Cartridge-type Chemical Vapour Locks from TECHAP

Transcript of Cartridge-type Chemical Vapour Locks from TECHAP

Cartridge-type Chemical Vapour Locks® from TECHAP

Absorption of hazardous and pollutant chemical vapours produced during the filling, decanting and draining of closed pressureless storage tanks and containers

For all current chemicals, acids, lyes, oils and solvents For removal of CO2 from air when storing demineralised water For extracting humidity from gas atmospheres for materials which absorb

humidity (H2SO4) Suitable for installation in enclosed and outside positions Ease of handling, with problem-free cartridge exchange Protects against emissions Sterile filtration Pressure vacuum breakers

02.1-1

S 0

3/2

00

5

Process engineering and components

Environmental protection and operational safety

In the chemicals industry, decanting and emptying processes involving liquid chemi-cals is a daily activity in many different types of application. It is not a rare occurrence for large quantities of poisonous vapours to be released in the process; these can be harmful to health and can form explosive gas-air mixes.

The evaporation rate depends on many factors, but the estimated quantity involved is massive: in Germany alone, around 700,000-800,000 tonnes of chemicals (excluding petrol) are decanted every year, and as a result polluting our environment, attacking machinery and also posing a potential health risk. By contrast, using TECHAP chemical vapour locks for closed pressureless storage tanks and containers, transport containers and replacement containers guarantees high levels of operational safety and environ-mental protection. The dangerous exchange of chemicals is made easy, and safe.

In the standard finish, the chemical vapour locks are PVC containers with a transparent cylinder section, based on a cartridge system. The binding agent which absorbs the harmful vapours which are created is located here in the filter bag, which is subsequent-ly disposed of with the used binding agent.

TECHAP has the right solution for all currently-used chemicals. Existing old-style che-mical vapour locks with a loose binding agent can be retrofitted cost-favourably for cartridge operation. In addition, we are always ready to develop individually-customised solutions to satisfy your requirements.

Our wealth of experience of chemical materials, their characteristics and the legal regulations pertaining to them make us the ideal partner for companies in the chemicals value-added chain.

Chemical vapour locks from TECHAP

3 Design

3 Advice on installation

4 Chemical vapour locks 4 for pressureless storage tanks and containers

6 Suction lances with chemical vapour locks 6 for transport containers and special tanks 7 for 1,000 litre replacement containers and others

8 Additional equipment and accessories 8 Heating units 8 Rain protectors 9 Clamp connectors 9 Pressure vacuum breakers 10 Waste gas pre-washers 10 Quick-acting fill protector 12 Dust filters 13 Binding agents 13 Model reactions 13 Chemicals which can be processed 14 Model applications 15 Retrofitting kits for old-type chemical vapour locks for use with cartridges

02.1-2 Subject to technical modifications.

02.1-3Subject to technical modifications.

Chemical vapour locksDesign / Advice on installation

Design

All our chemical vapour locks are based on the cartridge system. In this design, the binding agent is already contained in the filter bag, which is subsequently disposed of with the used binding agent. In the standard finish, the housing is in PVC with a trans-parent cylinder section. For models with the additional label “G”, the housing is in PP, with a glass cylinder. The housing can also be supplied in the V4A steels (e.g. 1.4571 stainless steel). No materials containing asbestos or silicone are used in the manu-facture of these items.

As a special finish, chemical vapour locks can also be manu-factured to withstand pressures of up to 2 bar. Models above the size of the SL5 can also be equipped for use in outside situations, with a self-regulating heating element. The element is then inte-grated into the filter bag. To protect the binding agent against the rain, a rain protector is required. Other than to change the car-tridges, no maintenance is needed. The consumption of binding agents BM1 and BM4 is shown by the change in the colour indica-tors. The depletion of binding agent BM2 can only be determined by measurement or odour test.

Housing

Housing

Cylinder part

Supporting base

Supporting base

Binding agent

Chemical vapour lock

Cartridge

Advice on use and installation

• The storage tank should not be overfilled.

• The liquid must not penetrate into the binding agent or into the cartridge.

• The fill rate as shown in the table should never be exceeded.

• With fill procedures involving compressed air, the chemical vapour lock should always be over-dimensioned by one size, in order to ensure operational safety. Installation of a quick- action shut-off device is recommended.

