Captn Wil's Fuel Polishing System

Transcript of Captn Wil's Fuel Polishing System

8/8/2019 Captn Wil's Fuel Polishing System

http://slidepdf.com/reader/full/captn-wils-fuel-polishing-system 1/14

10/15/2006 08:27 PMCaptn Wil's Fuel Polishing System: Trawlers & Trawlering How To

Page 1 of 14http://www.trawlersandtrawlering.com/howto/captnwil.html

No obligation. Click here to request your free copy.

Gulf Coast Filters

Racor Filters

Fuel polishing aboard aGrand Banks 36

China Doll's experiencewith fuel polishing

Testimonial

Diesel fuel polishing system components: 1) Gulf Coast Filter F-1; 2) Gulf Coast Filter F-1

element; 3) Gulf Coast Filter O-1 JR; 4) Racor 500 2-micron element cut away to show

filter depth; 5) Walbor 6802 continuous-duty diesel fuel pump.

Captn Wil's Diesel Polishing System

By Wil Andrews

Conditions of Use

You are free to use the information in this report in any non-commercial way. The user is responsible to verify that theinformation is suitable to his application and takes sole responsibilityfor any use made of the material.

A Work In Progress

The most common reason for marine diesel engines in general, andrecreational trawler diesel engines in particular, to fail to run isassociated with "bad diesel fuel." The things that make the diesel fuelbad generally have nothing to do with the original quality of the fuel.The problems come about because of the condition of the fuel we

buy and what happens to the fuel when it gets stored, sometimes atthe suppliers' facilities, but most often in our own vessels.

HOME PORT

CIRCUMNAVIGATORS

PASSAGEMAKING

ARCTURUS

TRAWLER TRAVELS

LIVING THE LIFESTYLE

LOOPING THE LOOP

CIRCLE OF FRIENDS

HOW TO

WIT WONDER & WISDOM

HORROR STORIES

MULTIHULLS

LINKS GALORE

BOOKSTORE

INTRO TO FORUMS

THE ONE AND ONLY T&T

BUY! SELL! TRADE!

GREAT LOOP LIST

PASSAGEMAKING LISTPOWER CATAMARAN LIST

FIND WHAT YOU NEED

WELCOME

DONATIONS

ADVERTISING

TRAWLER WORLD

CONTACT US

Ads by Google

Fuel Filtration - Racor The most trusted name infuel filtration - Racor.www.parker.com

Lubriquip Pumps &FiltersLubriquip Pumps Modu-Flo AL-25, HLJ Filters,Maxi-Flo, EO, Maxi-Monitor

devcocorp.com/lubriquip

Various Expansion

8/8/2019 Captn Wil's Fuel Polishing System

http://slidepdf.com/reader/full/captn-wils-fuel-polishing-system 2/14

10/15/2006 08:27 PMCaptn Wil's Fuel Polishing System: Trawlers & Trawlering How To

Page 2 of 14http://www.trawlersandtrawlering.com/howto/captnwil.html

Advertise on this site

All types of Bellows andExpansion Joints to fityour piping systemswww.usbellows.com

Woma GB LtdManufacturers of Water Jetting Equipment up to

3000 bar www.woma.gb.com

Mr. Funnel-simplyamazingMr. Funnel Separateswater from gas or diesel -Ship within 24 hours !www.fourwinds-ii.com

To get anything from this epistle, you must accept the fact that thiswhole thing is a work in progress. The work is to find out how tokeep the fuel we burn Just Like New. The progress in this workcomes in fits and starts, and next year I'm sure I'll know more aboutthe solution to the problem than I know now. Getting the wholeanswer is difficult because while it is of vital concern to usrecreational trawler captains, it is a minor problem when consideredin light of the events of the nation and world. There is no money

dedicated to finding the solution to this problem by eithergovernment or industry. There are companies selling productsproclaiming that their product will solve the problem, but I am notaware of any formal scientific studies that speak to the causes andsolution of this problem. That leaves it to amateurs like CaptnWil,and others, to see this work in progress to a conclusion for therecreational boating world. I encourage all of you to make tests andkeep records so the whole body of information can be shared by allof us. We make judgments based on our observations, experiences,and faith in advice given by others. It is important that we strive tobe able to change those judgments when the evidence suggests achange is called for.

