2.00

2.95

3.08

4.45

2.72

6.58

Chain No. Pitch E(mm)Sidebar Pin

T(mm) H(mm) D (mm) A(mm)

R( mm)Min.Ult.StrengthQ(KN)

Weight

KG/FT

● Combination Chains (C Type & BRH Type)

Please contact Shining for different attachments

COMBINATION CHAINS FOR FEED & WASHING TABLES

6 www.cobaltchains.com

468HT

678HT

698HT

998HT

X348

X458

X678

102.39

153.19

153.19

229.39

76.99

102.39

153.19

41.28

33.32

39.67

39.67

19.05

25.91

33.32

11.43

18.29

15.06

8.26

10.41

12.19

18.29

47.75

50.80

68.33

64.01

26.92

36.58

50.80

19.05

22.23

28.58

28.58

12.70

15.88

22.23

84.07

76.96

95.25

98.43

44.45

55.58

76.96

29.51

21.34

26.19

25.40

13.21

16.76

21.34

22.23

25.40

31.75

28.58

14.27

17.48

25.40

311.5

378.3

602.9

602.9

106.8

213.6

378.3

Chain NoT(mm) H(mm) D(mm) A(mm)

sidebar PinB(mm) C(mm)

Min.Ult.StrengthQ(KN)

AveragePitch E(mm)

P P

AD

E

H

C

B

T

P P

AD

E

H

C

B

T

● Drop Forged Rivetless chains are typically used asoverhead conveyors on automotive assembly lines, paint lines, appliance assembly lines, sugar mills and in the meat packaging industry.

● These chains have no rotating parts, therefore suffer less from the abrasion caused by sand/dirt, that can come into the mill with the cane. All parts and heat-treated and “T” pins ensure positive locking action in the sidebars.

DROP FORGED RIVETLESS CHAINS FOR FEED AND WASHING TABLES

Regular Type X Type

a CROMANT chain company

7Telephone: 309-698-9250

25.40

28.70

28.70

28.70

31.75

31.75

28.70

31.75

31.75

38.10

31.75

38.10

44.45

44.45

50.80

69.85

69.85

69.85

69.85

76.20

69.85

76.20

76.20

76.20

81.00

88.90

107.95

101.60

88.90

111.125

111.125

111.125

111.125

111.125

143.10

111.125

111.125

111.125

111.125

131.83

203.20

203.20

36.58

76.20

76.20

76.20

76.20

76.20

76.20

76.20

76.20

76.20

76.20

114.30

76.20

127.00

9.65

12.70

12.70

12.70

14.27

14.27

14.27

12.70

12.70

12.70

14.30

16.00

19.05

17.53

31.75

41.40

41.40

41.40

41.40

41.40

41.40

41.40

44.45

42.93

45.50

55.60

69.85

69.85

220

270

315

380

450

450

270

450

630

720

420

750

810

1350

Pitch

P

Sidebar

T(mm) H(mm) D(mm) A(mm) R(mm) F(mm)

Pin Bush Roller

W(mm) W1(mm) K(mm)AverageUltimateStrengthQ(KN)

Chain NoE(mm)

minC(mm)

MAIN CANE & AUXILLIARY CARRIER CHAINS

0904

09060

SS996

09061

1796

1797

2178

2198

09063

09065

113C

SS800R

B5513

C2630

101.6

152.4

152.4

152.4

152.4

152.4

152.4

152.4

152.4

152.4

152.4

203.2

228.6

304.8

30.99

38.10

38.10

38.10

38.10

38.10

39.67

38.10

38.10

38.10

38.40

45.97

61.09

69.85

7.87

9.65

9.65

9.65

9.65

9.65

9.525

12.70

10.41

12.70

12.70

12.70

16.00

16.00

44.45

50.80

50.80

57.15

57.15

57.15

50.80

60.45

60.45

60.45

65.00

71.37

69.85

88.90

17.53

19.05

19.05

19.05

22.23

22.23

22.23

22.10

23.88

26.92

22.20

25.58

31.75

35.05

81.00

97.00

98.40

97.00

99.00

99.00

95.23

112.00

102.10

107.89

111.20

124.00

142.62

133.60

The sidebar can be used Curve Sidebar.

