Cameron EDPHOT for STC10 WH System

-

Upload

nikhil-suri -

Category

Documents

-

view

1.464 -

download

18

description

Transcript of Cameron EDPHOT for STC10 WH System

-

S U B S E A S Y S T E M S

STC-10 Subsea Wellhead SystemOperation and Maintenance Manual 339Rev2 - February 2012

EMERGENCY DRILL PIPE HANG-OFF TOOL(EDPHOT)

I. General Information

A. Description and Function

During severe weather conditions it may be necessary to release the drilling riser from the BOP stack to allow the rig to drive off during a storm or under extreme heave conditions. If there is drill pipe in the hole, it is usually preferable to pull the bottom hole assembly (BHA) up into the cased portion of the hole. Cameron has developed the Emer-gency Drill Pipe Hang-off Tools (EDPHOT) to reduce the trip time now required to shut down offshore drilling operations during adverse weather. These hang-off tools are for utilization with the 18-3/4 STC-10 Wellhead Systems. These tools enable the rig operator to retrieve a minimum number of drill pipe joints, re-enter the hole with the hang-off tool attached, and hang the remaining drill pipe on the Cameron well-head or BOP ram. The tool may be configured with a variety of running and test tools to adapt to the current configuration of the wellhead.

B. Specifications

1. The hang-off capacity of the 4-1/2 API IF tool connections is 500,000 lbs. (226 800 kg).The hang-off capacity of the 5-1/2 API FH tool connections is 600,000 lbs. (272,200 kg). The hang-off capacity of the 6-5/8 API FH tool connections is 750,000 lbs. (340,200 kg).

2. See illustration for major dimensions.

C. Space Out Considerations

The lower body of the EDPHOT will not land or locate in the Cameron wellhead housing bore protectors, the reduced bore/extended length wear bushings, or in an empty wellhead housing. For this reason, the EDPHOT may be configured with a variety of running and test tools if the lower body cannot be used.

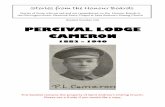

EDPHOT

UpperBody

JettingSub

Body

LowerBody

Weldment

-

STC-10 Subsea Wellhead SystemOperation and Maintenance Manual340 Rev2 - February 2012

The lower body of the EDPHOT will land on any of the Cameron casing hanger wear bushings with the pup joint and shank adapter extending into the BOP stack. The relationship of the EDPHOT and the pipe rams and shear rams is critical. It is very important that the length of the pup joint be correctly sized so that the BOP pipe rams effect an annular seal and the shank adapter head is correctly positioned between the rams.

The pipe ram sealing must occur on the 5.0 inch outside diameter of the pup joint or the shank adapter when the drill string is hung off.Therefore, the length of the pup joint of each EDPHOT MUST be care-fully sized so that the pipe rams can close on the pup joint or the shank adapter and the blind shear rams can close above the shank adapter head. With this critical factor in mind, Camerons Subsea Wellhead En-gineering Department stresses that EDPHOTs MAY NOT BE INTER-CHANGED BETWEEN RIGS OR STACKS. Variations in stack or rig di-mensions can cause the shear rams or pipe rams to foul on a pup joint or shank adapter threads. It is recommended that pup joint lengths and stack-up dimensions be checked and verified PRIOR to any transfer of equipment between rigs or when stack modifications are contemplated.

In this manner, the pup joint can be modified as necessary, or, an-other can be supplied. All in-house sales orders and/or inquiries for EDPHOTs should be directed to the Subsea Wellhead Engineering Department for verification of dimensions and applicability prior to the manufacture of tools.

-

S U B S E A S Y S T E M S

STC-10 Subsea Wellhead SystemOperation and Maintenance Manual 341Rev2 - February 2012

II. Operation

A. Running the EDPHOT

1. Once the string that is to be hung-off is hanging in the rotary table, make up the EDPHOT to the top connection of the string.

2. Make up drill pipe to the EDPHOT running tool assembly and pick up the hang-off string. Note the string weight to be hung-off.

