Calculation of molecular weight distribution using ...

Transcript of Calculation of molecular weight distribution using ...

© 2021 The Korean Society of Rheology and Springer 65

Korea-Australia Rheology Journal, 33(1), 65-78 (February 2021)DOI: 10.1007/s13367-021-0006-0

www.springer.com/13367

pISSN 1226-119X eISSN 2093-7660

Calculation of molecular weight distribution using extended Cole-Cole

model and quadratic mixing rule

Junghaeng Lee1, Sangmo Kim

2 and Kwang Soo Cho

1,*1Department of Polymer Science and Engineering, Kyungpook National University, Daegu, Korea

2S-OIL, Seoul, Korea

(Received April 24, 2020; final revision received December 8, 2020; accepted December 30, 2020)

We suggest a numerical method to calculate molecular weight distribution from linear viscoelastic data. Thecalculation method consists of three components: (1) a viscoelastic model of a monodisperse polymer asa function of molecular weight; (2) the mixing rule connecting viscoelastic data of monodisperse andpolydisperse polymers through molecular weight distribution; (3) an algorithm which calculates the molec-ular weight distribution from the chosen mixing rule. Since we cannot measure the relaxation modulus ofall monodisperse samples, we need an accurate monodisperse model for any molecular weight. It is knownthat a dynamic test is more reliable than a relaxation test, while the mixing rule needs relaxation modulus.Hence, we should have a smart numerical method that can convert dynamic data to relaxation modulus withthe minimum conversion error. If we use the numerical method, then we have to generate numerical datafrom the model. Then it takes quite a long time. On the other hand, if we have a monodisperse model withthe analytical relaxation spectrum, then calculation time can be reduced dramatically. Since the conversionfrom relaxation modulus to dynamic modulus suffers from smaller errors than the reverse conversionbecause of ill-posedness of the interconversion, the analytical conversion can be implemented more quicklyat an acceptable level of errors. This paper proposes a new method satisfying the requirements.

Keywords: molecular weight distribution, extended Cole-Cole model, quadratic mixing rule, fixed point

iteration, continuous relaxation time distribution

1. Introduction

There is a report Park et al. (2015) that the rheological

method for calculating molecular weight distribution

(MWD) is more reliable than gel permeation chromatog-

raphy (GPC) in some polymer systems such as ultrahigh

molecular weight polyethylene. It does not mean that the

rheological method is always better than GPC. The rhe-

ological method is complimentary to GPC in some cases.

Since we think that most rheological methods have merits

and demerits, it is a meaningful attempt to improve the

rheological method.

For this reason, many rheological methods for calculat-

ing MWD have been studied (Anderssen and Mead, 1998;

Carrot and Guillet, 1997; Des Cloizeaux, 1988; Friedrich

et al., 2009; Guzman et al., 2005; Lang 2017; Léonardi et

al., 2002; Maier et al., 1998; McGrory and Tuminello,

1990; Mead, 1994; Nobile and Cocchini, 2008; Park et al.,

2015; Pattamaprom et al., 2008; Thimm et al., 1999;

2000; Tsenoglou, 1987; Tuminello, 1986; Van et al., 2002;

Wasserman, 1995; Wu, 1985). In order to calculate a MWD,

we need an equation connecting the linear viscoelastic

functions of the polydisperse polymer and its ingredient

polymers with narrow MWD. This equation is called a

mixing rule, and the generalized mixing rule is proposed

by Anderssen and Mead (1998):

, (1)

where represents the relaxation modulus of the

monodisperse polymer of molecular weight M, is the

weight fraction of the monodisperse chains, b is a mixing

rule parameter, MC is the critical molecular weight,

is the maximum molecular weight used to calculate the

MWD. Since the double reptation theory predicts ,

Eq. (1) is a generalization.

Maier et al. (1998) determined from the binary

mixture of nearly monodisperse polystyrenes (PS’s) with

different molecular weights. The determination of the

optimum depends mainly on the choice of kernel func-

tion:

, (2)

where is the plateau modulus. In the determination of

, they did not use . They determined by

using regression fitting to for chosen values

of . The validity of the model for monodisperse polymers

is tested by the experimental data of nearly mono-

disperse polymer samples with polydisperse index (PDI)

≤1.1. Hence, their regression might deteriorate the results.

Use of regression for the determination of

m max

1

( ) ( , ) forN

i i CG t G t M M M M

m( , )G t M

maxM

2

3.84

o

( , )( , ) m i

i

N

G t MF t M

G

o

NG

( , )F t M

F1/

M t 1

o[ ( ) ]N

G t G

F1/

M t *Corresponding author; E-mail: [email protected]

Junghaeng Lee, Sangmo Kim and Kwang Soo Cho

66 Korea-Australia Rheology J., 33(1), 2021

seems to originate from excessive confidence in GPC

MWDs. If a perfect sample of monodisperse polymer is

injected into GPC, no Dirac delta function is obtained

from any GPC. Since GPC MWDs contain an inevitable

error, it is meaningless to use it to estimate the viscoelastic

properties of monodisperse samples, which are necessary

for the calculation of MWD via the mixing rule. However,

the GPC MWD of polydisperse samples, of course, must

be necessary for checking the validity of the calculation.

Bae and Cho (2015) used the relaxation modulus calcu-

lated from the dynamic data of nearly monodisperse sam-

ples rather than and showed that agrees

well with experimental data of binary and quartic blends

of nearly monodisperse PS’s. The support for the validity

of can also be found in Ruymbeke et al. (2002) and

Pattamaprom et al. (2008). Hence, we will use .

In the choice of the model for the monodisperse poly-

mer, it is of importance whether the model can fit the

experimental data of nearly monodisperse samples with

various molecular weights. Many researchers do not seem

to care about the importance of the monodisperse model

because they used unrealistic models such as the single

Maxwell model (Lang, 2017; Tsenoglou, 1987; Tuminello,

1986; Maier et al., 1998; Mead, 1994). The calculation of

the MWD from rheological data needs a monodisperse

model as accurate as possible. The parameter estimation is

usually made by the dynamic data, while the mixing rule

needs the relaxation modulus for MWD calculation. It is

advantageous to use a monodisperse model which has an

analytic relation between relaxation and dynamic moduli

because such a model improves the calculation time and

prevents errors that may occur during the interconversion

between the two types of modulus. Assume that an accu-

rate monodisperse model is available in the form of relax-

ation modulus and we have to determine the model

parameters from dynamic modulus data. Then the process

of the determination of the model parameters involves

additional errors due to the conversion. If an accurate

model is given in the form of dynamic moduli (or the

Laplace transform of creep compliance), then we can

determine the model parameters with quite small errors.

