Cadillac HEATX · The Cadillac® HEATX BTU / Energy Meter is designed to measure the energy...

Transcript of Cadillac HEATX · The Cadillac® HEATX BTU / Energy Meter is designed to measure the energy...

Cadillac® HEATX

GENERAL INFORMATION

Rev 0512

Wall Mount

Panel Mount

RESET

ACCUM TOTAL

PROGRAM

Cadillac®

Sensor OIML PT1000 Klasse4

3225.024

HEATX

T: 1° C.…. 200°C ∆T: 3°C….199°C

ENERGY KBTU

Cadillac® Energy Systems

RESET

ACCUM TOTAL

PROGRAM

Cadillac®

Sensor OIML PT1000 Klasse4

3225.024

HEATX

T: 1° C.…. 200°C ∆T: 3°C….199°C

ENERGY KBTU

CENTRAL STATION STEAM CO.® 15615 SW 74TH AVE., STE #150 TIGARD, OR 97224 PHONE: 888-556-3913 FAX: 503-624-6131 @ WWW.CADILLACMETER.COM

CENTRAL STATION STEAM CO.® 15615 SW 74TH AVE., STE#150 TIGARD, OR 97224 PHONE: 888-556-3913 FAX: 503-624-6131 WWW.CADILLACMETER.COM

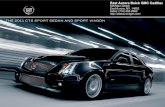

THE ENERY SYSTEM OF CHOICE The Cadillac® HEATX BTU / Energy Meter is designed to measure the energy consumed in hot water heating and chilled water cooling systems. The meter is a rate and totalizing device, which is capable of calculating and displaying Volume, Energy, Temperatures and Peak Energy usage. Combined with Cadillac®’s superior flow meter technologies the HEATX provides the most accurate, repeatable, and maintenance free energy system available in the industry. The Cadillac® HEATX BTU / Energy Meter measures the temperature in the feed and return lines via two precision matched 4-wire RTD’s and from this calculates the density and enthalpy of the water. In addition, by also measuring the volume of water flowing in the system via the Cadillac® flow meter, the HEATX will then compute, display, and output the Energy consumed.

Rev 0113

The Cadillac® HEATX BTU / Energy Meter measures the temperature in the feed and return lines via two precision matched 4-wire RTD’s and from this calculates the density and enthalpy of the water. In addition, by also measuring the volume of water flowing in the system via the Cadillac® flow meter, the HEATX will then compute, display, and output the Energy con-sumed. Power is Calculated: P = V x ρ x (htv-htr) Where: P = Power (watts) V = Volumetric flow Rate ρ = Density htv = Specific enthalpy at Feed temperature htr = Specific enthalpy at Return temperature

THE NEW INDUSTRY STANDARD Combined with Cadillac®’s superior flow meter technologies the HEATX BTU / Energy meter has quickly become acknowledged as the industry standard. Customers choose the Cadillac® HEATX BTU / Energy Meter because of proven:

APPLICATIONS • Energy consumption data source for energy management system, DCS, district-wide systems. • Energy-Customer Billing from accurately totalized Energy / BTU measurements. • Basis for internal cost distribution using campus-wide systems. • Efficiency measuring and monitoring from central control rooms. • Direct Energy / BTU measurements at both Boiler and point of use locations.

FEATURES

MODES OF OPERATION •••• Heating Mode: Where Positive ∆T’s only are totalized.

•••• Cooling Mode: Where Negative∆T’s only are totalized.

•••• Heating/Cooling Mode: Where the flow of energy may be for either heating or cooling. In this mode the energy total is increased regardless of whether the ∆T is positive or negative.

•••• Charge/Discharge Mode: Where two separate registers totalize positive and negative totals.

