CEMA

-

Upload

sara-lopez -

Category

Documents

-

view

67 -

download

1

description

Transcript of CEMA

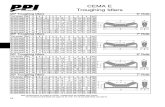

CALCULATIONconveyor No. 27A/27BDocument No. GID-064-CHP-1152Project : Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW)REV. 2PRP. BY: AV CHD BY: AV APP BY: AVSubject : Conveyor Design Calculation as per 5th edition of CEMADated 07.12.06INPUT DATA : EL. 12.0M (RL 35.25 M)P3P1EL. 0.0 (GL 27.0 M)PRIMARY SECONDARY P2EXISTING PLANTSCRAPER SCRAPEREL. 0.0 (FFL 23.25 M)EL. (-)6M (RL 21.0 M)NEW PLANT LEVELV PLOW SCRAPERSP2473.974 (27A)476.324 (27B)PROFILE OF CONVEYORS 27A / 27BConveying Capacity (Q)650TPHBelt Width (b)1000mmHorizontal Belt Length c/c of Pulley (L)49.000mLift (H)5.700mDeveloped length of belt (L1)49.330mAverage angle of Inclination of Belt Conveyor2DegreesPercent Slope3%Belt Speed (v)2.90m/secMaterialCoalBulk Density of Material (r)0.8T/m3Lump Size of Material (Minus)30mmAngle of Surcharge20DegreesIdler Diameter152.4mmCarrying Idler Spacing (Si)1.0mTroughing Angle35DegreesAcceleration due to gravity (g)9.807m/sec2Nos. of Drive Pulley (P1)1Nos. of Tail/ Take up/ Bend Pulleys (P2)7Nos. of Snub Pulley (P3)1Nos. of Belt Scrapers (Ns)3Conversion Factors1 Pound0.4536Kgs.1 Meter3.2808Feet1 Feet0.304801Meters1 inch25.4mmSpeed 100 Ft/ Min0.50813Mtr/Sec1 FT3/hr0.028317M3/hrCALCULATIONS :BELT SPEED CHECK :CAPACITY AS PER TABLE 4.3 PAGE 53 OF CEMAWidth of 1000 mm wide conveyor belt in inches39.37inchSpeed - 100 Ft per Minute0.508m/secCapacity of Conveyor (with standard edge distance) as per table 4.3 for 36 inch belt, 20 deg surcharge angle at 0.508 mtr. /sec5886.0FT3/hrCapacity of 39.37 inch (1000 mm) wide belt (By interpolating 36 inch & 42 inch capacity of table 4.3) at 0.508 m/sec7168.2FT3/hrCapacity at 1 m/sec14107.02FT3/hrCapacity in M3/ hr399.47M3/hrCapacity in TPH ( M3/hr * Density) at 1 m/sec (q)319.57TPHCapacity required to be conveyed (Q)650TPHMin. Belt speed required (Q/q) v'2.03m/secBelt speed considered (v)2.90m/secFilling factor (v' / v)0.7014%HENCE BELT SPEED SELECTED IS O.K.VALUE OF FACTORS USED IN CALCULATION :1). Weight Of Material , Wm = Q/(3.6*v) =62.26Kg/m2). Weight Of belt , Wb as per Phoenix Yule catalogue page 8 & 9 for selected rating of 500/4-HD with Top cover 5mm and bottom cover 3mm16.772Kg/mCarcass unit weight for given rating3.1Kg/ m2Unit weight of rubber per mm of thickness1.11Kg/ m2Belt weight (Wb)= Belt width*(Unit carcass wt.+ (Top cover thk+ Bottom cover thk)*Unit rubber wt.)3). Ambient Temp. correction factor from page 89 of CEMA, Kt =1.04). Idler Friction Factor, Kx = 0.00068(Wb+Wm)+Ai/SiForce to overcome Frictional Resistance & Rotate Idlers(Ai) for 152.4mm (6 inch) idlers as per page 91 of CEMA (5% extra for V type return Idlers)1.575lbsKx = 0.00068(22.106+130.72)+(1.575* 0.4536)/1.2 =0.7685).Factor for Resistance to Flexure of Belt & Load (Ky)Length of conveyor in feet =(L1* 3.2808)161.843Feet(Wb+Wm) / (0.4536* 3.2808) in lbs/ feet53.107lbs/feetValue of Ky for given length, wt. & slopes as per table 6.2 Page 930.0250CALCULATION OF EFFECTIVE TENSION AT DRIVING PULLEY (Te)1). Tension due to Idlers Friction, Tx = L1*Kx*Kt37.89Kgs2). Tension due to resistance of Belt to Flexure for carryingIdlers, Tyc = L1*Ky*Wb*Kt20.68Kgs3). Tension due to resistance of Belt to Flexure for returnIdlers, Tyr = L1*0.015*Wb*Kt12.41Kgs4). Tension due to resistance of Material to Flexure ,Tym = L1*Ky*Wm76.78Kgs5). Force needed to Lift the Material, Tm = H*Wm354.89Kgs6). Force to accelerate the Material,Tam = 1000*Q*v/(3600*g)53.39Kgs7)Tension due to Belt Scraper resistance (Tbc):-Tension due to each scraper (Nsc) = 3 lbs/ inch(considered for half material removal from belt) as per table 6-60.053575Kgs/ mmTbc= Nsc* Belt Width* No. of Scrapers=Nsc*B*4160.724409Kgs8)Tension due to Skirtboard Friction, Tsb = Lb(Cshs2+6)Length of skirtboard Lb5000mmSkirtboard Friction Factor as per table 6.7 (Cs)0.0754Depth of Material touching Skirtboard (10% of Belt width)as per page 101 (hs)100mmTsb = Lb(Cshs2+6) = 0.4536(12000/(25.4*12)*(0.0754*(140/25.4)2+6)53.342Kgs9). Tension due to Pulleys resistance as per Appendix C page 405, Tp (For non-drive pulleys)Resistance of belt to flex over each pulley Tp(1)Tp(1) = 9b(0.8+0.01Tav/b)*(Bt/Dp)Resistance of each pulley brg, seal etc Tp(2)Tp(2) = 0.01*(ds/Dp)*Rwhereb=width of belt (1400mm)55.12inchBt= Conveyor Belt thickness (6+3+5.2) mm0.56inchDp= Pulley Diameter 