• Avoid sudden pressure shocks and impacts or decompressions, especially during filling procedures and when displacing pres-sure form the supply tank.

• With new plants, the pressure loss in accordance with the nominal flow rate for BM1 is approx. 1-13 mbar. For BM2 and BM4, it is 0.5-10 mbar (at nominal velocity).

• The cartridges with binding agent BM2 are to be replaced at regular intervals (roughly half-yearly).

• For binding agents BM1 and BM2, the heater should only be activated when there is a risk of frost.

• For binding agent BM4, the heater should always be activated.

• With the cartridge design, the heating element is integrated into the filter bag. On site, the binding agent - e.g. BM4 - is then filled into the installed filter bag. These filter bags are to be replaced after they have been filled twice with binding agent; if binding agent BM1 is used, then the filter bag must be replaced after each use.

• The base glued to the cylinder part is always at the bottom. With the PPH finish and VA finish the sealed-in part is similarly to be used as the base.

• If being set up outside, the chemical vapour locks must be pro-tected against rain and sun using our rain protector, as well as against frost.

• Avoid temperatures over 50°C for PVC products, 80°C for the PP finish, and 40°C when using binding agent BM1.

• Take note of the possible heating of the storage tank through insolation. Black tanks can be heated to temperatures of up to 80°C. This temperature generates significant volumes of vaporised gas. Run-off pipes must be installed with the fall on the chemical vapour lock running away from the tank, so that no condensate can flow back. Condensate caused by tempe-rature gradients must be avoided at all costs.

• Always follow instructions and regulations, such as DIN, UVV, VDE, VBF, ZVEI and TA-Luft, and other national and internatio-nal specifications (e.g. German water conservancy law - WHG).

Chemical vapour locksfor pressureless storage tanks and containers

Overview of types of chemical vapour locks for pressureless storage tanks and containersType SL0K PVC BL1G 2 x BL1GD SL1K SL3K SL5KMax. air quantity 200 litres/h 500 litres/h 500 litres/h 1.500 litres/h 5.000 litres/h 15.000 litres/hDimensions (in mm) SL5K and abovewith one base flan-ge, optionally with two flanges

Matching cartridge types with 1µ fine filter (filter unit for single use)

Typ BM1 … BM1K0 BM1KBL BM1KBL BM1K1 BM1K3 BM1K5Typ BM2 … BM2K0 BM2KBL BM2KBL BM2K1 BM2K3 BM2K5Typ BM4 … BM4K0 BM4KBL BM4KBL BM4K1 BM4K3 BM4K5

Type SL7K SL9K SL11KMax. air quantity 30.000 litres/h 72.000 litres/h 150.000 litres/hDimensions (in mm) SL5K and above with one base flan-ge, optionally with two flanges

Matching cartridge types with 1µ fine filter (filter unit for single use)

Typ BM1 … BM1K7 BM1K9 BM1K11Typ BM2 … BM2K7 BM2K9 BM2K11Typ BM4 … BM4K7 BM4K9 BM4K11

Flanges to DIN and ANSI standard on request. Other connectors, e.g. clamp connectors, to ISO on request.

02.1-4 Subject to technical modifications.

130

130

02.1-5Subject to technical modifications.

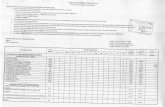

Ordering data for chemical vapour lock® with the cartridge systemType Case Standard binding agent

Weight in kg *)

Max. air quantitylitre/h

Material Lid/Cylinder

Flange/Screw thread

Order No. *)

BM1K BM2K BM4K

Order No. Order No. Order No.

