CENTRIFUGAL PUMP - SPX FLOW€¦ · The W+ centrifugal pump is exclusively intended for pumping ......

Transcript of CENTRIFUGAL PUMP - SPX FLOW€¦ · The W+ centrifugal pump is exclusively intended for pumping ......

FOR M NO.: L453147G B R EVI S ION: 06/2013

CE NTR I FUGAL PU M P

OPE RATI NG MAN UAL

W+

R EAD AN D U N D E R STAN D TH I S MAN UAL PR IOR TO OPE RATI NG OR S E RVICI NG TH I S PROD UCT.

GB

Form no.: L453147GB– revision 06/2013

Table of contents Page

For spare parts, see separate spare parts list.

1. General description 21.1 Intended use 2

2. Sectional drawing 3

3. Warnings 4

4. Introduction 64.1 The W+ range 64.2 The W+ pump, standard and auxiliary equipment 64.3 Identificationofpumpmodels 64.4 Identificationofmotormodels 64.5 Handling and transport 74.6 Weights 7

5. Installation of pump 85.1 Positioning 85.2 Lining up the pipe system 85.3 Power supply 85.4 Liquidsupplyforflushedshaftseal 85.5 Connectingsteamandsteamcondensateforasepticuse 8

6. Start-up and operation 96.1 Checkingthepumpforforeignmaterial 96.2 Checkingthepump 106.3 Starting the pump 106.4 Flushing liquid 10

7. Service and maintenance 117.1 Checkingtheshaftseal 117.2 Replacingtheshaftseal 117.3 Replacingthemotor 137.4 Recommendedinventoryofspareparts 14

8. Technical data 15

8.1 Soundpressureandsoundeffectlevel 158.2 MaximumpermissibleoutletpressureforW+pumps 168.3 Tightening torques 168.4 Cleaningrecommendation 16

1

APV

GB

Form no.: L453147GB– revision 06/2013

1. General description

Thisoperatingmanualshouldbereadcarefullybythecompetentoperatingandmaintenancepersonnel.

Itmustbepointedoutthatwewillnotacceptanyliabilityfordamageorfaultsresultingfromfailingtocomplywiththisoperatingmanual.

Descriptionsanddatagivenhereinaresubjecttotechnicalchanges.

1.1 Intended useTheW+centrifugalpumpisexclusivelyintendedforpumpingliquids,especiallyinfoodandbeverageinstallations.

Refrainfromusingthepumpinamannerwhichexceedsthescopeandspecificationsstatedbelow.

Anyuseexceedingthemarginsandspecificationssetforthisconsideredtobenotintended.

Themanufacturerisnotliableforanydamageresultingfromsuchactivities.Theuserwillbearthefullrisk.

Caution! Improperuseofthepumpleadsto: - damage -leakage -destruction -potentialfailuresintheproductionprocess

2

APV

GB

Form no.: L453147GB– revision 06/2013

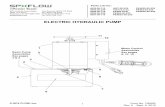

2. Sectional drawing

1a Pump housing2a Cap nut3 O-ring4 Impeller6 O-ring7a Backplate8 Locatingpin9a Clamp ring10 O-ring11 Shaft14 Extensionframe

5.1 Fasteningkitforsinglemech.seal

5.3 Pressure ring5.4 Drain pipe5.5 O-ring5.6 Stationarysealface5.7 Rotarysealface5.8 Pin5.9 Fasteningkitfordouble

mech.seal5.10 O-ring5.11 Pressure ring

Section1:SinglemechanicalshaftsealforshaftsofØ25andØ35Section2:DoublemechanicalshaftsealforshaftsofØ25andØ35Section3:SinglemechanicalshaftsealforshaftsofØ55Section4:DoublemechanicalshaftsealforshaftsofØ55

Section 1

Section 3

Section 2

Section 4

3

APV

GB

Form no.: L453147GB– revision 06/2013

3. Warnings

1. Readthroughtheinstructionsbeforeinstallingthepumpandstartingitup.Ifindoubt,contactyourlocalSPXFlowTechnologyrepresentative.

2. Checkthatthespecificationsofthemotorandmotorcontrolunitarecorrect.Thisappliesinparticulartoapplicationswhichcarryariskofexplosion.

