Carbon

-

Upload

urip-s-setyadji -

Category

Documents

-

view

55 -

download

2

Transcript of Carbon

Carbon and Graphitefor Plain Bearings Applications

Graphite SpecialtiesBusiness Unit

SGL CARBON GmbHWerk Ringsdorff

Drachenburgstraße 1D-53170 BonnPhone: +49 (228) 841-394Fax: +49 (228) 841-456Internet: www.sglcarbon.com

This information is based on our pre-sent state of knowledge and is intend-ed to provide general notes on ourproducts and their uses. It should nottherefore be construed as guaranteeingspecific properties of the productsdescribed or their suitability for a par-ticular application. Any existing indus-trial property rights must be observed.The quality of our products is guaran-teed under our General Conditions ofSale.

02 02/3E Printed in Germany

Projected bearing area I · d1 ≥ —

Projected bearing area I · d1 ≥ —

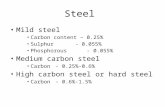

Design Guideline / CalculationsMaterial Grade Recommendations forPlain Bearings

Base materials are carbon graphite, graphite and resinbonded graphite, also usedwith special impregnations(antimony or resin) depend-ing on the application. Therange of use includes wet run-ning, mixed and dry running.

Small batch and unit production

EK 20Carbon graphite grade with good dry running properties. Suitable for wet running plain bearings.

EK 24Carbon graphite grade with very good dry running properties.Particularly suited for dry running use and for use in media with poor lubricating properties.

EK 40Graphite grade for dry running plain bearings.

High volume production

EK 23Carbon graphite grade, pressed-to-size, with very good dry running properties. Suitable for plain bearings running wet and dry.

®RIDURID V 1640Resin bonded material for wet running bearings.

Cylindrical bearings, flanged bearings(DIN 1850, Sheet 4)

d1 = bearing bore (mm)d2 = bearing outside diameter (mm)d3 = flange diameter (mm)s = bearing wall thickness (mm)l = bearing length (mm)f = radial or axial load (N)p = specific radial or axial load (N/mm2)b = flange thicknessv = rubbing speed (m/s)

Bearing size

0.3 ... 0.5 % of shaft diameter at operating temperature (warm clearance)

0.3 ... 0.5 % of shaft diameter at fitting temperature (cold clearance),

if shrunk into a metal housing

0.1 … 0.15 for mixed running

0.15 … 0.25 for dry running

Bearing clearance

Coefficient of friction

v (m/s)

F0.3

F1.5

l ≤ 2d1

≤ 1

≤ 0.1

Dry running and mixed running

Bearing size 1)

0.1 ... 0.3 % of shaft diameter at operating temperature (warm clearance)

0.1 ... 0.3 % of shaft diameter at fitting temperature (cold clearance),

if shrunk into a metal housing

0.01 … 0.05

Bearing clearance1)

Coefficient of friction

1) Observe the laws of hydrodynamics

v (m/s) ≤ 20 F1.5 l ≤ 20d1

Projected bearing area I · d1 ≥ —

Wet running

Outside diameter IT 6 / IT 7

Bore IT 7 / IT 8

Outside diameter Ra = 6.3 µm … 3.2 µm

Bore Ra = 3.2 µm … 0.8 µm

Cold press fitting

Shrink fitting

Bonding

Tolerances

Surface finish

Bearing design

Fitting

Counter surface material(Surface finish)

Information for wet and dry running

Do not subject bearing to tension, shear or bending stress

Generally hard materials, HV > 250 Rt = 0.5 … 0.8 µmCylindrical bearing for pumps in the chemical industry

f x 45°

fl

d 1 d 2

15°

IT 8

f x 45°

f

b

d 1 d 2

15°

IT 8 A

d 3

A

r

Type M Type N

32

Specialty Graphites from SGL CARBON

Axial Bearings

Given valuesrubbing speed v = 0.5 m/sload P = 150 Ntemperature 60 °C

Determining bearing sizeProjected bearing area

l x d1≥ — = = 500 mm2

Bearing bore

d1 ≥ — , we choose d1 = l

d1 = √ 500 = 22.36 mmrounded up d1 = 23 mm

Bearing length

l = = 21.7 mm

rounded up l = 22 mm

Bearing outside diameter d2 = d1 + 2ssmin = 0.15 x d1 = 3.45 mm23 + 2 x 3.45 = 29.9rounded up d2 = 30 mm

Bearing dimensionsØ 30/23 x 22 mm

Bearing clearance Dry running0.3 ... 0.5 % of shaft-Ø d

Shaft diameterd = 23 h6

Bearing clearance (min.)0.3 % x 23 = 0.069 mm(is added to nominal bore)

Bearing tolerances(see below)

Bearing outside diameterchosen s6 (cold press fitting)

Bearing borechosen F7

Bearing lenghtDIN 7168 medium

Resulting in:Ø 23.069 F7/30 s6 x 22 ± 0.2

d 3 d 1

b

The following informationapplies also when calculating theface surfaces of cylindrical andflanged bearings when loadedaxially.

