C2005 Ukur Kejuruteraan 2

Transcript of C2005 Ukur Kejuruteraan 2

1

AREA AND VOLUME

2.1 INTRODUCTION

Estimation of area and volume is basic to most engineering schemes such as

route alignment, reservoirs, construction of tunnels, etc. The excavation and

hauling of material on such schemes is the most significant and costly aspect of

the work, on which profit or loss may depend. Area may be required in

connection with the purchase or sale of land, with the division of land or with the

grading of land. Earthwork volumes must be estimated :

to enable route alignment to be located at such lines and levels that cut

and fill are balanced as far as practical.

to enable contract estimates of time and cost to be made for proposed

work.

to form the basis of payment for work carried out.

It is frequently necessary as part of engineering surveying projects to determine

the area enclosed by the boundaries of a site or the volume of earthwork

required to be moved. Many of the figures involve accepted mensuration

formulae (see 1.6 ) but it is more common to meet irregular shapes and these

require special attention.

2.2 PLAN AREAS

The basic unit of area in SI units is the square metre (m²) but for large areas the

hectare is a derived unit.

1 hectare (ha) = 10 000 m² = 2.471 05 acres

2.2.1 Conversion Of Plannimetric Area Into Actual Area

Let the scale of the plan be 1 in H (or as representative fraction 1/H). Then 1 mm is equivalent to H mm and 1 mm² is equivalent to H² mm² is equivalent to H mm², i.e. H² x 10-6 m²

2

2.3 AREA CALCULATION

Areas of ground may be obtained from the plotted plan but results are only as

accurate as it is possible to scale off the drawings. Accuracy is greatly increased

by using the measurements taken in the field. In most surveys the area is

divisible into two parts :

a) The rectilinear areas enclosed by the survey lines

b) The irregular areas of the strips between these lines and the

boundary

In order to calculate the area of the whole, each of these areas must be

evaluated separately because each is defined by a different form of geometrical

figure.

2.3.1 Rectilinear Areas

The method of evaluating the rectilinear area enclosed by survey

lines depends on the method of survey.

a) If chain surveying is used, the areas of the triangles forming the survey

network are calculated from the field dimensions from the formula :

Area = √ (s(s – a) (s – b) (s – c))

Where a, b and c = the lengths of the triangles sides and

s = (a + b + c) / 2

b) If traversing is used and the survey stations are coordinated, the computed

coordinated are used in the area calculation.

Whichever calculation method is used, checks must be applied to prove

the area calculations. In a chain survey network the work must be

arranged so that two different sets of the triangles forming the rectilinear

figure are used in evaluating the total area, which is thus twice calculated.

These two results will not normally agree precisely because the network

will not be geometrically perfect. Owing to observational errors, the two

results are meaned to produce the final rectilinear area. When areas are

calculated from coordinates, the calculation must be repeated another way

to prove the result.

3

2.3.2 Irregular Areas

Unless boundaries are straight and the corner points coordinated there

are usually irregular strips of ground between the survey lines and the

property boundaries. The area of the irregular strips are either positive or

negative to the rectilinear area and since they are divided up by offsets

between which the boundary is supposed to run straight, they are

computed as a series of trapezoids. The mean of each pair of offsets is

taken and multiplied by the chainage between them. Where the offsets are

taken at regular intervals, the trapezoidal rule or Simpson’s rule for areas

is used, (see section 2.6).

NOTE

a. The field work should be arranged to overcome difficulties with

corners. This is usually achieved by extending the survey line to the

boundary, allowing for the triangular shape which may occur.

b. In order to check the irregular area the calculations should be

repeated by another person, or a check against gross error may be

made taking out a planimeter area of the plot.

2.4 CALCULATING AREA FROM A CHAIN SURVEY

The figure shows the rectilinear area ABCD, which is calculated first. Their

regular strips between the

chain lines and the

boundary must be

separately evaluated and

either added or subtracted

as necessary from the

main rectilinear area

calculation result. The

following data were

obtained from the chain

survey of the site :

AB - 63.0 m

4

BC - 45.0 m CD - 60.0 m DA - 78.0 m BD - 93.3 m AC - 76.0 m

SOLUTION

The rectilinear area from A = √ ((s – a) (s – b) (s – c))

Chainage AD

Offset

A 0.0 0.0 16.0 6.0 33.0 7.0 40.0 0.0 49.0 7.0 61.0 7.0 68.0 0.0 B 78.0 11.0 89.0 5.0 93.0 9.0

Chainage CD

Offset

C 0.0 0.0 10.0 4.2 20.0 6.4 30.0 8.1 40.0 10.3 50.0 11.3 D 60.0 13.2

AB and BC are straight boundaries. Offsets to the

irregular boundaries are as follows :

5

The area of triangle ACD = √(107(31) (47) (29))

= 2126.3 m2

The area of triangle ABC = √(92(29) (47) (16))

= 1416.4 m2

Area of ABCD = 2126.3 + 1416.4

= 3542.7 m2

Check :

The area of triangle ABD = √((117.15 (54.15) (39.15) (23.85))

= 2433.8 m2

The area of triangle ABD = √(( 99.15 (39.15) (54.15) (5.85)))

= 1108.9 m2

Area of ABCD = 2433.8 + 1108.9

= 3542.7 m2

Area of triangle ABD: Plus Minus

(0+6) x 2 x 16 = 48.0

(6+7) x 2 x 17 = 110.5

(7+0) x 2 x 7 = 24.5

(0+7) x 2 x 9 = 31.5

(7+7) x 2 x 12 = 84.0

(7+0) x 2 x 7 = 24.5

(0+11) x 2 x 10 = 55.0

(11+9) x 2 x 15 = 150.0

388.5 140.0

- 140.0

248.5 m2 (total plus area on AD)

6

2.5 CALCULATING AREAS FROM COORDINATES

A = Area

SPECIMEN QUESTION

Calculate the area of the figure ABCDEF of which the coordinates are listed

below.

SOLUTION

The calculation is tabulated as shown :

Station Easting Northing

E + E Double Longitude

ΔN

A 150 100 B 95.2 164.3 245.2 64.3 15 766.36 C 127.9 210.7 223.1 46.4 10 351.84 D 176.3 239.8 304.2 29.1 8 852.22 E 219.4 222.4 395.7 -17.4 6 885.18

F 237.5 163.8 456.9 -58.6 26

774.34

A 150 100 387.5 -63.8 24

722.50

34 970.42 58

382.02

34

970.42

2A = 23

411.60

7

Area = 11 705.8 m2

= 1.1706 ha

2.6 AREAS OF IRREGULAR FIGURES

There are several practical situations where it is necessary to estimate the area

of irregular figures. Examples include estimation of areas of plots of land by

surveyors, areas of indicator diagrams of steam engines by engineers and areas

of water planes and transverse sections of a ship by naval architects. There are

many methods whereby the area of an irregular plane surface may be found and

these include:

(a) Use of a planimeter,

(b) Trapezoidal rule,

(c) Mid-ordinate rule and

(d) Simpson’s rule.

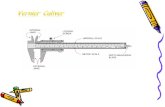

2.6.1 The planimeter

A planimeter is an instrument for directly measuring areas bounded by an

irregular curve. There are many different types of the instrument but all

consist basically of two rods AB and BC, hinged at B (see Fig. 2.1). The

end labelled A is fixed, preferably outside of the irregular area being

measured. Rod BC carries at B a wheel whose plane is at right angles to

the plane formed by ABC. Point C, called the tracer, is guided round the

boundary of the figure to be measured. The wheel is geared to a dial

which records the area directly. If the length BC is adjustable, the scale

can be altered and readings obtained in mm2, cm2, m2 and so on.

FIGURES 2.1 : Planimeter

(Source : Mathematics for

Technicians, S. Adam)

8

2.6.2 Trapezoidal rule

To find the area ABCD in Fig. 2.2, the base AD is divided into a number of

equal intervals of width d. This can be any number; the greater the

number the more accurate the result. The ordinates y1, y2, y3, etc. are

accurately measured. The approximation used in this rule is to assume

that each strip is equal to the area of a trapezium.

FIGURE 2.2 : Trapezoidal rule (Source : Mathematics for Technicians, S.

Adam)

The area of a trapezium = ½ (sum of the parallel sides) (perpendicular

distance between the parallel sides).

Hence for the first strip, shown in Fig. 2.2, the approximate area is ½ (y1 +

y2)d. For the second strip area is ½ (y1 + y2)d and so on. Hence the

approximate area of

ABCD = ½ (y1 + y2)d + ½ (y3 + y4)d + ½ (y3 + y4)d + ½ (y4 + y5)d

+ ½ (y5 + y6)d + ½ (y6 + y7)d

= ½ y1 d + ½ y2 d + ½ y2 d + ½ y3 d + ½ y3 d + ½ y4 d + ½ y4 d

+ ½ y5 d + ½ y5 d + ½ y6 d + ½ y6 d + ½ y7 d

= ½ y1 d + ½ y2 d + ½ y3 d + ½ y4 d + ½ y5 d + ½ y6 d + ½ y7 d

= d [ ( y1 + + y7 ) / 2 + y2 + y3 + y4 + y5 + y6 ]

Generally, the trapezoidal rule states that the area of an irregular figure is

given by:

9

Area = (width of internal) [½ (first + last ordinate) + sum of remaining

ordinates]

2.6.3 Mid-ordinate rule

FIGURE 2.3 : Mid-

ordinate rule method

(Source : Mathematics

for Technicians, S.