3. Run the EDPHOT to the wellhead. Stop when the EDPHOT is approximately 20 ft. above the LMRP.

4. Activate the heave compensator and adjust it to support only the weight of the drill pipe above the EDPHOT.

5. Slowly land off the EDPHOT on the wear bushing or heavy wall bore protector.

6. Slack off the hang-off string weight to get the EDPHOT running tool assembly at neutral weight.

7. Close the lower and/or middle rams of the BOP on the pup joint/ shank adapter .

NOTEIf the ball or flex joint of the lower marine Riser Package (LMRP) has a restrictive ID wear bushing, retrieve this wear bushing before running the EDPHOT.

NOTEPull enough drill pipe to ensure the Bottom Hole Assembly (BHA) will be inside cased hole when the EDPHOT lands inside the 18-3/4 wellhead housing.

NOTEIf using a running or test tool in place of the EDPHOT lower body, refer to that tools running procedure for landing instructions, except when using the 18-3/4 Wellhead Housing Running & Test Tool, refer to special running procedures for landing and lock-ing instructions later in this procedure.

-

STC-10 Subsea Wellhead SystemOperation and Maintenance Manual342 Rev2 - February 2012

8. Slowly rotate the running tool assembly to the right (CW) (approximately 2 turns) to disconnect the running tool assembly from the shank adapter. Retrieve the running tool assembly to the surface.

9. Close the BOP shear rams.

D. Retrieving The EDPHOT

1. Inspect the EDPHOT running tool assembly threads and o-ring for damage.

2. Grease the threads, seal surface and lead-in chamfer of the running tool assembly.

3. Make up the running tool assembly to the drill pipe retrieval string.

4. Run the tool into the hole, stopping prior to entering the LMRP.

5. Activate and adjust the heave compensator to support the weight of the retrieving string.

6. Slowly land the running tool assembly on the shank adapter and rotate the retrieval string to the left (CCW) (approximately two turns) until shouldered out. When a torque build-up is noted, stop turning and relieve the torque.

NOTEIf certain test tools are used in place of the EDPHOT lower body to hang off drill pipe, some BOP testing may be performed at this time. Consult with Camerons Subsea Wellhead Engineering Department to determine what type of testing may be performed.

NOTEThe EDPHOT may be retrieved using the EDPHOT running tool assembly or by using a 4-1/2 API IF drill pipe connection. When using the running tool assembly, it has a centralizer funnel to assist in re-establishing the connection. When using either con-nection, the BOP stack pipe rams may be used to centralize the make-up joint in the BOP stack to assist in re-establishing the connection.

NOTEIf it is suspected debris has accumulated on the head of the shank adapter, lower the running tool assembly to just above the shank adapter and circulate through the retrieval string to clean the debris off of the shank adapter.

-

S U B S E A S Y S T E M S

STC-10 Subsea Wellhead SystemOperation and Maintenance Manual 343Rev2 - February 2012

7. Ensure proper well control procedures are followed and then open the pipe rams.

8. Retrieve the EDPHOT to the surface with a straight vertical pull.

9. Should a collapsed formation be encountered, reciprocate the string and circulate to work the string free. DO NOT rotate to the right (CW) as this will disconnect the EDPHOT from the running tool assembly.

E. Running The EDPHOT with 18-3/4 HSG Running & Test Tool

1. Assemble the 18-3/4 Housing Running & Test Tool to the pup joint (if required) and the shank adapter. See Figure 2.

2. Install the running tool assembly on the shank adapter by left hand rotation (approximately 2 turns) and shoulder out. Rack back the tool in the derrick.

3. Once the string that is to be hung-off is hanging in the rotary table, make up the EDPHOT to the top connection of the string.

4. Make up drill pipe to the EDPHOT running tool assembly and pick up the hang-off string. Note the string weight to be hung-off.

NOTEIf the ball or flex joint of the lower marine Riser Package (LMRP) has a restrictive ID wear bushing, retrieve this wear bushing before running the EDPHOT.

NOTEPull enough drill pipe to ensure the Bottom Hole Assembly (BHA) will be inside cased hole when the EDPHOT lands inside the 18-3/4 wellhead housing.