3. Observethatapumpmaybeunstableandmaytilttotheforeontoitsinlet port when having a relatively small motor and being assembled onbracketsinsteadofbeingequippedwithaframewithadjustablefeet.Becarefulduringtheinstallationofsuchapump.(Forthisreason, the W+50/600 pump is equipped with an anti-tilting unit.)

4. Donotstartthepumpbeforeallpipeconnectionshavebeenfittedcarefullyandtightened.Specialprecautionsmustbetakenwhenthepumpisusedtopumphotand/orhazardousliquids.Insuchcasesfollowthelocalregulationsforpersonalsafetywhenworkingwiththeseproducts.

5. Donotstartthepumpbeforethemotorshroudorshaftguardhasbeensecurelyfitted.

6. Thepumpcontainsrotatingparts.Neverputyourhands,fingersorobjectsintoapumpwhileitisinoperation.

7. Nevertouchtheshroudduringoperation,asitcanbecomeveryhot.

8. Nevertouchthepumpbodyduringoperationifthepumpisbeingusedforhotmedia,asthereisariskofbeingburnt.

9. Ifthepumpisoperatingwithliquidmediabuthasnocirculation,theliquidwillheatupandmayturnintovapour,whichcouldcauseanexplosion.

10. Alwaysremoveallassemblyandauxiliarytoolsfromthepumpbeforestarting it up.

11. Neverhosedownorcleantheelectricmotordirectlywithwaterorcleaningfluid.

12. Neverliftthepumpattheshroud,asitisnotdesignedtocarrytheweightofthemotor.Removetheshroudbeforeliftingthepump.Alwaysusesecurelyfittedliftingstrapswhenliftingwithacraneorsimilarliftinggear.

13. Neverdismantlethepumpbeforethemotorhasbeendisconnectedfromthepowersupply.Removethefusesanddisconnectthecablefromthemotorterminalbox.

14. Theinstallationofallelectricalpartsmustbecarriedoutbyqualifiedpersonnel.

4

APV

GB

Form no.: L453147GB– revision 06/2013

3. Warnings

15. Neverdismantlethepumpuntilthepipesystemhasbeendrained.Rememberthatliquidwillalwayscollectinthepumpbody.Ifthepumpistobeusedforhotand/orhazardousliquids,specialprecautionsmustbetaken.Insuchcasesfollowthelocalregulationsforpersonalsafetywhenworkingwiththeseproducts.

16. Thefollowingvaluesspecifiedforthepermissiblepressuremustnotbeexceeded:Max. 18 bar W+10/8, W+22/20, W+30/80, W+35/55, W+35/35,

W+110/130Max. 14 bar W+25/210, W+30/120,W+50/600, W+50/8,

W+55/35, W+55/60, W+60/110, W+65/350, W+70/40, W+80/80

Thea.m.valuesarealsovalidforthecorrespondingmodelsintheWa+ and Wi+ ranges. It is important to remember that the maximum outletpressurevaluesapplywhenwaterisatatemperatureof20°C.

5

APV

SPX Flow TechnologyHermana Frankego 9, 85-862 Bydgoszcz POLAND

XXXXXX

W+22/20 125

3412032

GB

Form no.: L453147GB– revision 06/2013

4. Introduction

4.1 The W+ rangeThismanualcoversthestandardversionsoftheW+pumpaswellastheasepticversions:Wa+andpumpswithaninducer(Wi+).Checkthepump'snameplatetodeterminewhetheryouhaveoneofthesemodels.TheWHP+andW+140/50aredescribedinaseparatemanualwhichissuppliedwiththepump.TheWK+(pedestalpumpversion)isdescribedinasupplementarymanual.

4.2 The W+ pump, standard and auxiliary equipmentStandard options:

- Withorwithoutmotorcover. - Withframeandfeetorfirmsupports. - Withshaftsealincarbon/SiCorSiC/SiC. - Witho-ringsinEPDMorFPM(Viton). - Withsinglemechanicalordoublemechanicalseal,fittedforwater-

flushedorsteam-flushedshaftseal(Wa+)

Additional options: - Heating/coolingjacket. - Casing drain. - Soundabsorbingmotorcover. - Pumpcart. - Inducer(Wi+). - DoubleO-ringsealforpumphousing,fittedforsterileflushing

purposes. - Heavydutyclampringwhichincreasesthepump'smaximum

permissibleoutletpressureto25bar(availableforW+30/120,W+55/35,W+55/60,W+60/110,W+70/40)orto20bar(availableforW+80/80).