SL0K 200 PVC/PVC G 3/4“ PP 860 4008 860 4051 860 4052 860 4080 0,2

BL1-G 500 PTFE/Glass G 1/2" 860 0106 860 4058 860 4044 860 4033 0,6

2x BL1-G 500 PTFE/Glass G 1/2" 860 0004 860 4058 860 4044 860 4033 1,0

SL1K 1.500 PVC/PVC G 3/4" 860 4010 860 4011 860 4055 860 4081 0,3

SL1KVA-G 1.500 V4A/Glass G 3/4" PP 860 4135 860 4011 860 4055 860 4081 1,0

SL1KVA-G 1.500 V4A/Glass 860 4235 860 4011 860 4055 860 4081 1,3

SL3K 5.000 PVC/PVC G 2" 860 4040 860 4042 860 4056 860 4082 1,0

SL3KPP-PVC 5.000 PP/PVC G 2" 860 4140 860 4042 860 4056 860 4082 1,2

SL3KPP-G 5.000 PP/Glass G 2" 860 4034 860 4042 860 4056 860 4082 2,2

SL3KVA-G 5.000 V4A/Glass 860 4251 860 4042 860 4056 860 4082 3,9

SL5K 15.000 PVC/PVC 860 4045 860 4046 860 4047 860 4083 2,8

SL5.2K 15.000 PVC/PVC 860 4060 860 4046 860 4047 860 4083 3,5

SL5KPP-PVC 15.000 PP/PVC 860 4145 860 4046 860 4047 860 4083 3,0

SL5.2KPP-PVC 15.000 PP/PVC 860 4160 860 4046 860 4047 860 4083 3,3

SL5KPP-G 15.000 PP/Glass 860 4069 860 4046 860 4047 860 4083 4,0

SL5.2KPP-G 15.000 PP/Glass 860 4141 860 4046 860 4047 860 4083 4,5

SL5KVA-G 15.000 V4A/Glass V4A 860 4253 860 4046 860 4047 860 4083 7,7

SL5.2KVA-G 15.000 V4A/Glass V4A 860 5253 860 4046 860 4047 860 4083 10,0

SL7K 30.000 PVC/PVC 860 4070 860 4076 860 4071 860 4084 3,2

SL7.2K 30.000 PVC/PVC 860 4078 860 4076 860 4071 860 4084 4,0

SL7KPP-PVC 30.000 PP/PVC 860 4170 860 4076 860 4071 860 4084 3,0

SL7.2KPP-PVC 30.000 PP/PVC 860 4146 860 4076 860 4071 860 4084 3,5

SL7KPP-G 30.000 PP/Glass 860 4179 860 4076 860 4071 860 4084 5,3

SL7.2KPP-G 30.000 PP/Glass 860 4171 860 4076 860 4071 860 4084 5,9

SL7KVA-G 30.000 V4A/Glass V4A 860 4255 860 4076 860 4071 860 4084 9,2

SL7.2KVA-G 30.000 V4A/Glass V4A 860 5255 860 4076 860 4071 860 4084 11,7

SL9K 72.000 PVC/PVC 860 4073 860 4077 860 4072 860 4085 4,8

SL9.2K 72.000 PVC/PVC 860 4074 860 4077 860 4072 860 4085 5,7

SL9KPP-PVC 72.000 PP/PVC 860 4147 860 4077 860 4072 860 4085 4,4

SL9.2KPP-PVC 72.000 PP/PVC 860 4148 860 4077 860 4072 860 4085 5,0

SL9KPP/PMMA 72.000 PP/PMMA 860 4149 860 4077 860 4072 860 4085 4,8

SL9.2KPP/PMMA 72.000 PP/PMMA 860 5149 860 4077 860 4072 860 4085 5,5

SL9KPP-G 72.000 PP/Glass 860 4180 860 4077 860 4072 860 4085 8,6

SL9.2KPP-G 72.000 PP/Glass 860 4194 860 4077 860 4072 860 4085 9,3

SL9KVA-PMMA 72.000 V4A/PMMA 860 4254 860 4077 860 4072 860 4085 10,1

SL9.2KVA-PMMA 72.000 V4A/PMMA 860 5254 860 4077 860 4072 860 4085 12,9

SL9KVA-G 72.000 V4A/Glass V4A 860 4256 860 4077 860 4072 860 4085 14,0

SL9.2KVA-G 72.000 V4A/Glass V4A 860 5256 860 4077 860 4072 860 4085 16,5

SL11K 150.000 PVC/PVC 860 4190 860 4094 860 4096 860 4102 8,0

SL11.2K 150.000 PVC/PVC 860 4191 860 4094 860 4096 860 4102 9,5

SL11KPP-PVC 150.000 PP/PVC 860 4192 860 4094 860 4096 860 4102 6,1

SL11.2KPP-PVC 150.000 PP/PVC 860 4193 860 4094 860 4096 860 4102 7,1

SL11KPP-PMMA 150.000 PP/PMMA 860 5181 860 4094 860 4096 860 4102 5,9

SL11.2KPP-PMMA 150.000 PP/PMMA 860 5182 860 4094 860 4096 860 4102 7,0

SL11KVA-PMMA 150.000 V4A/PMMA V4A 860 4257 860 4094 860 4096 860 4102 13,5

SL11.2KVA-PMMA 150.000 V4A/PMMA V4A 860 5257 860 4094 860 4096 860 4102 17,4

Housing with 1 base flange 2 flanges (bottom and top) V4A flange from 1.4571 *) without binding agent Flanges to ANSI standard on request. Other connectors, e.g. clamp connectors, to ISO on request.

Chemical vapour locksfor pressureless storage tanks and containers

Suction lances with chemical vapour locksfor transport containers and special tanks

Order data Suction lances for transport containers

Lance type Description Adjustable length

Order No. Binding agents

Type Order No.