I feel confident that many individual organizations that haveexperienced this problem have come to a successful solution for theirparticular situation, but they have no reason to share their experiencewith us. That leaves us pretty much on our own.

What follows is my final solution to my problem. I hope it may be of help to you

In The Beginning

Like most who have experienced bad fuel problems, I first became

aware that such a problem was possible in 1989 when my "newto-me," four year old trawler engine quit while I was taking her homefrom a thousand miles away.

The boat had spent two winters in Chesapeake Bay mostly at thedock, made the trip down the ICW to the Keys, and I tookpossession in Miami. The engine had less than one thousand hourson it and the fuel tanks were less than half full. With the joy that isonly possible that first day you own a boat, we set out with eightguests toward North Carolina. Guests came and went along the way,and thankfully, there were no guests when the engine stoppedunderway the first time. Before I finally figured out that the problem

was a clogged fuel filter, and then found the proper element, theengine stopped eight times. The last time it stopped underway was ina passage that warns not to anchor because of unexploded ordnance.For a lot of reasons, that whole voyage is an experience I'll neverforget, but that's another story.

I did not know that this work in progress had really begun until theengine stopped while underway again in Chesapeake Bay thatsummer. It was an uncomfortable feeling to be unable to move in themiddle of the bay with night rising on and the wind coming. By thistime, I understood that the symptom of the problem was a cloggedfuel filter. I recognized that the problem was most likely to occur

when the boat was in a seaway and the fuel got stirred up. Thatrealization brought terror to my mind when we got caught in a Julystorm just off Cape Lookout with 60-knot winds and mountainous

8/8/2019 Captn Wil's Fuel Polishing System

http://slidepdf.com/reader/full/captn-wils-fuel-polishing-system 3/14

10/15/2006 08:27 PMCaptn Wil's Fuel Polishing System: Trawlers & Trawlering How To

Page 3 of 14http://www.trawlersandtrawlering.com/howto/captnwil.html

waves. If the engine had stopped then, those I love the most wouldbe cast into the breakers of Cape Lookout.

Keeping the engine running is always preventing an inconvenience,but sometimes it is a matter of survival. I continue this work becauseof both reasons, but most importantly because of the latter.

Early Efforts

After going through a Racor element every day for several days, Idecided to get to the bottom of the problem and clean the tanks. Thebottom of each tank had enough black sand-like stuff to fill two five-gallon buckets each.

What was that stuff? It was the stuff at the bottom of the tank. I havenever had a satisfactory answer about what it was. I am sure therewere ways to find out, but I have only seen speculation and theoryabout that stuff. That speculation and theory led to putting anadditive in the fuel to prevent it from forming again which additiveis unimportant.

The Pour-in Solution

It is very popular today to think that something you can pour into afuel tank will take care of your fuel problems. There is a large bodyof experience, including my own, to indicate that any pour- insolution only treats some of the symptoms, but that's not the realproblem with this procedure The problem is that while the immediatesymptoms may vanish, this cure begins to create its own set of problems. If you kill the bugs, their dead bodies will cause problemssometime in the future they just become part of the jelly that wantsto collect at the bottom of the tank, and we know where that leads. If

you emulsify the water in the tank, it still goes through your injectionpump and injectors, and will lead to a whole new set of problems.

The Absolute Solution

We'll talk in a little while about the Polishing System Solution, but if your system qualifies, you can get along just fine without any extrasystem.

The Maintenance Supervisor of the North Carolina Ferry System hasbeen most kind and helpful to me in my investigation of oil bypassfilters and diesel fuel storage problems. His observations and

experiences are from many engines on many automobile ferryboatsthat run long and hard. They put more hours on most engines in aweek than most recreational boaters do in a season. They burn morefuel in a month than we burn in a lifetime. When he tells me hisconclusions of his observations, I listen and believe.