P P

HC

WA

DRF

ET

K W1

P=6''

P=9''

Chain No

152.4

228.6

PitchP

38.9

38.9

D

77.8

80.0

H

17.0

17.0

K

50.8

50.0

T2

128.5

132.0

W

76.2

95.0

W2

12.30

9.58

WeightKG/FT

1423

1423

UltimateTensileQ(KN)

38.1

40.0

T1

Dimension

D

W T2

T1

P P

KW2

H

8 www.cobaltchains.com

2397 M14

2358 M14

1707 M14

2614 M14

2630 M14

12220 M14

1223 M14

2648 M14

152.4

228.6

304.8

304.8

304.8

304.8

304.8

304.8

55.5

49.23

76.20

69.85

69.85

70.64

70.61

92.20

10

12.70

12.70

15.88

15.88

15.88

15.88

19.05

63.5

63.50

63.50

88.90

88.90

101.60

101.60

101.60

22.2

22.23

25.40

31.75

34.90

38.10

38.10

41.40

116.00

154.20

154.76

161.90

162.70

161.44

195.58

196.85

31.75

32.20

38.10

44.30

47.75

53.98

53.98

82.55

44.5

44.45

57.15

63.50

63.50

79.38

88.90

101.60

380

472

617

900

980

1125

1350

1575

Chain No Pitch P E(mm) minSidebar Pin Bush Roller

AverageUltimateStrengthQ(KN)T(mm) H(mm) D(mm) A(mm) R(mm) F(mm)

P P

H E

T

DRF

OUTBOARD ROLLER CANE CARRIER CHAINS

4" HIGH END PLATES12" PITCH, HEAVY DUTYDOUBLE BEADED STEEL PANS

3/6" STEEL PANREINFORCING CHANNEL

OPTIONALIMPACT SHOES—RECOMMENDED FORSEVERE IMPACT

EXCLUSIVE TRI-LOK SADDLE DESIGN FOR LOADEQUALIZING AND REMOVAL OF ROLLER ANDBUSHING WITHOUT DISASSEMBLY OF CHAIN

STYLE #2 HEAT=TREATEDCAST IRON ROLLER

SQUARE STUB SHAFT

ROLLER SPACERCAST-IRONHEAT-TREATEDBUSHING

ALL STEELCONVEYOR CHAIN

a CROMANT chain company

9Telephone: 309-698-9250

INTERMEDIATE CARRIER CHAINS

Chain NoPitch

P T(mm) H(mm) D(mm) A(mm) R(mm)

1131

09060

09061

09063

1796

2198

152.4

152.4

152.4

152.4

152.4

152.4

39.63

38.10

38.10

38.10

38.10

38.86

9.53

9.65

9.65

10.30

9.65

12.70

50.80

50.80

57.15

61.90

57.15

57.15

19.05

19.05

19.05

23.83

22.23

22.35

99.00

97.00

97.00

102.10

99.00

112.00

28.60

28.70

28.70

31.75

31.75

31.75

76.20

69.85

69.85

76.20

69.85

76.20

66.00

88.90

88.90

100.00

88.90

99.31

209

270

380

630

450

450

PitchP

E(mm)min F(mm)

W(mm) StrengthQ(KN)

Sidebar Pin Bush Roller AverageUltimateChain No

T(mm) H(mm) D(mm) A(mm) R(mm)

C84

C69

228.60

304.80

73.00

69.85

14.28

15.88

82.06

101.60

31.75

35.24

160.00

163.00

38.00

42.00

76.20

106.90

209.55

209.60

291.31

295.00

18.00

20.00

1112.00

1350.00

E(mm) W1(mm) W2(mm) F(mm) K(mm)

AverageUltimateStrengthQ(KN)

BushingPinSidebar

W2F

W1

E

T

K

A RD

P P

H

10 www.cobaltchains.com

Chain NoPitch

P

E(mm)min T(mm) H(mm) D(mm) A(mm)

Sidebar Pin

R(mm) C(mm)Weight

KG/FT

Min. UltStrengthQ(KN)

