Carte Juin04-pour PAN - Technip flexible pipe with a Coflon® pressure sheath in the North Sea and...

Transcript of Carte Juin04-pour PAN - Technip flexible pipe with a Coflon® pressure sheath in the North Sea and...

Flexible pipe

Technologies and products

2

Technip Profile

Worldwide leader in engineering, project management andtechnologies, serving the oil & gas industry for 50 years

Revenues: 7.9 billion euros in 2007

23,000 people worldwide

Confirmed leadership and proprietary technologies in 3 business segments:

Offshore OnshoreSubsea

Engineering and fabrication offixed platforms for shallow waters(TPG 500, Unideck®)

Engineering and fabrication offloating platforms for deep waters(Spar, semi-submersible platforms,FPSO)

Leadership in floatovertechnology

Management of constructionyards

Gas treatment and liquefaction(LNG), Gas-To-Liquids (GTL)

Oil refining (refining, hydrogenand sulphur units)

Onshore pipelinesPetrochemicals (ethylene,

aromatics, olefins, polymers,fertilisers)

Biofuel and renewable energiesNon-oil activities (pyrotechnics,

life sciences, metals, buildings andinfrastructures)

Design, manufacture and supplyof deepwater flexible and rigidpipelines, umbilicals and risersystems

Subsea construction and pipelineinstallation services

Five state-of-the-art flexible pipeand umbilical manufacturing plants

Five spoolbases for reeledpipeline fabrication

A constantly evolving fleetstrategically deployed in the world'smajor offshore markets

Technip offers a broad range of services in engineering,

manufacturing, installation and retrieval of flexible pipe systems

with the most advanced integrated solutions for deepwater

and ultra deepwater field developments.

3FLEXIBLE PIPE

Flexible pipe

Technip is the most experiencedprovider of integrated solutions forsubsea field developments, based ona broad range of field-proven productsand services. In the early 1970’s, Technippioneered flexible pipe technology andused it to provide its clients with ever-higher levels of reliability and quality,even in the world's harshest anddeepest offshore environments.

For over 35 years our high pressureflexible products have providedoffshore operators with reliable andefficient subsea solutions worldwide.To date, more than 9,000km of Techniphigh-pressure flexible pipe has beeninstalled throughout the world.

Our products are versatile, corrosion-resistant and compliant, and they areeasy and quick to install, retrieve andre-use for marginal or evolutive fieldarchitectures, thus environmentallyfriendly.

They have carved out their place notonly for floating facilities but even inthe shallow and medium water marketsthat were once the exclusive domainof rigid steel flowlines. With internaldiameters ranging from 2" to 19", flexiblepipes are the product of choice forinfield lines.

At the same time, the flexible pipe'sversatility and ability to evolve withthe industry will continue to ensure itsplace within the deepwater and ultradeepwater markets that characterizenew offshore field developments.

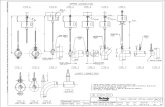

Standard Technip Flexible structure

IPB* (Integrated Production Bundle)

* Proprietary technology.

4 FLEXIBLE PIPE

What is flexible pipe?

A FIT-FOR-PURPOSESTRUCTURE

A flexible pipe is made up of severaldifferent layers. The main componentsare leakproof thermoplastic barriersand corrosion-resistant steel wires. The helically wound steel wires givethe structure its high-pressure resis-tance and excellent bending characte-ristics, thus providing flexibility andsuperior dynamic behaviour. Thismodular construction, where the layersare independent but designed tointeract with one another, means thateach layer can be made fit-for-purposeand independently adjusted to bestmeet a specific field developmentrequirement.

MAIN CHARACTERISTICSFLEXIBILITYFlexibility is the distinctive property offlexible pipe. A typical 8'' internaldiameter (ID) flexible pipe can safelybe bent to a radius of 2m or less. Thisis the reason why flexible dynamicrisers have been the enabling techno-logy for floating production systems.This flexibility is also important forflowlines laid on uneven seabed condi-tions. Flexibility makes it possible tospool the pipe on a reel or in a carouselfor efficient and quick transportationand installation.