The older ferryboats have Detroit engines and the newer boats haveCaterpillar engines. There are some facts about the operation thathave special meaning for us in seeing why this operation doesn'thave a fuel problem, but we do:

1. The Ferry System buys diesel fuel on State Contract and it isdelivered directly from the pipeline to his storage tanks.

2. There is never a time when the entire fuel supply remains in

8/8/2019 Captn Wil's Fuel Polishing System

http://slidepdf.com/reader/full/captn-wils-fuel-polishing-system 4/14

10/15/2006 08:27 PMCaptn Wil's Fuel Polishing System: Trawlers & Trawlering How To

Page 4 of 14http://www.trawlersandtrawlering.com/howto/captnwil.html

the tanks more than a very few weeks. In the summer, thecycle is not more than one week.

3. The engines on the ferryboats circulate a much largerquantity of diesel fuel than they burn. They circulate so muchthat all the Detroit engines and many of the Caterpillar enginesare equipped with coolers in the return line to the tank to keepfrom overheating the fuel in the tank. Keep this in your mind.

It will come up in a different light a little later.

4. The fuel in a ferryboat does not stay in the ferryboat fueltank more than a day when it operates and never more than afew days in most other cases.

5. The engines are fitted with Racor diesel filters with waterseparators and the normal fuel filters that are supplied by theengine manufacturer just like most recreational trawlers.Water separators are tended everyday.

6. At one time, a pour-in additive was used in the fuel. During

that time, high injector maintenance was experienced. After atime, use of the pour-in additive was discontinued, and afterthat cycle of injector maintenance was complete, the injectorproblems decreased materially.

7. Fuel storage tanks on land are entered and cleaned regularly.

The most important thing to understand is that the very high volumeof fuel used and long hours of operation in this installation, magnifyeverything about the operation.

If you can guarantee you get clean fuel and guarantee it will be

stored in clean tanks and guarantee it will remain in those tanks nolonger than a week or two, you won't need a Polishing System youalready have the Absolute Solution.

The Circulation Myth

The amount of diesel fuel circulated by the system is a veryimportant factor in connection with our storage problems. When Ifirst started researching this fuel storage problem, I heard stories thatthe Lehman-Ford 135 circulated 60 gph well, at least 30 gph.Wrong! No one knew the real answer because manufacturers do notcommonly provide that information, and no one I ever talked to had

ever measured it. I was shocked to observe that the Lehman-Ford135 returns 1.8 gph to the fuel tank at 2200 RPM.

I expect the high circulation rate story came from the fact that Detroittwo-cycle engines use circulated diesel fuel to cool the injectors.Most four-cycle diesels in the range of sizes used in recreationaltrawlers don't cool the injectors with circulated diesel fuel so theyonly need to circulate enough fuel to make sure the injection pumpalways has a positive head. That is, the lift pump must just pumpenough fuel to guarantee that fuel is always available to the injectionpump at positive pressure.

This low flow rate has a direct bearing on our general problem, but italso has a specific effect of the action of Racor filter units that havewhat is called turbine action. In most installations, the flow rate

8/8/2019 Captn Wil's Fuel Polishing System

http://slidepdf.com/reader/full/captn-wils-fuel-polishing-system 5/14

10/15/2006 08:27 PMCaptn Wil's Fuel Polishing System: Trawlers & Trawlering How To

Page 5 of 14http://www.trawlersandtrawlering.com/howto/captnwil.html

through the filter is far too low to allow the desired turbine action.

It is possible that your engine has a greater pumping rate thanindicated above. It is a very simple matter to measure the quantity of fuel returned to the tank. Just break into the return line to the tankand catch a known quantity of fuel in a known time and compute theflow rate. You can do this at the dock with the engine in neutral.Place a bucket under the return line and have a large zip-lock ready

to catch the measured fuel. Have the engine started and increased theRPM to cruising speed. Then catch fuel in the zip-lock for a timedinterval. The longer the timing interval the more accurate the resultswill be.