Given valuesshaft-Ø 20 mmrubbing speed v = 3 m/sload P = 500 Nmedium Watertemperature 30 °C

Determining bearing sizeBearing bored1 = 20 mm (given)

Bearing outside diameter d3

By going back and calculating fromthe required area

F = — = = 500 mm2,

it results in: F = — x (d32 - d1

2)

d3 = √ + d12

Bearing outside diameter chosen as d3 = 35 mm

Bearing lengthb ≥ 0.1 d3 (see design)

chosen as b = 5 mm

d3 = √ + 20 2

d3 = 32

Example: Axial bearing calculation, wet running

v (m/s) ≤ 1 A ≥ — v (m/s) ≤ 20 A ≥ —

0.1 … 0.25 0.01 … 0.05

Bearing surfaces fine ground to lapped Bearing surface lapped

Solid or split Solid or split, lubricating grooves

Cold press fitting, shrink fitting, bonded or screwed Cold press fitting, shrinkfitting, bonded or screwed

Usually hard materials, HV > 250 Usually hard materials, HV > 250

Rt = 0.5 … 0.8 µm Rt = 0.5 … 0.8 µm

Bearing area A (mm2)

Coefficient of friction

Surface finish

Bearing design

Fitting

Counter surface materials

(surface finish)

Dry running/Mixed running Wet running

P0.3

1500.3

l2

50023

Example: Cylindrical bearing calculation, dry running

F0.3

F1.0

P1.0

5001.0

π4

F x 4π

d1 d2 Housing diameter

before F7

after H7 … H8

before D8

after E8 … E92)

Method of fitting

Cold pressing

Shrink fit

Bonding

F1,0

s6 H7 about 150 1)

x8 … z8 H7 about 300 3)

In principle this is possible. We can recommend suitable bonding agents.

The recommendations of DIN 1850,Sheet 4 apply. Cold press fitting andshrink fitting are treated separately.

1) For housing materials having a thermal expansion � > 12 · 10-6/K the maximum operatingtemperature is correspondingly reduced. Press fitting is effected with a stepped fitting pin with a tolerance of h5.

2) We recommend that the bearing bore be finished to size after shrink fitting.3) For higher temperatures and for housing materials having a thermal expansion � > 12 · 10-6/K

the special tolerances and/or a locking arrangement may be employed – please enquire about this.

Fitting

54

Specialty Graphites from SGL CARBON

Recommended ISO-Tolerances Max. operating temperature

°C

500 x 4π

Dl

P

S

l

S

b

Bearing Design

In principle design shouldfollow the requirements ofDIN 1850, Sheet 4, “Carbon Bearings”. Inaddition we recommendfollowing the designrecommendations givenbelow:

• bearings for dry runningshould have a smoothbore

• when bearings are run-ning wet, bores shouldhave spiral grooves oraxial grooves accordingto the application. Groove design is shownin DIN 1850, Sheet 2.

Counterface Materials, Surface Finish, Wear Rates

Recommended are hard materials, HV > 250

• grey cast iron• steel, alloy, non-alloy

and nitrided (hard)• hard metal• aluminium oxide• silicon carbide• glass

Of limited use

• steel, alloy and non-alloy (soft)

• light metal alloys• chromium plated materials• non-ferrous metals• carbon materials

In dry running conditions thesurface finish should generallybe of a higher standard thanwhen a liquid film is present. In the latter case, even hydro-dynamically poor media such as water or petrol will achievesome compensating effect andreduce friction between themicro-irregularities of themating surfaces.

v < 0.5 m/s

p < 0.1 N/mm2Load

Rt µm

Surface finish of metallic counter parts

Avoid sharp steps in the boreand on the outside. Break sharp edges

Dimension l ≥ 0.1 D, if possible not below 3 mm

l < 2 ds = 0.15 ... 0.2 x dsmin = 3 mm

Cylindrical bearings should befully supported by the housingor by a special metal bush

Flange thickness should be atleast equal to wall thickness. Atransitional angle should beradiused. Housing thrust facefor flange to be machined.b ≥ s

Any arrangement to preventrotation such as a check plate orplain pin, should be in an un-loaded area not in the bore.Any keyway should be axialand milled out carefully to avoid breakage.

≈ 1

v < 1 m/s

p < 0.2 N/mm2

0.5 … 0.8 < 0.5

v < 3 m/s

p < 0.3 N/mm2

Wear rates of machined bearings of differ-ent carbon grades at a steady rubbing speed of 1 m/s and with increasing specific load when running wet.

Wear rates of machined bearings ofdifferent carbon grades at a steady rub-bing speed of 1 m/s and with increasingspecific load when running dry.

Wea

r [µ

m/h

]W

ear

[µm

/h]

Load (N/mm2) Bearing Ø 30/20 x 20 mm

EK 200

EK 40

EK 24

EK 305EK 2240EK 3245

EK 20

EK 24

EK 2240

EK 3245

EK 2200

EK 3205

76

0 0.5 1 1.5 2 2.5 3 3.5 4

Specific load (N/mm2) Bearing Ø 30/20 x 20 mm0 1 2 3 4 5 6

10

1

0.01

10

1

0.1

0.01

Specialty Graphites from SGL CARBON