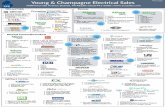

Cable Raceway

Transcript of Cable Raceway

-

7/28/2019 Cable Raceway

1/12

1

Welcome

Training:-

Cable Raceways

-

7/28/2019 Cable Raceway

2/12

1. Objective

2

To have batter understanding of Instrumentation ,Mechanical, Structural and Architectural interface with cable

raceways.

Understand various guidelines specified by client or

Standard.

Tender document

Design Criteria Document

S&L Standards

Any other Standards like IE rules, IS, BS etc.

-

7/28/2019 Cable Raceway

3/12

2. Introduction

Cable raceways are mainly of two types

Cable tray

Above ground cable tray

Under ground cable tray (Inside RCC trenches )

Conduit

Above ground conduit

Under ground conduit ( Inside RCC encased ductbank, Directly

buried)

3

http://localhost/var/www/apps/conversion/tmp/scratch_5/1trayiso.pdf -

7/28/2019 Cable Raceway

4/12

2. Introduction

Typical deliverables coming under Cable Raceway :Under Ground Electrical Raceway Layout Drawings (i.e. Duct bank Layout, CableTrench Layout, Burried cable / conduit Layout, Encased / Embedded Conduit Layoutetc)

Above Ground Electrical Raceway Layout Drawings (i.e. Duct bank Layout, CableTrench Layout, Burried cable / conduit Layout, Encased / Embedded Conduit Layoutetc)

Route Point Drawings

General Installation Notes / Details on Raceway System as part of General Notes &Details

Various processor used for praparation of above deliverables :

Raceway system Drawings : MP-1.01EID 7.01.03 Electrical Raceway Design

EID 7.01.05.03 - Cable Tray Supporting Arrangement

EID 7.01.05.04 - Cable Tray Layout, Support etc.

EID 7.01.06 - Cable Estimation & Routing DrawingEID 7.01.06.01 - Underground Raceway Design

EID 7.01.06.02 - Cable Trench Entry Details

EID 7.01.06.03 - Cable Vault Details

EID 7.01.06.03 Duct Bank Design GE Projects

4

-

7/28/2019 Cable Raceway

5/12

2. Introduction

There are two checklists for Raceway design:Underground raceway design for GE projects

Underground raceway design for Indian projects

5

-

7/28/2019 Cable Raceway

6/12

3. Raceway system design.

Redundant routes

Cable separation depending on service and voltage level

Cable tray

Conduit

Laying of cables

Inside cable tray

Inside conduit

Standard sizes and bending radius

Of Cable trays

Of Conduits

All above criteria are defined in Design Criteria Document of project.

6

http://localhost/var/www/apps/conversion/tmp/scratch_5/Kon_DCD_misc_rev4.pdf -

7/28/2019 Cable Raceway

7/12

3. Raceway system design.

Equipment list to which any type of cable is to be terminated. Load list

Feeder List

SLD

Instrumentation department

Location of these equipment

3D model

GA drawings prepared by Mechanical

Vendor Drawings

Any hand markups given by Instrumentation or mechanical department

Basic raceway roots are finalized with Mechanical and Civil

Approximate number of tray and ductbank size is calculated for various roots based on equipment location. Cable size for theseequipment are considered based on previous project experience or by engineering judgement.

Volume is blocked in 3D model and basic interference check is done and of any interference is found then it is resolved

Any specific size and configuration requirements to be conveyed to the equipment vendors.

To establish the size and configuration of any new electrical equipment rooms which may be built under the project scope.

To establish and convey space requirement for equipment to mechanical and civil.

To establish and convey the required floor or wall openings to the mechanical and civil.

To convey equipment loads to the civil.

To provide approximate distance between equipment so cable sizing can be done.

To establish the required input for other electrical physical design processes e.g. Grounding, Cable tray design.

7

-

7/28/2019 Cable Raceway

8/12

3. Raceway system design.

Now accurate tray / conduit sizing is done for all types based on criteriaspecified for raceway system design in DCD. Final inputs are taken from:

cable sizing calculation Instrumentation Inputs Cable list or MSDs Final equipment location from mechanical GA, vendor drawings, 3D model etc.

These Trays, ductbank, Manholes, Conduits etc. are accurately modeled. Conduit modeling : PDWB Ductbank, Manhole modeling : Microstation 3D Tray modeling : EDWB Interference Check : CADMS Drawing Preparation : CADMS Walkthrough : J-Space

If any interference is found then those are revolved with respectivedepartments. These interference also gives us inputs like wall cutout, floorcutouts required for the cable tray penetration.

Drawings are prepared using CADMS.

8

-

7/28/2019 Cable Raceway

9/12

4. Route point drawing

Concepts of Route point drawing

A cable tray routing drawing is a Road map that is used toidentify which path shall be used to route cable to a particular areaof the plant.

This drawings are started once Cable raceway drawing is approved byclient.

Route points are marked whenever cable changes its path.

Each route point is added to the cable tray model and model is insertedin CADMS.

Then Rout point drawing is prepared using CADMS.

Additionally equipment details like tag number of equipment is copiedfrom Equipment layout drawing to Route point drawing.

This cable tray model with route point details can be directlytransferred to WinCMS for cable routing purpose.

9

-

7/28/2019 Cable Raceway

10/12

5. Output of this process:

1 Cable raceway system drawings without any interference.

2 Total cable tray bill of material which can be used for

procurement of cable trays.

3 Plant model for Walkthrough

4 Route point drawing 5 Cable tray model with route point is transferred to WinCMS.

This will transfer all route points with length between them

and also with interconnectivity.

10

-

7/28/2019 Cable Raceway

11/12

5. Sample of raceway drawing:

5.1 Cable tray / trench layout (Under ground and Above Ground) :

Sample Drawing :

Photographs :

5.2 Route point drawings: Sample Drawing :

Photographs :

5.3 General notes and details: Sample Drawing :

5.4 Cable tray bill of material: Sample :

11

http://localhost/var/www/apps/conversion/tmp/scratch_5/bom.pdfhttp://localhost/var/www/apps/conversion/tmp/scratch_5/E04250-A.pdfhttp://localhost/var/www/apps/conversion/tmp/scratch_5/e04254-AB.pdfhttp://localhost/var/www/apps/conversion/tmp/scratch_5/routepoint.pdfhttp://localhost/var/www/apps/conversion/tmp/scratch_5/e04251-b-05112005.pdfhttp://localhost/var/www/apps/conversion/tmp/scratch_5/tray.pdf -

7/28/2019 Cable Raceway

12/12

Thank You

12