NOTEDue to the unpredictability of the amount of friction generated by the B.O.P. rams, care must be taken when making and breaking the EDPHOT running tool connection or when locking and unlocking the 18-3/4 Housing Running & Test Tool in the wellhead housing.

-

STC-10 Subsea Wellhead SystemOperation and Maintenance Manual344 Rev2 - February 2012

5. Run the EDPHOT to the wellhead. Stop when the EDPHOT is approximately 20 ft. above the LMRP.

6. Activate the heave compensator and adjust it to support only the weight of the drill pipe above the EDPHOT.

7. Slowly land off the 18-3/4 Housing Running & Test Tool in the wellhead housing using the heave compensator. Adjust the compensator to put 5000 to 10,000 lbs. down weight on the tool. Do not exceed 20.000 lbs. weight down on the running tool prior to locking it into the wellhead housing or damage to the wellhead housing may result.

8. Rotate the running string seven turns to the left (CCW) to lock the running tool to the wellhead housing. The tool can now carry up to 500,000 lbs. of hang-off weight.

9. Perform an overpull of 50,000 lbs. over the hang-off weight to verify the tool is locked in the wellhead housing.

10. Slack off the full hang-off string weight to get the EDPHOT running tool assembly at neutral weight. Close the lower and/or middle rams of the BOP on the pup joint/shank adapter.

11. Slowly rotate the running tool assembly to the right (CW) (approximately 2 turns) to disconnect the running tool assembly from the shank adapter. Retrieve the running tool assembly to the surface.

12. Close the shear rams in the BOP.

F. Retrieving The EDPHOT/18-3/4 HSG Running & Test Tool

NOTEThe EDPHOT may be retrieved using the EDPHOT running tool assembly or by using a 4-1/2 API IF drill pipe connection. When using the 18-3/4 Housing Running & Test Tool in place of the lower body, The 4-1/2 API IF drill pipe connection must be used to retrieve the EDPHOT. The BOP stack pipe rams may be used to centralize the make-up joint in the BOP stack to assist in re-establishing the connection.

-

S U B S E A S Y S T E M S

STC-10 Subsea Wellhead SystemOperation and Maintenance Manual 345Rev2 - February 2012

1. Run the retrieval string without the EDPHOT running tool assembly and with a 4-1/2 API IF pin down.

2. Close the lower and/or middle rams of the BOP on the pup joint/ shank adapter.

3. Slowly land the retrieval string on the shank adapter while slowly turning to the right (CW). Use the BOP stack pipe rams to centralize the retrieval string, if necessary.

4. When a torque build-up is noted, increase torque to 2000 ft-lbs. DO NOT exceed three turns. Between initial torque build-up and final torque as the shank adapter might have started to turn through the BOP rams. This will unlock the running tool from the wellhead housing. Relieve the torque.

5. Perform an overpull of 50,000 lbs. over the hang-off weight to verify the drill pipe connection is made up.

6. With an overpull of 5,000 lbs. over the hang-off weight, open all of the rams and slowly rotate to the right (CW) approximately seven turns to release the 18-3/4 housing running tool from the wellhead housing.

7. Retrieve the string to the surface. DO NOT exceed 750,000 lbs. of total pulling force. Should a collapsed formation be encountered, reciprocate the string and circulate to work the string free. DO NOT rotate the string to the left (CCW) as this will disconnect the drill string from the 18-3/4 Housing Running & Test Tool.

G. Running the EDPHOT to Land on the B.O.P. Rams

NOTEDue to the unpredictability of the amount of friction generated by the B.O.P. rams, care must be taken when making and breaking the EDPHOT running tool connection or when locking and unlocking the 18-3/4 Housing Running & Test Tool in the wellhead housing.

NOTEIf the ball or flex joint of the lower marine Riser Package (LMRP) has a re strictive ID wear bushing, retrieve this wear bushing before running the EDPHOT.

-

STC-10 Subsea Wellhead SystemOperation and Maintenance Manual346 Rev2 - February 2012

1. Assemble the EDPHOT according to the ram to be used to hang-off drill pipe. See Figure 3, 4 & 5 for the correct configuration.