32949 203.20 46.0 12.7 80.0 25.4 122.0 38.1 95.0 10.66 588

5002 FG35 E4P

5025 FG36 E4P

SS9957SJ

153.67

152.4

152.4

50.80

50.80

38.90

13.00

12.70

12.70

64.00

76.20

82.60

25.27

25.27

25.40

127.00

127.00

56.13

50.80

50.80

44.50

141.00

146.30

120.14

400

520

445

Chain NoPitch

P

E(mm)min T(mm) H(mm) D(mm) A(mm) R(mm)

C(mm)Average Ultimate

StrengthQ(KN)

BushPinSidebar

P P

H

A

DR

E

P P

HC

AD

E

T

A

DR

ET

C

P P

H

INTERMEDIATE CARRIER CHAINS (FG ATTACHMENTS)

FG ATTACHMENT

SS9957SJ

a CROMANT chain company

11Telephone: 309-698-9250

Chain No

907-E51 80.52 146.5 58.3 16.0 26.0 42.8 16.8 40.0 43.0 5.75 125

Pitch

PA B D E F K R W

Weight

KG/FT

Min. UltStrengthQ(KN)

Dimension

P

F

R

D

B

A

W

K

E

INTERMEDIATE CARRIER CAST LINK CHAINS

12 www.cobaltchains.com

Chain NoPitch

P A B D E G K W W1

Weight

KG/FT

Min. UltStrengthQ(KN)

Dimension

P

B W AD

G

E

K

W1

FORGED INTER CARRIER CHAINS

P=9''

P=12''

228.6

304.8

147.0

156.0

90.0

101.6

40.2

44.5

41.0

54.0

120.0

152.4

17.0

17.5

90.0

82.6

75.0

108.0

12.46

30.50

700

880

a CROMANT chain company

13Telephone: 309-698-9250

Block chain

P=200

Block chain

P=200

Block chain

P=250

Block chain

P=300

I

II

III

IV

200

200

250

300

27.0

27.0

34.0

52.0

8.0

8.0

16.0

20.0

45.0

45.0

75.0

110.0

19.3

19.3

31.8

44.3

57.0

57.0

87.4

117.0

25.0

25.0

38.0

50.0

2.99

2.83

8.11

16.69

175

210

600

1350

Chain No Style Pitch P E(mm)

min

Sidebar Pin BushWeight

KG/FT

Min. UltStrengthQ(KN)A(mm)D(mm)H(mm)T(mm) R(mm)

P

A E

H

P

T

P

A E

H

PT

P

A E

H

PT

P

A E

H

PT

DIFFUSER CHAINS

I II

III IV

14 www.cobaltchains.com

4103-F29

4103-F30

WH9103HD-F29

WH9103HD-F30

C

56.4

56.4

56.4

56.4

J

79.2

79.2

79.2

79.2

F1

66.5

66.5

66.5

66.5

G

50.8

50.8

50.8

50.8

T

10.4

10.4

9.7

9.7

4.36

4.36

5.15

5.15

DimensionsChain No

weight

KG/FT

P

R

E

A

JC

P

F1G

T

E

A DT

R

H

P

4103

WH9103HD

78.11

78.11

28.4

31.8

19.1

19.1

90.5

92.3

47.8

57.9

2.5

3.6

127.4

267.3

Chain NoPitch

P

E(mm)

min D(mm) A(mm)

Pin Bush

R(mm)

Weight

KG/FT

Min. Ult Strength

Q(KN)