Adam)

To find the area of ABCD in Figure 2.3 the base AD is divided into any

number of equal strips of width d. (As with the trapezoidal rule, the greater

the number of intervals used the more accurate the result.) If each strip is

assumed to be a trapezium, then the average length of the two parallel

sides will be given by the length of a mid-ordinate, i.e. an ordinate erected

in the middle of each trapezium. This is the approximation used in the mid-

ordinate rule.

The mid-ordinates are labelled y1, y2, y3, etc. as in Fig. 18.3 and each is

then accurately measured. Hence the approximate area of ABCD

= y1 d + y2 d + y3 d + y4 d + y5 d + y6 d

= d (y1 + y2 + y3 + y4 + y5 + y6 )

where d = ( length of AD / number of mid-ordinates )

Generally, the mid-ordinate rule states that the area of an irregular figure

is given by:

Area = (width of interval) (sum of mid-ordinates)

10

2.6.4 Simpson’s rule

FIGURE 2.4 : Simpson’s rule (Source : Mathematics for Technicians, S.

Adam)

To find the circa A BCD in Figure 2.4 the base AD must be divided into an

even number of strips of equal width d. Thus producing an odd number of

ordinates. The length of each ordinate, y1, y2, y3, etc., is accurately

measured. Simpson's rule states that (the area of the irregular area ABCD

is given by;

Area of ABCD = d / 3 [(y1 + y7 ) + 4(y2 + y4 + y6) + 2(y3 + y5)]

More generally, the calculation of the area of:

Area = 1/3 (width of interval) [(first and last ordinates) + 4( sum of

even ordinates) + 2 (sum of remaining odd ordinates)]

When estimating areas of irregular figures, Simpson's rule is generally

regarded as the most accurate of the approximate methods available.

11

Activity 2a

2.1 The values of the y ordinates of a curve and their distance x from the

origin are given in the table below. Plot the graph and find the area under

the curve by :

x 0 1 2 3 4 5 6

y 2 5 8 11 14 17 20

a) The trapezoidal rule

b) The mid-ordinate rule

c) Simpson’s rule

2.2 Sketch a semicircle of radius 10cm. Erect ordinates at intervals of 2 cm

and determine the lengths of the ordinates and mid-ordinates. Determine

the area of the semicircle using the three approximate methods. Calculate

the true area of the semicircle.

12

Feedback 2a

2.1)

FIGURE 2.5 : Graph of y against x

a) Trapezoidal rule Using 7 ordinates with interval width of 1 the area under the curve is:

Area = 1 [ ½ (2 + 20) + 5 + 8 + 11 + 14 + 17 ]

= [ 11 + 5 + 8 + 11 + 14 + 17 ]

= 66 square units

13

b) Mid-ordinate rule

Using 6 intervals of width 1 the mid-ordinates of the 6 strips are measured.

The area under the curve is:

Area = 1 (3.5 + 6.5 + 9.5 + 12.5 + 15.5 + 18.5)

= 66 square unit

c) Simpson’s rule

Using 7 ordinates, given an even number of strips, i.e. 6, each of width 1, thus

the area under the curve is:

Area = 1 / 3 [ (2 + 20) + 4(5 + 11 + 17) + 2 (8 + 14) ]

= 1 / 3 [ 22 + 4(33) + 2(22)]

= 1 / 3 [ 22 + 132 + 44 ]

= 198 / 3

= 66 square units

The area under the curve is a trapezium and may be calculated using the formula

½(a+b)h, where a and b are the lengths of the parallel sides and h the

perpendicular distance between the parallel sides.

Hence area = ½(2 + 20)(6) = 66 square units. This problem demonstrates the

methods for finding areas under curves. Obviously the three 'approximate'

methods would not normally be used for an area such as in this problem since it is

not 'irregular'.

14

2.2). The semicircle is shown in Fig. 2.6 with the lengths of the ordinates and

mid-ordinates marked, the dimensions being in centimetres.

FIGURE 2.6 : Sketch a semicircle

a) Trapezoidal rule Area = 2 [ ½ (0 + 0) + 6.0 + 8.0 + 9.15 + 9.80 + 10.0 + 9.80 + 9.15 + 8.0 +

6.0 ]

= 2 (75.90)

= 151.8 square units

b) Mid-ordinate rule

Area = 2 [ 4.3 + 7.1 + 8.65 + 9.55 + 9.95 + 9.95 + 9.95 + 8.65 + 7.1 + 4.3 ]

= 2 (79.10)

= 158.2 square units

c) Simpson’s rule

Area = 2/3 [ (0 + 0) + 4(6.0 + 9.15 + 10.00 + 9.15 + 6.00) + 2(8.0 + 9.8 +

8.0)]

= 2/3 [0 + 4(40.3) + 2(35.6)]

= 2/3 (161.2 + 71.2)

= 2/3 (232.4)

= 154.9 square units

The true area is given by π r² / 2, i.e π (10)² / 2 = 157.1 square units

15

2.7 VOLUME CALCULATION

In construction works, the excavation, loading, hauling and dumping of earth

frequently forms a substantial part of the project. Payment must be made for the

labour and plan needed for earthworks and this is based on the quantity or

volume handled. These volumes must be calculated and depending on the shape

of the site, this may be done in three ways :

i) by cross-sections, generally used for long, narrow works such as roads,

railways, pipelines, etc.

ii) by contours, generally used for larger areas such as reservoirs,

landscapes, redevelopment sites, etc.

iii) by spot height, generally used for small areas such as underground tanks,

basements, building sites, etc.

2.8 CROSS SECTION VOLUME CALCULATION

Cross-sections are established at some convenient intervals along a centre line

of the works. Volumes are calculated by relating the cross-sectional areas to the

distances between them. In order to compute the volume it is first necessary to

evaluate the cross-sectional areas, which may be obtained by the following

methods:

i) by calculating from the formula or from first principles the standard cross-

sections of constant formation widths and side slopes.

ii) by measuring graphically from plotted cross-sections drawn to scale, areas

being obtained by plannimeter or division into triangles or square.

NOTE :

The graphic measure of the cross-sectional area is most often used and provides

a sufficiently accurate estimate of volume, but for railways, long embankments,

breakwaters, etc., with fairly regular dimensions, the use of formulae may be

easier and perhaps more accurate.

2.8.1 Prismoidal Method

In order to calculate the volume of a substance, its geometrical shape and

size must be known. A mass of earth has no regular geometrical figure in

most approaches. The prismoid is a solid, consisting of two ends which

16

form plane, parallel figures, not necessarily of the same number of sides

and which can be measured as cross-sections. The faces between the

parallel ends are plane surfaces between straight lines which join all the

corners of the two end faces. A prismoid can be considered to be made up

of a series of prisms, wedges and pyramids, all having a length equal to

the perpendicular distance between the parallel ends. The geometrical

solids forming the prismoid are described as follows :

i) Prism, in which the end polygons are equal and the side faces are

parallelograms.

ii) Wedge, in which one end is a line, the other end a parallelogram,

and the sides are triangles and parallelograms.

iii) Pyramids, in which one end is a point, the other end a polygon

and the side faces are triangles.

The Prismoidal Formula

Let D = the perpendicular distance between the parallel end

planes

A1 and A2 = the areas of these end planes

M = the mid-area, the area of the plane parallel to the end planes and midway between them,

V = the volume of the prismoid and

a1, a2, m, v = the equivalent for any prism, wedge or pyramid forming the prismoid

then in a prism a1, = a2, = m and in a wedge a2 = 0 and m = 1/2 a1

and in a pyramid a2 = 0 and m = 1/4 a1

Prism volume v = D . a1 = D/6 (6 . a1 ) = D/6 (a1, + 4m + a2) Wedge volume v = ½ D . a1 = D/6 (3 . a1 ) = D/6 (a1, + 4m + a2) Pyramid volume v = 1/3 D . a1 = D/6 (2 . a1 ) = D/6 (a1, + 4m + a2)

As the volume of each part can be expressed in the same terms, the

volume of the whole can take the same form. Thus the prismoidal formula

is expressed in the following way :

V = D/6 (A1, + 4M + A2)

17

Note :

A. M does not represent the mean of the end areas A1 and A2 except

where the prismoid is composed of prisms and wedges only.

B. The formula gives the volume of one prismoid of which the end and

mid-sectional areas are known.

The prismoidal formula may be used to calculate volume if a series of

cross-sectional areas, A1, A2, A3,…. An, have been established a

distance d apart. Each alternate cross-section may be considered to be

the mid-area M of a prismoid of length 2d.