- W+pumpscanbesuppliedwithallstandardweldedferrules,e.g.unions,clamprings,flanges.

4.3 Identification of pump modelsAnameplateasshowninFig.1isfittedontheextensionframe.ExampleTypeW+22/20: Specifiesthepumpmodel(W+22/20).125: Indicatesthediameteroftheimpeller.Serialno.: IndicatesthepumpIDnumber.Orderno.: SpecifiestheSPXFTordernumber.Year: Showstheyearofmanufacture.Theemptyfieldcanbeusedtoidentifythepumpwithinanoverallsystem.

4.4 Identification of motor modelsTheplateindicatesthemotortypeandheightofconstruction(item2),motorcapacity(kW;item1),speed,etc.

Fig. 1

Fig. 2

6

APV

GB

Form no.: L453147GB– revision 06/2013

4. Introduction

4.5 Handling and TransportActwithcautionwhenliftingthepump.Allpartswithaweightofmorethan20kgmustbehandledwithasuitablehoistingdevice.Useacrane,forklifttruckorothersuitableliftinggear,andalwaysuse2hoistingbeltsinconjunctionwiththis.(Fig.3).Placethehoistingbeltsaroundtherearpartofthemotorandaroundtheextensionframe.Takecarethatthebeltsareevenlyloadedwhenthepumpislifted.

Caution! Alwaysuse2hoistingbeltsandneverfastenatthefrontofthepumpbody.

4.6 Weights

Fig. 3

Pump type

Motor80 90 100 112 132 160 180 200 225 250 280

0.75 kW 1.1 kW

1.5 kW 2.2 kW

3.0 kW 4.0 kW5.5 kW 7.5 kW

11.0 kW 15.0 kW 18.5 kW

22.0 kW30.0 kW 37.0 kW

45.0 kW 55.0 kW75.0 kW 90.0 kW

W+10/8 20 20 --- --- --- --- --- --- --- --- --- ---

W+22/20 28 29

33 36 41 46 57

62 --- --- --- --- --- ---

W+30/80 --- 53 56 61 66 77

82

117 127 138

--- --- --- --- ---

W+25/210* --- --- --- --- ---169 184 194

212 282 295 349 --- ---

W+35/35 --- 36 39 44 49 60

65

100 109 117

--- --- --- --- ---

W+35/55 --- 51 51 59 64 75

80

114 123 133

--- --- --- --- ---

W+30/120 --- 59 62 67 71 83

88

125 135 145

170 236 249 --- --- ---

W+50/600 --- --- --- --- --- --- 295 360 381 426 485 570

605

W+50/8 --- 45 48 53 58 69

73 --- --- --- --- --- ---

W+55/35 --- 54 59 66 71 82

87

127 136 147

--- --- --- --- ---

W+55/60 --- 61 64 71 76 88

93

127 136 146

171 226 251 --- --- ---

W+60/110 --- 68 71 76 82 94

99

132 141 151

176 225 250 295 --- ---

W+65/350 --- --- --- --- 132 137

171 180 190

220 295 330 363 420 505

540

W+70/40 --- 75 78 83 87 99

104

138 148 158

183 238 263 --- --- ---

W+80/80 --- 83 83 89 95 107

112

146 155 165

190 265 280 335 395 ---

W+110/130 --- --- 105 109 118 123

160 173 183

218 276 300 355 415 500

535

* 1500 rpm only

Theweightsmayvarydependingonaccessoriesandfittings,andarethereforeintendedonlyasareferencevalueforhandling,transportandpackagingactivities.

7

APV

GB

Form no.: L453147GB– revision 06/2013

5. Installation of pump

5.1 PositioningThefollowingmustbeobserved: Thepumpmustbepositionedsothatthesuctionpipeisasshortaspossibleandthereisaslopinggradienttowardsthesuctionportofthe pump.Keepthenumberofvalves,bendsandtee-piecesonthesuctionside to an absolute minimum.Theremustbesufficientspacearoundthepumpforpipingandaccessformaintenance.

5.2 Lining up the pipe systemEnsure that the pipe system is adequately underpinned with pipe supportssothatthepumpbodyisnotsubjecttostrainfromortheweightofthepipesystem.