Magnetic Fuel Units

Long-time CaptnWilreaders will remember that one manufacturer of these units threatened CaptnWil with legal action because of dissatisfaction at not being able to manipulate the way a WestMarine Trawler Fest seminar was conducted. For that reason, I willoffer no opinions about these devices. I will just say that a very

effective Diesel Polishing System can be fashioned without usingthese units and the rest of this report will not mention them again.

They are only mentioned here to let long-time readers know thereason why.

Where Does The Crud Come From: Water

It is generally agreed that water in the fuel tank causes all sorts of hell. The experts tell us that algae is born, lives, multiplies, and diesin the surface between the water and diesel fuel. These critters andtheir residue are a major source of trouble. The moral is: no water,

no algae.

Most of the water gets into our tanks by water condensing on theinside surface of the fuel tank and less often on the surface of thediesel fuel itself. This occurs every time the temperature of a surfaceis below the dew point temperature of the air to which it is exposed.

Without getting too technical, more moist air will have a higher dewpoint temperature than less moist air and be more likely to causecondensation. It is also helpful to note that the condensation alwaysoccurs on the warm side of the surface -- the beer glass sweats on theoutside, and your port lights sweat on the inside in the winter. Thank

God for the first, but lament the latter.

This all means that condensation can only occur in your diesel tankwhen the temperature of the surfaces of the tank and/or the dieselfuel itself is below the dew point of the air INSIDE THE TANK. If you see condensation on the outside of your tank or on your fuellines, there is no condensation going on inside your tank. Theproblem can only occur when you don't see such condensation.Condensation on the surface of the diesel fuel itself is seldomconsidered, but is a fact. It works similar to fog at sea.

There are two ways to prevent condensation on a surface. (1) Raise

the temperature of the surface above the dew point of the air or (2)Reduce the dew point of the air below the temperature of the surface.Your automobile defroster works like the first case and your air

8/8/2019 Captn Wil's Fuel Polishing System

http://slidepdf.com/reader/full/captn-wils-fuel-polishing-system 6/14

10/15/2006 08:27 PMCaptn Wil's Fuel Polishing System: Trawlers & Trawlering How To

Page 6 of 14http://www.trawlersandtrawlering.com/howto/captnwil.html

conditioner works like the second case. Desiccant filters can also bemade to work like the second case.

The most common means to prevent condensation in fuel tanks is tokeep the tanks full. If they are full, there is no air in them so nocondensation can occur. It is especially important to keep the tanksfull when the boat is idle for a period of time.

Desiccant filters in the vent lines have tremendous possibilities. If they can be fitted properly, they will keep most of the moisture inthe air from entering the fuel tank, which will lower the dew point of the air to very low levels. Their installation and care in commonrecreational trawlers offer some problems that I have not been ableto solve. The limiting factors include their physical size and therequirement that they do not get contaminated with diesel fuel. Ihope someone will come up with a means of using them with ourdiesel tanks because they could almost eliminate the condensationproblem in diesel fuel tanks.

Where Does The Crud Come From: Dirt

There is more junk in fresh diesel fuel pumped from a high volumesupplier than I would ever imagine. That is one of the reasons thatengine manufacturers always put diesel fuel filters on their engines.We seldom see this crud because most modern fuel filters are spin-on types with the element hidden from view.

I have a Gulf Coast fuel filter mounted on my pickup truck. One of its features is that the top of the filter container can be removed atany time for inspection of the element. On a recent 10,000-mile landtrip, I replaced the element before leaving and had to replace it at5,000 miles because the crud in the element caused fuel flow

problems on steep grades at full load. During that trip, all fuel waspurchased at high volume truck stops.

It is one thing to get such dirt into a 20-gallon fuel tank and quiteanother to get it into a 300 or 400-gallon fuel tank on a trawler. Thecomplete fuel turnover rate in the 20-gallon tank guarantees that theentire contents of the tank will be kept stirred up and the crud willquickly end up in our fuel filter. In the 400-gallon, on the other hand,the dirt will just settle to the bottom of the tank like the silt in thedelta of a river. It will build there over time so that it can cause itsworst evil at our most critical moment.