Then the volume of the first prismoid of length 2d :

= 2d / 6 (A1, + 4A2 + A3)

and of the second = 2d / 6 (A3, + 4A4 + A5)

and of the nth = 2d / 6 (An-2, + 4An-1 + An)

summing up the volumes of each prismoidal :

V = d / 3 (A1, + 4A2 + 2A3 + 4A4…… + 2An-2 + 4An-1 + An)

Which is Simpson’s rule for volumes.

Specimen Question

Calculate, using the prismoidal formula, the cubic contents of an

embankment of which the cross-sectional areas at 15m intervals are as

follows :

Distance (m) 0 15 30 45 60 75 90

Area (m2) 11 42 64 72 160 180 220

Solution,

V = 15 / 3 (11 + 220 + 4 ( 42 + 72 + 180 ) + ( 64 + 160))

V = 5 ( 231 + 1176 + 448 )

V = 9275 m3

18

Note :

A. The 15m interval is divided by 3, as the length of the individual

prismoids used is 30m, which in the prismoidal formula is divided

by 6.

B. A mass of earth, length double the usual cross-sectional interval of

15m, 20m or 25m, is considerably different from a true prismoid, so

this method is not as accurate as it would be if the true mid-

sectional area had been measured. This results in the use of

prismoids of length equal to, instead of double, the interval between

cross-sections.

2.8.2 End Areas Method

It is no more accurate to use the prismoidal formula where the mid-

sectional areas have not been directly measured than it is to use the end

areas formula, particularly as the earth solid is not exactly represented by

a prismoid. Using the same symbols the volume may be expressed as :

v = d [ ( A1 + A2) / 2 ]

although this is only correct where the mid-area is the mean of the end

areas :

M = ( A1 + A2) / 2

However, in view of the inaccuracies that arise in assuming any

geometric shape between cross-sections and because of bulking and

settlement and the fact that the end areas calculation is simple to use, it is

generally used for most estimating purposes.

Note :

A. The summation of a series of cross-sectional areas by this method

provides a total volume :

V = d{[( A1 + A2) / 2 ] + A2 + A3 + …… An-1}

19

Specimen Question

Calculate, using the end areas method, the cubic contents of the

embankment of which the cross-sectional areas at 15m intervals are as

follows :

Distance (m) 0 15 30 45 60 75 90

Area (m2) 11 42 64 72 160 180 220

Solution

V = 15{[ (11 + 220) / 2 ] + 42 + 64 + 72 + 160 + 180 }

V = 9502.5 m3

2.9 VOLUME CALCULATION FOR CONTOUR LINES

Contour lines may be used for volume calculations and theoretically this is the

most accurate method. However, as the small contour interval necessary for

accurate work is seldom provided due to cost, high accuracy is not often

obtained. Unless the contour interval is less than 1m or 2m at the most, the

assumption that there is an even slope between the contour is incorrect and

volume calculation from contours become unreliable.

The formula used for volume calculation is the end areas formula of Simpson’s

rule for volumes, the distance d in the formula being contour interval. The area

enclosed by each contour line is measured, usually by plannimeter, and these

areas A1, A2, etc., are used in the formula as before ( see the end areas

method). If the prismoidal method is used, each alternate contour line is

assumed to enclose a mid-area or the outline of the mid-area can be interpolated

between the existing contour intervals.

This illustration shows an area contoured at 5m intervals and how the contours of

proposed works, in this case a dam wall with an access road through a cutting,

shown as packed lines, define the plan outline of the works. This also allows the

volume of the earthworks to be calculated using the positions of the contour

lines.

20

Picture 4.1 : Intersection Of Contoured Surfaces (Source : Land Survey,

Ramsay)

The volume of the dam wall and the amount of cut may be obtained from the

contour lines by calculating the volume of ground within the working area down to

a common level surface and then calculating the new volume from the formation

contour lines, the difference being the change in volume due to the works. This

volume calculation is more usually carried out by using the cross-sectional

method. The use of contours is a practical method of calculating volumes in

several cases, one of which being the calculation of water at various levels in a

reservoir. For example, in picture 4.1 the volume of water which could be

contained up to the level of the 60m, contours could be calculated as follows

from these data :

Contour above datum (m) 50 52.5 55 57.5 60

Area (m2) 12 135 660 1500 1950

Using the end areas method :

V = 2.5 { [ (12 + 1950)/2] + 135 + 660 + 1500 }

= 8190 m3

Using Simpson’s rule from the prismoidal formula :

21

V = ( 2.5 / 3 ) [ 12 + 1950 + 4(135 + 1500) + 2 (660) ]

= (2.5 / 3 ) (9822)

= 8185 m3

Note :

The small volume of water below 50m (not included in the above calculation)

would be estimated from the interpolated depth of 2m at the deepest point, using

the end areas formula, the lowest end area being 0, thus :

V = [ ( 12 + 0 ) / 2 ] x 2

V = 12m3

This would then be added to either of the results above.

2.10 VOLUME CALCULATION FROM SPOT HEIGHT

This is a method of volume calculation frequently used on excavations where

there are vertical sides covering a fairly large area, although it can be used for

excavation with sloping sides. The site is divided into squares or rectangles, and

if they are of equal size the calculations are simplified. The volumes are

calculated from the product of the mean length of the sides of each vertical

truncated prism ( a prism in which the base planes are not parallel ) and the

cross-sectional area. The sizes of the rectangles is dependent on the degree of

accuracy required. The aim is to produce areas such that the ground surface

within each can be assumed to be plane.

Specimen Question

Picture 4.2 shows the reduced levels of a rectangular plot which is to be

excavated to a uniform depth of 8m above datum. Calculate the mean level of

the ground and the volume of earth to be excavated.

Note :

a) The mean or average level of the ground is that level of ground which would

be achieved by smoothing the ground off level, assuming that no bulking

would take place.

b) The mean level of the ground is the mean of the mean height of each prism. It

is not the mean of all the spot heights.

22

Picture 4.2 : Calculating volume from spot height

on a levelling grid. (Source : Land Survey, Ramsay)

Solution

(a) Calculation from rectangles :

Station R.L.

Number of times the Product

R.L. is used = n (R.L.) x n A 12.16 1 12.16 B 12.48 2 24.96 C 13.01 1 13.01 D 12.56 2 25.12 E 12.87 4 51.48 F 13.53 2 27.06 G 12.94 1 12.94 H 13.27 2 26.54 J 13.84 1 13.84

∑n = 16 207.11

Mean level = 207.11 / 16

= 12.944 m

Depth of excavation = 12.944 – 8.00

= 4.944

Volume = Total area x Depth

= 30 x 20 x 4.944

= 2966.4 m3

23

(b) Calculation from triangles

It is usually more accurate to calculate from triangles as the upper base of the

triangular prism is more likely to correspond with the ground plane than the larger

rectangle. The mean level of each prism is then the mean of the three height

enclosing the triangle instead of four as before.

Station R.L. Number of times the Product

R.L. is used = n (R.L.) x n

A 12.16 1 12.16

B 12.48 3 37.44

C 13.01 2 26.02

D 12.56 3 37.44

E 12.87 7 90.09

F 13.53 2 27.06

G 12.94 2 25.88

H 13.27 2 26.54

J 13.84 2 27.68

∑n = 24 310.55

Mean level = 310.55 / 24

= 12.940 m

Depth of excavation = 4.960

Volume = 30 x 20 x 4.944

= 2966.4 m3

Note :

The diagonal forming the triangles would be noted in the field book on the grid

layout to conform most suitably with the ground planes.

24

Activity 2b

2.3) An embankment is to be formed with its centre line on the surface (in the

form of a plane) on full dip of 1 in 20. If the formation width is 12.00m and

the formation heights are 3.00m, 4.50m and 6.00m at intervals of 30.00m,

with side slopes 1 in 2, calculate the volume between the end sections.