Caution! Duringthesuctionprocess,thepumpmaytendtovibrate.Apipesupportshouldbeplacedclosetothepumpsuctiontopreventpipeworkvibrationcreatingexcessivenoise.

5.3 Power supplyThemotormustbeconnectedviaacontrolcabinettothenetworkincompliancewiththelocalregulations.Moreover,themotormustbeconnectedinaccordancewiththeinstructionsindicatedintheinnersideoftheconnectingboxlidofthemotor.Themotorshouldbeconnectedinsuchawaythatthemotorandthereforetheimpellerareanti-clockwisewhenviewedfromthefrontinthedirectionofthesuctionportofthepumpbody.(Fig.4).

5.4 Liquid supply for flushed shaft sealPumpswithaflushedshaftsealarefittedwithtwoPTFEhoseconnectorsonthesealingflange.Thehoseconnectorsare1/8inchandfit6.0mmhoses.Therequiredflowquantityamountsto15–30l/h.The maximum permissible pressure is 7 bar.

Thehoseconnectionshouldalwaysbepositionedverticallywiththefluidinletbelowandtheoutletabove(Fig.5).Fluidconsumptioncanbelimitedbyinstallingasolenoidvalveonthesupplyside.Theopen/closefunctionofthesolenoidvalvecanbecontrolledbythepump'sstart/stopsequence.Donotusesteamorsteamcondensateontheconnectionforflushingliquids.Ifyouwishtousesteamasasealant,aspecialasepticpipeconnectormustbeused.Forconnectorssee5.5.

5.5 Connecting steam and steam condensate for aseptic useWhenstaticdoublesealsareused,theconnectionforsteamorsteamcondensateatthepumpbodyisprovidedwithfittingsfor8 mm stainless steel pipes.Steamofupto150°Cand5barcanbeused.

Fig. 4

Fig. 5

8

APV

GB

Form no.: L453147GB– revision 06/2013

6. Start-up and operation

Beforestartingthepump,dismantleandcleanthesuctionpipe. Anyforeignmaterialinthepumpshouldberemoved.

6.1 Checking the pump for foreign materialRemovethepumpbodyasdescribedbelow.Thesectionaldrawing(page3)istobeusedforreferencepurposes.

1. Disconnectthepowersupply.

2. Removethepumpbody(items1a,1b)byunscrewingtheclampring(item9a)orbodyscrews,andcarefullyextractfromthebody.

3. Turntheimpeller(item4)toensurethatthereisnoforeignmaterialbehind it.

4. Removeanyforeignmaterialfrominsidethepump.

5. Whenthepumpbodyiscleanandfreeofforeignmaterial,reassemblethe pump.

Mountthepumpbodyasdescribedbelow:

6. Checkthatthelocatingpin(item8),whichisinstalledinthetopofthebackplate,fitswiththedetentinthepumpbodyandcarefully(toavoiddamagetotheO-ring)pressthepumpbody(item1a,1b)insoitcoverstheO-ring(item6).Thenfastenwiththeclampring(item9a)orbodyscrewsandapplythecorrecttighteningtorque.

M10: max.35Nm(25ft-lb)

7. Checkthatthepipeunionshavebeentightenedproperlyandthatthepipesupportshavebeenfitted.

Tofacilitatethefittingofthefrontcoverandpumphousing,werecommendthattheO-ringislubricatedwithathinlayeroffood-friendly,acid-freegreaseorsoap.

9

APV

GB

Form no.: L453147GB– revision 06/2013

6. Start-up and operation

6.2 Checking the pumpTocheckthatthepumpisworkingsatisfactorily,pourwaterintothepumpandstartitmomentarily.Checkthedirectionofrotation.Fig.6.Listenforanyunusualnoises.Inpumpswithwater-flushedorsteam-flushedshaftseals,thesealchambermustbefilledwithwater/steam.

Caution! Neverallowthepumptorunwithoutliquid,asthiswillruintheshaftseal.

6.3 Starting the pumpCheckthefollowingbeforestartingthepump:

- Thattheshaftguardhasbeenfittedproperly. - Thatthereisunobstructedaccessforliquidandthatthepumpis

primed. - Thatthevalveonthedischargesideisclosed.

Thevalveonthedischargesideisclosedduringstart-uptopreventthemotorfromoverloading,butshouldbeopenedagainassoonasthe pump has been started.