Where Does The Crud Come From: Other Stuff

Then there's that black stuff that begins by discoloring the fuel filter,then discolors the fuel, then makes the fuel black and puts jelly-likestuff on the fuel filter, and then just shuts down the whole fuelsystem.

I can't find anything about this condition in the literature, but Isuspect it is the result of the solids from the original crude oilsettling out and returning to their natural state. No matter what thecause, it is an ever-present, ever-continuing condition that adds tothat awful mix at the bottom of our tanks. Let diesel fuel stand long

enough and it will turn black.

The Real Nature Of The Beast

8/8/2019 Captn Wil's Fuel Polishing System

http://slidepdf.com/reader/full/captn-wils-fuel-polishing-system 7/14

10/15/2006 08:27 PMCaptn Wil's Fuel Polishing System: Trawlers & Trawlering How To

Page 7 of 14http://www.trawlersandtrawlering.com/howto/captnwil.html

Except in rare cases, the factors that make our fuel storage problemsproceed at a very slow pace. It may take months or years for theproblem to become evident, but when it shows its ugly head, it is"full growed up." It is mean and ugly and spoiling for a fight.Remember that the first time it happened to me there were ten-gallons of crud at the bottom of each fuel tank.

The important thing to remember about my first

experience with this problem is that just removing thesymptoms did not remove the problem. The problemcame back three years later.

The second time it happened to me I vowed to solve the problem so Iwould not get the symptoms.

Design Considerations

While it now seems obvious, the real objective escaped me for sometime in this venture. The objective is to return and/or keep the fuel just like new. That's just what the NC Ferry System does by their

high turnover rate. But that statement needs to be refined a little. Weneed to determine just where we want to make the fuel just like new.The answer to that question will determine where our design goes.

The common system with one secondary and one primary fuel filtertries to keep the fuel that enters the injection pump just like new andthe only effect on the remaining fuel is the returned clean fuel. Oncewe understand that most of our engines return very little fuel to thetank it becomes obvious that this system has little or no effect on thefuel in our tank. The fuel in the tank keeps getting less and less justlike new, and filter replacement intervals decrease.

Depth Type Filters

Depth type filters provide better filtration than edge type filters andare available with much larger capacities than edge type filters. Likemost on this list, I was introduced to depth type filters very late inthe game. I did not even know of their existence until after I initiallysolved my fuel problem with a polishing system using a Racor edgetype filter.

Gulf Coast Filters (GCF) manufactures the depth type filters I haveexperience with, but there are many other manufacturers of suchfilters. I have every reason to expect that those filters perform well.

The basic concept of the depth type filter is that the fuel passesthrough a lot of filter media. For example, the fuel travels from oneend of a roll of paper towels to the other as it passes through a GCFF-1 fuel filter thus the depth. It is that eleven plus-inches of contactwith the filter media that makes this filter so efficient. It is its hugevolume, when compared to the volume of a Racor-500 or 900 thatgives it such an impressive capacity.

Depth type filters are not required for the diesel polishing system,but they will increase the efficiency of the system and reduce themaintenance. I will describe the application of these filters as we go

along, but you can just substitute any other quality filter you desire.

The System

8/8/2019 Captn Wil's Fuel Polishing System

http://slidepdf.com/reader/full/captn-wils-fuel-polishing-system 8/14

10/15/2006 08:27 PMCaptn Wil's Fuel Polishing System: Trawlers & Trawlering How To

Page 8 of 14http://www.trawlersandtrawlering.com/howto/captnwil.html

I do not have a separate polishing system and a normal fuel supplysystem. I modified the existing fuel system to incorporate thepolishing capacity into it.

I also recommend that a single fuel/polishing system supply all thefuel to every engine on the boat. If your total diesel circulationrequirements are not more than 60 GPH, a single Racor-500 or GCFF-1 will handle your needs quite well. Systems that require greatercirculation rates are beyond the scope of this report and will not becovered here. CaptnWil will be happy to discuss designs for suchsystems if desired.

The system consists of the appropriate filters connected to acontinuous duty electric fuel pump with the piping arranged tocirculate the fuel from the tank through the filters and back to thetank.