Cartridges(only for ST1K and ST1K-FV)

BM1K 860 4051

BM2K 860 4052

BM4K 860 4080

ST1K-FV for gas-sing liquids

• Cartridge system• With base valve

30 litres 320 … 500 mm 860 4041

60 litres 610 … 900 mm 860 4050

ST1K for gassing liquids

• Cartridge system• No base valve

610 … 900 mm 860 4048

TA1-FV for non-gassing liquids

• Without cartridge system• With base valve

30 litres 320 … 500 mm 860 0038

60 litres 610 … 900 mm 860 0049

TA1 for non-gas-sing liquids

• Without cartridge system• No base valve

610 … 900 mm 860 0039

Order data Accessories

Description Description Order No.

Level switch

*) contact load 60V, 300mA

Teflon, cable 5 metre*) 350 0316

Teflon, cable 10 metre*) 350 0315

Retainer for level switch PVC adjustable 860 0321

Thread adaptor equal to 70 x 6 860 0310

equal to 57 x 4 860 0311

Reducer 70 x 6 / 57 x 4 860 0312

Draw spindle Thread 57 x 4 860 0313

Thread 70 x 6 (standard) 860 0314

External thread 860 0320

Hose transitions on request

Suction lances for gassing (ST1K) andnon-gassing (TA1) liquids: • Adjustable length• Max. of 2 level switches (in PVC or

PTFE) possible• Level switch can be used as a closer

or opener, by reversing the float• Easy-to-handle suction lances - they

are simply inserted into the transport container and screwed tight

• Return flow connector: G 1/4“• Special lengths on request• Suction port with union nut + insert d

16 available

Transport container

Model application10

5 m

m

Level switch

Draw spindle

min

. 610

mm

m

ax. 9

00 m

m

Cartrige

Draw spindle

Level switch

Suction lance ST1K Suction lance TA1

02.1-6 Subject to technical modifications.

02.1-7Subject to technical modifications.

Suction lances with chemical vapour locksfor 1,000 litre replacement containers and others

Order data Suction lances for transport containers

Lance type Description Adjustable length

Order No. Binding agents

Type Order No.

Cartridges(only for ST2K and ST2K-FV)

BM1K 860 4011

BM2K 860 4055

BM4K 860 4081

ST2K-FV for gas-sing liquids

• Cartridge system• With base valve

700 … 1,300 mm 860 4186

ST2K for gassing liquids

• Cartridge system• No base valve

700 … 1,300 mm 860 4187

TA2-FV for non-gassing liquids

• Without cartridge system• With base valve

700 … 1,300 mm 860 0185

TA2 for non-gas-sing liquids

• Without cartridge system• No base valve

700 … 1,300 mm 860 0183

Order data Accessories

Description Description Order No.

Level switch

*) contact load 60V, 300mA

Teflon, cable 5 metre*) 350 0316

Teflon, cable 10 metre*) 350 0315

Retainer for level switch PVC, ST 2 / TA 2 860 0297

Connection parts Insert union nutO-Ring D 25 / DN 20

860 0299

Hose transitions on request

Elbow joint PVC, removable 860 0319

PPH, removable 860 0320

Screw lid S 160 x 7 mm 860 0315

S 240 x 6 mm 860 0316

Suction lances for gassing (ST2K) andnon-gassing (TA2) liquids: • Adjustable length• Max. of 2 level switches (in PVC or

PTFE) possible• Level switch can be used as a closer

or opener, by reversing the float • Easy-to-handle suction lances - they

are simply inserted into the transport container and screwed tight

• Return flow connector G 1/4“• Special lengths on request• Suction port with union nut + insert d 25 available

1.000 l chaingingcontainer

adju

stab

le

adjustable

Elbow jointadjustable length

alternative also with base valve

Model application

Cartridge

Draw spindle

Level switch

Return plug

Suction lance ST2K Suction lance TA2

Additional equipment and accessoriesHeater units/Rain protector

Heater units for SL5K … SL11K

Description Suitable for types Order No.