Note! Thepumpshouldnotbeleftrunningtoolongwithoutpumping(typically15minutesifthepumpedliquidisnothot),becauseitwillgetwarmandtheprimingliquid will evaporate.

6.4 Flushing liquidInpumpswithaflushedshaftseal,checkthatthesupplyinletfortheflushingmediumisopenandthattheflowofthemediumisadequate(approx.15-30litres/hour).

Fig. 6

10

APV

GB

Form no.: L453147GB– revision 06/2013

7. Service and maintenance

7.1 Checking the shaft sealCheckthepump'sshaftsealforleaksonaregularbasis.Iftheshaftsealisleaking,replaceitoritsrelevantpartsasdescribedbelow.

7.2 Replacing the shaft sealThesectionaldrawing(page3)showsthepositionandconstructionoftheshaftseal(applyingbothtoordinarysealsandsealswithliquid/steamflushing).

Toreplacetheshaftsealitisnecessarytodismantlethepump.Followthestepsdescribedbelowandrefertothesectionaldrawing(page3).

1. Disconnectthepowersupplyinthemotorisolatorbyremovingthefusesanddisconnectingthecables.

2. Turnoffthesteamandflushingliquidsupply.

3. Closethepumpsuctionanddischargepointanddrainthepumphousing.Ifthepumpisusedforhotand/oraggressiveliquids,specialprecautionsmustbetaken.Insuchcases,observethelocalregulationsforpersonalprotectionwhenworkingwiththeseproducts.

4. Opentheclampring(item9a)orthehousingscrewsoncetheinletand outlet pipes have been properly isolated. Dismantlethepumphousing(item1a,1b)andremovetheimpeller(item4).

5. Takethestationarysealface(item5.6)installedinthebackplate(item7a,7b)outwithyourfingers.

6. Removetheo-ring(item5.5)fromthestationarysealface.

7. Useyourfingerstoremovetherotarysealface(item5.7)fittedintheimpeller(item4).

8. Removetheo-ring(item5.5)fromtherotarysealface.

9. Cleanthechambersofthestationaryandrotarysealfacewithairor water.

9a Therearstationarysealface(item5.6)ismountedonthepressurering*(item5.11).Therotarysealface(item5.7)ismountedontheshaft(item11).Theseareremovedinthesamewayasthefrontsealcomponents.*TheW+50/600pumphas2identicalpressurerings.

Dismantling the pump

Dismantling the shaft seal

11

APV

GB

Form no.: L453147GB– revision 06/2013

7. Service and maintenance

10. ChecktheO-ringsforsignsofstiffness,lackofelasticity,brittlenessand/orchemicalcorrosion.Replacewornordamagedparts.

11. Checkthestationaryring(item5.6)androtaryring(item5.7)forsignsofwear.Wearsurfacesmustbecompletelyfreeofcracks.Ifthisisnotthecase,boththestationaryringandtherotaryringmustbereplaced.

11aInthecaseofwater-flushedshaftsealsandasepticshaftseals,checktherearsealrings(item5.6,5.7)forwear,andreplaceifnecessary.

12. Fitthenewo-ringsonthestationarysealfaceandrotarysealface.

Caution! Remember to moisten these with water.

13. Fittherotarysealfaceontheimpellerwithoutusingtools.

Note! Thenotchintherotarysealfacemustbeinstalledsothatitfitswiththedrivingpin(item5.8)intheimpeller hub.

13aInthecaseofdoublemechanicalshaftseals,alsofitarotarysealface(item5.7)witho-ring(item5.5)inthelocationontheshaft–again without using tools.

14. Fitthestationarysealfaceinthebackplatewithoutusingtools.

Note! Installthestationarysealfacesothatitfitswiththepininthebackplate.Checkthatthestationarysealfaceispositionedsothatitslidesbackandfortheasilywithinthebackplate.

14aWhenfittingnewdoublemechanicalshaftseals,removethedrainpipe(item5.4)beforefittingtheminthepressurering(item5.9)orbackplate(item7a,7b).* The W+50/600 pump is not equipped with a drain pipe.

15. Afterfitting,cleanthesurfacessubjecttowear.

15aFordoublemechanicalshaftseals,re-mountthebackplate(item7a,7b).

