Case - Stainless Steel Sculpture Bean

-

Upload

phschemguy -

Category

Documents

-

view

6 -

download

2

description

Transcript of Case - Stainless Steel Sculpture Bean

-

Outdoor Stainless Steel Sculpture

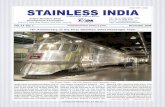

The problem: Corrosion resistance and weldabilityArtist Anish Kapoor was inspired by liquid mercury when he designed Cloud Gate, one of the worlds largest outdoor sculptures. Referred to by locals and visitors alike as The Bean because of its elliptical shape, the stainless steel sculpture was designed to span 66 feet and soar 33 feet above Chicagos Millennium Park. The enormous size of the sculpture required a material with a high degree of reflectivity, almost like liquid mercury; would be easy to fabricate and maintain; and would resist Chicagos humid summer air and salty road and sidewalk treatments in North Americas Midwestern harsh winter.

The solution: T316L plate168 plates of 316L grade stainless steel from Outokumpu were selected as the sculptures material. (Outokumpu also provided welding consultation during the fabrication of Cloud Gate.) The largest stainless steel plates average 7 feet in width, 11 feet in length, and weigh as much as 1,500 pounds a piece. Plates were plasma cut into square and pie shapes and then attached to a superstructure of O-shaped rings and pipe trusses. The final stainless steel sculpture weighs more than 110 tons and required more than 2,500 lineal feet of seam welds. It took two years to grind and polish the stainless steel plates and an additional year to weld the .3-to-.5 inch seams between the plates. To achieve superior reflectivity, 316L with 0.002 percent maximum sulfur was specified. The low sulfur levels were essential for the perfect, blemish-free, mirrored finish desired for the sculpture. Outokumpus stainless steel plate was chosen for its superior metallurgical cleanliness and lack of slag inclusions (which allows it to aptly mimic liquid mercury); its long-life expectancy; its corrosion resistance; and its minimal maintenance requirements.

What is 316L? 316L is a molybdenum-containing austenitic stainless steel intended to provide improved corrosion resistance relative to 304 and 304L. 316L stainless steel is suitable for moderately corrosive process environments, particularly those containing chlorides (in this case the salt used to treat Chicagos icy roads and sidewalks during the winter). Low sulfur levels in stainless steel are regularly specified for cleanrooms and other applications where surface imperfections are unacceptable. For most architectural and other aesthetic applications, a 0.005 percent sulfur content is suitable.