PRINCIPLE OF OPERATION

♦ ACCURACY, DEPENDABILITY, CONSISTENCY, LOW MAINTEN ANCE, RANGEABILITY

CMAG/EMAG HEATX HOT/CHILLED WATER ENERGY SYSTEM

1256.78 ENER GY KBTU

Cadillac® Energy Systems

HEATX

CMAG/EMAG Flow Meter

HEATX in Wall Mount Enclosure

12”

12”

Flow Direction

115 VAC power to CMAG/EMAG & HEATX Panel

Pulse output from CMAG/EMAG to

HEATX

4-Wire Precision Matched RTD Temp Assemblies

Hot/Chilled Water Return Line Hot/Chilled Water Feed Line

Modbus RTU RS-485, Modbus-IP or BACnet IP Ethernet, N2 Output

to BMS

Pulse output from HEATX to BMS

Cadillac®

CENTRAL STATION STEAM CO.® 15615 SW 74TH AVE., STE #150 TIGARD, OR 97224 PHONE: 888-556-3913 FAX: 503-624-6131 @ WWW.CADILLACMETER.COM Rev 0113

Energy and Flow Measurement for Campus and Central Utility Plants

RESET

ACCUM TOTAL PROGRA M

Cadillac®

Sensor OIML PT1000 Klasse4

3225.024

HEATX

T: 1° C.…. 200°C ∆T: 3°C….199°C

ENERGY KBTU

Cadillac® Energy Systems

0

0

0

0

0

0

0

Campus Chilled Water Return

0

BTU-102

BTU-103

BTU-104

BTU-101

FT-105

FT-106

FT-107

TT-102 FT-101

TT-101

FT-104

TT-107

FT-102

TT-103

FT-103

TT-105

TT-108

0

Campus Chilled Water Supply

FT-108

TT-106

TT-104

FT-109

Cooling Towers

Packaged Chiller

Packaged Chiller

Packaged Chiller

Packaged Chiller

With no moving parts or flow line obstruction the CMAG has no mechanical drift, which require re-calibration, and does not cause system head loss creating an unwanted heat source (for chilled water systems), as do all other me-chanical and differential pressure flow technologies typically used. The flow profile independent tube design makes the CMAG ideal for retrofits, requiring only enough piping straight run to fit the meter in-line. Mounting next to turbulence generating devices such as elbows, tees, valves and pumps are of no concern for the CMAG!

By implementing the CMAG flow meters as part of the HEATX Energy System, users remove the most inaccurate component of the system and in turn now have the highest accuracy volumetric flow device available for measuring energy usage. With a 300:1 turn down and +/- 0.25% of rate accuracy the CMAG flow meter effectively doubles the overall accuracy of the entire system by itself, while provid-ing a maintenance free non-mechanical flow technology.

With 4-times the accuracy of mechanical or differential pres-sure flow elements, such as tur-bine, variable orifice, pitot tube, orifice plates, etc., the CMAG provides the HEATX system with the ultimate volumetric flow measuring solution.

Precision matched 4-Wire PT100 RTD’s with calibrated resistance +/- 0.01% at 0ºC, provides unparalleled system temperature accuracy.

The HEATX BTU / Energy meter is accurate to OIML R75 Class 4 and EN1434 Standards.

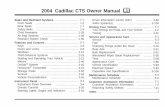

Wall Mount

RESET

ACCUM TOTAL

PROGRAM

Cadillac®

Sensor OIML PT1000 Klasse4

3225.024

HEATX

T: 1° C.…. 200°C ∆T: 3°C….199°C

ENERGY KBTU

Cadillac® Energy Systems

12.0”

12.0”

Wall Mount HEATX provided in a prewired, fuse protected, NEMA6 e n c l o s u r e w i t h i n t e r n a l 120AC/24VDC power supply for easy field mounting and termination.

3.4”

1.0” 1.7”

Panel Mount HEATX for those instal-lations where electrical panel already exists in the field.

Panel Mount

Sensor OIM L PT1000 Klasse4

RESET

ACCUM TOTAL

PROGRAM

Cadillac®

3225.024

HEATX

T: 1° C.…. 200°C ∆T: 3°C….199°C

ENERGY KBTU

6.0”

6-

5+

1+

58

2-

10+

Input Current Pulse Input

11-

RTD0 Signal Shields

Pulse Reed Coil

Flowmeter

HEATX Energy Meter

24-

58

58

4-

25+

7+

8-

3+

Input Current

51-

50+

16+

17-

53-

52+

Comms

Pulse Out

55-

54+

Signal Shields

RTD1 Power Input 12-24 VDC 100 mA max.