16. Fittheimpeller(item4).Remembertousethepropertighteningtorque. M10: 45Nm(33ft-lb) M14: 70Nm(52ft-lb) M20: 200Nm(148ft-lb)

17. Checkthatthelocatingpin(item8)inthetopofthebackplatefitswith the detent in the pump body. To prevent damage to the O-ring, carefullypressthepumpbody(item1a,1b)insothatitcoverstheO-ring(item6).Thenfastentheclampring(item9).

Remember to use the proper tightening torque:M10: max.35Nm(25ft-lb)

Checking parts for wear

Fitting

12

APV

GB

Form no.: L453147GB– revision 06/2013

7. Service and maintenance

7.3 Replacing the motorThestandardmotoroftheW+pumphasalockedfrontbearing.Ifthemotorisreplaced,thenewmotormustalsohavealockedfrontbearing.Themotorbearingisenclosedandpermanentlylubricated.

A"smallflange"(B34)forframesizesanda"largeflange"(B35)incaseoflargeconstructions.

Whenreplacingthemotor,followtheinstructionsbelow.Forthereplacementofbearings,seethemotorsupplier'sserviceinstructions.

1. Switchoffthepowersupply,andthendisconnectthepumpandmotorfromthesystem.

2. Remove the pump body. See 7.2, paragraph 1-4.

3. Dismantle the impeller.

4. Removethemotorshroudand,ifpossible,placethepumpverticallyonthemotor'sfancover.Fig.7.

5. Releasethefourmotorflangescrewsandremovethem(Fig.7).

6. Liftthebackplate(item7)andextensionframe(whicharestillboltedtogether)offtheshaft.SeeFig.10. Removethespacerflange(item17)(wherefitted).

7. SeeFig.8.Loosenthescrewsatthebaseoftheshaft,removetheshaftandreplacethemotor.

8. SeeFig.9.Beforemountingthenewpumpshaft,removeanydirtandgreasefromthemotorshaftandthebase'sinternalclampingsurfaces.Looselymountthepumpshaft.Positionthebalanceholeoverthekeyway.

9. Fitthebackplateandextensionframeovertheshaft.

10. Tighten the bolts.

11. Standthepumpbackonitslegs/brackets.

12. Fittheimpellerandsecureitwiththecapnut/inducer.

Remember to use the proper tightening torque:M10: 45Nm(33ft-lb)M14: 70Nm(52ft-lb)M20: 200Nm(148ft-lb)

Fig. 7

Fig. 8

Fig. 9

Rearflange

Screw

Extensionframe

Motor

Shaft

Screw

Motor

Keyway

Motorshaft

Balancehole

Pumpshaft

13

APV

GB

Form no.: L453147GB– revision 06/2013

7. Service and maintenance

13. Placetheplasticstaragainsttheimpeller.Fig.10.

14. Fitthepump/screwhousingandfastenwiththeclampring.

15. Pushtheshaftforwarduntiltheimpelleristouchingtheplasticstar.See Fig. 11.

16. Tightentheshaftscrews(item11). Remember to use the proper tightening torque: M8: 30Nm(22ft-lb) M10: 55Nm(41ft-lb) M12: 80Nm(59ft-lb) M16: 180Nm(132ft-lb)

17. Remove the star by pulling it out through the inlet.

7.4 Recommended inventory of spare parts

Seal kitsThesealkitfortheW+pumpconsistsofthewearpartsforthepumpasspecifiedinthesparepartslist.

Numberofpumpsinservice0–5 5–20 >20

Sealkits number number kits/10pumps

Normaloperation 2 3 1Specialneeds 3 6 2

Service kitsTheservicekitconsistsofseveralmainpumpcomponentswhicharenotconsideredwearpartsbutmayneverthelessneedtobereplaced:theshaft,impeller,capnutandfixingkit.

Numberofpumpsinservice0–5 5–20 >20

Servicekits number number kits/10pumps

Normaloperation 0 1 1Specialneeds 1 2 1

Fig. 10

Impeller

Plasticstar

Pump body

Fig. 11

14

APV

GB

Form no.: L453147GB– revision 06/2013

8. Technical data

8.1 Sound pressure and sound effect levelMeasurementshavebeencarriedoutinaccordancewithISO3743,Grade2andISO3746,Grade3.Tolerance:±3dB.

LpAindBreferstothesoundpressurelevelatadistanceofonemetrefromthesurfaceofthepumpataheightof1.6mabovefloorlevel(cf.ECDirective(89/392/EEC).