2. Install the running tool assembly on the shank adapter by left hand rotation (approximately 2 turns) and shoulder out. Rack back the tool in the derrick.

3. Once the string that is to be hung-off is hanging in the rotary table, make up the EDPHOT to the top connection of the string.

4. Make up drill pipe to the EDPHOT running tool assembly and pick up the hang-off string. Note the string weight to be hung-off.

5. Run the EDPHOT to the wellhead. Stop when the EDPHOT is approximately 20 ft. above the LMRP.

6. Activate the heave compensator and adjust it to support only the weight of the drill pipe above the EDPHOT.

7. Slowly lower the EDPHOT lower body (or shank adapter head) into the B.O.P. using the heave compensator. Slowly close the B.O.P. rams that will carry the string weight just below the EDPHOT lower body (or shank adapter head) on the drill pipe.

8. Slack off the full hang-off string weight to get the EDPHOT running tool assembly at neutral weight.

9. Slowly rotate the running tool assembly to the right (CW) (approximately 2 turns) to disconnect the running tool assembly from the shank adapter. Retrieve the running tool assembly to the surface. Close the shear rams in the BOP.

NOTEPull enough drill pipe to ensure the Bottom Hole Assembly (BHA) will be inside cased hole when the EDPHOT lands on the B.O.P. rams.

NOTEThe configuration of the EDPHOT will depend on the type of ram to be used to hang-off drill pipe. The two types are the pipe ram and the variable bore ram (VBR). Incorrectly configuring the EDPHOT for the ram type to be used, or hanging excessive weight, could damage the B.O.P. ram and/or the EDPHOT. Check with your B.O.P. manufac-turer for more information on ram capability and capacity.

-

S U B S E A S Y S T E M S

STC-10 Subsea Wellhead SystemOperation and Maintenance Manual 347Rev2 - February 2012

Part No.

646340-01

Approx Wt.

1630 LBS

Length Width Min ID

17.37 3.25207.24

Emergency Drill PipeHang Off Tool Assembly

UpperBody

Jetting SubBody

LowerBody

Weldment

207.24

36.00

138.18

33.06

17.37

-

STC-10 Subsea Wellhead SystemOperation and Maintenance Manual348 Rev2 - February 2012

Description: EMERGENCY DRILL PIPE HANGOFF TOOLPart No.: 646340-01P/N Revision: A02

ITEM QTY. PART NO. DESCRIPTION1 1 646337-01 BODY, UPPER, FOR EMERGENCY DRILL2 1 708628 5 IN OD PUP JOINT (TO SUIT 5 PIPE3 1 646339-01 WELDMENT, LOWER BODY, EMERGENCY

-

S U B S E A S Y S T E M S

STC-10 Subsea Wellhead SystemOperation and Maintenance Manual 349Rev2 - February 2012

-

STC-10 Subsea Wellhead SystemOperation and Maintenance Manual350 Rev2 - February 2012

EDPHOT Checklists

Before Running EDPHOT

Thoroughly clean the tool with clean fresh water.

Remove the thread protectors and inspect the tool joint threads for damage. Repair/clean up the tool joint threads, as required.

Inspect the stub acme threads and o-ring on the running tool assembly. Repair/clean up the stub acme threads and replace the o-ring, if necessary.

Thoroughly grease the running tool and shank adapter threads, seals and lead-in chamfers.

Assemble the EDPHOT in order to adapt to the current configuration of the wellhead.

If necessary, the centralizer on the EDPHOT running tool assembly may be removed for running the EDPHOT.

Install the running tool assembly on the shank adapter by left hand rotation (CCW) (approximately 2 turns) and shoulder out. Rack back the tool in the derrick.

After Retrieving EDPHOT

Wash the tool with fresh water.

Inspect the stub acme threads and o-ring on the running tool assembly. Repair/clean up the stub acme threads and replace the o-ring, if necessary.

Inspect the tool joint connections and install thread protectors.

If a running or test tool was used in place of the EDPHOT lower body, refer to that tools assembly/disassembly/maintenance procedures for instructions

Store the tool(s) in the can(s) provided on the tool skid. The can(s) should contain enough water soluble oil solution to sub merge the tool(s).