INSTALLABILITYBecause the flexible pipe comes in acontinuous length, laying speedcommonly averages 500m per hour.Separate sections are connected ondeck during installation, eliminating theneed for any intermediate riser basestructure or subsea connections. Thiselimination of interfaces reduces riskin operation.

MODULARITYThe independent layers of a flexiblestructure enable it to be tailored tothe precise needs of a specific deve-lopment. Simple flexible pipes formedium pressure water transportcomprise only four layers. The mostcomplex flexible pipes may have up to19 layers.

Beyond the basic fluid barriers andstress-resistant wires, additional layerscan be included to prevent wearbetween steel layers (in dynamic appli-cations) or to provide improvedthermal insulation ("standard" flexiblepipe already has a much better insula-tion coefficient than that of steel pipe).

Besides including new thermoplasticor steel layers within the product, it isalso possible to assemble plastic hoses,electrical cables or optical fibersaround a flexible pipe to produce anIntegrated Service Umbilical (ISU®), orinclude active heating for flow assu-rance in deepwater to produce anIntegrated Production Bundle* (IPB).

In 2001/2002, Technip participated inthe DEMO 2000 JIP, demonstrating itsability to supply heat traced flexible,including gas lift tubes and tempera-ture monitoring optical fibers withinthe same line. Heat tracing and moni-toring allow temperatures to beperfectly tuned within the coreproduction flexible in order to meetflowing or cool down requirements.This type of flexible pipe provides an"all-in-one" solution for deepwaterapplications.

* Proprietary technology

5FLEXIBLE PIPE

Flexible pipe: re-usability for anenvironmentallyfriendly product

CORROSION RESISTANCESince the steel wires are not in direct contact with the conveyed fluid, they donot require the same corrosion resistance as steel pipe. This means that our designexperience and knowledge of gas diffusion through thermoplastic materials enableus to use carbon steel where the equivalent rigid pipe application would requiremuch more expensive corrosion-resistant alloys.

HIGH PRESSURE RESISTANCEFlexible pipes resist all fluid pressures currently encountered in the most severesubsea applications. Again, the modularity of the flexible pipe manufacturingprocess enables us to adjust thickness, shape and number of steel wire layers tomeet the specific requirements of our clients.Modularity enables flexible technology to cover very different applications:

kill & choke line for drilling (up to 15,000 psi)drain pipes and foam lines for onshore refinery applicationsproduction flexible products already installed in waters down to 1,890m

Even more important, it means that the flexible pipe structure is constantly evol-ving to meet stringent field specifications:

higher pressures (up to 7,200 psi for a 9” ID, up to 10,000 psi for a 7.5" ID) ondynamic riser applications

higher temperatures (up to 130°C)enhanced insulation through thick foam fillers laid on SZ machineactive heatingdesigns available for ultra deepwater and qualification for 3,000 mwd (ongoing)

VERSATILITY AND RE-USABILITYMoreover, flexible pipe is the only product, environmentally friendly, which canbe recovered and reinstalled several times to be used successively for severalmarginal or evolutive fields as regularly done for years in Brazilian waters.

The combination of flexibility,installability, modularity, corrosion

and high pressure resistance, re-usability and versatility explains

why flexible pipe is an overall cost-effective solution.