Calculate

a). Volume by mean areas

b). Volume by end areas

c). Volume by prismoidal rule

2.3 Given the previous example but with the centre line turned through 90º,

calculate volume

a) By mean areas b) By end areas c) By prismoidal

25

Feedback 2b

2.3 Area (1) = h1 (w + mh1)

= 3.00 [ 12.00 + (2 x 3.00) ] = 54.00 m2

Area (2) = 4.50 [ 12.00 + (2 x 4.50) ] = 94.50 m2

Area (3) = 6.00 [ 12.00 + (2 x 6.00) ] = 144.00 m2

Volume :

a). By mean areas

V = W(A/n) = 60.00 ( 54.00 + 94.50 + 144.00 ) / 3

= 5850.0 m3

b). By end areas

V = w ( A1 + 2A2 + A3 ) / 2

= 30.00 (54.00 + 189.00 + 144.00) / 2

= 5805.0 m3

c). By Prismoidal Rule

V = w ( A1 + 4A2 + A3 ) / 3

= 30.00 (54.00 + 378.00 + 144.00)/3

= 5760.0 m3

2.4 A = m ( h²0 k² + w² / 4 + wh0 m) + wh0

( k² - m² )

Cross-sectional areas

A1 = 2 [ (3.00² x 20² ) + ( 0.25 x 12.00²) + ( 12.00 x 3.00 x 2 ) + (12 x 3.00) ( 20² - 2² ) = [ (3600.00 + 36.00 + 72.00) / 198 ] + 36.00 = 54.73 m² A2 = [ ( 8100.00 + 36.00 + 108.00 ) / 198 ] + 54.00 = 95.64 m² A3 = [ ( 14400.00 + 36.00 + 144.00 ) / 198 ] + 72.00 = 145.64 m²

26

Volume a). By mean areas V = 60.00 ( 54.00 + 95.64 + 145.64 ) / 3 = 5920.2 m³ b). By end areas V = 30.00 ( 54.73 + 191.28 + 145.64 ) / 2 = 5874.8 m³ c). By prismoidal rule V = 30.00 ( 54.73 + 382.56 + 145.64 ) / 3 = 5829.3 m³

Self Assessment

Calculate the volumes in Figure 1 and Figure 2.

Figure 1

Figure 2

27

Feedback to Self Assessment

Figure 1

A1 = [ ( 0.75 + 4.75 ) / 2 ] x 7 = 19.25 ft²

A2 = [ ( 0.75 + 3.75 ) / 2 ] x 5 = 11.25 ft²

A3 = [ ( 0.75 + 2.75 ) / 2 ] x 3 = 5.25 ft²

Volume, V = L / 6 ( A1 + 4Am + A2 )

= 17 / 6 (19.25 + 4 x 11.25 + 5.25)

= 17 / 6 ( 19.25 + 45.00 + 5.25 )

= 17 / 6 ( 69.50 )

= 1181.50 / 6

= 196.92 ft³

= 7.29 yrd³

Figure 2

Volume, V = h / 3 ( area of base )

= 27.4 / 3 ( 13.5 x 13.5 )

= 1664.6 m³

28

MASS HAUL DIAGRAM

3.1 INTRODUCTION

Mass-haul diagrams (MHD) are used to compare the economics of the various

methods of earthwork distribution on road or railway construction schemes. With

the combined use of the MHD plotted directly below the longitudinal section of

the survey centre-line, one can find :

i. The distances over which ‘cut and fill’ will balance.

ii. Quantities of materials to be moved and the direction of movement.

iii. Areas where earth may have to be borrowed or wasted and the amounts

involved.

iv. The best policy to adopt to obtain the most economic use of plan.

3.2 DEFINITION AND IMPORTANT PHRASES

Bulking An increase in volume of earthwork after excavation

Shrinkage A decrease in volume earthwork after deposition and

compaction.

Haul distance (d) The distance from the working face of the excavation to

the tipping point.

Average haul distance

(D)

The distance from the centre of gravity of the cutting to

that of the filling.

Freehaul Distance The distance, given in the Bill of Quantities, included in

the price of excavation per cubic metre.

Overhaul Distance The extra distance of transport of earthwork volumes

beyond the freehaul distance.

Haul

The sum of the product of each load by its haul

distance. This must equal the total volume of excavation

multiplied by the average haul distance, i.e. ∑ vd = VD

Overhaul The product of volumes by their respective overhaul

distance. Excess payment will depend upon overhaul.

Station Metre A unit of overhaul, viz. 1 m3 x 100 m.

Borrow The volume of material brought into a section due to a

deficiency.

Waste The volume of material taken from a section due to

excess

29

Figure 3.1 : Mass-haul diagram (Source : Land Survey, Ramsay)

Figure 3.2 : Freehaul and Overhaul (Source : Land Survey, Ramsay)

30

3.3 CONSTRUCTION OF THE MASS-HAUL DIAGRAM

Volumes of cut and fill along a length of proposed road are as follows :

Volume

Chainage Cut Fill 0

100 290 200 760 300 1680 400 620 480 120 500 20 600 110 700 350 800 600 900 780

1000 690 1100 400 1200 120

Draw a mass-haul diagram and exclude the surplus excavated material along

this length. Determine the overhaul if the freehaul distance is 300 m.

Volume Aggregate Chainage Cut Fill volume

0 100 290 + 290 200 760 + 1050 300 1680 + 2730 400 620 + 3350 480 120 + 3470 500 20 + 3450 600 110 + 3340 700 350 + 2990 800 600 + 2390 900 780 + 1610

1000 690 + 920 1100 400 + 520 1200 120 + 400

3470 3070 3070

check 400

31

Figure 3.3 : Mass-haul diagram (Source : Land Survey, Ramsay)

Graphical Method (figure 3.3)

i. As the surplus of 400 m³ is to be neglected, the balancing line is drawn

from the end of the mass-haul curve, parallel to the base line, to form a

new balancing line ab.

ii. As the freehaul distance is 300 m, this is drawn as a balancing line cd.

iii. From c and d, draw ordinates cutting the new base line at c1d1.

iv. To find the overhaul :

a) Bisect cc1, to give c2 and draw a line through c2 parallel to the base

line cutting the curve at e and f, which now represent the centroids

of the masses acc1 and dbd1.

b) The average haul distance is the centroids of the masses acc1 and

dbd1.

c) The overhaul distance = the haul distance – the free haul distance

Planimetric method

Distance to centroid = haul / volume

= (area x horizontal scale x vertical scale) / volume ordinate

from area acc1

area scaled from mass-haul curve = 0.9375 cm²

horizontal scale = 1 cm = 200 cm

vertical scale = 1 cm = 1600 cm³

Therefore

32

haul = 0.9375 x 200 x 1600 = 300 000

volume (ordinate acc1 ) = 2750

distance to centroid = 300 000 / 2750 = 109.1 m

chainage of centroid = 350 – 109.1 = 240.9 m

for area dbd1

area scaled = 1.9688 cm²

Therefore

haul = 1.9688 x 320 000 = 630 016

volume (ordinate dd1 ) = 2750

distance to centroid = 229.1 m

chainage of centroid = 650 + 229.1 = 879.1 m

average haul distance = 879.1 -240.9 = 638.2 m

overhaul distance = 638.2 – 300 = 338.2 m

Therefore

overhaul = 338.2 x 2750 = 9300 station metres

Instead of the above calculations, the overhaul can be obtained direct, as the

sum of the two mass-haul curve areas acc1 and dbd1 is:

Area acc1 = (302 950) / 100 station metre

Area dbd1 = (634 950) / 100 station metre

Total area = overhaul = (936 900) / 9369 station

metre

Proof :

Take any cutoff by a balancing line, Figure 5.4. Let a small increment of area δ A

= (say) 1 m³ and length of haul be L. Then

δA = 1 m³ x L / 100 station metre

Therefore

A = n x 1 m³ x ( ∑L / n )

= total volume x average haul distance

Therefore, Area = total haul

33

Activity 3a

3.1 Below are the definitions used in this unit. Fill in the blank with the

appropriate terms.

an increase in volume of earthwork after

excavation

a decrease in volume earthwork after

deposition and compaction.

the distance from the working face of the

excavation to the tipping point.

the distance from the centre of gravity of

the cutting to that of the filling.

the distance, given in the Bill of quantities,

included in the price of excavation per

cubic metre.

the extra distance of transport of earthwork

volumes beyond the freehaul distance.

the sum of the product od each load by its

haul distance. This must equal the total

volume of excavation multiplied by the

average haul distance, i.e. ∑ vd = VD

the product of volumes by their respective

overhaul distance. Excess payment will

depend upon overhaul.

a unit of overhaul, viz. 1 m3 x 100 m.

the volume of material brought into a

section due to a deficiency

the volume of material taken from a section

due to excess

34

Feedback 3a

3.1).

an increase in volume of earthwork after

excavation

a decrease in volume earthwork after deposition

and compaction.

the distance from the working face of the

excavation to the tipping point.

the distance from the centre of gravity of the

cutting to that of the filling.

the distance, given in the Bill of quantities,

included in the price of excavation per cubic

metre.

the extra distance of transport of earthwork

volumes beyond the freehaul distance.

the sum of the product of each load by its haul

distance. this must equal the total volume of

excavation multiplied by the average haul

distance, i.e. ∑ vd = VD

the product of volumes by their respective

overhaul distance. excess payment will depend

upon overhaul.

a unit of overhaul, viz. 1 m3 x 100 m.

the volume of material brought into a section

due to a deficiency

the volume of material taken from a section due

to excess

Station Metre

Borrow

Waste

Bulking

Shrinkage

Haul Distance (d)

Overhaul

Haul

Overhaul Distance

Freehaul Distance

Average Haul

Distance

35

Self Assessment

The table shows the stations and the surface levels along the centre-line, the formation level being at an elevation above datum of 43.5 m at chainage 70 and thence rising uniformly on a gradient of 1.2%. The volumes are recorded in m³, the cuts are plus and fills minus.