JUICE STRAINER/CUSH CUSH ELEVATOR

4103 WH9103HD

4103 WH9103HD

F29/F30

a CROMANT chain company

15Telephone: 309-698-9250

0401

3135

2184

3184

09060

09061

09063

1796

2198

9184

9185

F9184

8184

B5509

101.6

152.4

152.4

152.4

152.4

152.4

152.4

152.4

152.4

152.4

152.4

152.4

203.2

228.6

33.27

31.75

34.90

35.05

38.10

38.10

38.10

38.10

38.10

38.10

38.10

39.60

45.97

37.85

9.65

9.65

9.50

9.65

9.50

9.65

10.30

9.65

12.70

12.70

12.70

12.70

12.70

9.65

41.40

50.80

50.80

60.45

50.80

57.15

61.90

57.15

57.15

63.50

63.50

63.50

69.85

57.15

16.00

19.05

22.23

22.35

19.05

19.05

23.83

22.23

22.35

23.88

23.88

23.88

25.40

22.23

89.66

90.68

95.20

109.47

97.00

97.00

102.10

99.00

112.00

112.80

112.80

112.80

96.77

76.45

23.88

28.70

31.75

31.75

28.70

28.70

31.75

31.75

31.75

31.75

31.75

31.75

38.10

31.75

50.80

88.90

76.20

76.20

69.85

69.85

69.88

69.85

69.85

76.20

88.90

76.20

88.90

76.20

57.15

60.45

91.90

65.02

88.90

88.90

100.08

88.90

98.55

98.43

98.43

98.43

81.79

79.25

200

250

356

380

270

380

630

450

450

787

787

787

751.5

450

Chain No

Pitch

P

E(mm)

min

Sidebar Pin Bush Roller Average Ultimate

W(mm) Strength

Q(KN)T(mm) H(mm) D(mm) A(mm) R(mm) F(mm)

BAGASSE CONVEYOR AND ELEVATOR CHAINS

Sidebar and attachment according to customers’ requirements

16 www.cobaltchains.com

Chain No C F W2TK W W1

WeightKgs/mt

K2

SUGAR BUCKET ELEVATORS

SS102B

SS111

SS110

SS856

28.4

31.2

53.8

47.8

25.4

38.1

25.4

47.8

162.8

190.5

162.1

228.6

10.4

14.2

10.4

14.2

9.7

9.7

9.7

12.7

66.5

91.9

73.2

107.9

44.5

58.7

44.5

57.2

134.9

158.8

134.9

160.3

13.4

22.7

12.8

34.3

B

Pitch E(mm) Bush

P min T(mm) H(mm) D(mm) A(mm) R(mm)SS102B 101.6 53.8 9.7 38.1 15.7 110.5 25.4

SS111 120.9 66.8 9.7 50.8 19.1 129.6 36.6

SS110 152.4 53.8 9.7 38.1 15.7 110.5 31.8

SS856 152.4 76.2 12.7 63.5 25.4 154.3 44.5

Chain NoSidebar Pin

a CROMANT chain company

17Telephone: 309-698-9250

A

D

E

T

P

H

P

BOILER GRATE CHAINS

Chain NoPitch

P

E(mm)

min

Sidebar Pin Min. UltStrength

G(KN)

Weight

KG/FTT(mm) H(mm) D(mm) A(mm)

18 www.cobaltchains.com

HEAVY DUTY ROTARY DRIVE CHAINS FOR PESSURE FEEDER ROLLERS

1031

1032

3075

3514

1242

1245

5031

5035

6065

1353

6060

6560

P

78.11

78.11

78.11

88.90

103.20

103.45

127.00

127.00

152.40

103.89

152.40

165.10

min

38.10

38.10

38.10

38.10

49.20

49.30

69.90

65.00

76.20

57.20

82.60

82.60

7.90

7.90

9.70

12.70

12.70

14.20

15.70

19.10

19.10

15.70

22.40

22.40

H(mm)

38.10

41.10

44.60

57.20

57.20

60.50

88.90

88.90

120.70

76.20

127.00

127.00

D(mm)

15.90

15.90

16.50

22.20

22.20

23.80

31.80

34.90

44.50

33.30

44.50

44.50

85.90

87.10

93.70

112.80

124.00

130.00

158.80

168.10

185.90

146.10

204.70

204.70

R(mm)

31.80

31.80

31.80

44.50

44.50

45.20

63.50

63.50

76.20

66.50

88.90

88.90

216.00

270.00

337.50

630.00

630.00

765.00

1395.00

1575.00

2700.00

945.00

2700.00

2700.00

Chain No.Pitch (mm) E(mm)

T(mm) A(mm)

AverageUltimateStrengthQ(KN)

BushPinsidebar

H

P P

AED

R

T

a CROMANT chain company

19Telephone: 309-698-9250

ENQUIRY REF:________________________________________ QUANTITY:_____________________________________________

CHAIN REF:______________________ ATTACHMENT:______________________ STYLE(C,A,G ETC):________________________

NO. OF STRANDS:______________________ LENGTH:_______________________THICKNESS:_____________________________

MATERIAL:_____________________________________________BOLT DIA: _____________________________________________

ADDITIONAL INFORMATION:____________________________________________________________________________________

_____________________________________________________________________________________________________________

__________________________________________________DRAWING No._______________________________________________

SLATS AND SCRAPER

20 www.cobaltchains.com

SUGAR CHAIN SPROCKETS

Cobalt Chains is the number one source for industry-standard and custom sprockets. Our CAD

department is able to design virtually any combination of sprockets for your individual application.