Note that the conversion from dynamic moduli to the

relaxation modulus suffers from smaller errors than the

reverse conversion (Cho et al., 2017). Furthermore, if the

monodisperse model allows analytical conversion, we can

get a more accurate relaxation modulus of monodisperse

polymers.

Hence, we focus on the development of such a mono-

disperse model first. Although Pattamaprom et al. (2008)

showed that molecular models could accurately describe

the experimental data of nearly monodisperse samples,

such models suffer from complicated conversion between

relaxation and dynamic moduli. Hence, we will modify

the model suggested by Marin and Graessley (1977) which

provides analytical conversion.

The discrete version of the mixing rule is a linear equa-

tion of . Although the regression for Eq. (1) looks

simple, the solution must satisfy both of the following

constraints:

. (3)

Furthermore, it is well known that the calculation of is

a kind of ill-posed problem (Maier et al., 1998; Mead,

1994; Park et al., 2015; Thimm et al., 1999). In order to

calculate the MWD, we will modify the fixed-point iter-

ation method (FPI) which was developed for the contin-

uous relaxation time spectrum by Cho and Park (2013).

Although there are many algorithms to calculate relax-

ation time spectrum (Bae and Cho, 2015; Honerkamp and

Weese, 1989; Honerkamp and Weese, 1993; Stadler and

Bailly, 2009) and there are even programs available for

free (Takeh and Shanbhag, 2013; Shanbhag, 2019), the

fixed-point iteration is a simple iterative method and always

gives non-negative values of the spectrum if and only if

the initial spectrum is non-negative. Furthermore, it has

the ability of regularization. Since solving the mixing rule

for MWD is similar to the calculation of the relaxation

spectrum, we adopted FPI which avoids the occurrence of

negative values of . Nonlinear regularization prevents

the negative , too. However, we guess that FPI is much

simpler and faster than nonlinear regularization.

Hence, this paper consists of three parts: the validity of

the monodisperse model, the MWD calculation algorithm

based on the fixed-point iteration and the results and dis-

cussion.

2. Linear Viscoelastic Model for Monodisperse Poly-mers

2.1. Extended Cole-Cole modelMarin and Graessley (1997) suggested a phenomeno-

logical model motivated from the Cole-Cole model which

can be expressed by the Laplace transform of creep com-

pliance as follows

. (4)

Since the compliance of the glassy state Jg is negligibly

small (~109 Pa1), we will omit it. The zero-shear viscos-

ity, and the two retardation times 1 and 2 must

depend on molecular weight strongly compared with the

compliances J1 and J2. It is a reasonable assumption that

the two exponents 1 and 2 are nearly independent of

molecular weight (Marin and Graessley, 1977). The omis-

sion of Jg in Eq. (4) implies that the model seems to con-

sist of 7 parameters. However, as for monodisperse

polymers, the zero-shear viscosity and the steady-state

F1/

M t 2

2

2

0

1

1 and 0

N

1 2

1 2

o 1 2

1( )

1 ( ) 1 ( )g

J JsJ s J

s s s

�

o

o

Calculation of molecular weight distribution using extended Cole-Cole model and quadratic mixing rule

Korea-Australia Rheology J., 33(1), 2021 67

compliance satisfy

,

(5)

where and are fitting parameter dependent on the

kind of polymer, MC is the first critical molecular weight,

MC is the second critical molecular weight and .

Many experimental results show that (Rubinstein

and Colby, 2003), and there have been theories to explain

this behavior using molecular models (Doi and Edwards,

1986; Watanabe, 1999). It is known that the first critical

molecular weight is approximately two times of the entan-

glement molecular weight (Me), while the second critical

molecular weight is about six times as high as (Cho

et al., 2004).

Equation (5) is a phenomenological formula for the

experimental behavior such that zero-shear viscosity is

proportional to for and to M for

and the steady-state compliance is proportional to for

and converge to a specific value for

(Rubinstein and Colby, 2003).

We will introduce the molecular weight dependence to

and in Eq. (4) by use of . We consider

is nearly independent of molecular weight because it rep-

resents the relaxation process for the short length scale.

Finally, we model the molecular weight dependencies of

the parameters of Eq. (4) as follows

(6)

Equations (4) and (6) indicate that the model has nine

material parameters such as , , , , , , r

and . The empirical parameter r is chosen because

is not valid for some polymers and the mea-

surement of is usually less precise than that of . The

determination of the parameters suffers from the wide

range of the values of them as well as the dynamic moduli

and frequencies vary in logarithmic scale. Hence, conven-

tional methods for nonlinear regression based on the gra-

dient method are not effective. For this problem, we

adopted the Monte Carlo method (Kim et al., 2018) which

is similar to simulated annealing (Aarts and Korst, 1989)

without annealing process. The exponent is introduced

to check the validity of the regression method since it is

well known that .

Since available experimental data is often given by

dynamic moduli instead of , we need

, (7)

where i is the imaginary unit , and

are storage and loss compliances, and and

are storage and loss moduli, respectively. Application of

Eq. (7) to Eq. (4) yields

. (8)

Dynamic modulus is obtained from Eq. (8) as follows

.

(9)

2.2. Determination of parameter of extended Cole-

Cole modelWe used the data of Schausberger et al. (1985) and Jeon

(2010). The reference temperature is 180°C. The samples

are all PS with narrow MWD (PDI < 1.1), as listed in

Table 1.

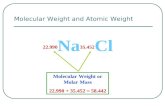

The dynamic moduli of the PS’s in Table 1 are shown in

Figs. 1 and 2 and the regression results are listed in Table

2.

As expected, is obtained. The entanglement

molecular weight was determined as 12,300 g/mol

which is little bit lower than but close to the values in the

literature (16,625 g/mol (Pattamaprom, 2008); 17,000 g/

mol (Rubinstein and Colby, 2003); 14,900 g/mol (Vega et

o

eJ

1

e o

o o e( ) 1 , ( )

1

C

C C C

M M M MM J M J

M M M M

e

o J

3.4

3.4

eM

o

3.4M

CM M

CM M

M

CM M

CM M

1J

2J

o

e( )J M

2

1

e

o o

1 2

e

e e

( ) 1 ,

( ) for 1, 2,1

( ) ,

2 , .