The system has evolved over the almost two-years that I have beeninvestigating this problem. That evolution has come about as I havelearned more about the subject from my own observations and the

experiences of others.

The single most important discovery is that a great amount of circulation is necessary to keep a substantial quantity of fuel just likenew. My pump circulated about 50 gph and it ran at least 48 hoursevery week. With a fuel capacity of 600 gallons, I turned the fuelover a little more than three times per week. Continuous circulationis not too much.

Components

The major components of the system are:

1. Walbro fuel pump. The factory phone number is (517)872-2131. I bought mine from Peterson Co whose phonenumber is (800) 537-6212. This little pump is protected bya five-amp circuit breaker so it draws hardly any current.It is marketed to replace the original diaphragm operatedfuel pump on diesel engines and is rated for continuousduty.

If you choose another pump, make sure it is rated forcontinuous duty.

2. Gulf Coast Filters F-1 fuel filter and waterseparator. The phone number is (800) 398-8114. Thisfilter is recommended to be the main fuel filter if it can befitted in the space. It uses a roll of Bounty paper towels.The element replacement cost of this filter is alwaysattractive, but if you have a very dirty system to clean up,you will appreciate it even more. In addition, it filters inthe sub-micron range and will add life to your injectionpump and injectors.

This filter has the best water separator I have seen. It isefficient and very large.

The only drawback about this filter is the verticalclearance it requires. It must be mounted vertically for the

8/8/2019 Captn Wil's Fuel Polishing System

http://slidepdf.com/reader/full/captn-wils-fuel-polishing-system 9/14

10/15/2006 08:27 PMCaptn Wil's Fuel Polishing System: Trawlers & Trawlering How To

Page 9 of 14http://www.trawlersandtrawlering.com/howto/captnwil.html

water separator to work. The whole thing with clearanceabove the filter requires about 33 inches of total verticalclear space. The vertical clearance can be reduced toabout 24 inches if a tilting mount is fashioned to facilitateremoving the element.

If you can make it work, your troubles will be rewardedwith a marvelous filter.

This filter is rated at 250 HP and can be paralleled if theengine capacity is above that.

3. Gulf Coast Filter O-1 Jr. If you can't make the F-1 fit,you can use a Jr. It was originally designed as a smallbypass oil filter, but can serve very well as a fuel filter.

It comes with a molded-in orifice to restrict the flow in oilbypass work. If you use the filter for fuel, drill out theorifice. I use one on a 180 HP engine.

This unit uses a roll of toilet paper as the element and canbe fitted most anywhere in any position. Its drawbacks arethat it has less capacity than the F-1 and does not have awater separator. If you use this filter, you must make surea water separator is in the system.

4. Racor Filter and Water Separator. If you choose notto use either of the GCF units above, you will need onelike the Racor. This unit is well known to all and isavailable from many sources. The larger the size thelonger the element will last, but its capacity will be verysmall, and its element replacement cost will be large when

compared with the GCF filters above.

The Racor water separator works fine and the elementwon't pass water. Be sure to use the 2-micron element inthis and any other work.

There are other similar units on the market and I expectthey work fine, but I don't have experience with them. Of course, Racor elements can be obtained almost anywherethere is water.

5. Tubing, Valves, and Fittings. Type L soft copper

tubing or USCG-approved hose can be used. The copperis better, but the hose is easier. I went with the hose. Isuggest flare fittings for either material. Use the same sizelines as is on your fuel system now.

Several valves are in the system. The West Marine cataloglists _-inch ball fuel valves that I like and alsoconventional Tempo fuel valves. Either will work well.Use Loctite 242 on the screw fittings. I've never had aleak with this stuff.