Flexible pipe:a cost-effectivesolution

6 FLEXIBLE PIPE

THE WORLDWIDEREFERENCEIn the early 70's, Technip pioneered

flexible pipe design, manufacture and

installation, and has now accumulated

more than 35 years of field-related in-

depth experience worldwide (see map

on page 8). Our aim and strategy is to

base our leadership on technological

differentiation and, in that respect, the

flexible pipe product is our historical

reference. We are committed to resear-

ching new solutions to better serve

our clients’ needs. We introduced

Coflon®, Crossflex®, Gammaflex®,

various types of Cofoam® insulation

materials, both Zeta and Teta vault

profiles, the Vertical Laying System*,

Steep Wave and Pliant Wave® riser

configurations, midwater arch confi-

gurations and buoyancy modules,

Integrated Service Umbilicals® (ISU®)

and multibore risers. Technip has also

pioneered the development of most

of the analytical and numerical tools

used to design flexible flowlines and

riser systems.

Today, this drives us to find the most

reliable and client-focused solutions

for the deep and ultra deepwater

challenges that lie ahead.

THE WIDEST RANGE OF SERVICESTechnip is the only offshore contractor

that seamlessly integrates design, engi-

neering, manufacturing and installation

services to its clients' benefit. The staff

of our regional business units regularly

interfaces with our clients worldwide.

Technip's Product Engineering Division

(PED) coordinates the flexible pipe-

related engineering within our regional

business units.

FLEXIBLE PIPE PLANTSTechnip currently operates two flexible

pipe plants:

Flexi France (Le Trait, France)

Flexibras (Vitória, Brazil).

Based on a normalised 8" ID pipe, the

current capacity of Technip plants

reaches a total of 860 km of product

per year.

A third flexible pipe manufacturing

plant is being built in Malaysia to

service the Asia Pacific and Middle East

subsea markets, thus extending the

overall production capacity to 1,060 km

of normalised 8" flexible pipe per year

in 2010.

PIPELAYWe own and operate a large fleet ofdynamically positioned vessels, four ofwhich are dedicated to flexible pipelay.The Deep Blue, the flagship of theTechnip fleet, is the only vessel of herclass to lay both flexible and rigid pipes(reel-lay and J-lay) down to 3,000mwater depth. In addition, Technip isalso the leading supplier of reeled rigidpipe solutions worldwide. All theseassets and capabilities are integratedby our unique Project Managementorganisation. It enables us to compareand optimize the solutions we offerto our clients and provide theoptimum flowline and riser systems,rigid or flexible for any offshore deve-lopment.

* Patented technology.

Providing the best suited solutionsfor our clients’ field developments

7FLEXIBLE PIPE

EXCELLENCEIn addition to manufacturing and supply activities, Technip offerssolutions tailored to clients’ needs. With our long offshore fieldexperience and our intimate knowledge of the technical challengesfaced by flexible pipes, we can and do deliver the highest qualityflexible products available anywhere in the world.

All Technip activities are placed within an integrated Quality Systemwhich ensures that our organisation, manufacturing process, productsolutions and services are reliable and efficient. The Group is certifiedISO 9001 and its flexible pipe plants have received the API 17Jcertification for the design and manufacture of unbonded flexiblepipe. The Group is applying permanent improvement processesthroughout its organisation.

Field experienceand milestones

Since 1972, the yearly OTC award for companies has beenhonouring the one company (amongst operators andcontractors), that has significantly contributed to theoffshore oil and gas industry. In that respect, we obtainedthe 1995 OTC award for the design, manufacture andinstallation of flexible steel pipe used in floatingproduction systems, deepwater developments and highpressure pipes for drilling and well servicing.