LwAindicatesthesoundpowerlevel.OperatingconditionsA,BandCaredefinedasfollows:

a) Nominalflowandmax.permissibleoperatingpressureb) Nominalflowand60%operatingpressurec) 60%flowandmax.permissibleoperatingpressure

Thenominalflowandmax.permissibleoperatingpressureinthecaseoftheW+55/60,forexample,are60m³/hratanoperatingpressureof5.5bar,andsoon.

ThisinformationonlyappliesifthemotorusedisanABBaluminiummotorandthesizeofthemotormatchesthepowerrequirementofthe pump.

Thenoiselevelmayincreaseconsiderablyifreducers(reduction/expansionfittings)aremountedontheinlet/outlet.

Thevaluesshownapplywhenthepumpsoperateat2900rpmandthereisashroudoverthemotor.Ifthepumpsoperateat1450rpm,thevaluesarereducedbyapprox.20dB.ThevaluesfortheW+25/210 apply at 1450 rpm.

Operating conditions

LpA LwAA B C A B C

W+10/8 65 62 60 79 77 74W+22/20 67 65 61 81 79 75W+30/80 75 73 68 89 87 82

W+25/210 69 68 64 83 82 78W+35/35 69 67 64 83 81 78W+35/55 72 70 67 86 84 81

W+30/120 76 74 72 90 88 86W+50/8 69 68 64 83 82 78

W+50/600 75 75 73 89 89 87W+55/35 69 68 68 83 82 82W+55/60 74 70 68 88 84 82W+60/110 76 74 72 87 85 84W+65/350 86 88 82 100 102 98W+70/40 75 69 69 89 83 83W+80/80 75 73 72 89 87 86

W+110/130 79 76 76 93 90 90

Please note that the sound emitted by a pump may vary considerably.Itdependsonthepumpdesign(size/speed/shroud/installation)aswellasontheliquidtypeandpumpingconditions.

15

APV

GB

Form no.: L453147GB– revision 06/2013

8. Technical data

8.2 Maximum permissible outlet pressure for W+ pumpsThemaximumpumpoutletpressurespecifiedbelowmustnotbeexceeded(appliestowaterat20°C).

Max. 18 bar: W+10/8, W+22/20, W+30/80, W+35/55, W+35/35, W+110/130

Max. 14 bar: W+25/210, W+30/120, W+50/600, W+50/8, W+55/35, W+55/60, W+60/110, W+65/350, W+70/40, W+80/80

TheabovevaluesalsoapplytothecorrespondingWa+andWi+models.

8.3 Tightening torquesRequiredtorquestotightenthepumpshaftonthemotorshaft:M8: 30Nm(22ft-lb)M10: 55Nm(41ft-lb)M12: 80Nm(59ft-lb)M16: 180Nm(132ft-lb)

Caution! Ensurethatthekeygrooveinthemotorshaftcanbeseenthroughtheholeinthestubshaft. Fig. 12.

Requiredtorquetotightenthecapnutandtheinducer:M10: 45Nm(33ft-lb)M14: 70Nm(52ft-lb)M20: 200Nm(148ft-lb)

Requiredtorquetotightentheclampconnectionatthepumpbodyandbodycover:M10: max.35Nm(25ft-lb)

8.4 Cleaning recommendationThepartsofthepumpswhichbecomewetasaresultofmediaarecleanedusingthecleaningagentintheconnectedpipelines.Cleaningagents,timesandcyclesmustbemodifiedaccordingtoindividualapplicationdependingonthedegreeandnatureofcontamination.Verifythecompatibilityoftheindividuallyselectedcleaningprocessesandagentswiththesealmaterialsbeingused.

Subjecttochange.

Fig. 12

16

APV

W+CE NTR I FUGAL PU M P

Original operating manual

S PX Flow Technology Poland sp. z o.o.

Hermana Frankego 9

85-862 Bydgoszcz, Poland

P: (+48) 52 525 9900

F: (+48) 52 525 9909

SPX reserves the right to incorporate design and material changes

without notice or further obligation.

Design features, materials of construction and dimensional data,

as described in this bulletin, are provided for your information only

and should not be relied upon unless confirmed in writing. Please

contact your local sales representative for product availability in

your region.

For more information please visit www.spx.com.

ISSUED 06/2013 –

COPYRIGHT © 2013 SPX Corporation