Two vacuum gauges are specified. Every vacuum gaugemust be fitted with a shut-off valve. If the gauge doesn'thave a shut-off valve, and it breaks, you can't run theengine and if you have a bottom outlet fuel tank, you run

8/8/2019 Captn Wil's Fuel Polishing System

http://slidepdf.com/reader/full/captn-wils-fuel-polishing-system 10/14

10/15/2006 08:27 PMCaptn Wil's Fuel Polishing System: Trawlers & Trawlering How To

Page 10 of 14http://www.trawlersandtrawlering.com/howto/captnwil.html

the risk of emptying the fuel tank into the bilge. Do Not! Isay, Do Not use the Racor gauge that replaces the T-handle. It cannot be fitted with a shutoff valve.

A check valve will be included in the piping diagrams. Itcan be obtained from most local shops that do dieselinjector pump and similar work. Its use will be discussedin the circuit description section.

6. Timer. While a timer is not required, providing onecosts little. I used an Intermatic Spring Wound 12-hourTimer Switch, model FF12HH. It provides a disconnectswitch as well as a 12-hour timer. I bought mine fromGrainger.

Fuel Piping Basics

A basic fundamental in designing a diesel fuel system for any boat isto design the system so that the boat will not have to stop if a fuelfilter gets clogged or an instrument breaks. There are many situations

where not having engine power is extremely dangerous. It is sodangerous that the Rules Of The Road have a special category andrules for it, "Vessel Not Under Command." It is necessary to designthe piping so that just adjusting a few valves will allow fuel to flowso the vessel can remain under command.

This basic requirement is at the heart of the diagrams shown. It is thereason that valves are shown for each vacuum gauge and the reasonfor the two-filter arrangement in both diagrams.

You will notice that the GCF F-1 and O-1 JR. are piped in serieswith a Racor in "Polishing System With Gulf Coast Filter." This ispossible because the F-1 and JR will filter particles much smallerthan the Racor and the Racor will remain clean almost forever. If theF-1 gets clogged up, you may safely bypass it with its bypass valves

8/8/2019 Captn Wil's Fuel Polishing System

http://slidepdf.com/reader/full/captn-wils-fuel-polishing-system 11/14

10/15/2006 08:27 PMCaptn Wil's Fuel Polishing System: Trawlers & Trawlering How To

Page 11 of 14http://www.trawlersandtrawlering.com/howto/captnwil.html

and just use the Racor until you are in a place to replace the GCFelement. In like manner, if the Racor gets clogged up you can justbypass it and operate on the GCF alone until the Racor element ischanged

In "Polishing System With Racor Filters," the Racor filters are pipedin parallel because they have the same filtering efficiency.

In both cases, the vessel can continue underway by adjusting thevalves.

Everything possible should be done to keep from having to makefilter changes underway. That is the purpose of the vacuum gauges.If they are inspected often they will, in most cases, give amplewarning so panic actions underway are not necessary. The bypasspiping allows for the unexpected situation when it occurs.

System Operation

It is recommended that the Walbro fuel pump beoperated all the time the engine is operated in additionto any weekly pumping schedule as required.

This will mean that you are polishing the fuel any time you areunderway. If you are on a cruise that means you may not need tooperate the polishing system on its weekly schedule. You can justoperate on the weekly schedule when the boat is idle.

In any event, you should pump enough to turn the fuel over at leastthree times per week. More is better than less.

Check Valve

I try to avoid using check valves in any piping system wherepossible because they are prone to fail because of crud accumulatingon the working parts. This system uses a check valve that lives in thevery clean diesel fuel that we have just polished. It should stay cleanand have a very long life.

8/8/2019 Captn Wil's Fuel Polishing System

http://slidepdf.com/reader/full/captn-wils-fuel-polishing-system 12/14

10/15/2006 08:27 PMCaptn Wil's Fuel Polishing System: Trawlers & Trawlering How To

Page 12 of 14http://www.trawlersandtrawlering.com/howto/captnwil.html

The system is designed so that the Walbro just keeps a positive headon the engine lift pump while underway and bypass most of the fuelaround the engine. If the Walbro were to fail while underway, theengine lift pump would try to draw fuel from the engine return lineand the engine would stop running because of air in that line. Thecheck valve will prevent that problem. The two-way valve in thesame line can be used to close the return as well, but the check valve just makes it more convenient.