Chn Surface Vol Chn Surface Vol Chn Surface Vol Level Level Level

70 52.8 74 44.7 78 49.5 +1860 -1080 -237

71 57.3 75 39.7 79 54.3 +1525 -2025 +362

72 53.4 76 37.5 80 60.9 +547 -2110 +724

73 47.1 77 41.5 81 62.1 -238 -1120 +430

74 44.7 78 49.5 82 78.5

1) Plot the longitudinal section using a horizontal scale of 1 : 1200 and a vertical scale of 1 : 240.

2) Assuming a correction factor of 0.8 applicable to fills, plot the MHD to a

vertical scale of 1000 m3 to 20 mm.

3) Calculate total haul in stn. m and indicate the haul limits on the curve and section.

4) State which of the following estimates you would recommend.

a) No freehaul at 35 p per m³ for excavating, hauling and filling b) A freehaul distance of 300 m at 30 p per m³ plus 2 p per stn m for

overhaul.

36

Feedback to Self Assessment

1) The volume at chainage 70 is zero 2) The mass ordinates are always plotted at the station and not between

them. 3) The mass ordinates are now plotted to the same horizontal scale as

the longitudinal section and directly below it. 4) Check that maximum and minimum points on the MHD are directly

below grade points on the section. 5) Using the datum line as a balancing line indicates a balancing out of

the volumes from chainage 70 to XY and from XY to chainage 82.

Total haul (taking each loop separately) = total volume x total haul distance. The total haul distance is from the centroid of the total cut to that of the total fill and is found by bisecting AB and A’B’, to give the distances CD and C’ D’. Total haul = ( AB x CD ) / 100 + ( A’ B’ x C’D’ ) / 100 = ( 3932 x 450 ) / 100 + ( 1516 x 320 ) / 100 = 22 545 stn m

37

a) If there is no freehaul, then all the volume is moved regardless of distance for 35 p per m³.

Estimate costs : ( AB + A’ B’ ) x 35 p = 5448 x 35 = 190 680 p

b) The purpose of plotting the free haul distance on the curve is to assess the overhaul.

From MHD : Cost of freehaul = (AB + A’B’) x 30 p per m³ = 163 440 p Cost of overhaul = [ EG ( JK – EF ) / 100 + E’G’ (J’K’ – E’F’) / 100 ] x 2p = 13 628 p Total cost = 163 440 + 13 628 = 177 068 p The second estimate is cheaper by 13 612 p = £136.12 All the dimensions in the above solution are scaled from the MHD

38

CURVES

4.1 INTRODUCTION

In the geometric design of motorways, railways and pipelines, the design and setting out of

curves is an important aspect of an engineer’s work. The initial design is usually based on a

series of straight sections whose positions are defined largely by the topography of the area. The

intersections of pairs of straights are then connected by horizontal curves. In the vertical design,

intersecting gradients are connected by curves in the vertical plane. Curves can be listed under

three main headings as follows:

1. Circular curve of constant radius

2. Transition curves of varying curves (spirals)

3. Vertical curves.

4.2 CIRCULAR CURVES

Horizontal, circular or simple curves are curves of constant radius required to connect two

straights set out on the ground. Such curves are required for roads, railways, kerb lines, pipe

lines and may be set out in several ways, depending on their length and radius. Figure 4.1

illustrates how two tangents are joined by a circular curve and shows some related circular curve

terminology. The point at which the alignment changes from straight to circular is known as the

BC (beginning of curve).The BC is located at a distance T (sub tangent) from PI (Point of tangent

intersection).

The length of a circular curve (L) is dependent on the central angle (∆) and the value of R

(radius). The tangent deflection angle (∆) is equal to the curve’s central angle (Figure 4.2). The

point at which the alignment changes from circular back to tangent is known as the EC (end of

curve). Since the curve is symmetrical about the PI, the EC is also located at distance T from the

PI. From a study of geometry, we recall that the radius of a circle is perpendicular to the tangent

at the point of tangency. Therefore, the radius is perpendicular to the back tangent at the BC and

to the forward tangent at the EC. The terms BC and EC are also referred to by some agencies as

PC (point of curve) and PT (point of tangency) and by others as TC(tangent to curve) and

CT(curve to tangent).

39

Figure 4.1 Circular Curve Terminologies

(Source: Surveying With Construction Application, B.F. Kavanagh)

4.2.1 Circular Curve Geometry

Most curve problems are calculated from field measurements (∆ and the chainage of PI) and from

design parameters(R). Given R (which is dependent on the design speed) and ∆, all other curve

components can be computed. An analysis of Figure 4.2 will show that the curve deflection angle

(PI, BC, EC) is ∆/2 and that the central angle at O is equal to ∆, the tangent deflection. The line

(O-PI), joining the centre of the curve to the PI, effectively bisects all related lines and angles.

a) Tangent:

In Triangle BC, O, PI,

2tan

2tan

RT

R

T

b) Chord :

In triangle BC, O, B

40

2sin2

2sin2

1

RC

R

C

c) Mid- ordinate:

2cos

2cos

ROB

R

OB

but OB = R- M

2cos1

2 cos R M - R

RM

d) External:

In triangle BC, O, PI

O to PI = R + E

12

sec

1

2cos

1

2cos

R

RE

ER

R

41

Figure 4.2 Geometry Of The Circle.

(Source: Surveying With Construction Application, B.F. Kavanagh)

e) Arc:(Figure 4.3)

3602

3602

RL

R

L

where is expressed in degrees and decimals of a degree.

Figure 4.3 Relationship Between The Degree Of Curve (D) And The Circle.

(Source: Surveying With Construction Application, B.F. Kavanagh)

The sharpness of the curves is determined by the choice of the radius R; large

42

radius curves are relatively flat, whereas small radius curves are relatively sharp.

D is defined to be that central angle subtended by 100 ft of arc. (in railway

designs, D is defined to be that central angle subtended by 100 ft of chord.)

From Figure 4.3, D and R:

RD

R

D

58.5729

2

100

360

Arc:

DL

D

L

100

100

f) Deflection angle

Figure 4.4 Deflection angle.

(Source: Land Surveying, Ramsay J.P. Wilson)

In ∆ T1AO, curve T1A = R x 21

Curve T1A = Chord T1A

1(rad) = Curve T1A / 2R

= Chord T1A

1(minutes) = (Curve T1A x 180 x 60) / 2R

= (1718.9 x chord T1A) / R

EXAMPLE 4a

43

Refer to Figure 4.5, Given ∆ = 16 ° 38’

R = 1000 ft and PI at 6 + 26.57, calculate the

station of the BC and EC. Calculate also

lengths C, M and E.

SOLUTION:

ft

RT

18.146

'198tan1000

2tan

ft

RL

31.290

360

6333.1610002

3602

PI at 6 + 26.57

-T 1 46.18

BC = 4 + 80.39

+L 290.31

EC = 7 + 70.70

Figure 4.5 (Source: Surveying With

Construction Application, B.F.

Kavanagh)

44

ft

RE

ft

RM

ft

RC

63.10

)1'198(sec1000

12

sec

52.10

)'198cos1(1000

2cos1

29.289

'198sin10002

2sin2

4.2.2 Compound Circular Curves

A compound circular curves are curves formed when of two (usually) or more circular arcs

between two main tangents turn in the same direction and join at common tangent points. Figure

6.4 shows a compound curve consisting of two circular arcs joined at a point of compound curve

(PCC). The lower chainage curve is number 1, whereas the higher chainage curve is number 2.

The parameters are R1, R2, ∆1, ∆2 (∆1 + ∆2 = ∆), T1 and T2. If four of these six or seven

parameters are known, the others can be solved. Under normal circumstances, ∆1, ∆2, or ∆, are

measured in the field, and R1 and R2 are given by design considerations, with minimum values

governed by design speed.

Although compound curves can be manipulated to provide practically any vehicle

path desired by the designer, they are not employed where simple or spiral

curves can be used to achieve the same desired effect. Practically, compound

curves are reserved for those applications where design constraints (topographic

or cost of land) preclude the use of simple or spiral curves, and they are now

usually found chiefly in the design of interchange loops and ramps. Smooth

driving characteristics required that the larger radius be more than 1-1/3 times

larger than the smaller radius (this ratio increases to 1-1/2 when dealing with

interchange curves).

Solutions to compound curve problems vary, as several possibilities exist as to which of the data

are known in any one given problem. All problems can be solved by use of the sine law or cosine

law or by the omitted measurement traverse technique. If the omitted measurement traverse

technique is used, the problem becomes a five-sided traverse (Figure 4.6) with sides R1, T1, R2

45

and (R1- R2) and with angles 90°, 180° - ∆° + 90°, 180°+ ∆2° and ∆1°. An assumed azimuth that

will simplify the computations can be chosen.

Figure 4.6 Compound Circular Curves

(Source: Surveying With Construction Application, B.F. Kavanagh)

4.3 Reverse Curves

Reverse curves are seldom used in highway or railway alignment. The instantaneous change in

direction occurring at the point reverse curve (PRC) would cause discomfort and safety problems

for all but the slowest of speeds. Additionally, since the change in curvature is instantaneous,

there is no room to provide super elevation transition from cross-slope right to cross-slope left.