C C

C

k k

C

C C

M MM

M M

M MJ M J k

M M

MM

M

M M M rM

1

2

2

eM

e

o

1J

2J

e6

CM M

o

eJ o

3.4

( )J s�

i (i ) ( ) i ( )

1( ) i ( )

( ) i ( )

J J J

G GJ J

�

2i 1 ( )J ( )J

( )G ( )G

2

21

2

21o

1 ( ) cos2( )

1 2( ) cos ( )2

( ) sin1 2( )

1 2( ) cos ( )2

k

k k

k

k k

k

k

k

kk

k k

k

k

k

kk

k k

J J

J J

2 2 2 2

( ) ( )( ) , ( )

( ) ( ) ( ) ( )

J JG G

J J J J

3.46

eM

Table 1. Specification of monodisperse polystyrene samples.

Sample Mw [kg/mol] PDI

PS 1 34 1.05

PS 2 65 1.06

PS 3 125 1.06

PS 4 292 1.07

PS 5 757 1.07

PS 6 2540 1.05

mPS 111k 111 1.07

mPS 79K 79 1.04

Junghaeng Lee, Sangmo Kim and Kwang Soo Cho

68 Korea-Australia Rheology J., 33(1), 2021

al., 2004)). As for the steady-state compliance, literature

values (Montfort et al., 1986) are about 105 Pa1 which

has the same order of in Table 2. According to Fuchs

et al. (1996), it is known that . Then we can

generate dynamic moduli of monodisperse PS for all

molecular weights we need using these parameters obtained

above. It should be remarked again that our phenomeno-

logical model is easier than molecular models in the con-

version between relaxation and dynamic moduli, as shown

in the Appendix.

The terminal constants such as and can be

obtained from experimental data through the following

. (10)

On the other hand, the model implies that .

We compared the terminal constants from experimental

data and the model prediction, Eq. (6) in Fig. 3. The zero-

shear viscosity agrees with the model entirely while the

steady-state compliance shows considerable deviation. It

is interesting that irrespective of the deviation in the

steady-state compliance, the fit of dynamic moduli is suc-

1J

o o

e N2.4J G

o

o

eJ

o

o e 2 20 0

o

( ) ( )lim , lim

G GJ

o

e 1 2J J J

Fig. 1. (Color online) Comparison of regression results and

experimental data of storage modulus of monodisperse polysty-

rene measured by Schausberger et al. (1985) and Jeon (2010).

Symbol and solid lines are experimental and regression data,

respectively.

Fig. 2. (Color online) Comparison of regression results and

experimental data of loss modulus of monodisperse polystyrene

measured by Schausberger et al. (1985) and Jeon (2010). (Sym-

bol and solid lines are experimental and regression data, respec-

tively.)

Table 2. Monte Carlo regression results (Reference temperature

180°C).

k = 1 k = 2

[Pa1] 2.18 × 105

5.10 × 106

0.36 0.59

[s] 2.44 × 10-4

3.46

[Pa·s] 33.90

r 3.52

Me [kg/mol] 12.30

kJ

k

2

e

o

Fig. 3. (Color online) Comparison of the zero-shear viscosity [a] and the steady-state compliance [b] calculated from the extended Cole-

Cole model and the experimental data of Figs. 1 and 2.

Calculation of molecular weight distribution using extended Cole-Cole model and quadratic mixing rule

Korea-Australia Rheology J., 33(1), 2021 69

cessful. The overestimation in Fig. 3b would be explained

by the sensitivity of the steady-state compliance on MWD

(Doi and Edwards, 1986; Kwon et al., 2019). In Ref.

(Kwon et al., 2019), our group considered the effect of the

PDI on and using the log-normal distribution

MWD. Figures 20 and 21 of Ref. (Kwon et al., 2019)

show the calculation result of and using a quadratic

mixing rule for the log-normal distribution MWD. In

those two figures, we can see that the sensitivity of on

MWD is more significant than . Zero shear viscosity is

almost constant when the PDI is less than 1.2, while the

increment of is much bigger than even if the PDI

starts to deviate slightly from 1. In addition, Fig. 7.5 of

Doi and Edwards (1986) shows severe scatters of the

experimental data of (monodisperse samples). It sup-

ports numerical simulation. That is, we can see that is

more affected by PDI than unless PDI is precisely 1.

Also, the extended Cole-Cole model describes well the

linear viscoelasticity of monodisperse PS (Figs. 1 and 2).

One may also guess that the overestimation indicates the

problem of the model prediction. To check the model pre-

diction, we impose a constraint of .

The value is chosen from the experimental

data of Fig. 3b. This constraint makes Fig. 3b better and

Fig. 3a maintains its accuracy while the fitting quality of

Figs. 1 and 2 slightly decreases. Since the accuracy of Fig.

3b is not more important for the calculation of MWD than

the accuracy of Figs. 1 and 2, we will not use the con-

straint.

The parameter is much smaller than the result

of Cho et al. (2004) . This discrepancy seems to con-

tribute to the inaccuracy in Fig. 3b. However, the inaccu-

racy of Fig. 3b does not deteriorate the fitting quality of

Figs. 1 and 2.

As similar to the results of Marin and Graessley (1977),

the exponents 1 and 1 have the values of 0.36 and 0.59,

respectively. These parameters control the shapes of the

relaxation time spectrum as well as the retardation time

spectrum.

We need to consider the entire molecular weight range

beyond Mr. Mr is the transition molecular weight at which

the exponent of changes from 3.4 to 3.0. According to

Vega et al. (2004), Mr evaluated from the polydisperse

polymer is about 400-500 kg/mol which is about 15 times

of Mc. However, they estimated Mr from monodisperse

samples and they could not find Mr up to M = 2500 kg/

mol. This result corresponds with our result in Fig. 3a.

Then we do not have to consider scaling relation beyond

Mr because, in this paper, the effect of molecular weight

beyond 2500 kg/mol is less than 1%. It will be shown in

Table 3.

o o

eJ

o

o

eJ

o

eJ

o

o

eJ

o

o

eJ

o

eJ

o

5 1

1 21.8 10 PaJ J

5 11.8 10 Pa

3.52r

6r

o

Table 3. Composition of polydisperse polystyrene samples.