- + - + - + - +

4-20mA

Relay Relay

- +

3.9”

CENTRAL STATION STEAM CO.® 15615 SW 74TH AVE., STE #150 TIGARD, OR 97224 PHONE: 888-556-3913 FAX: 503-624-6131 @ WWW.CADILLACMETER.COM Rev 0113

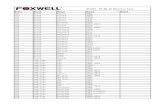

HEATX MODEL NUMBER STRUCTURE

CADILLAC® ENERGY AND FLOW MEASUREMENT SYSTEM GENERAL SPEC IFICATIONS

ENERGY SYSTEM SPECIFICATION: ♦ The entire Energy Measurement System shall be supplied, calibrated, and commissioned (if necessary) by a single manufac-

ture, Central Station Steam Co, and shall consist of a Energy / BTU meter, a non-mechanical flow meter, and two precision matched temperature sensors/thermowells. A certificate of NIST traceable calibration for all primary elements shall be pro-vided with each system.

ENERGY / BTU METER: ♦ Provide a Cadillac® HEATX Energy / BTU Meter. The BTU meter shall provide the following measurements at the local

display and as outputs* to an Building Control System. Energy Total, Energy Flow Rate, Volumetric Flow rate, Volume Total, Feed Temp, Return Temp, or ∆T. Output signals shall be either Serial RS-485 (Modbus RTU), Modbus TCP/IP, BACnet/IP, N2, and pulse (Open Collector). Each meter shall be factory configured for its specific application, and shall be reprogramma-ble using the front panel keypad (no special tools or computer required). Meter will be field adjustable for zero adjustment to any ∆T offset for specific application conditions. *Output options vary by model code and digital communications.

TEMPERATURE SENSORS: ♦ Temperature sensors shall be shall be precision matched, bath calibrated, NIST Traceable, 4-Wire PT100 RTD’s. Temperature

sensors will require no external power, and will include thermowell assembly and junction style head with terminations for landing field wiring. Temperature sensors shall be accurate to +/- 0.01% of temperature span. (with meter adjustment capabil-ity) system differential temperature accuracy will be +/- 0.10°F or better .

FLOW METER: ♦ Provide a Cadillac® CMAG Magnetic flow meter. The meter will have no moving parts, provide no flow obstruction, create

no head loss / heat gain, will not be orientation sensitive, and may be installed in any location it may physically fit into the piping system, while providing an accuracy of +/- 0.50% of rate. If meter is installed with 1.5 pipe diameters up and down-stream from its centerline the meter will be accurate to +/- 0.25% of rate. (In meter sizes 1/2” thru 3” the 1.5 diameter straight run requirement is met within flow tube). Meter will have minimum 300:1 turndown at stated accuracy (+/- 0.25% of rate). Meter will be provided with integral or remote electronics including a local 2-line backlit LCD for parameter viewing and easy interface / configuration. Meter will be preconfigured for application, but may be field adjusted through local display (no spe-cial tool or computer required).

Central Station Steam Co. provides a Cadillac® CDIS remote display station option for Saturated Steam Mass flow measure-ments for use with the CV-P, CV-HS, CV-U Vortex flow meters. The CDIS display has the same electronics platform and enclo-sure as the HEATX BTU / Energy meter and configures in a similar fashion for the same look and feel. Please contact Central Station Steam Co. for more information on this offering.

Remote Display for Saturated Steam Mass Flow HEATX Cadillac Energy / BTU Meter

P Panel Mount W Wall Mount

0 Output(s): Pulse & Serial Modbus RTU1 Output(s): Pulse & Modbus TCP/IP2 Output(s): Pulse & BACnet/IP Client3 Output(s): Pulse & N2

DC Power Supply: 12-24 VDCAC Power Supply: 100 130 VAC

X No RTD Temp sensors suppliedY User Specified Insertion Length

S Approvals: OIML R75 CompliantX Approvals: None