1973 First flexible pipe installed in Congo for ElfEmeraude

1974 First flexible flowline in the North Sea onMobil Beryl

1976 First dynamic flexible riser in Brazil onPetrobras Garoupa

1978 First flexible riser with heat tracing inIndonesia on Conoco Udang

1982 First flexible riser with thermal insulation

1986 First dynamic flexible riser system installedin the North Sea on Balmoral Sun Oil

First flexible pipe with a Coflon® pressuresheath in the North Sea and Spain

1987 Largest diameter of flexible riser (19" ID) onStatoil Statfjord C

1988 New depth record for flexible riser (567m)in the Gulf of Mexico on Conoco Jolliet

1989 First flexible pipe with a Crossflex® pressuresheath

1992 First installation using the VLS (Vertical LayingSystem)* on Saga Snorre

1994 First flowline (16" ID, 3.5 km) manufacturedin carousel

First ISU® (Integrated Service Umbilical) onNorsk Hydro Troll

1997 New depth records for flowline (1,709m) andriser (1,390m) in Brazil on Petrobras MarlimSul

1998 First flexible riser with a Teta pressure armouron Norsk Hydro Visund and Enterprise OilPierce

2000 New depth record for flowline (1,877m) onPetrobras Roncador

2001 Implementation of the first Product IntegrityManagement System (PIM) on the Åsgardfield, Norway

2002 Installation of the deepest flowline (1,886m)on Petrobras Roncador

2003 First project using 46mm thick insulationfillers - Agip Abo (550m) in West Africa

2004 First qualification for 2,100mwd (DIP testoffshore Brazil, 7” and 9” ID flowlines)

2005 Installation of the deepest riser (7.5" ID -10,000 psi for water injection) in 1,890m forBP Thunder Horse in the Gulf of Mexico

Extension of BV certification to 15,000 psi

2006 First supply and installation of 8 x 11”Integrated Production Bundle (IPB)* dynamicrisers in 1,400mwd for Total Dalia, offshoreAngola

2007 Supply and installation of the world's firstsmooth bore 14” ID dynamic riser for gasexport on Statoil Åsgard, Norway

2007 Installation of the deepest single sectionriser for an 8" HP/HT sour service produc-tion application in 1,500 mwd for ChevronAgbami in Nigeria * Proprietary technology.

St-John’s

Industrial and Engineering/Research Facilities

(P) = Flexible pipe plant (S) = Rigid pipe spoolbase

(U) = Umbilical plant

Macaé

London Newcastle (U)

Evanton (S) Aberdeen

Rio de Janeiro

Vitória (P) Barra do Riacho (S)

Sales and Projects offices Geographical breakdown of flexible pipe volumes supplied by Technip since 2000

Houston (U)

Luanda

Perth

Mumbai

Kuala Lumpur

Singapore Lobito (U)

Dande (S)

Paris Le Trait (P)

Orkanger (S) Oslo

Tanjung Langsat (P) (operational in 2010)

Mobile (S)

Skandi Arctic (delivery in 2009)

Seamec 1

Skandi Achiever

Seamec 2

Seamec 3

Geoholm (owned by Geo Rederie II, Norway - service contract)

Alliance

Deep Blue

Sunrise 2000

Venturer

Constructor

Orelia

Wellservicer

Normand Pioneer (owned by Solstad - long term charter)

Deep Pioneer

Seamec Princess

Apache

New Deepwater Pipelay Vessel (delivery in 2010)

Skandi Vitoria (delivery end 2009)

15%

15%

60%

3%

1%

1%

5%

%

8 FLEXIBLE PIPE

To-date, more than 9,000 km of Technip

flexible pipe has been manufactured

and installed worldwide.

A worldwide presence and experience

Dynamic test rig

9FLEXIBLE PIPE

Performance

Largest internal diameter: 19” ID exportriser on Statfjord C (Norway) and BongaOffloading lines (Nigeria)

Deepest production flowline in Brazil: 6” ID - 1,886m, Roncador

Deepest and highest value of diametertimes pressure: 7.5” ID 10,000 psi, waterinjection risers and flowlines, ThunderHorse (Gulf of Mexico)

Innovative proprietary technology:flexible Integrated Production Bundle (IPB)*,1,400m Dalia, Angola

World's first 14" ID smooth bore gasexport dynamic riser, Åsgard, Norway.Successfully tested to a max. flow of48MSm3/d