658 mm -considering Dia of drive Pulleys25.90inchds= Pulley shaft Dia 150 mm (assumed)-considering Dia of drive Pulley6.00inchTav = Average tension at pulley as per following:-:-For calculating the wrap average Tension all the tensions calculated above Tav =(Tx+Tyc+Tyr+Tym+Tm+Tam+Tbc+Tsb) can be added and divided by factor 0.4536 to get average tension in lbs1697.78lbsR= Resultant radial load (Vector sum of Average belt tension (Tav) & pulley weight (Wp))Weight of pulley assumed (Wb)- considering appx. wt. of drive pulley1500lbsR = ((Tav)2+(Wp)2)1/22265.4958653445lbsTp(1) = 9b(0.8+0.01Tav/b)*(Bt/Dp) for Single pulley11.8645868883lbsTp(1) for single. non drive pulley in Kgs.5.3817766125KgsTp(1) for 7Nos. non drive pulleys in Kgs.37.6724362878KgsTp(2) = 0.01*(ds/Dp)*R for single pulley5.2482529699lbsTp(2) for single non drive pulley in Kgs.2.3806075472KgsTp(2) for 7 Nos. non drive pulleys in Kgs.16.6642528301KgsTotal pulley resistance for non drive pulleys Tp=Tp(1) + Tp(2)54.34KgsHENCE TOTAL EFFECTIVE TENSIONTe = Tx+Tyc+Tyr+Tym+Tm+Tam+Tbc+Tsb+Tp =824.45KgsMOTOR POWER CALCULATION :Belt Kw , Pb = Te*v*g/1000 =23.45Kwwhere Te is effective tension, v is belt speed & g is acceleration due to gravityDrive pulley power Pd=N*(Tp(1)+Tp(2))*v*g/10000.22Kwwhere N is no. of drive pulleys, Tp(1) & Tp(2) pulley resistance, v is beltspeed & g is acceleration due to gravityAdd 5% extra for speed reduction loss on Pb& Pd= 1.05(Pb+Pd)2.60KwPower at motor shaft, Pm = Pb+Pd+5% reducer margin =26.27KwDesign margin on motor required as per tender20%Motor Power with 20% margin=Pm*1.231.53KWSELECTED MOTORS36.00KWBELT TENSION CALCULATIONS:-SLACK SIDE TENSION CALCULATION :Minimum Tension for 2% Sag, To = 6.25*Si(Wb+Wm) at tail end close to loading point493.95KgsSlack side Tension T2 as per formula T2=To+(H*Wb)-TyrWeight of return belt =H*Wb95.60KgsResistance of return belt Tyr= 0.015*L1*Wb*Kt12.41Hence T2577.14Kgs.Slack side Tension T2 as per formula T2=Te*CwCw is Wrap factor as per Table 6.8For Manual (screw take up) for lagged pulley0.7For automatic takeup Single with snub, 200 Deg & with lagging0.42For Dual Lagged Pulley0.11As these conveyors are provided with single drive use Cw0.42T2 = Te*Cw346.27KgsTaking Higher of the above three Values, T2633.64KgsTIGHT SIDE TENSION CALCULATION :Tight Side Tension at Pulley, T1 = Te+T21458.09KgsBELTING SELECTION :Maximum operating Tension in Belt,Tmax = T1/(b)T1 as calculated above1458.09KgsT1 in KN = T1*g/ 100014.30KN/Mb = belt width in Mtr.1.00MtrTmax = T1/(b)14.30KN/MSelect Belting from Phoenix Yule Catalogue400/3Nylon-NylonHeavy-DutyFR GradeRecommended Maximum allowable Belt Working Tensionfor selected Belting from Phoenix Yule Catalogue (Tall) =40KN/MRatio of Max Tension to all tension = Tmax/ Tall35.7488%As this ratio is less than 85 % allowed in NIT selected rating is OKMax. belt width for satisfactory Load Support considering1000mmthe given Belt rating as per Phoenix Yule CatalogueMinimum Belt Width required for satisfactory Troughingfor selected Belting as per Phoenix Yule Catalogue500mmHence selected Belt Width OKMINIMUM PULLEY DIAMETERS REQUIRED AS PER PHOENIX YULE CATALOGUE :- Drive Pulley Diameter (P1)315mm- Tail/Take Up/ Bend Pulley Diameter (P2)200mm- Snub Pulley Diameter (P3)250mmPULLEYS SELECTED :- Drive Pulley Diameter + 14 thk Lagging (P1)508mm- Tail/Take Up/ Bend Pulley Diameter+ 10 thk lagging (P2)520mm- Snub Pulley Diameter + 10 thk lagging (P3)420mmGEAR BOX REDUCTION RATIO :-Drive Motor RPM N1440rpm- Drive Pulley RPM, n = v*60000/(p*diameter of Drive Pulley)109.03rpm- Gear Box Reduction Ratio required ,i = N/n13.21Gear ratio selected20.00- Final Belt Speed as per Selected Gear Box Reduction Ratio1.92m/sec-Gear box KW rating = 1.25 * Motor KW45KWOUTPUT :Motor Power Selected36KWSlack Side Tension (T2)633.64KgsTight Side Tension (T1)1458.09KgsBelt Rating Selected400/3HD- N/NRecommended Maximum Belt Working Tension40.00KN/MSelected Drive Pulley Diameter (P1)508mmSelected Tail/Take Up/ Bend Pulley Diameter (P2)520mmSelected Snub Pulley Diameter (P3)420mmSelected Gear Box Reduction Ratio20REVISION-1REVISED AS PER M/S DESEIN COMMENTS REF NO. 438 DATED 25.09.2006.ALSO REVISED AS PER REVISED CONVEYOR LAYOUT DUE TO RL DIFFERENCE OF NEWPLANT & EXISTING PLANT.REVISION-2CONVEYOR LENGTH REVISED DUE TO SHIFTING OF JT-11 AS PER REVISED PLOT PLAN NO.GID-064-CHP-1157 REV 1.M/S DESEIN COMMENTS REF NO. 559 DATED 10.11.2006. ALSO INCORPORATED.