For binding agents BM1 and BM2, the he-ater should only be activated when there is a risk of frost. For BM4, the heater should always be activated.

HE1Self-regulating heater230 V, 50/60 Hz, 0,3 A, 60 W

SL5/7/9K 860 0059

HE2Self-regulating heater 230 V, 50/60 Hz, 0,3 A, 90 W

SL11K 860 0198

Atex-protection zone 1explosion protectionfor heater

SL7/9/11K 860 0199

Temperature switch for für He1 und He2Switch-on temperature can be selected> 0°C; Power supply 230V, 50/60Hz; Relay contact load max. 10 A inductive

SL5/7/9/11K 860 0201

Rain protectors for types SL3K … SL11K

Dimensions Description Suitable for types Order No.

RH1PP rain protector in PPB = 375 mm, H = 151 mm

SL3K … SL7K 860 0087

RH2PP rain protector in PPB = 485 mm, H = 165 mm

SL9K … SL11K 860 0197

RH3VA rain protector in V4AB = 405 mm, H = 140 mm

SL3K and SL7K 860 4196

RH4VA rain protector in V4AB = 470 mm, H = 165 mm

SL9K and SL11K 860 4197

DIN railmounting

0

10

2030

40

50

60

7 6 1 2

4 5 3

70 mm45 mm68 mm

32 mm

2 13

PE

L1

N

Mains connectionPE = GroundL1 = PhaseN = Neutral

02.1-8 Subject to technical modifications.

02.1-9Subject to technical modifications.

Additional equipment and accessoriesClamp connectors/Pressure vacuum breakers

Clamp connectors to ISO 2852 and accessories

Instead of flanges or screw threads, chemical vapour locks can be equipped with clamp connectors in rigid PVC or V4A, for a supplementary charge.Please quote order number. Clips and seals are ordered separately.

Nominal diameter Diam. D PVC clamp conn. V4A clamp conn. Viton seal PTFE seal Clips

PVC / V4A mm inch mm Order-No. Order-No. Order-No. Order-No. Order-No.

25 / 25,4 20 50,5 860 0325 860 0335 860 4325 860 4425 860 4525

32 / 33,7 25 50,5 860 0326 860 0336 860 4326 860 4426 860 4526

40 / 41,0 32 64,0 860 0327 860 0337 860 4327 860 4427 860 4527

50 / 50,8 40 64,0 860 0328 860 0338 860 4328 860 4428 860 4528

63 / 63,5 50 77,5 860 0329 860 0339 860 4329 860 4429 860 4529

70 / 70,0 65 91,0 860 0324 860 0350 860 4333 860 4433 860 4533

75 / 76,2 65 91,0 860 0330 860 0340 860 4330 860 4430 860 4530

90 / 88,9 80 106,0 860 0331 860 0341 860 4331 860 4431 860 4531

100 / 101,6 119,0 860 0332 860 0342 860 4332 860 4432 860 4532

110 / 114,3 100 130,0 860 0343 860 0345 860 4334 860 4434 860 4534

140 / 139,7 125 155,0 860 0344 860 0346 860 4335 860 4435 860 4535

Pressure vacuum breakers

Order No. Description

Pressure vacuum breakers to protect storage tanks, mainly when filling using compressed air

860 8000 Flanges in PVC, DN 100 PN 10/16 preset to 5-30 mbar, not heatedVA, heatable, for external use on request

Dimensions (in mm) Model applications

A = Connection to storage tankB = Air feed and venting pipe1 = Overpressure valve2 = Vacuum valve

1–2% gradient

DN 100 PN 10/16

DN 1

00

121

Ø160

195

325

Additional equipment and accessoriesWaste gas pre-washer/Quick-acting fill protector

Waste gas pre-washer for SL3K-SL11K

Mist collectorNozzle

Deflector

Screen

Flange (t. and b.)DN100 or DN125

TypesPre-washers are available in four sizes. They are equipped with a mist collector, a spray nozzle, a deflector, a DN10 splash wa-ter connection for demineralised water (where there is a purity requirement), and 2 flanges top and bottom (DN100 or DN125, or G 2“).