Mw [kg/mol]M1 Weight

Fraction

M2 Weight

Fraction

2.89 0.001 0.001

5.57 0.002 0.002

9.10 0.004 0.004

19.60 0.008 0.008

37.90 0.03 0.03

96.40 0.15 0.148

190 0.26 0.257

355 0.358 0.353

706 0.14 0.139

1090 0.039 0.038

2890 0.008 0.01

3840 0 0.007

4480 0 0.003

total 1 1

Fig. 4. (Color online) Dynamic moduli of M1 and M2 mixtures (symbols). The lines are those calculated from the calculated MWD

and the monodisperse model.

Junghaeng Lee, Sangmo Kim and Kwang Soo Cho

70 Korea-Australia Rheology J., 33(1), 2021

3. Algorithm for Solving MWD from the MixingRule

3.1. Experimental dataWasserman and Graessley (1992) made two mixtures of

monodisperse PS’s with the compositions listed in Table

3. We digitized the dynamic moduli of M1 and M2 which

are shown in Fig. 4. To convert the dynamic moduli to the

relaxation modulus, we adopted the fixed-point iteration

of Cho and Park (2013). From the spectra of Fig. 5, we

calculated the relaxation moduli of M1 and M2, as shown

in Fig. 6 (Ferry, 1980). The vertical lines in Fig. 5 are the

Davies-Anderssen lines (Davies and Anderssen, 1997)

which indicate the effective range of relaxation time for a

given range of frequency of the experimental data.

By carefully looking at Fig. 6 one recognizes that the

relaxation modulus from calculated MWD shows better fit

for than for where can be interpreted as

the relaxation time at which the movement of the polymer

chain first feels the entanglement effect. It is because the

quadratic mixing rule is valued for the regime of fully

developed entanglement. Although the distinction about

is very small in Fig. 6, the application of of the

whole time range of Fig. 6 gives MWD mostly different

from the MWD calculated from with . It will

be shown in Fig. 11.

To obtain from the monodisperse model, we

used the Fuoss-Kirkwood relation (Fuoss and Kirkwood,

1941):

. (11)

et

et

e

e ( )G t

( )G te

t

( , )G t M

1 2 2

Im (i ) Re (i )H G G

Fig. 5. (Color online) Relaxation time spectrum of polydisperse

PS sample: [a] M1 sample and [b] M2 sample. Dashed line indi-

cates Davies-Anderssen line (Davis and Anderssen, 1997).

Fig. 6. (Color online) Relaxation moduli of M1 and M2 calcu-

lated from the spectra of Fig. 5 (symbols) and those calculated

from the calculated MWD and the monodisperse model (lines).

The vertical line represents the entanglement relaxation time

. We calculate MWD using data from the time domain

above . The agreement between symbols and lines reveals

that our algorithm is acceptable.

150

e

℃

150

e

℃

Calculation of molecular weight distribution using extended Cole-Cole model and quadratic mixing rule

Korea-Australia Rheology J., 33(1), 2021 71

Long manipulation of equations in the Appendix, we

finally have

. (12)

Then Eq. (12) gives the relaxation modulus of the ingre-

dient PS. The validity of Eq. (12) is checked, as shown in

Fig. 7. We calculated the relaxation time spectra of the

monodisperse PS’s in Figs. 1 and 2 in two ways, such as

fixed-point iteration and the use of Eq. (12). Analytically

calculated spectra agree with the numerically calculated

ones very well. Now we can calculate the relaxation mod-

uli of the monodisperse PS’s in Table 3. The relaxation

moduli are stored in the computer program to be used in

the calculation of the MWD of M1 and M2 mixtures.

Note that the parameters obtained from the data of Figs.

1 and 2 are those for 180°C while the dynamic modulus

data of Wasserman and Graessley (1992) are determined

at the reference temperature of 150°C. Since the shift fac-

tor is nearly independent of molecular weight, we

obtained the Williams-Landel-Ferry (WLF) parameters

from Schausberger et al. (1986) and Jeon (2010). The value

of the shift factor from 180°C to 150°C is .

Because we have to remove time region below the

Rouse regime (Thimm et al., 2000), it needs to calculate

which is the entanglement relaxation time at 150℃.

We can derive using the result of Schausberger et al.

(1985) and the shift factor obtained above. We determine

by the use

(13)

Its value is about 103 s. This value is shown as a dotted

line in Fig. 6. Then we use the relaxation modulus of M1

and M2 data for times longer than 103 s.

3.2. Modified FPI for MWD calculationAs mentioned in the Introduction, we will calculate

. Here, we used the Greek alphabet in order to dis-

tinguish the index for time . The Greek index denotes

the molecular weight. Since the discrete mixing rule of

Eq. (1) is a linear equation, the sum of the square error to

be minimized is

, (14)

where is the number of times and N is the number of

molecular weights. The normal equation of Eq. (14) is

given by

, (15)

where

.(16)

Directly solving Eq. (15) might result in negative weight

fractions for some molecular weights because of the errors

imbedded in and . Hence, we consider

the following iteration equation:

. (17)

This is the fixed-point iteration (Cho and Park, 2013).

Note that n indicates the iteration number. If the initial

MWD then all is not negative. To meet the

constraints of Eq. (3), we did rescaling such that

(18)

for each iteration step.

Since the molar mass of the monomer of PS is about

104 g/mol, as for the interval of molecular weight of

, N is approximately 5 million.

The use of such large N is not practical. For the first iter-

ations, we choose small and the molecular weights

, (19)

where and . The ini-

tial MWD of the first iteration is taken as the uniform dis-

tribution such that

. (20)

Although various initial conditions could be chosen, we

adopt the simplest one: uniform distribution. If the initial

MWD is closer to the real one, then the iteration would be

Re

2 2

Re Im Re

2( , )

( ) 4

VH M

U V V

10 Tlog 1.65a

150

e

℃

150

e

℃

150

e

℃

3.4

o

e o e

e

MJ

M

it

2

1 1

11 ( , )

( )

TN N

m i

i i

G t MG t

TN

1

N

S g

1 1

( , ) ( , ) ( , ),

( ) ( )

T TN N

m i m im i

i ii i

G t M G t M G t MS g

G t G t

( , )m i

G t M

( )i

G t

( 1) ( )

( )

1

log logn n

N

n

g

S

(0)0

( )n

1

n

n

N

n

3 610 g/mol 5 10 g/molM

10N

max min

min

log( )log log ( 1), 1,2, ,

1

M MM M N

N

min1000 g/molM

6

max5 10 g/molM

(0) 1, 1,2, ,N

N

Fig. 7. (Color online) Relaxation time spectra obtained from the

extended Cole-Cole model and FPI method.