We specialize in unique design solutions to overcome abrasion or corrosion problems in industries

such as sugar, waste-to-energy, cement, pulp and paper, commercial grain handling and chemi cals &

fertilizers.

a CROMANT chain company

21Telephone: 309-698-9250

The design details are then sent to our fabrication department for replication in one of any number of

combinations of steel alloy’s and heat treatments. You can rely on Cobalt Chains to provide you with

the best long term solution for your specific application.

22 www.cobaltchains.com

STAINESS STEEL TUBES FOR JUICE HEATERS/EVAPORATORS/VAC-PANS

CARBON STEEL FOR BOILERS/JUICE HEATERS/EVAPORATORS/VAC-PANS

RANGE: 6.0MM OD to 168.3MM OD

GRADES: AISI-304, 304L, 316, 316L, 439.

STANDARDS: ASTM A-213, A-249, A-269, A-270, A-312, A-376,A-554, A-668 and A-358, A-778

ALSO DIN, IS, JS, and BRITISH STANDARDS

INFORMATION NEEDED TO QUOTE:

ITEMSOD (Tolerance) Wall (Tolerance)Length (Tolerance)

QtyMaterial

StandardPacking Test

Certificate

HT (Annealing)Insider-Levelling

Surface condition (Polishing)Surface condition (Pickling)

YES NO

a CROMANT chain company

23Telephone: 309-698-9250

STAINESS STEEL TUBES FOR JUICE HEATERS/EVAPORATORS/VAC-PANS

CARBON STEEL FOR BOILERS/JUICE HEATERS/EVAPORATORS/VAC-PANS

Specification

ASTM A312 A778 JIS G3459

Tolerance for Stainless Steel Pipe

O.D.

(mm)

Tolerance

(mm)

O.D.

(mm)

Tolerance

(mm)

48.26

~

114.30

+0.8

-0.8

114.30

~

219.08

+1.6

-0.8

219.08

~

457.2

+2.4

-0.8

457.20

~

660.40

+3.2

-0.8

660.40

~

863.60

+4.0

-0.8

863.60

~

1219.20

+4.8

-0.8

+22.5%

-12.5%

Wall thickness Straightness

6.4mm/6M

Length

+50mm

-0mm

≥defined

length

ASTM

JIS

<30mm

±0.30mm

≥30mm

±1%

W.T.

Tolerance

m<2m

±0.2mm

≥2mm

±10%

48.26≤

+0.4

-0.8

Specification

ASTM A249 A269 JIS G3463

Tolerance for Boiler and Heat-Exchanger Stainless Steel Tube

Wall Thickness Length

+50mm

-0mmASTM

JIS

≤60 ±0.2560~80 ±0.3080~100 ±0.40100~120 +0.40 -0.60

120~160 +0.40 -0.80

12.7~38.1 ±0.13

38.1~88.9 ±0.25

88.9~139.8 ±0.38

ItemOutside Diameter(mm)

+0.4mm -0mm

+20% -0mm

+22% -0mm

<2mm

≥2mm

-

<40mm

<40mm

≥40mm

≥defined length

ToleranceW.T.O.D.

±10%

Outside Diameter

www.cobaltchains.coma CROMANT chain company

Ex��p�i�n�� P�rf��m�n��, S����i�� Re��lt�

Formerly

a CROMANT chain company

Ex��p�i�n�� P�rf��m�n��, S����i�� Re��lt�

Formerly200 Catherine Street • Unit 7B (Box 8)

East Peoria, IL 61611, USA

Telephone: 309-698-9250 Facsimile: 309-698-9259

www.cobaltchains.com

Exceptional Performance, Superior Results