NoteHighly concentrated chemicals such as hy-drochloric acid (above a 33% concentrati-on) or ammonium hydroxide (above a 25% concentration) are highly gassing and thus consume disproportionately high amounts of binding agent. A higher depletion of bin-ding agent may also occur due to higher temperatures. To normalise consumption, use of a waste gas pre-washer is recom-mended. It significantly reduces the con-centration in the waste gas, thus prolonging the lifetime of the downstream cartridges considerably.

Description Volume of waste gas

D(mm)

H(mm)

DN Flow resistance with rated load

Splash watermax.

Weight Order No.

Waste gas pre-washer up to 5 m3/h 160 362 G 2" approx. 0,5 … 1 mbar 25 l/h 2 kg 860 2030

Waste gas pre-washer 50 m3/h 270 638 100 approx. 0,5 … 1 mbar 50 l/h 8 kg 860 2050

Waste gas pre-washer 72 m³/h 325 638 100 approx. 0,5 … 1 mbar 70 l/h 10 kg 860 2075

Waste gas pre-washer 150 m3/h 420 745 125 approx. 0,5 … 1 mbar 90 l/h 13 kg 860 2150

Quick-acting fill protector

To safeguard the storage tank when using a compressed air feed from the feed tank, TECHAP offers its quick-acting fill protec-tor as a complete unit (fast-closing valve including control unit, sensor and bypass valve with pipework) in nominal diameters DN 32, 40, 50, 65 and 80. There is a choice of the following materials: PVC, PP.

The problemIf the feed tank is impinged with com-pressed air to drive the liquid into the storage tank or even just to maintain the flow, then the vapour-saturated volume of compressed air - i.e. two to three times

the volume of the feed tank - will have to be disposed of as soon as the feed tank is empty. Since this exhaust air arrives at the storage tank at a speed between 20 and 30 times the normal rate, no cleaning device will be able to clean this volume and discharge it instantly, with the result that the storage tank (which is designed for pressureless operation) can be impin-ged with a pressure of up to 3bar, at least for a short while. In the case of a speci-fied fill rate of 15m3/h, for example, then depending on the size of the pipes and the pressure, an exhaust air volume of up to 300-450m3/h may result.

TECHAP chemical vapour locks have been designed for a nominal fill rate and must not be loaded above that rate. Surge chambers or washers experience break-through, without performing their actual task of cleaning the air.

Information on fill rates is to be checked in all instances, especially for filling using compressed air. The chemical vapour trap must be desi-gned to accommodate this rate, or the size of the pipe reduced to ensure that the indicated fill rate is observed (please refer to container licensing and other regulati-ons). Installing a baffle in the fill pipe is recommended. If necessary, reduce pres-sure.

The solutionSince the supplier cannot as a rule be ex-pected to prevent break-through of air consistently and without exception during manual operations, installing a quick- acting gate valve in the fill pipe is essential.

NotesWith fill procedures involving compressed air, the TECHAP chemical vapour lock should always be over-dimensioned by one size, in order to ensure operational safety.The quick-acting fill protector is to be used only with conductive liquids. The sensor closes the main pipe as soon as it detects air, which is then discharged via the bypass with a built in orifice.

Water spray connectorWaste gas pre-washer max. 5 m3/h2 x G2“ connectorsDimensions as per SL3 K

Standard version with washing water return to the tank.

Separate arrestor at extra charge.

02.1-10 Subject to technical modifications.

02.1-11Subject to technical modifications.

Additional equipment and accessoriesQuick-acting fill protector

Schematic diagram for the quick-acting fill protector

Installed length approx. 1.300 mm

1 Measurement sensor2 Quick-acting gate valve (pneumatic)3 Pneumatic control valve4 Manual bypass valve5 Control unit

Order data Quick-acting fill protector

Description Connector Order No.