RESEARCH & DEVELOPMENTTechnip spends yearly about EUR 15 million on flexible pipe in its research centers.The Product Engineering Division has full responsibility for Technip's flexible pipeR&D program and is equipped with a full range of test facilities, including a state-of-the-art laboratory for advanced material testing and analysis, making it possibleto simulate realistic service conditions on actual pipe samples. The R&D activity is oriented towards extending the current product range byintroducing new products and materials. Cost reduction and manufacturing quality isa permanent and parallel objective of these efforts. When a given development hascome to fruition, its qualification testing is frequently carried out under the auspicesof a JIP (Joint Industry Program). This enables key operators to participate in thetransition between the development phase of an application and the "real" marketableand industrial phase.Complex development projects are carried out within dedicated task forces. Thiswas the case for Technip's integrated Ultra Deep Water development program. Thistask force developed a new generation of flexible pipes primarily for deep and ultradeepwater.

A client-oriented company

dedicated to cost-effectiveness

and technology

A client-focused organisation

* Proprietary technology.

10 FLEXIBLE PIPE

Vertical Laying System (VLS)*

* Patented technology

ENGINEERINGThe Group engineering organisationresponds to and meets two main chal-lenges: being close to our clients inorder to answer their needs while atthe same time ensuring a sustainedlevel of engineering excellence is avai-lable in all parts of the Group. This isachieved through a combination of:

local engineering departments ineach business unit, able to performmost engineering tasks related to aproject, within the project teams.

a centre of excellence located inLe Trait (France), sharing the same siteas the main flexible pipe manufacturingfacility.

This Product Engineering Division (PED)ensures support to the business units,consolidates the experience acquiredthroughout the Group and developsnew products and materials via arobust and innovative R&D program.Information exchange between thebusiness units is routed via PED whichconsolidates the knowledge andensures a reliable and efficient engi-neering service across the Group.

PIPE INTEGRITYMANAGEMENTThe lifetime of offshore field develop-ments can be as long as 20 to 30 years.Operators must have continuous focuson their assets throughout the field’slife. Hence, monitoring of the opera-tional data is key in assessing integrityand ensuring safe and optimal opera-tion of the pipeline system. In coope-ration with Force Technology, Techniphas set up a Pipe Integrity Management(PIM) system where relevant opera-tional “data monitoring” and inspec-

tion results are gathered into a data-base, treated and analysed. A RiskBased Inspection program is also esta-blished and various support servicescan be included. A first PIM system wasimplemented in 2001 for the Åsgardfield in the North Sea, Norwegiansector.

MANUFACTURINGManufacturing is organised under aglobal factory policy whereby the twoflexible pipe factories of Le Trait(France) and Vitória (Brazil) are managedin an approved and similar manner, byapplying common quality and safetyGroup standards. As the manufacturing centre of excel-lence, Flexi France, the Le Trait plant,has the facilities and capability toproduce the widest range of flexiblepipes. It is where all our innovative pipedesigns are first manufactured andtested. Flexibras, our flexible pipemanufacturing plant located in Vitória(Brazil), has primarily been establishedto supply the local market but can alsosupply flexible pipe internationally.

INSTALLATIONBecause of our integrated approach toflexible pipe technology, we havealways considered installation as a partof our core business activity and wehave always ensured that our vesselsand equipment are designed to installthe flexible products we have deve-loped and manufactured. The Sunrise2000, the Constructor, the DeepPioneer and our ultra deepwater vessel,the Deep Blue, are specialist installa-tion vessels, which in terms of decklayout and installation equipment,benefit from the Group's intimate

knowledge of the flexible pipe productand which have therefore become keyto our ongoing success. The Deep Blue’sPLS (Pipe Lay System) can also installrigid pipe, either by reel lay or J-lay.As far as equipment is concerned, wehave developed and patented the VLS*(Vertical Laying System). The systemallows for the efficient installation offlexible flowlines and risers in deep-water and harsh environments. Theutilisation of the VLS makes it safer tolay flexible lines especially whenequipped with intermediate connec-tions, buoyancy modules or otherancillaries, for a 425-tonne capacity. Technip’s installation innovations havenow extended to the fabrication of anew PPS (Portable Pipelay System)design which was used on severalprojects, for a 350-tonne capacity.