Junghaeng Lee, Sangmo Kim and Kwang Soo Cho

72 Korea-Australia Rheology J., 33(1), 2021

finished earlier. As iteration goes, the MWD evolves to

lower the sum of the square error . If approaches to a

certain value, we stop the first iteration and generate a

new initial MWD for the second iteration process, which

has the doubled partition of molecular weight ( ),

by the interpolation of the last MWD of the first iteration

process. We repeat this procedure until decreases suffi-

ciently, as shown in Fig. 8.

We tested the number of molecular weights at the first

iterations and observed as a function of iteration number

, as shown in Fig. 9. Before , the sum of

square error reached its saturate values. Of course, the

higher N, the lower the saturated sum of square error.

We set at the first iterations. At every 200 iter-

ations, we doubled the number of molecular weights, as

shown in Fig. 10. As mentioned before, the initial MWD

of the first iterations is the uniform one . When

the first doubling of N ( ), is calculated

from the interpolation explained in Fig. 8. At ,

we used and the initial MWD is the inter-

polation of . As for the first three doublings, we can

find a dramatic reduction of while after the fourth dou-

bling, continuous reduction of is observed.

Since FPI is an iteration algorithm, it needs a stopping

criterion. As shown in Fig. 9, we can stop the iteration

when a further increase of iteration does not give any sig-

nificant reduction of the sum of square error . One may

select the stopping criterion as . As

shown in Fig. 10, decreases and decreases as both N and

increases. We stopped the partition of molecular

2N N

itrN

itr40N

10N

(0) 110

itr200N

(200)

itr400N

40N

(400)

(399)

itr 1 itr

1N N

itrN

Fig. 8. (Color online) The modified FPI method is conducted by [1]. The initial MWD is taken by 1/N. [2] MWD after the Nitr times

iteration. [3] Addition of new components to the midpoints of neighbor molecular weight components. Doubling of the number of

molecular weights. (The interpolated MWD will be used as the initial MWD for the next iterations) [4] MWD calculated from the next

iterations (Nitr times again). This procedure is repeated until the sum of square error is lower than a certain value.

Fig. 9. (Color online) The results of the first iteration. As the

number of molecular weights increases, the sum of square error

at a high iteration number decreases. The saturated values of

were achieved at Nitr < 40.

Calculation of molecular weight distribution using extended Cole-Cole model and quadratic mixing rule

Korea-Australia Rheology J., 33(1), 2021 73

weight at 1280 since converged sufficiently. Although

higher N would give a smaller value for , we get to know

that the change in the shape of MWD becomes negligible.

Hence the users of this algorithm have to decide to stop

the iteration and the partitioning by observing the change

of the shape of MWD.

4. Results and Discussion

Figure 11 shows the final MWD’s for M1 and M2 mix-

tures, and . The symbols are the

weight fraction listed in Table 3 and the solid lines are the

MWD calculated from with and the dotted

lines are the MWD calculated from over the whole

range of time in Fig. 6. As the dotted lines show, imagi-

nary peaks appear at for both M1 and M2.

On the other hand, with gives acceptable

results. This reveals that the quadratic mixing rule is valid

for a fully entangled regime. It can also be said that our

strategy, the stepwise doubling of molecular weight points,

is quite effective, although the raw data were obtained

from the digitization of the graphs in Wasserman and

Graessley (1992).

Without a careful look, the two viscoelastic data of M1

and M2 would look similar, although M2 shows longer

relaxation at low-frequency range. Such longer relaxation

of M2 is originated from the small portion of higher

molecular weight, as shown in Table 3. Hence, we need to

magnify the high-molecular weight regime of Fig. 11.

Figure 12 is the magnification of Fig. 11 for high molec-

ular weights. Our algorithm shows considerable deviation

from the real MWD (symbols). The calculated MWD for

M2 shows higher values than that of M1. This qualitative

tendency agrees with the real MWD.

It is noteworthy that the mean relaxation time of mon-

odisperse polymers is longer than , if their molec-

ular weight exceeds 2100 kg/mol. However, the time

range of for both M1 and M2 is .

Thus, the discrepancy of Fig. 12 is natural because the vis-

coelastic data for is no longer enough to pre-

dict the MWD in the region of .

Theoretically, the molecular weight of a single polymer

chain must be the integer multiple of the molecular weight

of the monomer (say Mo). Hence, an extremely accurate

device for MWD, if existing, gave a train of peaks located

at the integer multiples of the molecular weight of the

monomer. However, GPC gives a continuous and smooth

MWD. If rheological data were free from any error and

the MWD calculation were perfect, then the calculated

itr1600N 1280N

( )G te

t

( )G t

2 kg/molM

( )G te

t

43 10 s

( )G t4 4

2 10 s 3 10 st

43 10 st

2100 kg/molM

Fig. 10. (Color online) The effect of partitioning. At every 200

iterations, the number of molecular weight N is doubled. Dou-

bling of N reduces dramatically until the number of the dou-

bling is three. However, such dramatic reduction becomes

continuous if the number of doubling exceeds four.

Fig. 11. (Color online) The final MWD’s with N = 1280. The

symbols are the original MWD of each polydisperse sample

listed in Table 3 and the solid lines are the MWD calculated from

G(t) with and the dotted lines are the MWD calculated

from G(t) over the whole range of time in Fig. 6.e

t

Junghaeng Lee, Sangmo Kim and Kwang Soo Cho

74 Korea-Australia Rheology J., 33(1), 2021

MWD with the extreme partition such that

must be a train of peaks. Cho and Park (2013) showed that

the application of FPI to a single Maxwell model gives the

relaxation spectrum which becomes the Dirac delta func-

tion as the iteration increases. Hence, one may expect that

the application of FPI to the MWD would give a train of

peaks if the partition of molecular weight is the extreme

one. However, it cannot be implemented because of the

memory problem in our computer. Furthermore, the effect

of the errors in rheological data prevents the prediction of

the train of peaks.

As for a binary mixture of nearly monodisperse samples,

we can take a narrower molecular weight range than M1

and M2 data. Hence, the partition of molecular weight can

be closer to the extreme one. Then we can confirm

whether the calculated MWD looks like a train of peaks.