However, reverse curves can be used to advantage where the instantaneous change in direction

poses no threat to safety or comfort.

The reverse curve is particularly pleasing to the eye and is used with great success on park

roads, form paths, waterway channels, and the like. The curve can be encountered in both

situations illustrated in Figure 4.7 a. and b. the parallel tangent application is particularly common

(R1 is often equal to R2). As with compound curves, reverse curves have six independent

parameters ( R1, ∆1, T1, R2, ∆2, T2); the solution technique depends on which parameters are

unknown, and the techniques noted for compound curves will also provide the solution to reverse

curve problems.

46

Figure 4.7 Reverse Curves (a-Non parallel curve, b- Parallel tangents)

(Source: Surveying With Construction Application, B.F. Kavanagh)

4.4 Transition Curves

The centrifugal force acting on a vehicle as it moves along a curve increases as

the radius of the curve decreases. A vehicle moving from the straight with no

centrifugal force acting upon it, into a curve would suddenly receive the

maximum amount of centrifugal force for that radius of curve. To prevent this

sudden lateral shock on passengers in the vehicle, a transition curve is inserted

between the straight circular curve

(Figure 4.8). The transition curve is a curve of constantly changing radius. The

radius (R) of transition curves varies from infinity at its tangent with the straight to

a minimum at its tangent point with the circular curve. The centrifugal force thus

builds up gradually to its maximum amount.

47

Figure 4.8 The Transition Curves.

(Source: Land Surveying, Ramsay J.P. Wilson)

The purpose of a transition curve then is to achieve a gradual change of direction from the

straight (radius ∞) to the curve (radius R) and permit the gradual application of super-elevation to

counteract centrifugal force.

The central fugal force tending to thrust a vehicle sideways on a curve is resisted by the friction

between the wheels and the surface. If the outer edge of the surface is raised or super elevated,

the resultant forces tend to reduce the frictional force necessary to hold the vehicle on the

surface. At a particular slope the frictional force necessary can be eliminated by the formula

below:

2

tangR

v

where v is the velocity and g is the acceleration due to gravity. As vehicle speeds vary, the

fractional resistance is always necessary and a vehicle may stop on the curve. The super

elevation must not be too great.

4.4.1 Spiral Curve and Composite Curve

A spiral is a curve with a uniformly changing radius. Spirals are used in highway

and railroad alignment changes from tangent to circular curves, and vice versa.

The length of the spiral curve is also used for transition from normally crowned

pavement to fully superelevated pavement.

S = shift

48

Figure 4.9 shows how the spiral curve is inserted between tangent and

circular curve alignment. It can be seen that at the beginning of the spiral

(T.S. = tangent to spiral) the radius of the spiral is the radius of the tangent

line (infinitely large) and that the radius of the spiral curve decreases at a

uniform rate until, at the point where the circular curve begins (S.C = spiral

to curve) the radius of the spiral equals the radius of the circular curve.

The spiral curve, used in horizontal alignment, has a uniform rate of

change of radius (curvature). This property permits the driver to leave a

tangent section of highway at a relatively high rate of speed without

experiencing problems with safety or comfort.

A composite curve is a curve that forms by combination of two transition curves or through

combination of two transition curves and a circular curve.

Figure 4.9 Spiral Curves

(Source: Surveying With Construction Application, B.F. Kavanagh)

4.5 Vertical Curves

Vertical curves are used in highway and street vertical alignments to provide a

gradual change between two adjacent grade lines. Some highway and municipal

agencies introduce vertical curves at every change in grade-line slope, whereas

other agencies introduce vertical curves into alignment only when the net change

in slope direction exceeds a specific value (for example 1.5% or 2%).

In Figure 4.10, g1 is the slope of the lower chainage grade line, g2 is the slope of

the higher chainage grade line, BVC is the beginning of the vertical curve, EVC is

the end of the vertical line, and PVI is the point of intersection of the two adjacent

49

grade lines. The length of vertical curve (L) is the projection of the curve onto a

horizontal surface and, as such, corresponds to plan distances.

The algebraic change in slope direction is A, where A = g2 – g1.

Example 4b:

g1 = +1.5% and g2= -3.2%

A = g2 – g1

= -3.2-1.5

= -4.7

The geometric curve used in vertical alignment designs is the vertical axis parabola. The parabola

has the desirable characteristics of

(1) a constant rate of change of slope, which contributes to smooth alignment

transition,

(2) ease of computation of vertical offsets, which permits easily computed curve

elevations

Figure 4.10 Vertical Curves (Profile View Shown)

(Source: Surveying With Construction Application, B.F. Kavanagh)

The origin of the axes is placed at the BVC (Figure 4.11), the general equation becomes y = ax2 +

bx, and because the slope at the origin is g1, the expression for slope of the curve at point

becomes

slopedx

dy

= 2ax + g1

The general equation can finally be written as y = ax2 + g1x

50

Figure 4.11 Types of Vertical Curve

(Source: Surveying With Construction Application, B.F. Kavanagh)

Activity 4a

4.1 Fill in the blanks with related circular curve terminology.

51

Figure 1

4.2 Solve the puzzle by using the clues as shown below.

Horizontal:

1) The __________ curve is a curve of constantly changing radius.

2) __________ curves are used in highway and street vertical alignment to provide a gradual change

between two adjacent grade lines.

3) __________ curves are curves of constant radius required to connect two straights set out on the

ground.

4) Circular curve is also known as ____________ curves.

Vertical:

5) The ________curves can be encountered in both situations which are a non parallel curve and

parallel tangents.

1 5

7

2

6

3

4

A

B

C

D B

B

E

H B

B

G B

B F B

B

I B

B J B

B

52

6) A _______ curve of two (usually) or more circular arcs between two main

tangents turning in the same direction and joining at common tangent points.

7) A ________ is a curve with a uniformly changing radius.

Feedback 4a

4.1

Figure 1

A – Back tangent

B – Point of intersection

C – Deflection angle

D – Radius

E – Mid ordinate

F – Long chord

G – Sub tangent

H – End of Curve

I – External

J – Length of curve

4.2

53

4.6 SETTING OUT CURVES

This is the process of establishing the centre-line of the curve on the ground by means of pegs at

10m to 30m intervals. In order to do this, the tangent and intersection points must be first fixed in

the ground in their correct positions.

The straights OI1, I1I2, I2I3,etc., will have been designed on the plan in the first instance(Figure

4.12). Using railway curves, appropriate curves will now be designed to connect the straights.

The tangent points of these curves will then be fixed making sure that the tangent lengths are

equal, i.e. T1 I1 = T2I1 and T3 I2 = T4I2. The coordinates of the origin, point O, and all the

intersection points will only now be carefully scaled from the plan. Using these coordinates, the

bearings of the straights are computed and using the tangent lengths on these bearings, the

coordinates of the tangent points are also computed. The difference of the bearings of the

straights provides the deflection angles(Δ) of the curves which, combined with the tangent length,

enables computation of the curve radius, through chainage and all-setting-out data. Now the

tangent and intersection points are set out from existing control survey stations and the curves

ranged between them using the methods detailed below.

Figure 4.12 Curve Setting Out

(Source: Engineering Surveying, W.Schofield)

1T

5R A N S I T I O N

7S E

P 2V E R T I

6C A L

I E O 3C I R C U L A R M

A S P

L E O

U

4H O R I Z O N T A L

D

54

4.6.1 Setting Out By Offsets With Tangent Angle Method The following methods of setting out curves is the most popular and it is called Rankine’s

deflection or tangential angle method, the latter term being more definitive.

In figure 4.13, the curve is established by a series of chords T1X, XY, etc. Thus, peg 1 at X is

fixed by sighting to I with the theodolite reading zero, turning off the angle 1 and measuring out

the chord length T1 X along this line. Setting the instrument to read the second deflection angle

gives the direction T1 Y, and peg 2 is fixed by measuring the chord length XY from until it

intersects at Y. The procedure is now continued, the angles being set out from T1 I and the

chords measured from the previous station. It is thus necessary to be able to calculate the setting

out angles as follows:

Assume OA bisects the chord T1 X at right-angles, then

Angle AT1 O =90°- 1 , but angle IT1 =90°

angle IT1A= 1

By radians arc length T1X= R21

1 rad = (arc T1X /2R) (Chord T1X / 2R)

1min = (chord T1X x 180º x 60) /2Rπ

= 1718.9(Chord / R)

or º = (Dº x Chord ) / 200 where degree of curve is used.

Figure 4.13 Tangent Angle Method (Source: Engineering Surveying, W.Schofield)

Example 4c:

The centre-line of two straights is projected forward to meet at I, the deflection angle being 30°. If

the straights are to be connected by a circular curve of radius 200 m, tabulate all the setting-out

data, assuming 20-m chords on a through chainage basis, the chainage of I being 2259.59 m.