Research and Development

11FLEXIBLE PIPE

Ultra deepwaterflexible pipe:current and

futurecapabilities

3,000 m

2,500 m

2,000 m

1,500 m

1,000 m

500 m

0 m

(assuming 425 tonnes max pipelay tension)

6” 8” 10”12” 14”

16”

Cu

rren

t

Fu

ture

UDW objective

Ultra deepwater extends from 1,000 to3,000m and beyond. Our 1997 worlddepth record in Brazil was achieved usingtraditional Technip structures and stan-dard materials.Technip further extended the opera-tional experience with the installationin 2002 of 6" insulated production flow-lines in 1,886m of water and with DeepImmersion Performance full scale tests(DIP) performed offshore Brazil in 2004(7” and 9” ID tested in 2,100m of waterdepth).Full use is being made of the modularity of flexible pipes and the Group's capacityto efficiently and effectively evolve them. In the case of the ultra deepwater deve-lopments, it is the steel layers that are most affected and each improvement answersa specific client-led challenge:

internal carcass for collapse resistancepressure vault for collapse and weight reductiontensile armours for weight reduction.

Another significant area is active heating and this is being addressed by adaptingthe field-proven ISU® concept to the circulation of hot water around the centralcore of the pipe. Other more peripheral lines can be used for gas lift. Thus, the ISU®lines with multi-functions are gathered in a single line and become the IntegratedProduction Bundle* (IPB) to guarantee flow assurance even for the deepest fields.

In deep and shallow waters, the Technip flexible pipe technology will continue tobe a core component supporting the evolution of the subsea oil industry and wewill therefore be in a position to offer our clients high quality and cost-effectivesolutions tailored to their very needs.

* Proprietary technology.

Towards ultra deepwater

CONTACTSFlexi FranceRue Jean Huré - BP 776580 Le Trait, FrancePhone: +33 (0)2 35 05 50 00Fax: +33 (0)2 35 37 49 60

FlexibrasJurema Barroso Street, 35Ilha do Príncipe - Vitória - ES29020-430 BrazilPhone: +55 27 21 23 9444Fax: +55 27 21 23 9799

HEADQUARTERSTechnipTour Technip6-8 allée de l’Arche92973 Paris La Défense Cedex France Phone: +33 (0)1 47 78 21 21Fax: +33 (0)1 47 78 33 40www.technip.com

Technip is a world leader in the fields of project management, engineeringand construction for the oil & gas industry, offering a comprehensive portfolioof innovative solutions and technologies.With 23,000 employees around the world, integrated capabilities and provenexpertise in underwater infrastructures (Subsea), offshore facilities (Offshore)and large processing units and plants on land (Onshore), Technip is a keycontributor to the development of sustainable solutions for the energychallenges of the 21st century.Present in 46 countries, Technip has operating centers and industrial assets(manufacturing plants, spoolbases, construction yard) on five continents,and operates its own fleet of specialized vessels for pipeline installation andsubsea construction.The Technip share is listed on Euronext Paris exchange and over the counter(OTC) in the USA.

www.technip.com

This

docu

men

t is

the

prop

erty

of

Tech

nip

and

is no

t in

tend

ed t

o be

a b

indi

ng c

ontr

actu

al d

ocum

ent.

Any

info

rmat

ion

cont

aine

d he

rein

sha

ll no

t re

sult

in a

ny b

indi

ng o

blig

atio

n on

the

par

t of

Tec

hnip

, or

any

of it

s af

filia

tes,

and

is pr

ovid

ed fo

r in

form

atio

n pu

rpos

es o

nly.

Tech

nip

- Pu

blic

Rel

atio

ns D

epar

tmen

t -

Janu

ary

2009

- P

hoto

cre

dits

: Tec

hnip