We test our algorithm for simulated data and two exper-

imental data (Maier et al., 1998 and Jeon, 2010). Figure

13 shows the calculation results of the MWD. As expected,

we have two sharp peaks similar to the delta function. The

1 oM M M

Fig. 12. (Color online) The magnification of Fig. 11 for high

molecular weights. The symbols are the original MWD of each

polydisperse sample and the blue-dotted line is M1 and the red-

solid line is M2.

Fig. 13. (Color online) Calculation results of MWD of binary mixtures: [a] Simulated MWD with 20% of PS (60 kg/mol) and 80%

of PS (177 kg/mol), [b] Experimental data of Maier et al. (1998), and [c] Experimental data of Jeon (2010). Symbols are original MWD

and solid lines are the calculation results of MWD.

Fig. 14. (Color online) Relaxation moduli corresponding to Fig 13. Symbols are conversion results from dynamic moduli and solid lines

are the calculation results from obtained MWD.

Calculation of molecular weight distribution using extended Cole-Cole model and quadratic mixing rule

Korea-Australia Rheology J., 33(1), 2021 75

calculated MWD for the simulated data agrees with the

original MWD (discrete one), while the calculated MWD

for the two experimental data does not agree with the

positions and heights of the peaks of the original MWD.

The discrepancy for the experimental data must originate

from the errors in the raw data. On the other hand, the

relaxation moduli calculated from the calculated MWD

agrees well with the relaxation moduli calculated from the

measured data of the dynamic modulus (Fig. 14). This

shows that a conversion from relaxation modulus to

MWD is an ill-posed problem as strong as that in the con-

version from dynamic modulus to relaxation spectrum.

Note that Maier et al. (1998) used the regularization

method (LRG) which gives a MWD similar to that of

GPC because of the features of LRG. Although the multi-

mode Maxwell model gives a viscoelastic spectrum like a

train of peaks, LRG gives overlapped broadened peaks.

On the other hand, the application of FPI to the spectrum

gives a train of sharp peaks for the multi-mode Maxwell

model. The width of peaks of the FPI, of course, depends

on the errors in the raw data. Since we believe that FPI is

more precise than LRG in the calculation of the spectrum,

we expect the application of FPI to be superior to the

LRG.

We generate 40 copies of Fig. 6a (the relaxation mod-

ulus of M1 with ) by adding 3% statistical errors in

order to show how stable our algorithm is. The errors are

the random variables generated from the normal distribu-

tion with the mean of zero and the standard deviation of

unity. We calculated the error bars of MWD as the stan-

dard deviation of the MWD’s calculated from the 40 cop-

ies of the relaxation modulus. As shown in Fig. 15, the

error bar is narrower than the results of a regularization

method (see Fig. 2 of Thimm et al. (1999)). Similar results

are obtained for M2. Figure 15 is the result from

and Fig. 2 of Thimm et al. (1999) is the MWD of a binary

blend of nearly monodisperse PS. It is remarkable that the

error bars for are much broader than those for

. This result agrees with that the quadratic mixing

rule is valid for .

Our algorithm is designed for the concept that MWD of

homopolymer is basically discrete because the molecular

weight of the polymer should always be an integer mul-

tiple of the molecular weight of the monomer except for

the terminal group. As for PS, the molecular weight of the

monomer is about 100 g/mol. Hence if we take the range

of molecular weight as then,

the partition of molecular weight is given by .

The number of molecular weight N is too high to give rise

to memory problems for a conventional personal com-

puter even if stepwise doubling (see Figs. 8 and 10) are

applied. If the quadratic mixing rule and the monodisperse

model are perfect, we expected that our algorithm would

give such discrete MWD for the extreme partition of

molecular weight. However, since the premises are not

perfect, the goal cannot be achieved. Furthermore, because

of the slight polydispersity of nearly monodisperse sam-

ples, the MWD of Table 3 is not really the discrete MWD.

Table 3 is just the mixing ratio. Hence, we need an

approximation based on continuous MWD:

et

80N

CM M

CM M

CM M

31 kg/mol 5 10 kg/molM

55 10N

Fig. 15. (Color online) The effect of the errors of G(t) on cal-

culated MWD. 40 copies of the G(t) of Fig. 6[a] are generated by

the addition of 3% statistical errors. The errors are generated

from the normal distribution with the mean of zero and the stan-

dard deviation of unity. The symbols represent the MWD of M1

without error. The error bars represent the standard deviation

from the MWD calculated from the 40 copies. It is remarkable

that error bars for M > MC are narrower than those for M < MC.

Note that the quadratic mixing rule is valid for M > MC.

Fig. 16. (Color online) Comparison of GPC data and the calcu-

lated MWD for the polydisperse PS produced by Aldrich. The

line represents the GPC data and the symbols represent the cal-

culated MWD. The vertical line means

which corresponds to . Since the time interval of G(t)

is , MWD cannot be calculated accurately for

molecular weight higher than the vertical lines by a rheological

method.

1330kg molM

7000s

3 310 s 7 10 st

Junghaeng Lee, Sangmo Kim and Kwang Soo Cho

76 Korea-Australia Rheology J., 33(1), 2021

. (21)

We expect that Eq. (21) will allow us to compare our

results with GPC MWD.

We applied the algorithm to commercial PS purchased

from Aldrich. The weight-average molecular weight

( ) of the PS is about 350 kg/mol and the number-aver-

age molecular weight ( ) is about 170 kg/mol. We mea-

sure dynamic modulus at 130, 150, 180, 200, 240 and

270°C and master curve were obtained by Time-tempera-

ture superposition (TTS). Figure 16 shows the comparison

of GPC data and the calculated MWD using Eq. (21) for

the commercial PS. The line represents the GPC data and

the symbols represent the calculated MWD. The vertical

line means and the mean relaxation time

of monodisperse PS is about 7000 s at .

Since the time interval of the relaxation modulus

is allowed by the TTS, the rheological

data is not sufficient to predict correct MWD, as shown in

Fig. 16. Although the weight-average molecular weight of

the PS is about 350 kg/mol (maker’s data), the portion of

is significantly high. Our measurement

of MWD gives the while the calculated

MWD gives . Figure 16 shows that the

time interval of relaxation modulus

gives a radical decrease of MWD at . We

could not check the ability of our method because of the

lack of experimental data.

Since we obtained MWD, we can recover relaxation and

dynamic moduli of M1 and M2 mixtures using the mon-

odisperse model, as shown in Figs. 4 and 6, respectively.