PVC PP

Quick-acting gate valveComplete unit with pipework and including control unit and sensorV = Screw connectorF = Flange

V DN32 860 0023 on request

V DN40 860 0024 on request

V DN50 860 0021 on request

V DN65 860 0019 on request

F DN80 860 0022 on request

Accessories for quick-acting fill protector

Dimensions [mm] Description Description Order No.

Wall-mounted housing for control unitDouble or triple housing on request. Inevitable if distance between measurement sensor and location of installation > 15 m

IP 54 860 0025

G1“ sensor with Cx appliance plug

PVC body with special meassuring pin

860 0027

RS1 control unit in plug-in housing,Dimensions in mm, 230V power supply,sensitivity and delay time pre-set.

Contact load: 230 V AC,0.5A inductive, earth externally,change-over contact

860 0028

For quick-acting gate valves and valves, see the ball valve product area

O-ringAppliance plug

Cx

Sterile filtersas single or intermediate use

Additional equipment and accessoriesDust filters

Dust filters

• Up to 8,000 litres of air per minute, in both directions• Filter fineness <2µm absolute• Low pressure loss - see diagram• Non-metallic, using plastic material with a flexible connector• Suitable for breathing filters• Easy assembly using a strap retainer, easy to replace• As a pre-filter for TECHAP chemical vapour locks

or as an independent (stand-alone) dust filter. Also available in protective housing.

Item Nominalcapacity

Dimensions in mm Insert depth

Weight V2A strap retainer to fasten filter

Order No. m³/min d1 d2 d3 h1 h2 e Order No. 860 3001 1 50 65 110 120 95 20 160 g 860 3021 860 3002 2 75 90 130 150 125 20 240 g 860 3022 860 3003 4 75 90 160 165 140 25 380 g 860 3022 860 3004 6 100 120 230 160 120 30 680 g 860 3023

Flow

resis

tanc

e

Volume flow

02.1-12 Subject to technical modifications.

mba

r

02.1-13Subject to technical modifications.

Binding agents

Binding agent type Description Bulk density

BM1 Calcium hydrate with colour indicator (bluish discolouration),when reacting with acid vapours, stable salts are produced

approx. 0.86 kg/l

BM2 Various activated carbon types, with no colour indicator (smell test or test stick) - various types and particle sizes

approx. 0.50 kg/l

BM4 Air-drying agent with colour indicator, can be reprocessed by heating to approx. 70-80 °C

approx. 0.90 kg/l

Notefor new plants, the pressure loss is approx. 1-13 mbar, in accor-dance with the nominal throughput for BM1. At nominal velocity! 0.5-10 mbar for BM2 and BM4.

Note on disposal: all information regarding disposal is offered as a recommendati-on, and requires clarification with the responsible authorities and supervisory bodies.

Binding agent/Model reactions/Chemicals which can be processed

Model reactions for binding agents

Binding agent BM1 Binding agent BM4

Binding agent BM1 largely comprises calcium hydroxide with a colour indicator.

Model reactions with hydrochloric acidCa(OH)2 + 2HCl = Ca(Cl)2 + 2H2O

Consumption at 20°C per 10m3 30% waste gases, approx. 260 g.

Model reaction with carbon dioxideCa(OH)2 + CO2 = CaCO3 + H2O

Consumption per 10m3 air approx. 8g. Despite the low consump-tion, the binding agent should be replaced in all cases at least once a year, to avoid formation of corridors and crusts. After a longer period in use, the colour indicator may become less active!

For CO2 removal, we recommend the use of the higher sized chemical vapour lock for the respective application, to increase the dwell time.

1 litre of BM4 moisture binding agent (bulk density = 730 g/l), at 20°C and 1.000 mbar air pressure takes up around 25 % by weight of its own bulk density:730 g/l /4 = 182,5 g water/litre of BM4 binding agent

120

100

80

60

40

20

0

706050403020100-10-20 °C

H20

with

in t

he A

ir g

/m3

Chemicals which can be processedChemical description Chemical Formula Chemical description Chemical FormulaAluminium chloride AlCl2 Monoethanolamine C2H7OHFormic acid HCO2H Sodium hypochloride NaClO / H2OAluminium sulphate (hygroscopic) AlSO4 Sodium bisulphate NaHSO3