Solution:

55

Tangent length = R tan Δ/2

= 200 tan 15°

= 53.59 m

Chainage of T1 = 2255.59 - 53.59

= 2206 m

1st sub-chord = 14 m

Length of circular arc = RΔ = 200(30°) rad = 104.72 m

From which the number of chords may now be deduced

1st sub-chord = 14 m

2nd, 3rd, 4th, 5th chords = 20 m each

Final sub-chord = 10.72 m

Total = 104.72 m {Check}

Chainage of T2; = 2206 m + 104.72 m = 2310.72 m

Deflection angles:

For 1st sub-chord = 1718.9 (14/200) = 120.3 min = 2° 00' 19"

Standard chord = 1718.9 (20/200) = 171.9 min = 2° 51' 53"

Final sub-chord = 1718.9 (10.72 /200) = 92.1 min = 1° 32' 08"

Check: The sum of the deflection angles = Δ/2 = 14° 59' 59" 15°

The error of 1" is, in this case, due to the rounding-off of the angles to the nearest second and is negligible.

4.6.2 Setting Out By Offset From The Tangent

The position of the curve (in Figure 4.14) is located by right-angled offsets Y set out from

distances X, measured along each tangent, thereby fixing half the curve from each side. The

offsets may be calculated as follows for a given distance X. Consider offset Y3, for example.

In ΔABO,

AO2 = OB

2 - AB

2

(R-Y3)2= R

2 – X3

2

and Y3=R-(R2-X3

2)½

Chord number

Chord length (m)

Chainage (m)

Deflection angle o , „

Setting-out angle

o , „

Remarks

1 14 2220.00 2 00 19 2 00 19 peg 1

2 20 2240.00 2 51 53 4 52 12 peg 2

3 20 2260.00 2 51 53 7 44 05 peg 3

4 20 2280.00 2 51 53 10 35 58 peg 4

5 20 2300.00 2 51 53 13 27 51 peg 5

6 10.72 2310.72 1 32 08 14 59 59 peg 6

56

thus for any offset Yi, at distance Xi, along the tangent

Yi = R - (R2 - Xi

2) ½

Figure 4.14 Setting Out By Offset From Tangent (Source: Engineering Surveying, W.Schofield)

4.6.3 Setting Out By Offset With Sub-Chords

In Figure 4.15 assume T1A is a sub-chord of length x, from equation

Offset CA = (½ chord x chord) / Radius = (chord2)/2R, the offset CA = O1 == X

2 / 2R.

As the normal chord AB differs in length from T1A, the angle subtended at the centre will be 2θ

not 2. Thus, the offset DB will not in this case equal 2CA.

Construct a tangent through point A, then from the figure it is obvious that angle EAB = θ, and if

chord AB = y, then offset EB = y2 / 2R.

Angle DAE = , therefore offset DE will be directly proportional to the chord length, thus:

DE = (O1 / x) y = (x

2 y)2Rx = (xy)/ 2R

Thus the total offset DB = DE + EB

= ( y / 2R) (x +y)

= (Chord / 2R) (sub-chord + chord)

Thus having fixed B, the remaining offsets to T2; are calculated as y2/R and set out in the usual

way.

If the final chord is a sub-chord of length x1, however, then the offset will be

(x1/ 2R)((x1 + y)

A more practical approach to this problem is actually to establish the tangent through A in the

field. This is done by swinging an arc of radius equal to CA,

57

i.e. x2 / 2R from Ti. A line tangential to the arc and passing through peg A will then be the

required tangent from which offset EB, i.e. y2/lR, may be set off.

Figure 4.15 Setting Out By Offset With Sub-chords

(Source: Engineering Surveying, W.Schofield)

4.6.4 Setting Out By Offset With Long-Chords

In this case (Figure 4.16) the right-angled offsets Y are set off from the long chord C, at distances

X to each side of the centre offset Y0.

An examination of Figure 6.16 shows the central offset Y0 equivalent to the distance T1A on

Figure 6.14, thus:

Yo = R –[R2 - (C/2)

2]1/2

Similarly, DB is equivalent to DB on Figure 6.14, thus:

DB=R-(R2 – X1

2) 1/2

and offset Y1, = Y0 - DB

:. Y1 = Y0- [R - (R2 - X1

2)'/

2]

and for any offset Yi, at distance Xi, each side of the mid-point of T1 T2,:

Y1, = Y0 - [R - (R2 - X

2)]

1/2

58

Figure 4.16 Setting Out By Offset With Long-chords

(Source: Engineering Surveying, W.Schofield)

4.7 Setting Out A Circular Curve.

Circular curves may be set out in a variety of ways, depending on the accuracy required, its

radius of curvature and obstructions on site. Methods of setting out are as follows:

Using one theodolite and a tape by the tangent angle method. This method can be used

on all curves, but is necessary for long curves of radius unless they are set out by

coordinates.

Using two theodolites. This method can be used on smaller curves where the whole

length is visible from both tangent points and where two instruments are available.

Using tapes only by the method of offsets from the tangent. This method is used for

minor curves only.

Using tapes only by the method of offsets from the long chord. This method is used for

short radius curves.

Normally, a circular curve is set up by using a theodolite and a tape (tangent angle method).

Before the curve can be set out the tangent points must be located on the ground. For any

particular pair of straights there is only one point on each straight for a curve of given radius or

degree to leave the first tangentially in order to join the other tangentially. These tangent points

cannot be scaled off a plan with sufficient accuracy and they must be located by field

observations. The tangent points are represented in Figure 4.17 by the points A and B. The

method of locating these tangent points is summarised in (a) to (h) as follows:

a) Set up the theodolite near A and extend straight towards P.

b) Set up on the straight BF and produce it to meet the line at P.

c) Mark the intersection of tangents at P.

d) Measure angle EPF and obtain angle θ.

e) Calculate tangent length PA by using the formula T = R tan ´θ.

f) Place pegs at A and B on the lines. (From P measure the lengths PA and PB = T and line

in the points A and B on the straights with the theodolite still set up at P. Mark the pegs at

A and B distinctively representing tangent points. This can be done by painting the peg or

by placing three pegs, the centre peg representing the tangent point.)

g) Set up at A and measure angle PAB, which should equal ´θ.

59

h) Complete the chaining of the first straight to A.

NOTE :

(i) The chaining of the first straight is completed by measuring the distance from the last chain

peg and noting the actual chainage of the tangent point A.

ii) In many cases the intersection points P may have been previously marked on the ground. In

such cases the field work consists of pegging the straights and measuring θ without having to

locate the intersection by the method described above.

After the tangent points have been pegged as described above, the points on the curve must be

located. The interval between chainage pegs on the curve should be measured along the actual

arc. As chords are used in locating the pegs, the difference in length should be calculated strictly

as they are slightly shorter than the arc distances. This would be done in precise work, e.g.

underground railways. In most practical cases where R exceeds twenty times the chord length

this difference is negligible. The tangent point A will seldom fall exactly at a peg interval. Since

the chainage must be continuous, the chord AG to the first point on the curve may be shorter than

the regular chord length which is c, usually equal to the peg interval or half the peg interval if

additional pegs are needed to mark the curve clearly on the ground. There will generally also be a

sub-chord at the end of the curve. Let these

sub-chord lengths be denoted by c' and c".

The method of locating the points on the curve is summarised in (a) to (k} as follows:

a) Obtain the first sub-chord c' = c — EA.

Assuming E is the position of the last chainage peg on the straight, then EA + c’ =c and as EA

has been measured and c is known, the length of the sub-chord can be obtained.

b) Calculate for chord length c.

This can be calculated from sin = (c/2R) or = 1718.9 ( c/R) minutes.

c) Calculate ’ for the first sub-chord.

This can be calculated in the same way as for , but for flat curves it can be obtained with

sufficient accuracy from ’ = (c’ /c)

d) Calculate the final sub-chord and its ".

Calculate from θ and the radius the length of the curve (L= Rθ). Then the chainage of A + L =:

chainage of B. The amount, by which the chainage of B exceeds and exact number of peg

intervals, plus the initial sub-chord, is the length of the end sub-chord c".

e) Draw up a table of deflection angles to the various points.

i) This will take the following form:

1st deflection angle to G = (c’/c) = ”

60

2nd deflection angle to H = ’ +

3rd deflection angle to K = ’+ + .

ii) The final deflection angle to tangent point B must equal ´θ, allowance being made for

the sub-chords,

i.e. ´θ = ' + + + . . . + ".

f) From A set out ’for the line AG.

The instrument is set up at A and P is sighted at a reading of 0° 00' 00" and the horizontal circle is

clamped with the lower clamp. The first deflection angle ’ is set on the vernier or optical

micrometer using the upper clamp and tangent screw only, so that the line of sight is along AG.

g) Place G a distance of c' m from A on line AG.

The zero of the tape is held at A and the distances marked with a peg, which is then moved on to

the line AG as defined by the theodolite sighting.

h) From A set out ’+ for the line AH.