Recovered dynamic moduli were calculated by using the

relaxation time spectrum obtained from the recovered

relaxation modulus. Good agreement between symbols

and lines reveals that our algorithm is quite acceptable

even though the raw data of dynamic moduli were obtained

from the digitalization of the graphs in Wasserman and

Graessley (1992).

5. Conclusions

Most linear viscoelastic data are measured by dynamic

test while mixing rule is expressed by relaxation modulus.

The extended Cole-Cole model has a good agreement

with the dynamic modulus of monodisperse polystyrenes

for all molecular weights we have. Thus, we can deter-

mine the parameters of the model from the experimental

data of monodisperse PS and calculate relaxation modulus

for any molecular weight. Since the model has an analyt-

ical equation for the relaxation spectrum, we can make

faster calculations than the use of any numerical method

of the conversion from dynamic modulus to relaxation

modulus.

It is a difficult problem to calculate MWD from the mix-

ing rule without any assumed model for MWD because

the weight fraction in the mixing rule must satisfy the con-

straints of Eq. (3). To solve the problem, we adopted the

modification of the fixed-point iteration which was orig-

inally developed for the continuous relaxation spectrum.

To reduce the computation load, we adopted a stepwise

doubling of the number of molecular weights. The calcu-

lated MWD was compared with known data. The com-

parison reveals that our algorithm is acceptable.

As for commercial polymer samples, previous algo-

rithms (Wasserman, 1995) without any MWD model give

a calculated MWD which is qualitatively similar to the

GPC MWD. Compared with these algorithms, we have a

strong point on the monodisperse model. Hence, we expect

that our algorithm will give, at least, similar accuracy.

Although we could not compare our algorithm with the

nonlinear regularization algorithm directly, it is reported

that the accuracy of FPI for the relaxation spectrum is

equivalent to nonlinear regularization (Bae and Cho, 2015).

Hence, we expect that our algorithm works as well as the

nonlinear regularization (Honerkamp and Weese, 1993).

Acknowledgment

This work was supported by the Mid-Career Researcher

Program through the National Research Foundation of

Korea (NRF) funded by the Ministry of Education, Sci-

ence and Technology (2017R1A2B1005506).

Appendix

Omitting glassy compliance ( ), the expression of

the extended Cole-Cole model can be written as

. (A.1)

Replacement of s by gives Eq. (8). In order to calcu-

late the relaxation time spectrum by use of the Fuoss-

Kirkwood relation, we need the following

. (A.2)

Then Eq. (8) yields

, (A.3)

1 1

1 1 1

d ( ) ( )( ) ; ( )

d log log ( )

n

n n

n

n n

w W M W MW M M

M M M

wM

nM

1330 kg molM

1330 kg molM

3 310 s 7 10 st

1000 kg/molM

400 kg/molw

M

230 kg/molw

M

3 310 s 7 10 st

930 kg molM

0g

J

2

1o

1( )

1 ( ) k

k

k k

JsJ s

s s

�

i

Re Im

Re Im

(i ) ( ) i ( )

(i ) ( ) i ( )

J U U

J V V

2

Re

1

2

Im

1

Re Im

2

Im

1o

1 1 cos2( )

2(1 ) 2

sin 2( )

2

( ) ( )

1 (1 )(1 cos2 )( )

2 (1 )

k k

k

k k k

k k

k

k k

k k k

k

k k k

zU J

z d

zU J

d

V U

z zV J

d z

Calculation of molecular weight distribution using extended Cole-Cole model and quadratic mixing rule

Korea-Australia Rheology J., 33(1), 2021 77

where

. (A.4)

Substituting of Eq. (A.2) with (A.3) into Eq. (9) and using

Eq. (11) yields the spectrum of the extended Cole-Cole

model:

. (A.5)

Then relaxation modulus can be calculated by Eq. (A.5)

as follows

. (A.6)

References

Aarts, E. and J. Korst, 1989, Simulated Annealing and Boltzmann

Machines: A Stochastic Approach to Combinatorial Optimiza-

tion and Neural Computing, Wiley.

Anderssen, R.S. and D.W. Mead, 1998, Theoretical derivation of

molecular weight scaling for rheological parameters, J. Non-

Newton. Fluid Mech. 76, 299-306.

Bae, J.E., and K.S. Cho, 2015, Logarithmic method for contin-

uous relaxation spectrum and comparison with previous meth-

ods, J. Rheol. 59, 1081-1112.

Carrot, C. and J. Guillet, 1997, From dynamic moduli to molec-

ular weight distribution: A study of various polydisperse linear

polymers, J. Rheol. 41, 1203-1220.

Cho, K.S., K.H. Ahn, S.J. Lee, 2004, Simple method for deter-

mining the critical molecular weight from the loss modulus, J.

Polym. Sci.: Polym. Phys. 42, 2724-2729.

Cho, K.S., and G.W. Park, 2013, Fixed-point iteration for relax-

ation spectrum from dynamic mechanical data, J. Rheol. 57,

647-678.

Cho, K.S., M.K. Kwon, J. Lee, and S. Kim, 2017, Mathematical

analysis on linear viscoelastic identification, Korea-Aust.

Rheol. J. 29, 249-268.

Davies, A.R. and R.S. Anderssen, 1997, Sampling localization in

determining the relaxation spectrum, J. Non-Newton. Fluid

Mech. 73, 163-179.

Des Cloizeaux, J., 1988, Double reptation vs simple reptation in

polymer melts, Europhys. Lett. 5, 437-442.

Doi, M. and S.F. Edwards, 1986, The Theory of Polymer Dynam-

ics, Oxford University Press, New York.

Ferry, J.D., 1980, Viscoelastic properties of polymers, John Wiley

& Sons

Friedrich, C., R.J. Loy, and R.S. Anderssen, 2009, Relaxation

time spectrum molecular weight distribution relationships,

Rheol. Acta 48, 151-162.

Fuchs, K., Chr. Friedrich, and J. Weese, 1996, Viscoelastic prop-

erties of narrow-distribution poly(methyl methacrylates), Mac-

romolecules 29, 5893-5901.

Fuoss R.M., J.G. Kirkwood, 1941, Electrical properties of solids,

J. Am. Chem. Soc. 63, 385-394.

Guzman, J.D., J.D. Schieber, and R. Pollard, 2005, A regular-

ization-free method for the calculation of molecular weight dis-

tributions from dynamic moduli data, Rheol. Acta 44, 342-351.

Honerkamp, J., and J. Weese, 1989, Determination of the relax-

ation spectrum by a regularization method, Macromolecules

22, 4372-4377.