Sulfamic acid H2NSO3H Sodium phosphate Na3PO4

Ammonium hydroxide *) NH3 + H2O Soda lye NaOH/H2OAcrylic acid C3H4O3 Oleum (half filtering speed) H2SO4+ SO3

Acetone Carbon dioxide (v-max. = 50% CO2) C3H6O Phosphoric acid (any concentration) H3PO4

Ethanoic acid CH3COOH Nitric acid (any concentration) HNO3

Ferrous chloride FeCl2 Hydrochloric acid **) HClFerric chloride FeCl3 Sulphuric acid ***) H2SO4

Formaldehyde in water HCHO+H2O Solution of hydrogen sulphide (toxic) H2S/H2OHydrofluoric acid HF+H2O Sulphurous acid (approx. 6% in water) H2SO3/H2OHydroxypropionic acid CH3CH(OH)CO2H Triethanolamine (hygroscopic) N(CH2CH2OH)Diamide hydrate (toxic) N2H4 / H2O Toluene C6H5CH3

Potassium hypochloride KClO / H2O Xylene C6H4(CH3)2Carbon dioxide CO2

Further chemicals on request. *) 24-26%, only decant with transfer pipe and pump (v = max. 50%)**) 30-33%, 33% solution only with pre-washer)***) any concentration, with 96% acid possibly may require feed air drying

Model applications

Decanting station with compressed air displacement

Installation of the quick-acting gate valve fill protector is urgently recom-mended if decanting involves use of compressed air.

NoteHere it is not only the exhaust air from the storage tank which needs to be cleaned, but also the compressed air from the feed tank, and taking into account the pressure being used for the entire volume being treated. If using the quick-acting gate valve as a fill shut-off in the event that the level is exceeded, the bypass valve must also be operated automatically.

To neutralisation

Automatic control switches

Quick-acting gate valve

Bypass

To the consumer

1 2 3

SL7K chemical vapour lockwith BM1K binding agent

ANSI or DIN

SL7K chemical vapour lockwith BM1K binding agent

HCI tankunder 33%

ANSI or DIN

H2SO4 tank96 - 98%

SL7.2K chemical vapour lock with BM4K binding agentand heater unit

HCI tank

over 33%

Pre-washer

SL7K chemical vapour lockwith BM1K binding agent

ANSI or DIN

02.1-14 Subject to technical modifications.

02.1-15Subject to technical modifications.

M3

Process engineering and components

Chemical vapour locks for absorption of hazardous and pollutant chemical vapours produced during the filling, decanting and draining of closed pressureless storage tanks and contai-ners.

Part-turn valve actuatorsimpinged on both sides or with a spring returnPivoting angle: 90°, 120°, 180°, 360° Torque 5-1,600 Nmwith the Miller Twin-Ball-System®

Process valvesTECHAP process valves are acid- and lye-resistant complete control units for practically all procedures involving ion exchange, such as water softening and desalination plants

ValvesPiston control valvesCeramic flat slide valvesMotor and pneumatic ball valvesBall check valvesInjection valves and on-off valves

TECHAP is a leading provider of products for process enginee-ring and customer-specific process solutions. Our products contribute to simplifying operating flows and operating proces-ses and increasing operational safety. Since our products are standardised, they can be supplied to very short deadlines any-where in the world.

The realisation of customised solutions is part of our work. We manufacture products which are precisely tailored to customer requirements. Flexibility and co-operation are instinctive to us.

Our product range for industrial uses includes

Jet pumpswith performance adjustment, for suction, thinning, conveying and creating a vacu-um; resistant to chemicals, with a choice of propellant, e.g.: water, liquid propel-lants, air, gases

Level switcheschemically resistant to acids and lyes, with reed contact magnetic switch, multiple potential uses, robust

UV radiation disinfection units for sterilising water, with subsequent micro-filtration

Specially-manufactured pro-ductsIf you were unable to find the compon-ents to fit your requirements in this list, please contact us. Specially-manufac-tured products are our forte.

Tel. +49.7152. 90 633-0

www.techap.de

?!

Techap GmbHBöblingerstraße 13 • 71229 LeonbergTel. + 49.7152. 90 633 - 0 Fax + 49.7152. 90 633 - 2www.techap.de • [email protected]

M3

02.1-16 Subject to technical modifications.