Three-Way Valve

The three-way valve is provided for those who do not want to run theWalbro underway. In that situation, turn the three-way valve to theproper position and adjust the two-way valve in the line that has thecheck valve.

Fuel Circuit

This is a CaptnWil Law when using the polishing system:

Return the fuel to the same tank it came from.

Any other procedure may lead to a fuel spill. That means makingsure the valves at the fuel tanks are always set properly.

Other pumping arrangements may be more efficient at cleaning upthe fuel, but the risk of a fuel spill removes them from consideration.

Day Tanks

Day tanks have become a popular topic of late, and a few words arenecessary about them in connection with a fuel polishing system.

The object of a day tank is to provide a "day's" quantity of fuel thatis guaranteed to be clean and dry for the engine. Sometimes it isused to overcome the problem of excessive suction heads on theengine lift pump.

It is important to remember that the clean and dry fuel in the daytank will be exposed to the same conditions that cause the fuel in themain storage tank to become bad. Given enough time, the fuel in theday tank will get to the same condition as the fuel in the main tank.A filter and a water separator are still required on the outlet of theday tank.

To provide the desired results, this tank must, in fact, be a "DayTank." That is, the fuel in this tank must remain there for only ashort time. All the problems of long-time fuel storage in the maintank will be present in the day tank if fuel remains in it for longperiods of time. Once it ceases to be a "Day Tank" it must be treated just like any other tank.

Wiring

All of the usual safety wiring practices should be followed and thepump should be protected with a 5-amp fuse or circuit breaker. Itwill be convenient to locate the switch or timer close to the helm.

8/8/2019 Captn Wil's Fuel Polishing System

http://slidepdf.com/reader/full/captn-wils-fuel-polishing-system 13/14

10/15/2006 08:27 PMCaptn Wil's Fuel Polishing System: Trawlers & Trawlering How To

Page 13 of 14http://www.trawlersandtrawlering.com/howto/captnwil.html

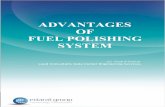

Used Gulf Coast Filter F-1 element and Racor 500 2-micron element: F-1 element shown

after 500 hours with clean fuel. Racor element cutaway showing pleating of element.

Introduction to Captn Wil Andrews

Wil Andrews has a passion for testing equipment and developingsystems.

For years, Captn Wil, as he is widely known, has applied hisengineering background in the search of the best in diesel polishing,anchors and other systems for trawlers. Even after family healthconsiderations led to the sale of AfterSail, a Krogen 42, Captn Wilremained an active and respected participant on the Trawlers &Trawlering List.

When you see the signature Captn Wil, you better be ready to tosspreconceived notions and advertising claims out the porthole

Much of the equipment testing and system development undertaken by Wil Andrews wasaccomplished aboard his beloved AfterSail, a Krogen 42 Pilothouse.

8/8/2019 Captn Wil's Fuel Polishing System

http://slidepdf.com/reader/full/captn-wils-fuel-polishing-system 14/14

10/15/2006 08:27 PMCaptn Wil's Fuel Polishing System: Trawlers & Trawlering How To

Page 14 of 14http://www.trawlersandtrawlering.com/howto/captnwil.html

If you wish to comment on the content of this page, please e-mail it to

Trawlers & Trawlering.

Stay informed with Trawler News from Trawlers & Trawlering!

Name: E-mail:

Submit Clear

© 1997-2006 Water World Productions, formerly Trawler World Productions. All rights reserved. Reproduction of material from any trawlersandtrawlering.compage without written permission is strictly prohibited. Any copyrighted images remain the property of the copyright owner and are believed to be used withpermission. Unsolicited letters, e-mails, articles and other materials submitted to us may be published, distributed and stored by Water World Productions andits assignees in whole or in part, in print or by any other means, including but not limited to electronic, and may be edited for clarity and space.

Trawlers & Trawlering and its abbreviation T&T, I'd Rather Be Trawlering, Passagemaking Under Power and its abbreviation PUP, Trawler Buy-Sell-Trade,Trawler News, Circumnavigator, and Power Catamaran World are trademarks of Water World Productions.

Contact us