Honerkamp, J., and J. Weese, 1993, A nonlinear regularization

method for the calculation of relaxation spectra, Rheol. Acta

32, 65-73.

Jeon, H.C., 2010, Effect of polydispersity on the viscoelasticity

of model homo-polystyrene melts, MS Thesis, Kyungpook

National University, Korea.

Kim, S, J. Lee, S. Kim, and K.S. Cho, 2018, Application of

Monte Carlo method to nonlinear regression of theological

data, Korea-Aust. Rheol. J. 30, 21-28.

Kwon, M.K., J. Lee, K.S. Cho, S.J. Lee, H.C. Kim, S.W. Jeong,

and S.G. Lee, 2019, Scaling analysis on the linear viscoleas-

ticity of Cellulose 1-ethyl-3-methyl Imidazolium Acetate solu-

tions, Korea-Aust. Rheol. J. 31, 123-139.

Lang, C., 2017, A Laplace transform method for molecular mass

distribution calculation from rheometric data, J. Rheol. 61,

947-954.

Léonardi, F., A. Allal, and G. Marin, 2002, Molecular weight dis-

tribution from viscoelastic data: The importance of tube

renewal and Rouse modes, J. Rheol. 46, 209-224.

Maier, D., A. Eckstein, Cr. Friedrich, and J. Honerkamp, 1998,

Evaluation of models combining rheological data with the

molecular weight distribution, J. Rheol. 42, 1153-1173.

Marin, G., and W.W. Graessley, 1977, Viscoelastic properties of

high molecular weight polymers in the molten state, Rheol.

Acta 16, 527-533.

McGrory, W.J. and W.H. Tuminello, 1990, Determining the

molecular weight distribution from the stress relaxation prop-

erties of a melt, J. Rheol. 34, 867-890.

Mead, D.W., 1994, Determination of molecular weight distribu-

tion of linear flexible polymers from linear viscoelastic mate-

rial functions, J. Rheol. 38, 1797-1827.

Montfort, J.P., G. Marin, and Ph. Monge, 1986, Molecular weight

distribution dependence of the viscoelastic properties of linear

polymers: the coupling of reptation and tube-renewal effects,

Macromolecules 19, 1979-1988.

Nobile, M.R. and F. Cocchini, 2008, A generalized relation

between mwd and relaxation time spectrum, Rheol. Acta 47,

509-519.

Park, J.W., J. Yoon, J. Cha, and H.S. Lee, 2015, Determination of

molecular weight distribution and composition dependence of

monomeric friction factors from the stress relaxation of ultra-

high molecular weight polyethylene gels, J. Rheol. 59, 1173-

1189.

Pattamaprom, C., R.G. Larson, and A. Sirivat, 2008, Determining

polymer molecular weight distributions from rheological prop-

erties using the dual-constraint model, Rheol. Acta 47, 689-

700.

Rubinstein, M. and R.H. Colby, 2003, Polymer Physics, Oxford

University Press, New York.

21 2 cos2

( ) ,2

k

k k k k

k

k k k

d z z

z

Re

2 2

Re Im Re

1 2 ( )

( ) ( ) 2 ( )

VH

U V V

1

Re

2 21 1 1

Re Im Re

2 ( )exp( )( ) d log

( ) ( ) 2 ( )

V tG t

U V V

Junghaeng Lee, Sangmo Kim and Kwang Soo Cho

78 Korea-Australia Rheology J., 33(1), 2021

Schausberger, A., G. Schindlauer, and H. Janeschitz-Kriegl, 1985,

Linear elastico-viscous properties of molten standard polysty-

rene, Rheol. Acta 24, 220-227.

Shanbhag, S., 2019, pyReSpect: A computer program to extract

discrete and continuous spectra from stress relaxation experi-

ments, Macromol. Theor. Simul. 3, 1900005.

Stadler, F.J., and C. Bailly, 2009, A new method for the calcu-

lation of continuous relaxation spectra from dynamic mechan-

ical data, Rheol. Acta 48, 33-49.

Takeh, A., and S. Shanbhag, 2013, A computer program to

extract the continuous and discrete relaxation spectra from

dynamic viscoelastic measurements, Appl. Rheol. 23, 1-10.

Thimm, W., C. Friedrich, M. Marth, and J. Honerkamp, 1999, An

analytical relation between relaxation time spectrum and

molecular weight distribution, J. Rheol. 43, 1663-1672.

Thimm, W., C. Friedrich, M. Marth, and J. Honerkamp, 2000, On

the Rouse spectrum and the determination of the molecular

weight distribution from rheological data, J. Rheol. 44, 429-

438.

Tsenoglou, C., 1987, Viscoelasticity of Binary Homopolymer

Blends, ACS Polym. Prepr. 28, 185-186.

Tuminello, W.H., 1986, Molecular weight and molecular weight

distribution from dynamic measurements of polymer melts,

Polymer Engineering and Science 26, 1339-1347.

Van Ruymbeke, E., R. Keunings, and C. Bailly, 2002, Determi-

nation of the molecular weight distribution of entangled linear

polymers from linear viscoelasticity data, J. Non-Newtonian

Fluid Mech. 105, 153-175.

Vega, J.F., S. Rastogi, G. W.M. Peters, and H.E.H. Meijer, 2004,

Rheology and reptation of linear polymers. Ultrahigh molec-

ular weight chain dynamics in the melt, J. Rheol. 48, 663-678.

Wasserman, S.H. and W.W. Graessley, 1992, Effects of polydis-

persity on linear viscoelasticity in entangled polymer melts, J.

Rheol. 36, 543-572.

Wasserman, S.H., 1995, Calculating the molecular weight distri-

bution from linear viscoelastic response of polymer melts, J.

Rheol. 39, 601-625.

Watanabe, H., 1999, Viscoelasticity and dynamics of entangled

polymers, Prog. Polym. Sci. 24, 1253-1403.

Wu, S., 1985, Polymer molecular-weight distribution from dynamic

melts viscosity, Polym. Eng. and Sci. 25, 122-128.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional

claims in published maps and institutional affiliations.

![Effect of Molecular Weight and Molecular Distribution on Skin … · 2016-01-07 · based materials . Nevertheless, molecular weight and molecular weight distribution effects on stru[10]](https://static.fdocuments.in/doc/165x107/5e750b4f6204df40457a83af/effect-of-molecular-weight-and-molecular-distribution-on-skin-2016-01-07-based.jpg)