This is the second deflection angle PAH obtained from the table in (e).

i) Set out GH =c.

The zero of the tape is now held at Q and the chord length or peg interval along the tape is

marked with a peg which is moved on to the line AH as given by the theodolite.

j) Repeat the same process to set out the remaining pegs.

i) Continue until the last peg on the curve has been placed and measure the remaining distance

to B which should equal the calculated length c" of the final sub-chord. Also set out the final

deflection angle, which should pass through tangent point B, indicating no disturbance of the

instrument.

ii) As a final check on the accuracy, locate point B by the deflection angle and sub-chord c". If this

position does not coincide with the tangent point B, the distance between the two is the actual

error of tangency. If this is large, indicating an error, the whole process must be repeated. Where

calculations are inaccurate by a few millimetres in the final placing of the pegs, it is usual to adjust

the last few pegs to secure tangency. In accurate tunnel work the degree of precision must, of

course, be greater.

61

k) The first chainage peg on BF will be c — c" from -B.

Having calculated the distance of the first chainage peg F on the second straight, chaining may

be proceeded with after moving the instrument to B or some other convenient point on this

straight.

Figure 4.17 Setting out a circular curve

(Source: Land Surveying, Ramsay J.P. Wilson)

Example 4d:

Two straights AP and PB intersect with an angle of deflection of 12º 20' as illustrated in Figure

6.17. They are to be connected by a circular curve of radius 600 m. The chainage of the

intersection point is 12 + 73.16. Calculate the setting-out data required to peg the curve at a

continuous chainage with pegs at 25m intervals.

Solution :

a) Calculate the tangent lengths from T == R tan ´θ

T = 600 tan 6° 10'

= 600 x 0.108046

= 64.83 m.

b) Calculate, the arc length from L = Rθ

L = 600 x 12° 20' x (2π / 360)

= 600 x 0.21526

= 129 .16 m.

c) Calculate the chainages:

Chainage of P = 12 + 73.16

Less T = 64.83

Chainage of A = 12 + 08.33

Add L = 129.16

Chainage of B = 13 + 37.49 m.

62

d) Calculate the sub-chords.

The last peg on the straight is at chainage 12 + 00, therefore the next peg

must be at chainage 12 + 25. There is still 8-33 m on the straight to the

tangent point, so there will be 25.00 — 8.33 = 16.67 m along the curve to

the first peg on the curve. Thus 16.67 m is the length of the first sub-

chord.

As the curve length is 12 9.16 m and the first sub-chord is 16.67 m, there is 129.16 – 16.67 =

112.49 of arc left. Four 25m standard chords make up the next 100m, leaving a final sub-chord of

12.49 m. The measurement of the arc distance by these chords is sufficiently accurate for most

practical purposes although theoretically the measured distance is shorter than the arc distance.

e) Calculate the deflection angles from = 1718.9( c/R)

= 1718.9 x (25/600)

= 71.62

= 1° 11. 62’

= 1° 11' 37.2”.

i) The initial sub-chord is 16.67 m, so its deflection angle will be in the proportion of:

(16-67 /25 ) x (1º11.62’) = 47.76’

= 47' 45.6”.

ii) The final sub-chord is 12.49 m, so its deflection angle will be in the proportion of:

(12.49 / 25) x 1° ll.62’ = 35.78’.

= 35’ 46.8”

g) Tabulate the deflection angles. The deflection angles are tabulated as follows:

Instrument at A = 12 + 08.33

To peg at P Chord Length Bearing

° ’ ”

12 + 25

12 + 50

12 + 75

13

13 + 25

16.67

25

25

25

25

00 00 00

+ 47 45.6

00 47.45.6

+ 1 11 37.2

1 59 22.8

+ 1 11 37.2

3 11 00.0

+ 1 11 37.2

4 22 37.2

+ 1 11 37.2

5 34 14.4

63

B = 13 + 37.49

12.49

+ 35 46.8

6 10 01.2 = ´θ (Check)

Table 4.1 Calculation Of Setting Out Circular Curve

(Source: Land Surveying, Ramsay J.P. Wilson)

NOTE: There is always likely to be minor rounding off of errors such as the 1.2”, which is

negligible. To keep these errors to a minimum the calculation is always carried out to 0.1”, but the

observed bearings are rounded off to 1" for more accurate work and frequently to 10" or oven

20", depending on the theodolite being used for setting out.

4.8 Obstructions To Setting Out

Obstructions on site may prevent normal setting out in a variety of ways. Most problems of this

kind can easily be overcome if setting out is by means of coordinates, but two common problems

which often arise are the following:

a) Where the intersection point is inaccessible.

b) Where there are obstructions to sighting the deflection angle to every point on the curve from

the initial tangent point.

4.8.1 The Inaccessible Intersection Point.

It may not be possible to measure θ at the intersection point if it is inaccessible e.g. on mountain

roads. By setting out a line such as XY in figure 4.18, and by measuring its length and the angles

α and β the triangle XPY can be solved for the lengths PX and PY and θ can be deduced. The

tangent points can then be located from X and Y and the curve set out in the usual way.

Figure 4.18 : An inaccessible intersection-point

(Source: Land Surveying, Ramsay J.P. Wilson)

4.8.2 Obstructions To Sighting The Deflection Angles.

Where obstructions prevent the sighting to every peg on the curve, the following procedure must

be adopted as illustrated in Figure 4.19.

64

(a) Pegs 2, 3 and 4 have been placed turning off deflection angle δ each time. Peg 5 cannot

be placed from peg 1 owing to an obstruction.

i) Triangle 1X4 is isosceles, therefore angle X14 = angle 14 X = 3.

ii) The angle between the chord 1-4 produced and the tangent X4 produced is also 3

and the angle is required to be turned off this tangent to locate peg 5.

iii) An angle of 180° + 4 is required to be turned off line 4-1 in order to locate the

direction 4-5.

b) Set up the theodolite at peg 4, sight peg 1 at a zero setting and turn of at an angle equal

to 180° + (5 - 1) = 180° + 4; i.e. must be multiplied by the number of standard chord

lengths between the two points being sighted to.

NOTE:

i) The longest possible backsight should always be used to orient the theodolite.

ii) If a sub-chord exists between the instrument and the point sighted to, the

angle to be turned off will be 180° + ( x Number of standard chords between the

pegs sighted) + ', the deflection angle of the sub-chord.

iii) The rule for obtaining the angle applies between any two pegs on any one circular curve.

Figure 4.19 : Obstructed Deflection Angles

(Source: Land Surveying, Ramsay J.P. Wilson)

4.9 COMPUTING AND SETTING OUT A TRANSITION CURVE

4.9.1 Introduction

It is normal to set out a transition curve using deflection angles from the tangent point or by

deflection distances for short transitions, in the same way as for circular curves. The deflection

angles for transitions are not equal as are those for circular curves. The chord length used is

often half that used on the circular curve. In practice the setting-out data are usually extracted

from tables which relate to various design speeds. The only calculations needed are for the

tangent lengths using the observed deflection angle .

65

Figure 4.20 : Transition Curve Detail

(Source: Land Surveying, Ramsay J.P. Wilson)

Once the tangent points have been established, the transitions are set out from both tangent

points to T1 and T2, the limits of the circular curve. Then from T1 or T2 the direction of the tangent

to the circular curve is obtained by turning off 2/3' (Figure 4.20) from the chord to the transition

and the circular curve deflection angles are set out as before.

4.9.2 Setting-out Calculations.

If the tabulated data are not available, the length of the transition must first be obtained from the

formula below:

The rate of change of radial acceleration

This forms part of highway design and is dependent on traffic speed, available space and the

radius to be adopted. The setting out surveyor will be provided with the transition length and the

radius or degree of curve. With this information and the observed deflection angle , the following

calculations are needed before setting out the pegs:

(a) Shift. This is calculated from:

L2

S=

24R

The radius R = 5729.58 /D, if only the degree of curve is given.

(b) Tangent lengths. This is calculated from:

This distance will be taped back from the intersection point and the two tangents T0, and T3

pegged.

(c) Deflection angles. The deflection angles for 10-, 15- or 20-m chords are calculated from:

where l is the continuous chainage along the transition. For small angles of deflection the

summation of the chord lengths may be taken to equal the lengths l.

The final deflection angle to locate T1 is 572.958 minutes, and ' is three times this value.

(d) Length of circular curve. This is obtained from R' in the usual way, where:

' = ( — 2') and

2'' = 57.2958 degrees.

RL

v3

2tan)( 2

1L

SRTP o

utesRL

ld min958.572

2

R

L

R

L

66

NOTE: If 2' is greater than , it is not possible for the transitions to be contained within the straights. Longer transitions leading to a curve of smaller radius will have to be used.

Example 4e.

Calculate the setting-out data for a 75m transition curve to connect an 8° circular curve joining two straights with an angle of deflection of 20° 00', using 15m chords.

Solution:

(a) To calculate the radius and shift:

(b) To

calcula

te the

tangen

t