Page &P of &N

MBD0007F323.doc

Attribute VB_Name = "Module1"

'' Macro1 Macro' Macro recorded 9/9/96 by material handling''Sub Macro1()Attribute Macro1.VB_Description = "Macro recorded 9/9/96 by material handling"Attribute Macro1.VB_ProcData.VB_Invoke_Func = " \n0" ActiveWindow.SmallScroll Down:=16End Sub

Attribute VB_Name = "ThisWorkbook"Attribute VB_Base = "0{00020819-0000-0000-C000-000000000046}"Attribute VB_GlobalNameSpace = FalseAttribute VB_Creatable = FalseAttribute VB_PredeclaredId = TrueAttribute VB_Exposed = TrueAttribute VB_TemplateDerived = FalseAttribute VB_Customizable = True

Attribute VB_Name = "Module1"

'' Macro1 Macro' Macro recorded 9/9/96 by material handling''Sub Macro1()Attribute Macro1.VB_Description = "Macro recorded 9/9/96 by material handling"Attribute Macro1.VB_ProcData.VB_Invoke_Func = " \n0" ActiveWindow.SmallScroll Down:=16End Sub

Attribute VB_Name = "ThisWorkbook"Attribute VB_Base = "0{00020819-0000-0000-C000-000000000046}"Attribute VB_GlobalNameSpace = FalseAttribute VB_Creatable = FalseAttribute VB_PredeclaredId = TrueAttribute VB_Exposed = TrueAttribute VB_TemplateDerived = FalseAttribute VB_Customizable = True